Emulsifying liquid wastewater membrane treatment process

An emulsion and membrane treatment technology, which is applied in neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Instability and other problems, to achieve the effect of reducing investment and operating costs, huge economic and social benefits, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific examples, but the present invention is not limited to these examples.

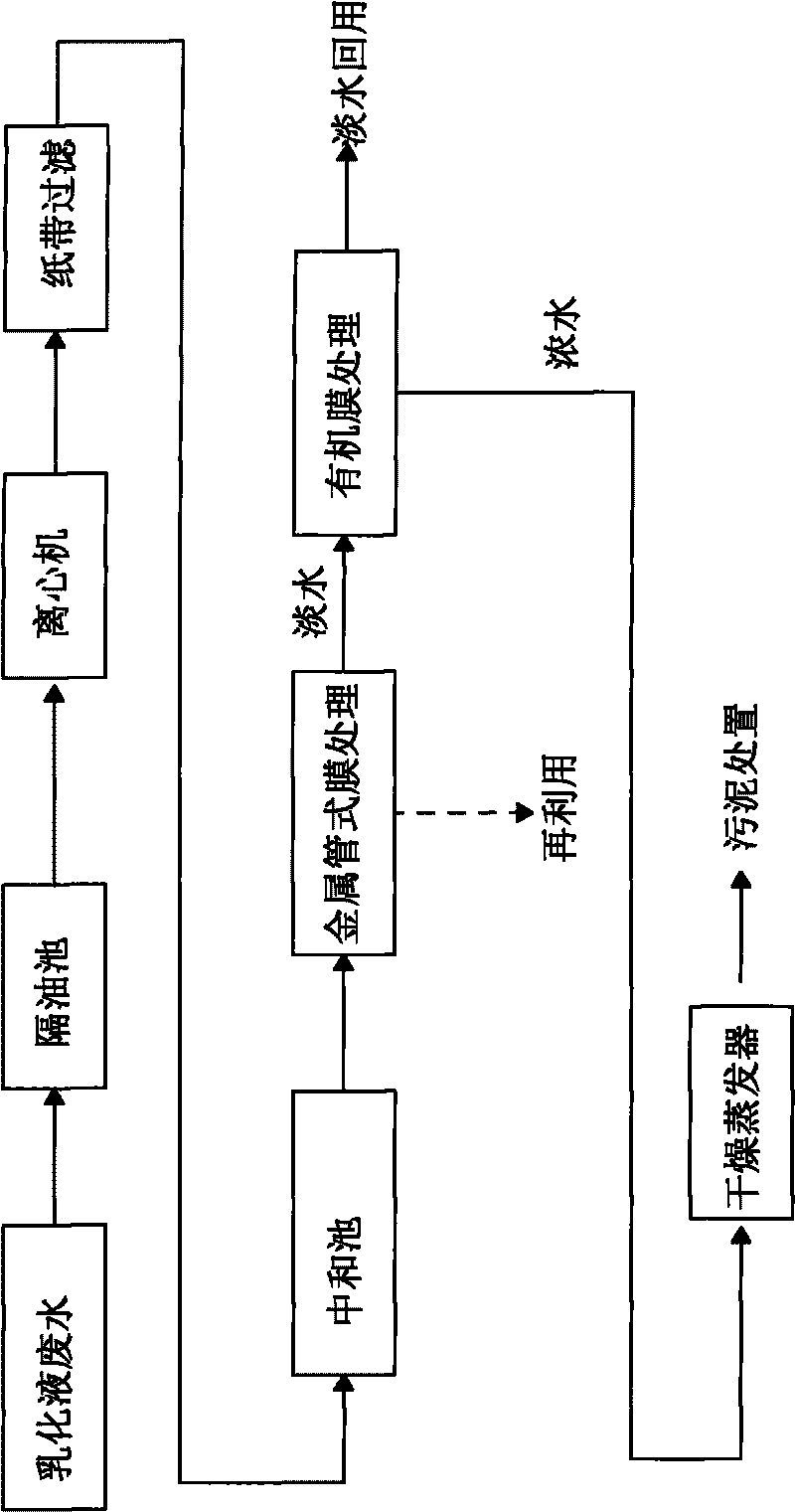

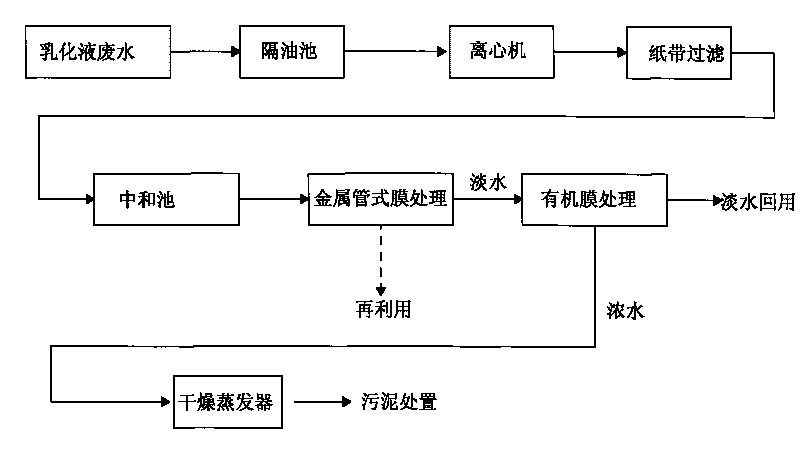

[0020] Such as figure 1 As shown, (1) pretreatment: the method is that the oil-containing emulsion wastewater enters the grease trap, and part of the oil in the grease trap pool will float on the liquid surface, and scrape it to one end of the grease trap with an oil scraper and slag scraper. The waste oil collection box is recycled, and the sludge at the bottom of the grease trap is regularly pumped to the sludge treatment system; the treated emulsion wastewater is sent to a centrifuge to remove solid particles, and the separation filter bag of the centrifuge is 500-4000 mesh. Then send it to the paper tape filter to further remove impurities; the emulsion wastewater after removing impurities enters the neutralization tank, and adjusts the pH to 4-13.

[0021] (2) Metal tubular membrane ultrafiltration: the pretreated emulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com