Diatomaceous earth breathing brick with high humidifying harm-reduction function and production method thereof

A diatomite and breathing brick technology is applied in the application field of decorative materials, which can solve the problems that affect breathing bricks to adjust humidity, absorb formaldehyde and odor, cannot form large-size samples, and control moisture content inconveniently, so as to achieve less decorative materials and plasticity. High, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

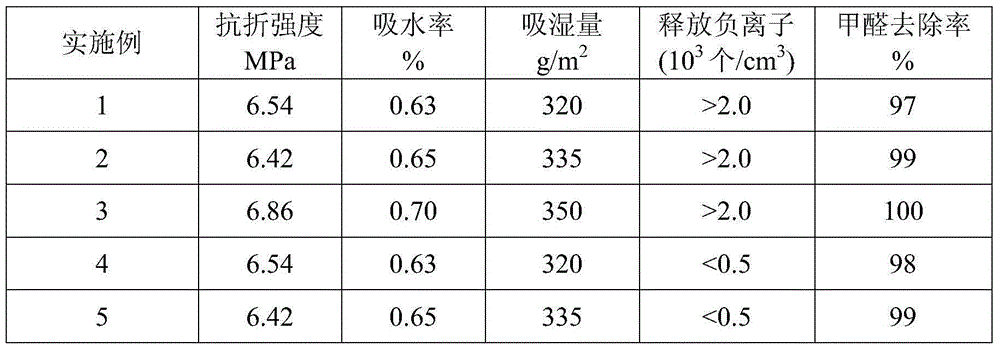

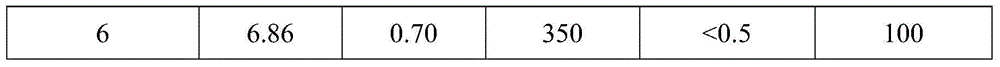

Examples

Embodiment 1

[0043] Concrete formula (weight percentage) of the present invention:

[0044] Diatomaceous earth: 80%;

[0045] Jilin soil: 7%;

[0046] Kaolin: 7%;

[0047] Talc: 1.5%;

[0048] Ceramic body reinforcement: 0.5%;

[0049] Industrial sodium carbonate: 0.5%;

[0050] Heavy calcium: 0.5%;

[0051] Superplasticizer: 1%;

[0052] Nano titanium dioxide: 0.5%;

[0053] Tourmaline powder: 1.5%.

[0054] Preparation:

[0055] Grind the above-mentioned diatomite and clay through a horizontal ball mill to a 200-mesh sieve balance ≤ 10%, then add other raw materials in the components into the horizontal ball mill and mix them evenly, add an appropriate amount of water, and mix them in the horizontal ball mill for 3 hours, Iron removal by iron remover, granulation by spray dryer, distribution by ceramic distribution machine, automatic press molding, muffle furnace at 800°C, and heat preservation for 30 minutes to obtain diatomite breathing bricks with high humidity control and ha...

Embodiment 2

[0057] Concrete formula (weight percentage) of the present invention:

[0058] Diatomaceous earth: 85%;

[0059]Jilin soil: 4.5%;

[0060] Kaolin: 4.5%;

[0061] Talc: 1.2%;

[0062] Ceramic body reinforcement: 0.7%;

[0063] Industrial sodium carbonate: 0.7%;

[0064] Heavy calcium: 0.7%;

[0065] Superplasticizer: 0.7%;

[0066] Nano titanium dioxide: 0.5%;

[0067] Tourmaline powder: 1.5%.

[0068] Preparation:

[0069] Grind the above-mentioned diatomite and clay through a horizontal ball mill to a 200-mesh sieve balance ≤ 10%, add other raw materials in the components to the horizontal ball mill and mix evenly, add an appropriate amount of water, and mix the materials through the horizontal ball mill for 2.5 hours , Iron removal by iron remover, granulation by spray dryer, cloth by ceramic distribution machine, automatic press molding, muffle furnace at 900°C, and heat preservation for 25 minutes to obtain diatomite breathing bricks with high humidity control and...

Embodiment 3

[0071] Concrete formula (weight percentage) of the present invention:

[0072] Diatomaceous earth: 90%;

[0073] Jilin soil: 2%;

[0074] Kaolin: 2%;

[0075] Talc: 0.5%;

[0076] Ceramic body reinforcement: 1%;

[0077] Industrial sodium carbonate: 1%;

[0078] Heavy calcium: 1%;

[0079] Superplasticizer: 0.5%;

[0080] Nano titanium dioxide: 0.5%;

[0081] Tourmaline powder: 1.5%.

[0082] Preparation:

[0083] Grind the above-mentioned diatomite and clay through a horizontal ball mill to a 200-mesh sieve balance ≤ 10%, then add other raw materials in the components into the horizontal ball mill and mix them evenly, add an appropriate amount of water, and mix them through the horizontal ball mill for 2 hours, Iron removal by iron remover, granulation by spray dryer, distribution by ceramic distribution machine, automatic press molding, muffle furnace at 1000°C, and heat preservation for 20 minutes to obtain diatomite breathing bricks with high humidity control and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com