Edible fungus antistaling method and apparatus

A fresh-keeping method and technology of a fresh-keeping device are applied in the direction of preservation of fruits/vegetables by freezing/refrigeration, etc., which can solve the problems of surface deformation of bacteria, surface deformation and collapse of edible fungi, and achieve the maintenance of metabolism, no surface deformation, and processing. The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0118] The fresh edible brown mushrooms harvested are kept fresh. The newly harvested edible fungi have a high water content, between 90%-95%. It is required that the temperature after preservation and processing be 0 ~ 3 ℃, and the humidity should be 85 ~ 88%.

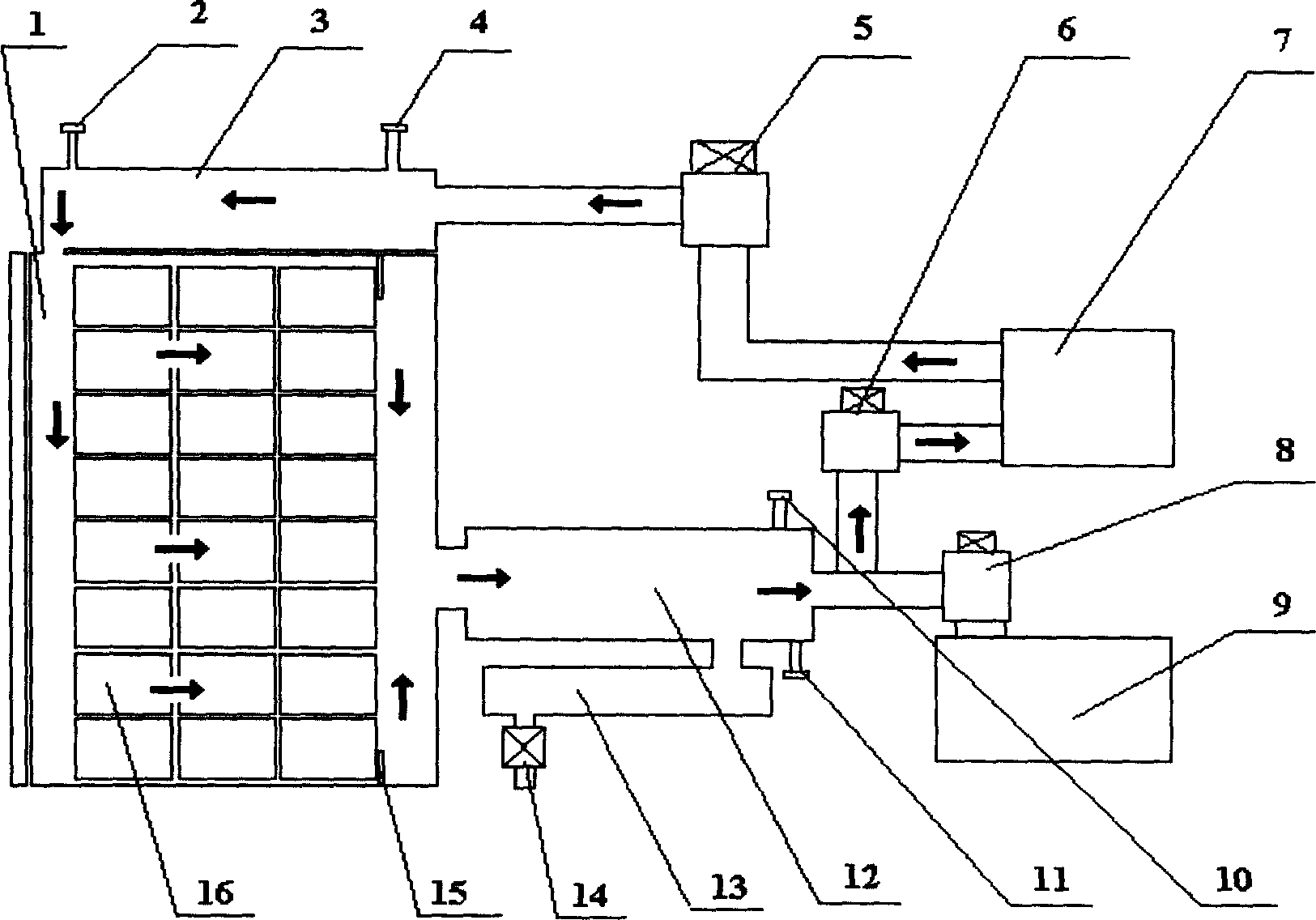

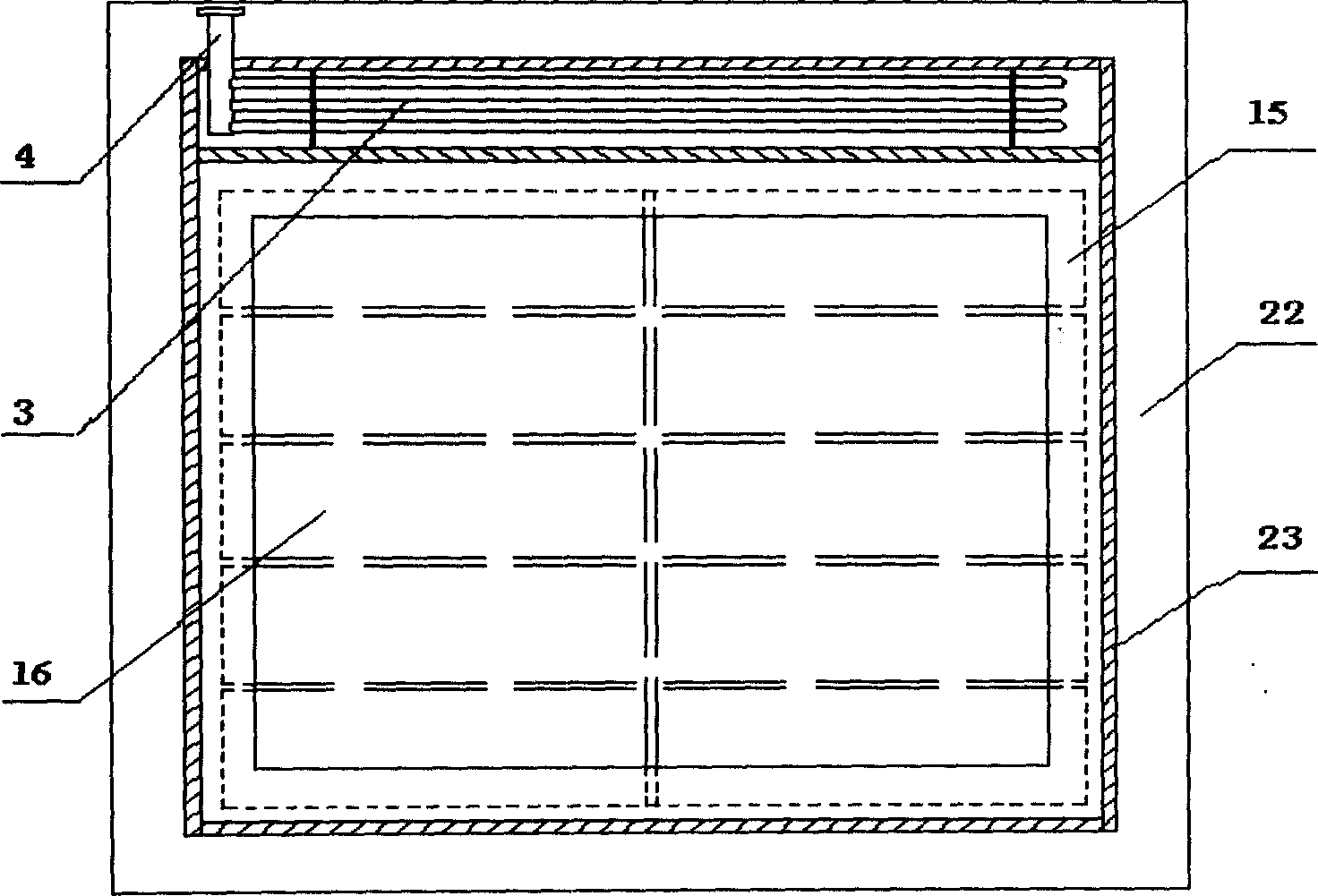

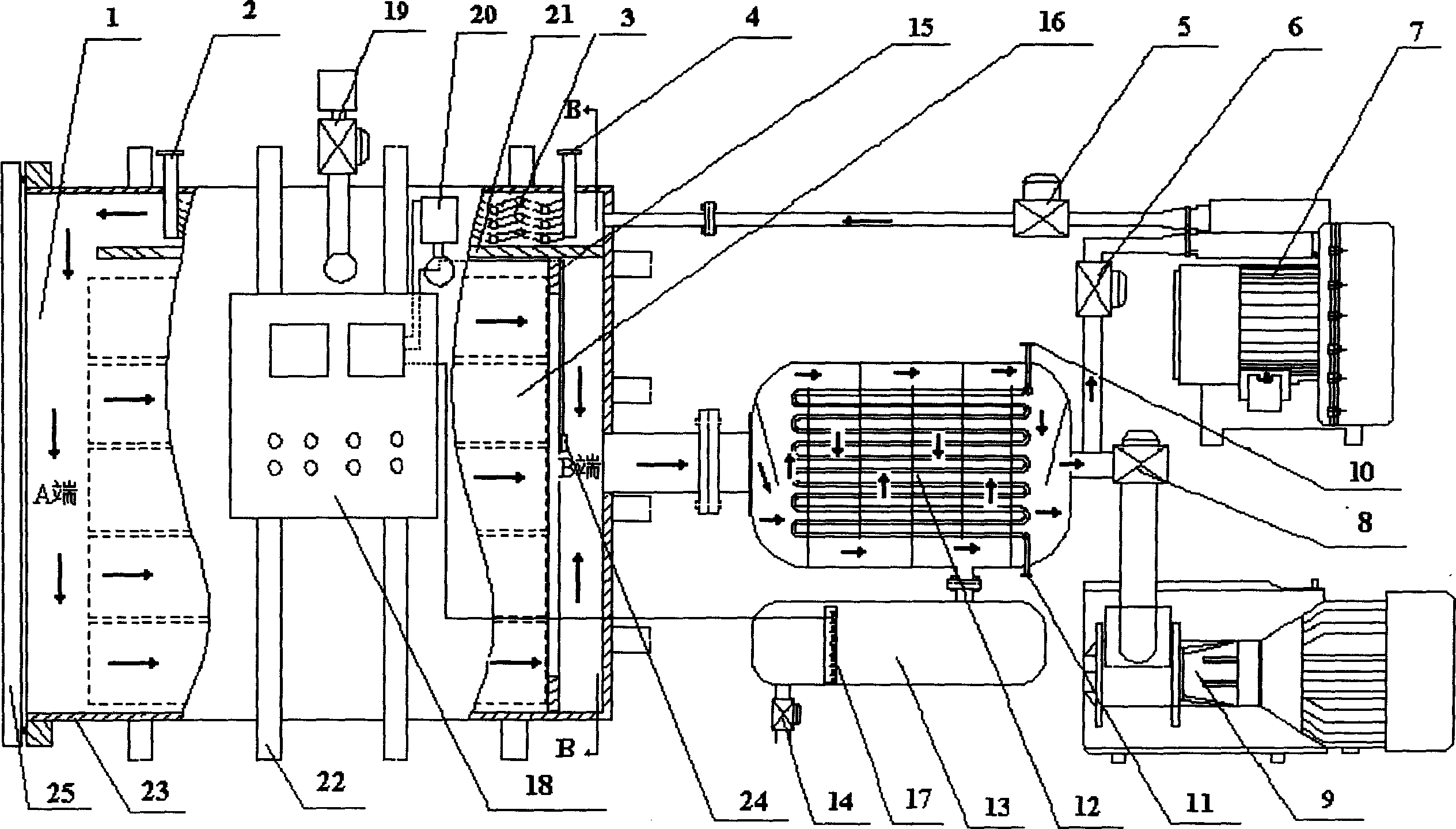

[0119]The structure of the preservation device of this embodiment is as follows.

[0120] in figure 1 The structure diagram of the edible fungus preservation device of the present invention shown and figure 2 In the illustrated embodiment, a cooling heat exchanger 12 is connected to the B end of the closed vacuum processing chamber 1, and a heating heat exchanger 3 is installed at the upper end of the vacuum processing chamber 1, and a partition is provided between the heating heat exchanger and the material.板21。 Board 21.

[0121] The inlet end of the cooling heat exchanger 12 is connected to the end B of the vacuum processing chamber 1, and the outlet end of the cooling heat exchanger 12 is connected to the suction pi...

Embodiment 2

[0153] The fresh shiitake mushrooms are kept fresh. The moisture content of newly harvested mushrooms is between 85% and 90%, and the temperature after preservation and processing is required to be between -1 and 2°C and the humidity between 74 and 76%.

[0154] In addition to the fresh-keeping process of edible fungi in Example 1 of the present invention, in the above process 2-A.. vacuum rapid cooling and dehumidification process, the air pressure in the vacuum processing chamber is reduced to an absolute pressure of 800-1000 Pa for 10-30 minutes , The temperature of the edible fungi is reduced to 5-8°C within 10-40 minutes, and then, except for the following steps, the other is the same as in Example 1, and the preservation treatment is performed.

[0155] 2-B. Air circulation condensation and dehumidification

[0156] That is, in the vacuum processing chamber, at a wind temperature of 5 to 35°C, air circulation is performed again for condensation and dehumidification, and the ...

Embodiment 3

[0164] The fresh shiitake mushrooms are kept fresh. The newly harvested mushrooms have a high water content, between 90%-95%, and require a temperature of -1 to 2°C and a humidity of 74 to 76% after preservation and processing.

[0165] Except that in the fresh-keeping process of edible mushrooms in the embodiment 2 of the present invention, except that the above-mentioned steps 2-B and 2-C are repeated twice, the fresh-keeping treatment is performed as in the second embodiment. As a result, a fresh-keeping processed shiitake edible mushroom with uniform temperature and humidity inside and outside the fungus, a humidity of 74-76%, and no surface deformation is formed.

[0166] According to Example 3, the fresh-keeping treatment of shiitake mushrooms has uniform temperature and humidity inside and outside the fungus, with a humidity of 74-76%, no surface deformation, and can be used for storage and transportation at low temperatures. Storage and transportation under low temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com