Tear-resistant food packaging bag film and preparation method thereof

A packaging bag and tear-resistant technology, applied in the field of packaging bag preparation, can solve the problems of poor tear resistance, impact on human safety, safety impact, etc., and achieve the effect of good antibacterial and good tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A tear-resistant food packaging bag film, the tear-resistant food packaging bag film is made of the following raw materials in parts by mass:

[0042] Linear high-density polyethylene 45g, polybutadiene rubber 15g, polypropylene glycol 10g, cellulose acetate 7g, bamboo charcoal fiber particles 2g, antibacterial agent 5g, antiaging agent 2g, ionic surfactant 2g, toughening agent 2g, even Joint agent 1g, polyethylene wax 2g, propylene glycol alginate 1g, ammonium persulfate 1g, stearic acid monoglyceride 1g.

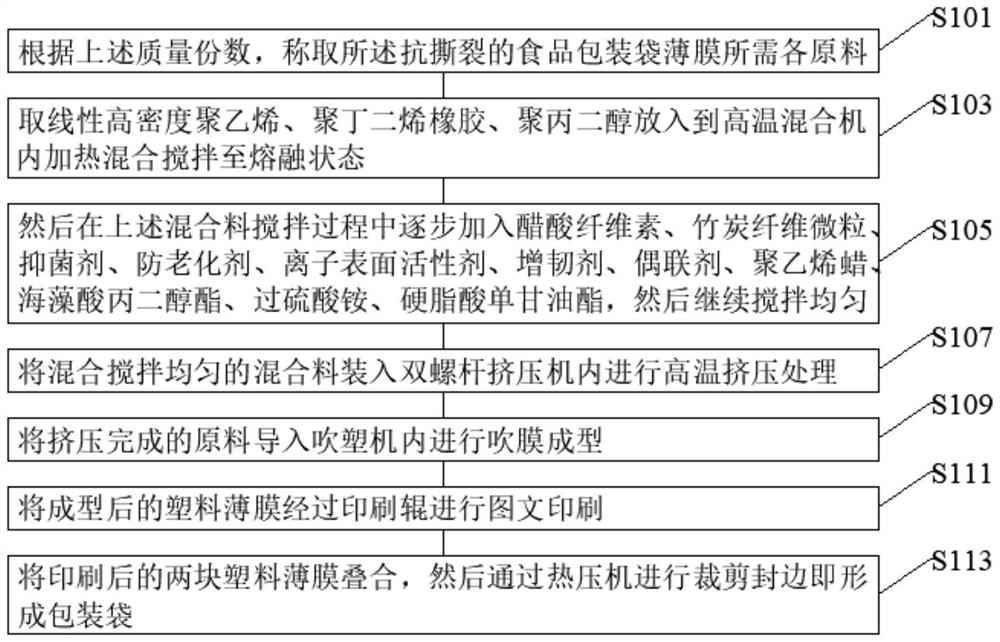

[0043] The preparation of the tear-resistant food packaging bag film comprises the following steps:

[0044] According to the above-mentioned mass parts, take each raw material required by the tear-resistant food packaging bag film;

[0045] Take 45g of linear high-density polyethylene, 15g of polybutadiene rubber, and 10g of polypropylene glycol and put them into a high-temperature mixer to heat, mix and stir until molten;

[0046] Then gradually add cellulose ac...

Embodiment 2

[0052] A tear-resistant food packaging bag film, the tear-resistant food packaging bag film is made of the following raw materials in parts by mass:

[0053] Linear high-density polyethylene 55g, polybutadiene rubber 20g, polypropylene glycol 12.5g, cellulose acetate 11g, bamboo charcoal fiber particles 2.5g, antibacterial agent 8.5g, anti-aging agent 3g, ionic surfactant 2.5g, toughening Agent 2.5g, coupling agent 1.5g, polyethylene wax 2.5g, propylene glycol alginate 1.5g, ammonium persulfate 2g, stearic acid monoglyceride 1.5g.

[0054] The preparation of the tear-resistant food packaging bag film comprises the following steps:

[0055] According to the above-mentioned mass parts, take each raw material required by the tear-resistant food packaging bag film;

[0056] Put 55g of linear high-density polyethylene, 20g of polybutadiene rubber, and 12.5g of polypropylene glycol into a high-temperature mixer, heat, mix and stir until molten;

[0057] Then gradually add cellulos...

Embodiment 3

[0063] A tear-resistant food packaging bag film, the tear-resistant food packaging bag film is made of the following raw materials in parts by mass:

[0064] Linear high-density polyethylene 65g, polybutadiene rubber 25g, polypropylene glycol 15g, cellulose acetate 15g, bamboo charcoal fiber particles 3g, antibacterial agent 12g, anti-aging agent 4g, ionic surfactant 3g, toughening agent 3g, even Joint agent 2g, polyethylene wax 3g, propylene glycol alginate 2g, ammonium persulfate 3g, stearic acid monoglyceride 2g.

[0065] The preparation of the tear-resistant food packaging bag film comprises the following steps:

[0066] According to the above-mentioned mass parts, take each raw material required by the tear-resistant food packaging bag film;

[0067] Put 65g of linear high-density polyethylene, 25g of polybutadiene rubber, and 15g of polypropylene glycol into a high-temperature mixer, heat, mix and stir until molten;

[0068] Then gradually add cellulose acetate 15g, ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com