Method for manufacturing decoration sheet material with concave-convex surface

A technology for decorative boards and surface bumps, which is applied in the production of boards and the production of concave-convex decorative boards. It can solve the problems of poor aesthetics, low formaldehyde content, and high formaldehyde content, and achieve strong impact resistance and low formaldehyde release. , The effect of high internal bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

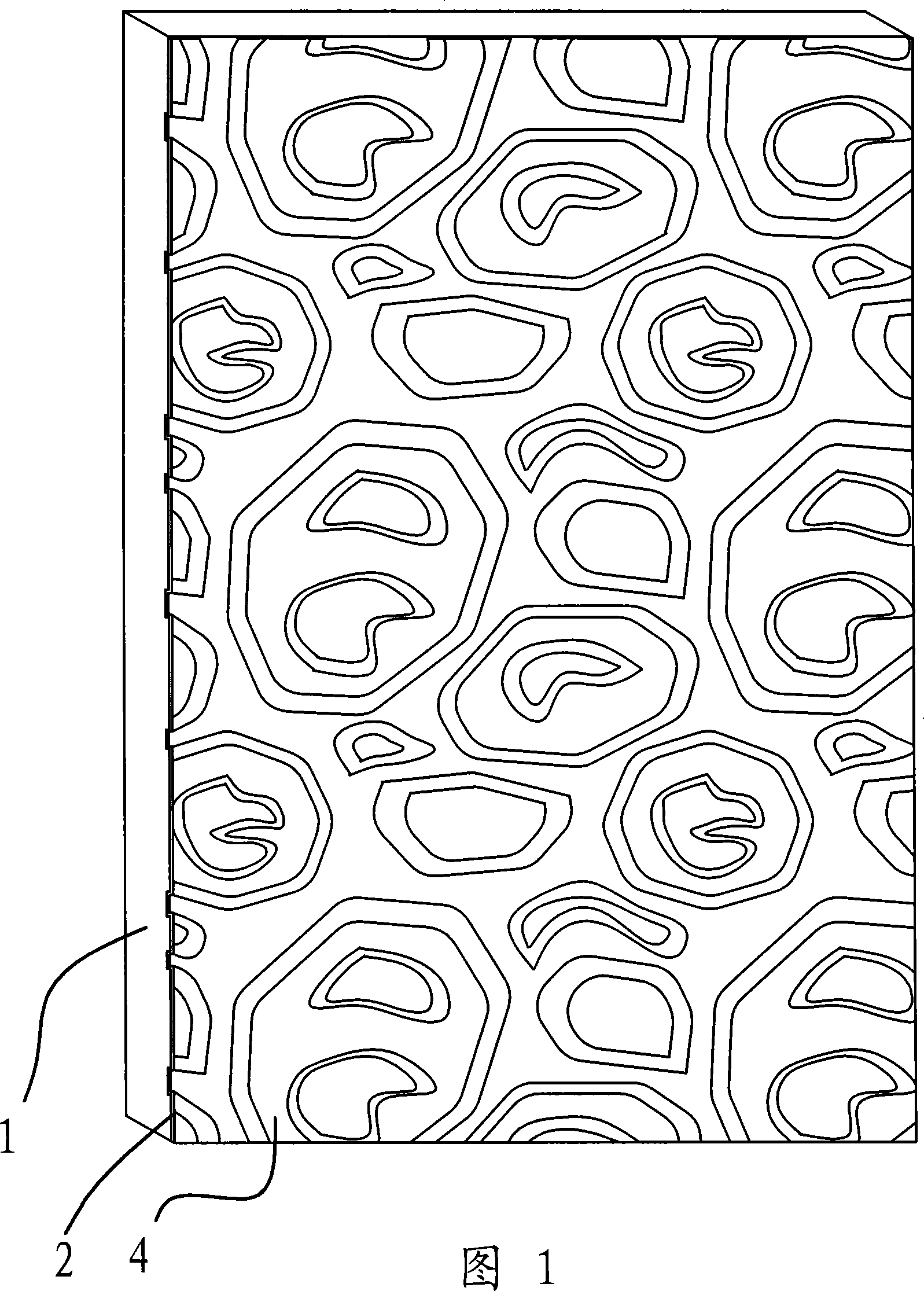

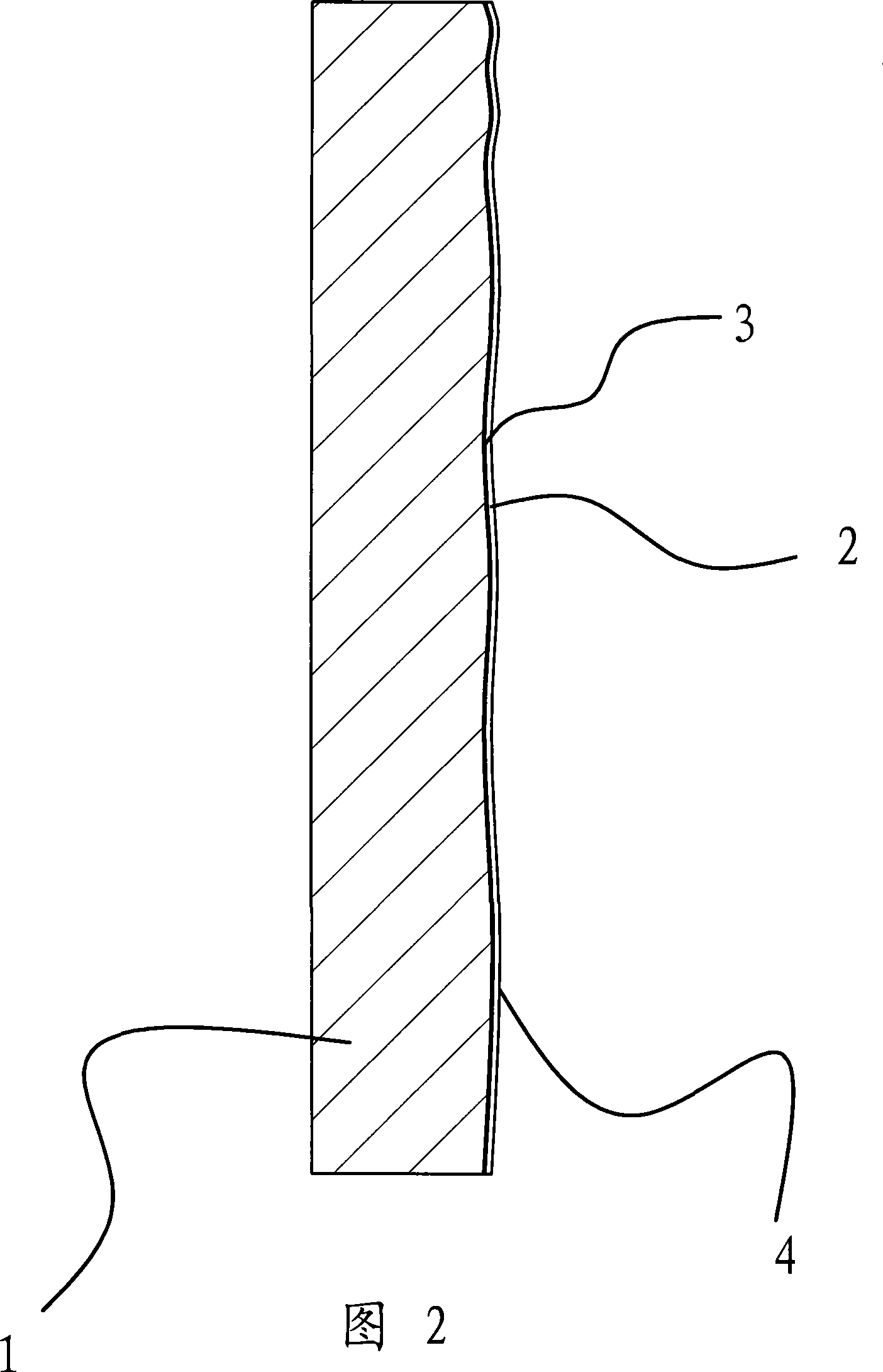

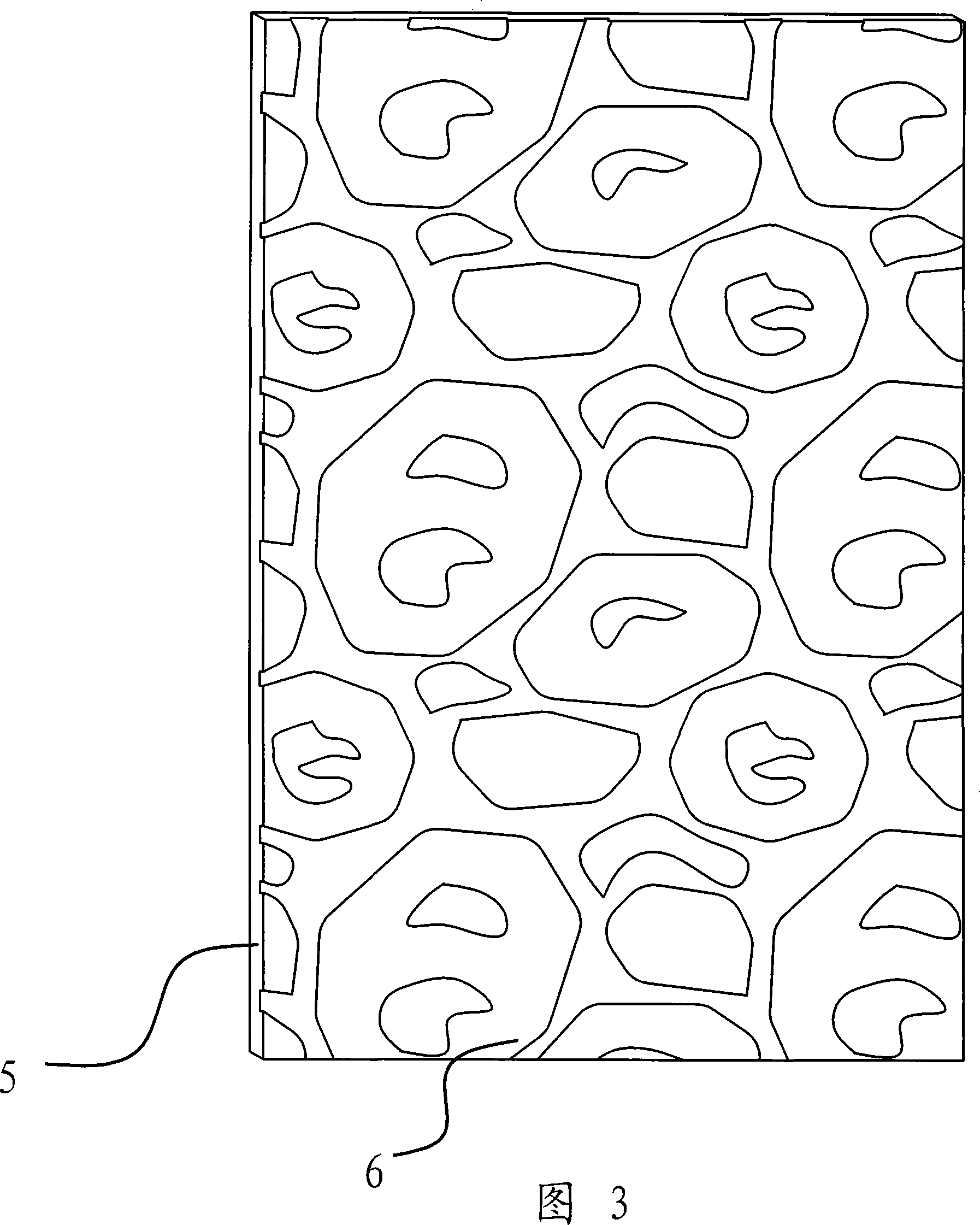

[0028] Dipping: select the decorative cardboard 2, and then transport it through the conveyor and immerse it in the melamine thermosetting resin, wherein the conveying speed of the conveyor is 10 m / min, dipping for 20 seconds so that both the front and back of the decorative cardboard 2 are soaked in the melamine thermosetting resin;

[0029] Drying: Put the above-mentioned soaked decorative paper in an oven to make it quasi-dry, wherein the drying temperature is 80°C, and the drying speed is 10 m / min;

[0030] Pressing: Lay the above-mentioned quasi-dry decorative paper on the medium-density board, and then convey it into the press through the conveyor, where the conveying speed of the conveyor is 10 m / min; it is carried out by the press at a high temperature of 200°C Pressing, the press is heated by oil heating, the pressure of the press is 94.2kg / cm 2 , wherein the bottom 7 of the press is provided with a concave-convex steel plate, and a silicone pad 8 is provided between ...

Embodiment 2

[0035]Impregnation: Select the decorative cardboard, and then transport it through the conveyor and dip it into the melamine thermosetting resin. The conveying speed of the conveyor is 15 m / min, dipping for 10 seconds so that both the front and back of the decorative cardboard are soaked in the melamine thermosetting resin;

[0036] Drying: put the above-mentioned soaked decorative paper in an oven to make it quasi-dry, wherein the drying temperature is 50°C, and the drying speed is 15 m / min;

[0037] Pressing: Lay the quasi-dry decorative paper above on the low-density board, and then convey it under the press through a conveyor, where the conveying speed of the conveyor is 15 m / min; through the press at a high temperature of 180°C Pressing, the press is heated by oil heating, the pressure of the press is 60kg / cm 2 , wherein the bottom 7 of the press is provided with a concave-convex steel plate, and a silicone pad 8 is provided between the steel plate and the bottom 7 of the...

Embodiment 3

[0039] Impregnation: select the decorative cardboard, and then transport it through the conveyor and dip it into the melamine thermosetting resin. The conveying speed of the conveyor is 5 m / min, dipping for 50 seconds so that both the front and back of the decorative cardboard are soaked in the melamine thermosetting resin;

[0040] Drying: put the above-mentioned soaked decorative paper in an oven to make it quasi-dry, wherein the drying temperature is 100°C, and the drying speed is 5 m / min;

[0041] Pressing: spread the above-mentioned quasi-dry decorative paper on the high-density board, and then convey it into the press through the conveyor, and the conveying speed of the conveyor is 5 m / min; it is carried out by the press at a high temperature of 250°C Pressing, the press is heated by oil heating, the pressure of the press is 100kg / cm 2 , for wherein the bottom 7 of the press is provided with a concave-convex steel plate, and a silica gel pad 8 is provided between the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com