Plastic composition, composite floor including plastic composition, and production method of floor

A technology for a plastic composition and a composite floor, which is applied to chemical instruments and methods, building structures, wood-layered products, etc., can solve the problems of complex production process, high production cost, and high requirements, and achieves simple process flow and service life. Long, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

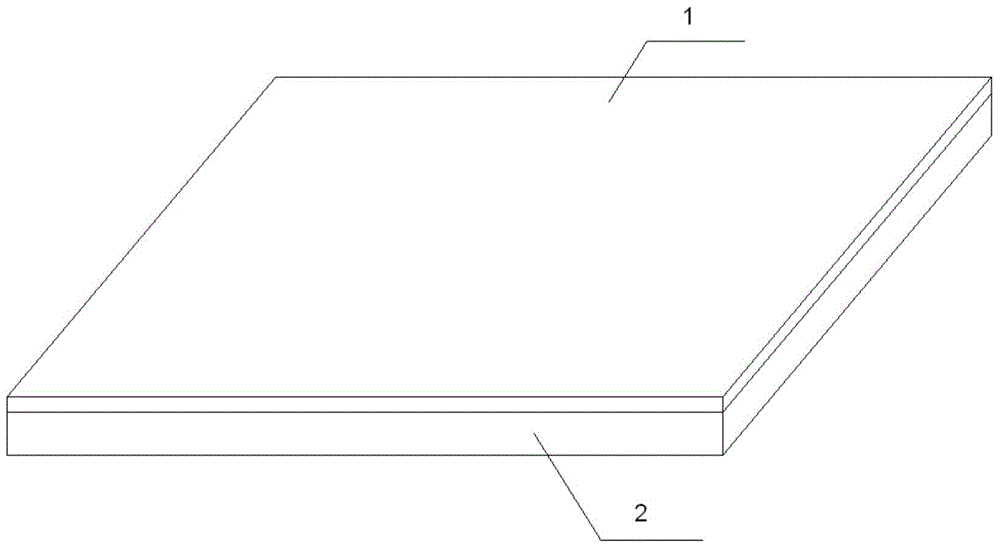

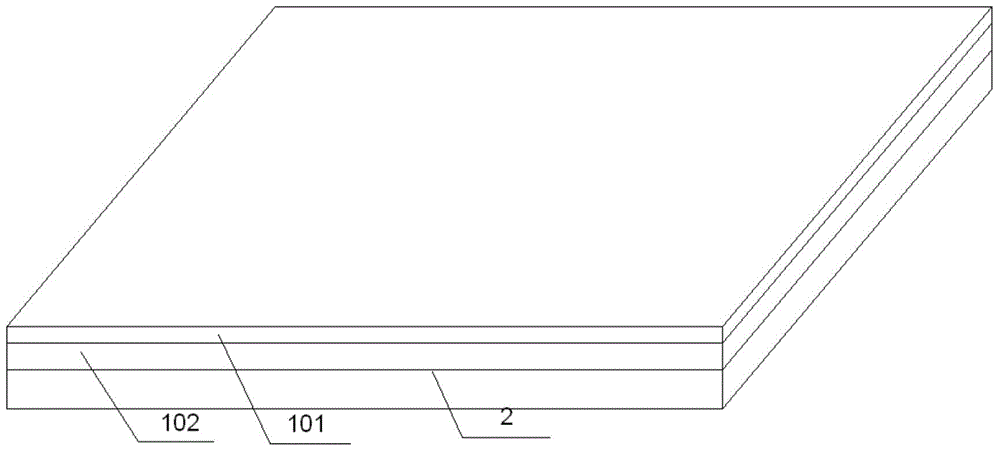

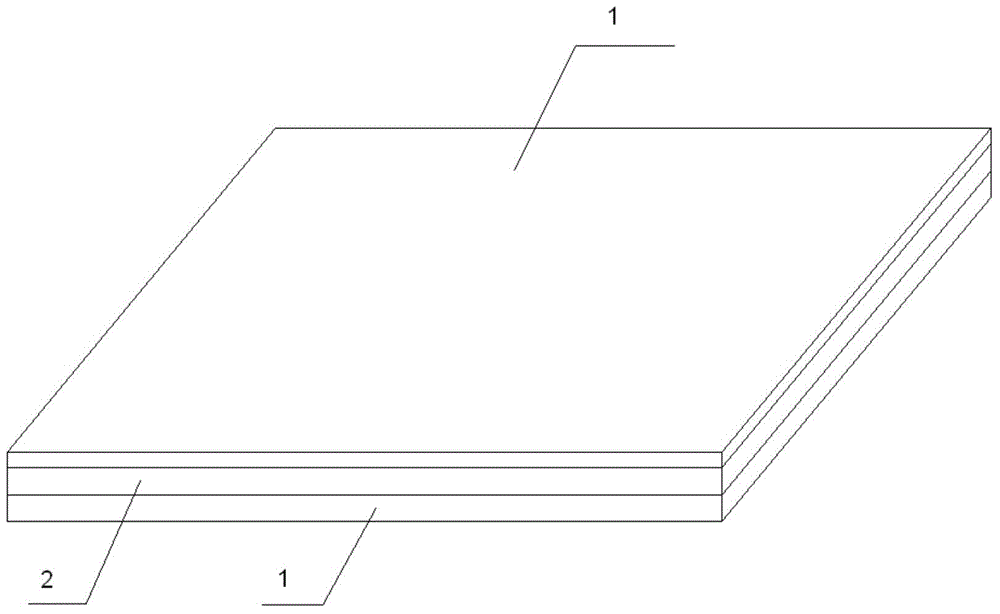

[0047] A method for preparing a composite floor, for preparing a composite floor, comprising the following steps:

[0048] (1) batching, according to 30 parts of polyvinyl chloride, 55 parts of stone powder, 0.5 part of polyurethane foaming agent, 0.5 part of calcium zinc stabilizer carries out material preparation;

[0049] (2) mixing, polyvinyl chloride, stone powder, polyurethane foaming agent and calcium-zinc stabilizer are mixed under heat and pressure to form a mixture;

[0050] (3) extrusion molding, the mixture is passed through an extrusion mold to form a plastic composition;

[0051] (4) cooling, the extruded plastic composition is cooled and formed;

[0052] (5) cutting, cutting the plastic composition after cooling and molding to form a support layer;

[0053] (6) Pressing, put the decorative layer and the supporting layer into the press in sequence, and apply cold pressure glue on the contact surface between the decorative layer and the supporting layer, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com