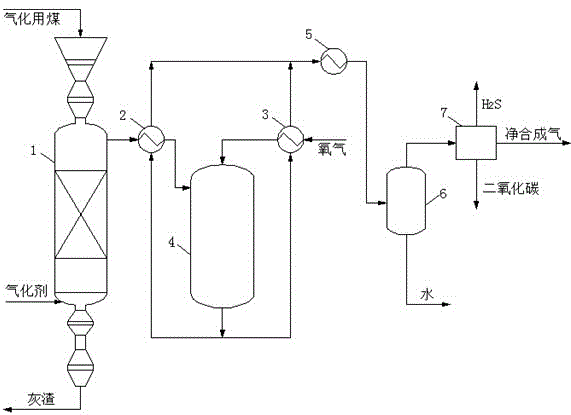

Process for producing clean synthesis gas from crushed coal

A synthesis gas and crude synthesis gas technology, applied in the direction of gasification process, hydrogen/synthesis gas production, petroleum industry, etc., can solve the problem of increasing equipment investment cost, operating cost, increasing difficulty of purification and separation, and increasing investment, investment and consumption Advanced problems, to achieve the effect of reducing equipment costs and operating costs, reducing ammonia nitrogen content, and reducing burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Lignite is added to the crushed coal pressurized gasifier with a pressure of 2.5MPa, and the temperature of the generated crude gas is 315°C, which is preheated to 900°C through a heat exchanger, and O 2 , together into the high-temperature cracking and reforming reactor, when the temperature reaches 1000°C, at this temperature, various oils, low-carbon hydrocarbons, CH 4 Reforming to generate CO, H 2 and other small molecules, NH 3 converted to N 2 . Various oils and low-carbon hydrocarbons are completely decomposed in the pyrolysis reforming reactor, NH 3 The conversion rate is as high as 98.6%. Compared with crude gas, the molar amount of CO in crude syngas increased by 1.5 times, and its standard volume fraction increased from 10.3% to 19.9%; H 2 The molar weight of the product is increased by 0.9 times, and its standard volume fraction is increased from 27.2% to 40.3%. In addition, CO 2 The standard volume fraction of H is reduced from 22.3% to 18.0%, H 2 T...

Embodiment 5

[0050] Lignite is added to a crushed coal pressurized gasifier with a pressure of 4.0MPa, and the temperature of the generated crude gas is 330°C, which is preheated to 900°C through a heat exchanger, and O 2 , together into the high-temperature cracking reactor, when the temperature reaches 1000°C, at this temperature, various oils, low-carbon hydrocarbons, CH 4 Reforming to generate CO, H 2 and other small molecules, NH 3 converted to N 2 . Various oils and low-carbon hydrocarbons are completely decomposed in the pyrolysis reactor, NH 3 The conversion rate is as high as 98.5%. Compared with crude gas, the molar amount of CO in crude syngas increased by 2.8 times, and its standard volume fraction increased from 8.6% to 21.1%; H 2 The molar weight of the compound is increased by 3.1 times, and its standard volume fraction is increased from 15.7% to 41.5%. In addition, CO 2 The standard volume fraction of H is reduced from 21.7% to 17.1%, H 2 The standard volume fractio...

Embodiment 9

[0055] Bituminous coal is added into a crushed coal pressurized gasifier with a pressure of 6.0MPa, and the temperature of the generated crude gas is 440°C, which is preheated to 900°C through a heat exchanger, and O gas preheated to 600°C 2 , together into the high-temperature cracking reactor, when the temperature reaches 1000°C, at this temperature, various oils, low-carbon hydrocarbons, CH 4 Reforming to generate CO, H 2 and other small molecules, NH 3 converted to N 2 . Various oils and low-carbon hydrocarbons are completely decomposed in the pyrolysis reactor, NH 3 The conversion rate is as high as 96.9%. Compared with crude gas, the molar amount of CO in crude syngas increased by 4.2 times, and the standard volume fraction of CO increased from 6.1% to 20.8%; H 2 The molar weight of H is increased by 4.6 times. 2 The standard volume fraction increased from 10.4% to 38.2%. In addition, CO 2 The standard volume fraction of H was reduced from 27.4% to 19.4%, and H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com