Industrial water treatment equipment and process

A technology for industrial water treatment and industrial wastewater, which is applied in water/sewage treatment equipment, water/sewage treatment, water treatment parameter control, etc. It can solve problems such as increased phosphorus removal costs, low treatment efficiency, and blockage of pipeline equipment to achieve improvement The effect of adsorption capacity and adsorption rate, fast flocculation and sedimentation speed, and solid flocculation sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

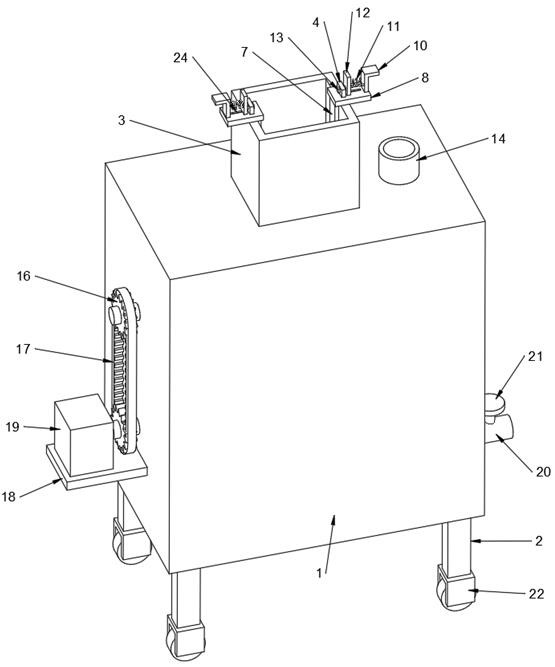

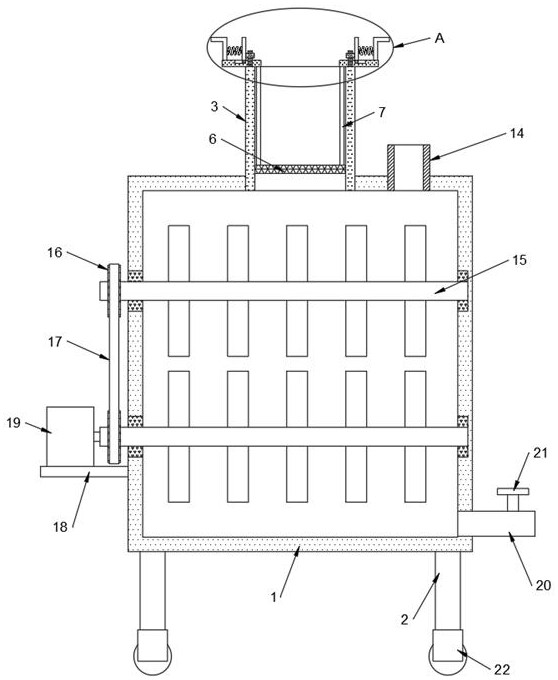

[0067] A kind of industrial water treatment process, comprises the following steps:

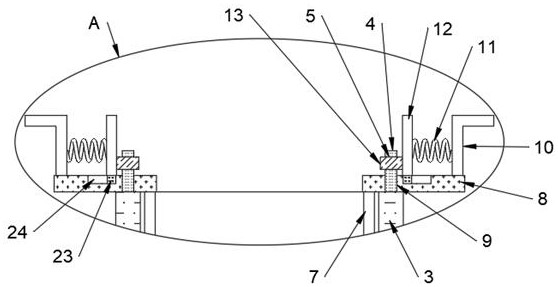

[0068] 1) Transport the industrial wastewater to the industrial water treatment equipment, and enter from the square pipe body of the industrial water treatment equipment, and under the action of the filter screen, the solid impurities in the wastewater are retained and filtered out;

[0069] 2) Then add phosphorus removal agent through the dosing tube;

[0070] 3) Start the servo motor, and the servo motor drives the two stirring paddles to rotate for stirring and mixing to remove phosphorus;

[0071] In step 1), the phosphorus content of the industrial wastewater is respectively 5-15 mg / L;

[0072] In step 2), the addition amount of the phosphorus removal agent is 80-120mg / L;

[0073] The phosphorus removal agent includes the following raw materials in parts by weight: 45 to 55 parts of ferrous sulfate pentahydrate, 12 to 16 parts of polyaluminum chloride, 20 to 27 parts of polyaluminum i...

Embodiment 2

[0100] A kind of industrial water treatment process, comprises the following steps:

[0101] 1) Transport the industrial wastewater to the industrial water treatment equipment, and enter from the square pipe body of the industrial water treatment equipment, and under the action of the filter screen, the solid impurities in the wastewater are retained and filtered out;

[0102] 2) Then add phosphorus removal agent through the dosing tube;

[0103] 3) Start the servo motor, and the servo motor drives the two stirring paddles to rotate for stirring and mixing to remove phosphorus;

[0104] In step 3), when stirring and mixing phosphorus removal, it is divided into 3 stages, the first stage is stirred at 400 rpm for 15 minutes, the second stage is stirred at 300 rpm for 20 minutes, and the third stage is stirred at 100 rpm / min, stirring for 18 minutes.

[0105] In this embodiment, the phosphorus removal agent includes the following raw materials in parts by weight:

[0106] 45 ...

Embodiment 3

[0132] A kind of industrial water treatment process, comprises the following steps:

[0133] 1) Transport the industrial wastewater to the industrial water treatment equipment, and enter from the square pipe body of the industrial water treatment equipment, and under the action of the filter screen, the solid impurities in the wastewater are retained and filtered out;

[0134] 2) Then add phosphorus removal agent through the dosing tube;

[0135] 3) Start the servo motor, and the servo motor drives the two stirring paddles to rotate for stirring and mixing to remove phosphorus;

[0136] In step 3), when stirring and mixing phosphorus removal, it is divided into 3 stages, the first stage is stirred at 500 rpm for 12 minutes, the second stage is stirred at 250 rpm for 24 minutes, and the third stage is stirred at 120 rpm. / min, stirring for 15 minutes.

[0137] In this embodiment, the phosphorus removal agent includes the following raw materials in parts by weight:

[0138] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com