Laver processing wastewater treatment facility and method capable of realizing ultra-clean discharge

A technology for processing wastewater and treatment facilities, which is applied in the fields of food industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc. Standards, unfavorable ecological environment sustainable development and other issues, to avoid dealing with load shocks, small footprint, and strong resistance to load shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

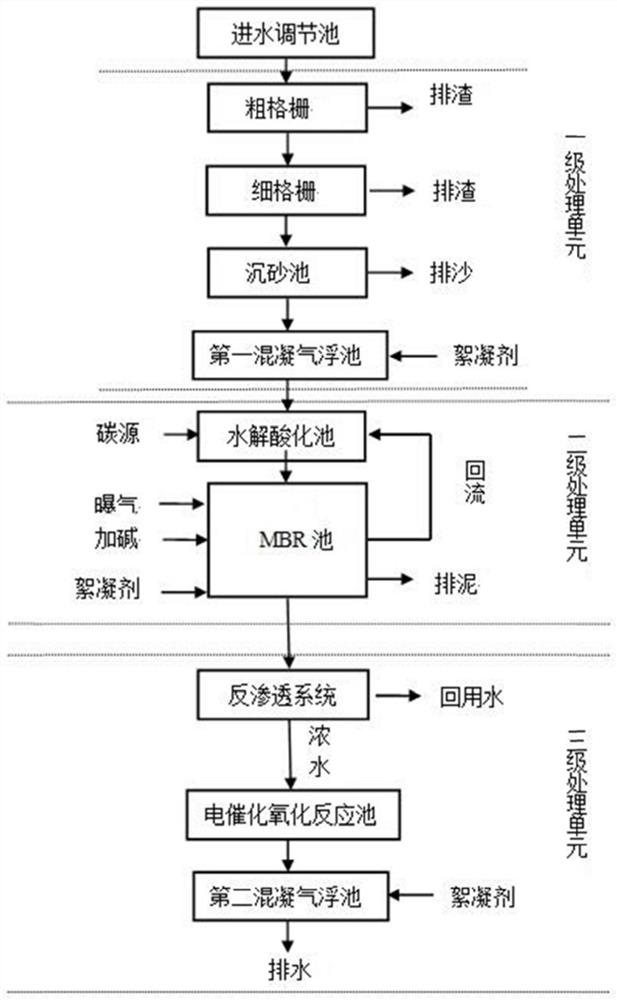

Method used

Image

Examples

Embodiment

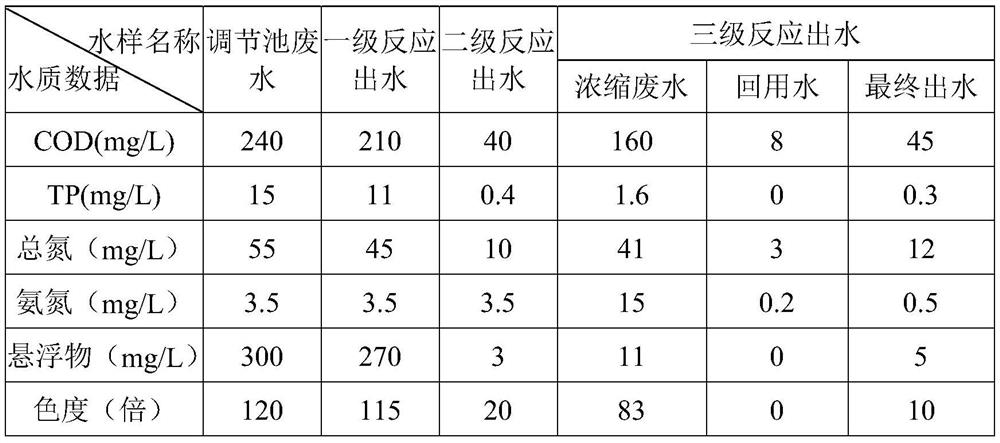

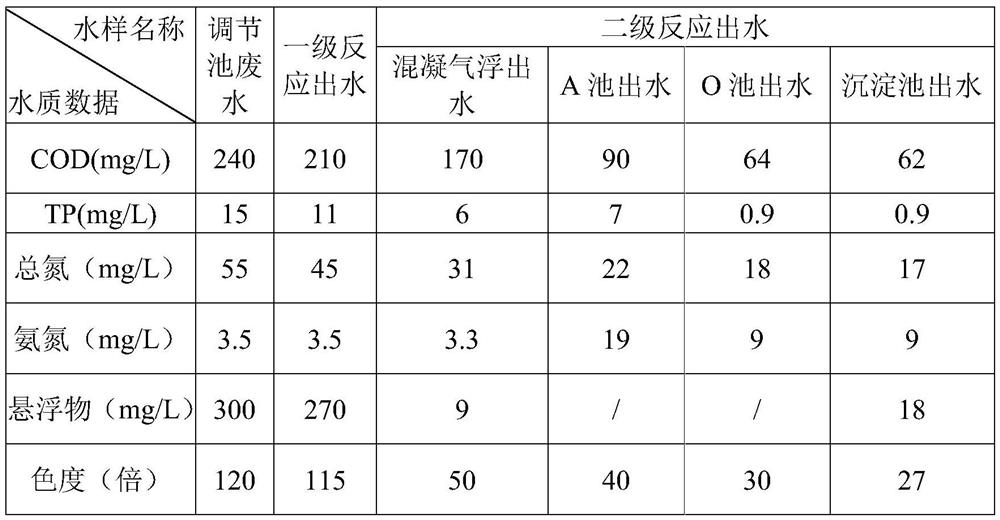

[0057] Aiming at the laver processing wastewater of a laver processing base in Lianyungang, the treatment facility and method of the present invention were used to carry out a pilot test, and relevant comparative facilities were set up to verify the beneficial effects of the present invention.

[0058]The first set of pilot facilities is the facilities described in the present invention. The second set of pilot facilities is a process in which the aerobic activated sludge method in the conventional process is used to replace the MBR tank and add a sedimentation tank, that is, to form a conventional A / O biochemical process together with the hydrolysis acidification tank (wherein the hydrolysis acidification tank is transformed into Pool A), and the reflux between the two ends of the biochemical process adopts nitrifying liquid reflux and sludge reflux, and the C / N ratio in the carbon source also adopts the ratio used in the conventional A / O biochemical process. The third set of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com