Sandwich silk filling core material

A technology for filling cores and silk, applied in the field of filling core materials, can solve the problems of poor softness and comfort, unavoidable problems such as silkworms, bacteria or mildew, avoiding easy agglomeration, easy production and reduction of use. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

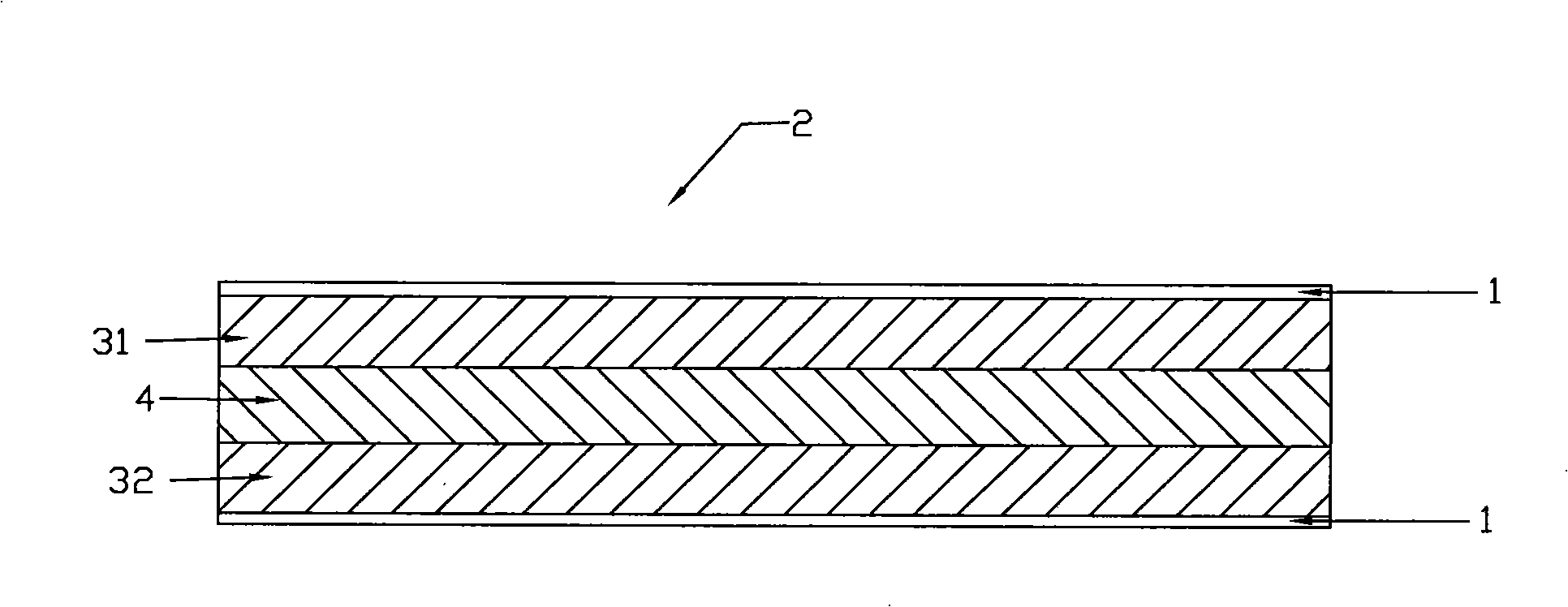

Embodiment 1

[0024] like figure 1 As shown, in this embodiment, the sandwich silk filling core material 2 includes the fixed fabric 1 on its outer surface, the upper surface silk layer 31 and the lower surface silk layer 32 adjacent to the fixed fabric 1, and the silk layer on the upper surface. The hemp fiber middle layer 4 between the layer 31 and the lower surface silk layer 32, the hemp fiber middle layer 4 is a pure jute fiber layer. Wherein, the quality of jute fiber is 70% of the total mass of sandwiched silk filling core material 2. According to the quality of the fixed fabric 1 used, the quality of the sandwich silk filling core material 2 of actual needs and the above-mentioned composition of the sandwich silk filling core material 2 select silk and jute fiber, then according to the thickness and thickness of the sandwich silk filling core material 2 made as required The silk and jute fibers are respectively processed and shaped by a carding machine, and then compounded, and the...

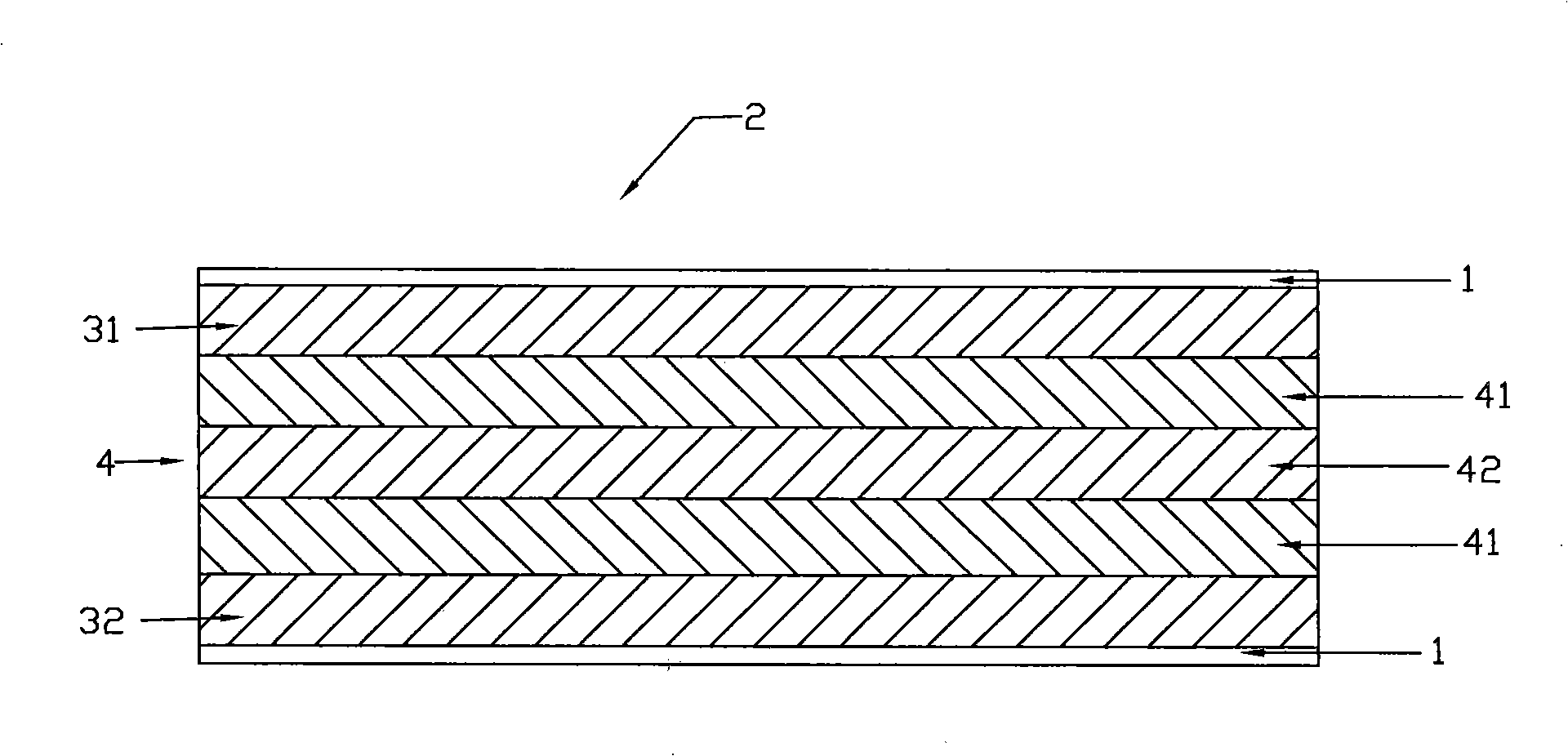

Embodiment 2

[0040] like figure 2 As shown, in this embodiment, the fixed fabric 1 is a hemp fabric fixed fabric, and the hemp fiber middle layer 4 of the sandwich silk filling core material 2 is formed by overlapping the middle silk layer 42 and the hemp fiber layer 41 The middle layer, when making the sandwich silk filling core material 2 of this embodiment, only needs to comb the silk and hemp fibers into the required size and thickness respectively, and then compound them together, so the damage to the hemp fiber or silk fiber It is less flexible and easier to manufacture. The hemp fiber is ramie fiber. The quality of hemp fiber accounts for 60% of the total mass of the whole sandwich silk filling core material 2 . Take the sandwich silk filling core material 2 of such a structure, under the same thickness of the sandwich silk filling core material 2, the more ramie fiber layers, the more evenly the ramie fiber layer and the middle silk layer 42 are dispersed, which is insect-proof,...

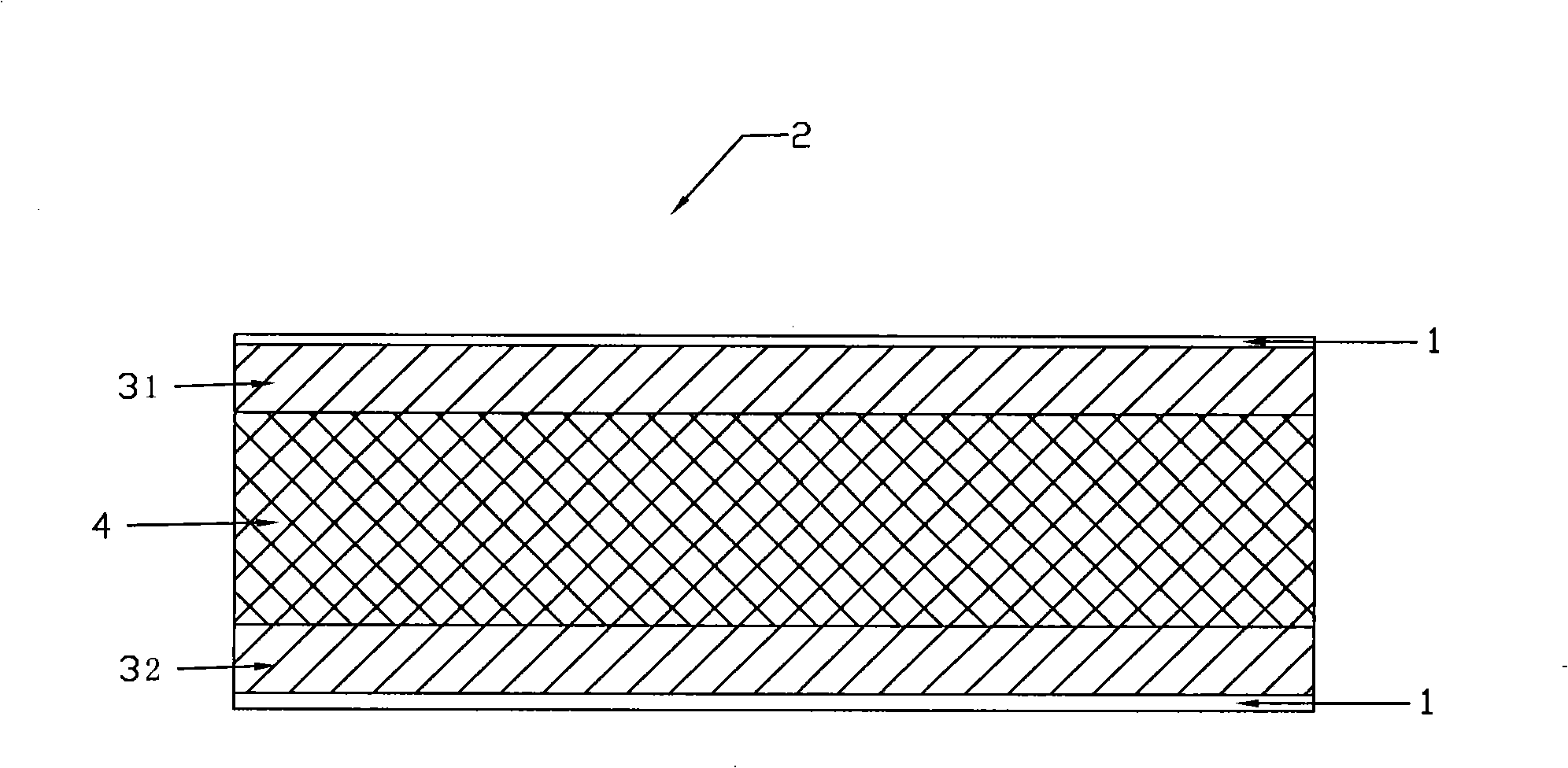

Embodiment 3

[0042] like image 3 As shown, in this embodiment, the fixed fabric 1 is a linen fabric fixed fabric, the hemp fiber middle layer 4 of the sandwich silk filling core material 2 is an intermediate layer formed by mixing silk and hemp fiber, and the sandwich silk filling core The hemp fiber in material 2 is flax fiber. The quality of hemp fiber accounts for 45% of the total mass of the whole sandwich silk filling core material 2 . Silk and hemp fiber adopt such a composite method, the silk and hemp fiber are directly mixed together, evenly mixed, when the content of hemp fiber is low, it can play a better role in insect repellent, antibacterial and antibacterial, and effectively prevent mold growth Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com