High-efficiency treatment process for removing marine spill oil

A treatment process and oil spill technology, which is applied in the cleaning of open water surfaces, water conservancy projects, and general water supply conservation, etc., and can solve problems such as low emulsification rate, high consumption of oil dispersant, and difficulty in satisfying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A treatment process for efficiently removing marine oil spills, comprising the following steps:

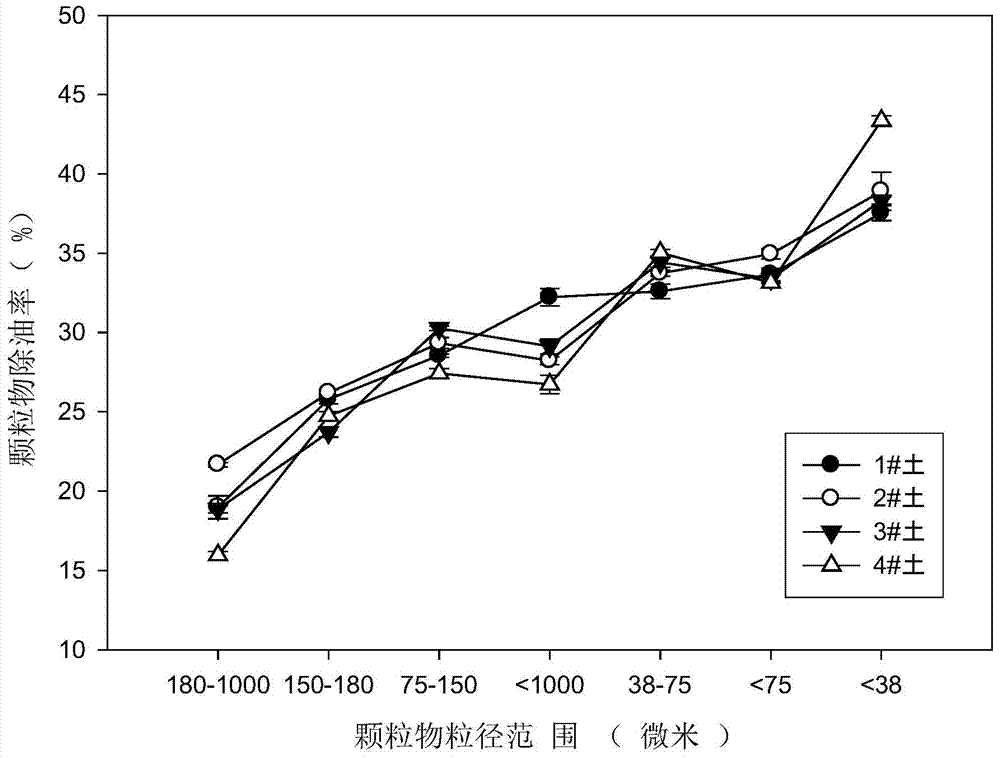

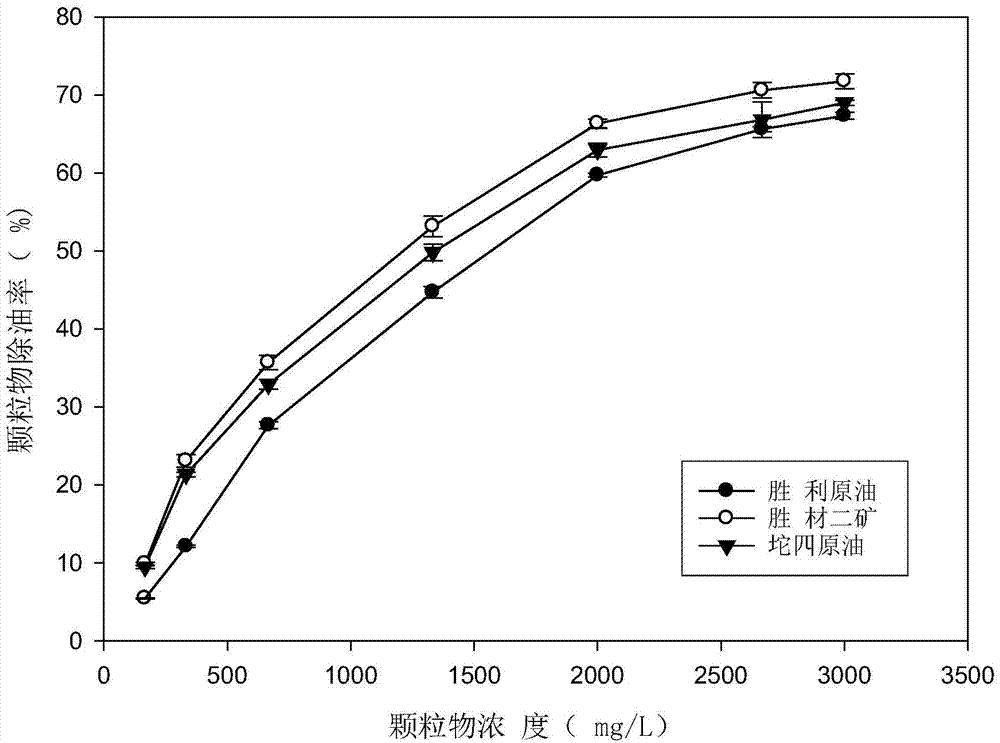

[0055] (1) Air-dry and sieve the sediments taken from the muddy beach at the mouth of the Yellow River to obtain particles with a particle size not greater than 38 μm, mix appropriate amount of particles with seawater, and prepare a particle solution of 1.0 to 3.0 g / L, canned storage;

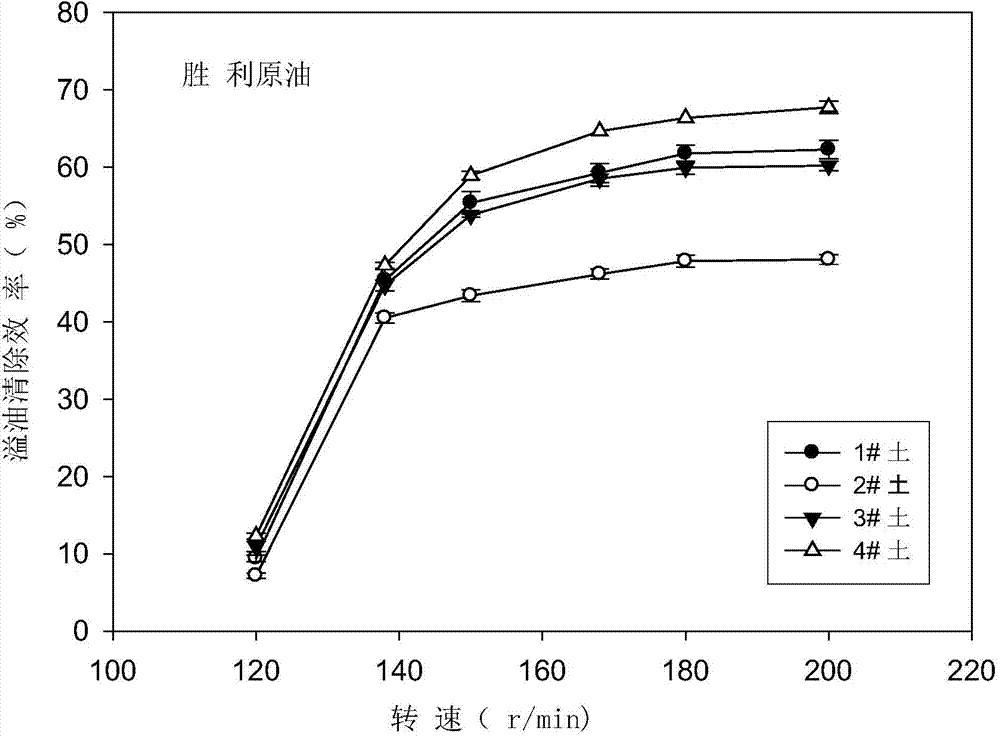

[0056] (2) Spray oil dispersant and a suitable concentration of particle solution to the surface of the oil spill, and use the stirring device to keep the oil spill area in a turbulent state until the oil spill is cleared. The mass ratio of the particles to the oil dispersant is 7.5:1, and the amount of the oil dispersant is 18% of the amount of oil spilled. The stirring device is a turbine agitator with one end fixed on the cleaning ship, and the rotation speed of the turbine agitator is 600r / min. The oil dispersant is Fuken oil dispersant. The density of the particles ranges from 2.5 to...

Embodiment 2

[0058] A treatment process for efficiently removing marine oil spills, comprising the following steps:

[0059] (1) Air-dry and sieve the sediments taken from the muddy beach at the mouth of the Yellow River to obtain particles with a particle size not greater than 38 μm, mix appropriate amount of particles with seawater, and prepare a particle solution of 1.0 to 3.0 g / L, canned storage;

[0060] (2) Spray oil dispersant and a suitable concentration of particle solution to the surface of the oil spill, and use the stirring device to keep the oil spill area in a turbulent state until the oil spill is cleared. The mass ratio of the particles to the oil dispersant is 10:1, and the amount of the oil dispersant is 20% of the amount of oil spilled. The stirring device is a turbine agitator with one end fixed on the cleaning ship, and the rotation speed of the turbine agitator is 138r / min. Described degreaser is bright degreasing agent. The density of the particles ranges from 2.5...

Embodiment 3

[0062] A treatment process for efficiently removing marine oil spills, comprising the following steps:

[0063](1) Air-dry and sieve the sediments taken from the muddy beach at the mouth of the Yellow River to obtain particles with a particle size not greater than 38 μm, mix appropriate amount of particles with seawater, and prepare a particle solution of 1.0 to 3.0 g / L, canned storage;

[0064] (2) Spray oil dispersant and a suitable concentration of particle solution to the surface of the oil spill, and use the stirring device to keep the oil spill area in a turbulent state until the oil spill is cleared. The mass ratio of the particles to the oil dispersant is 12:1, and the amount of the oil dispersant is 18% of the amount of oil spilled. The stirring device is a turbine agitator with one end fixed on the cleaning ship, and the rotation speed of the turbine agitator is 200r / min. Described degreaser is bright degreasing agent. The density of the particles ranges from 2.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com