Fiberboard and preparation method thereof

A production method and fiberboard technology, which can be applied to other seating furniture, mattresses, textiles, and papermaking, and can solve the problems of high sugar content, mildew, and insect growth in coconut fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

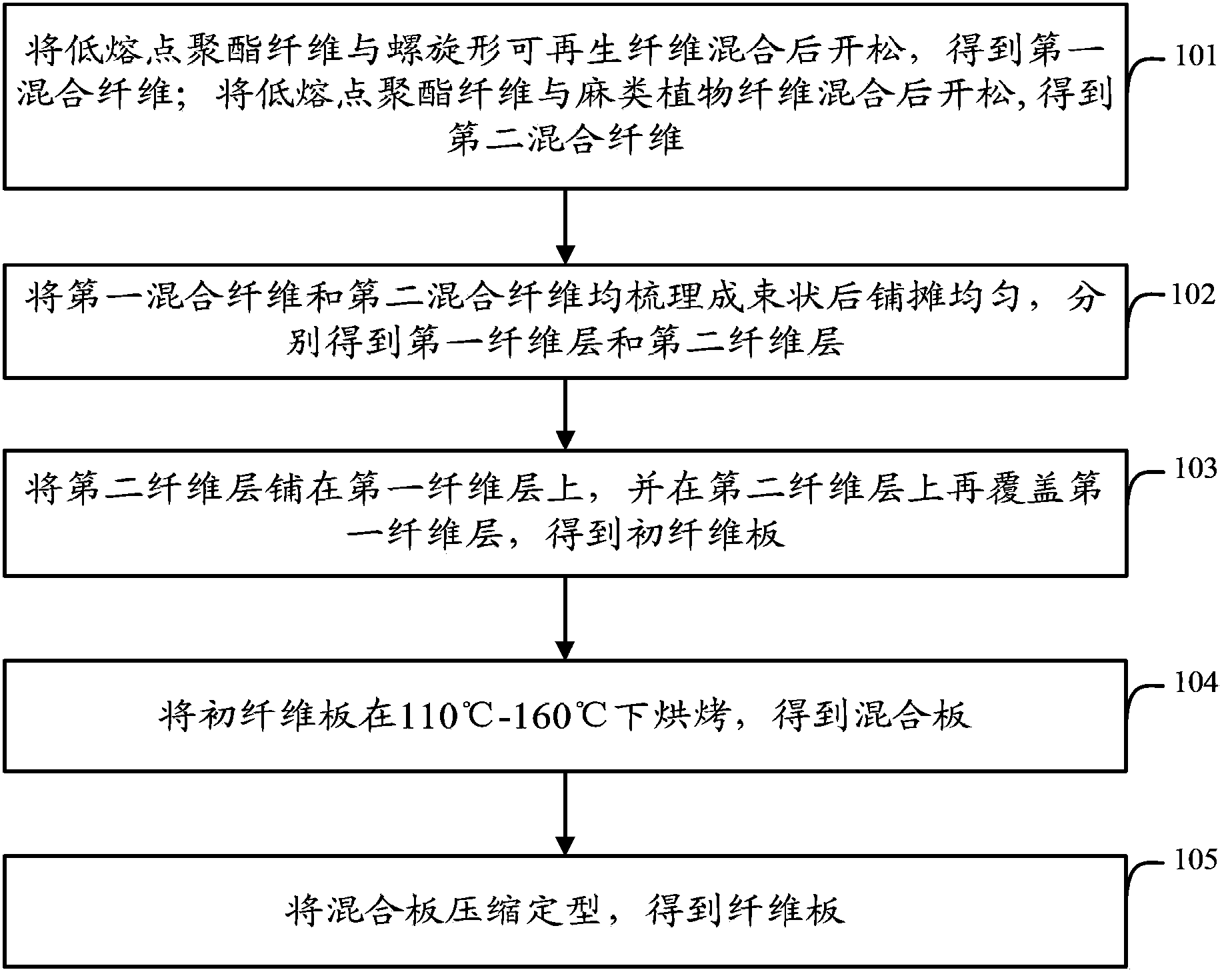

Method used

Image

Examples

Embodiment 2

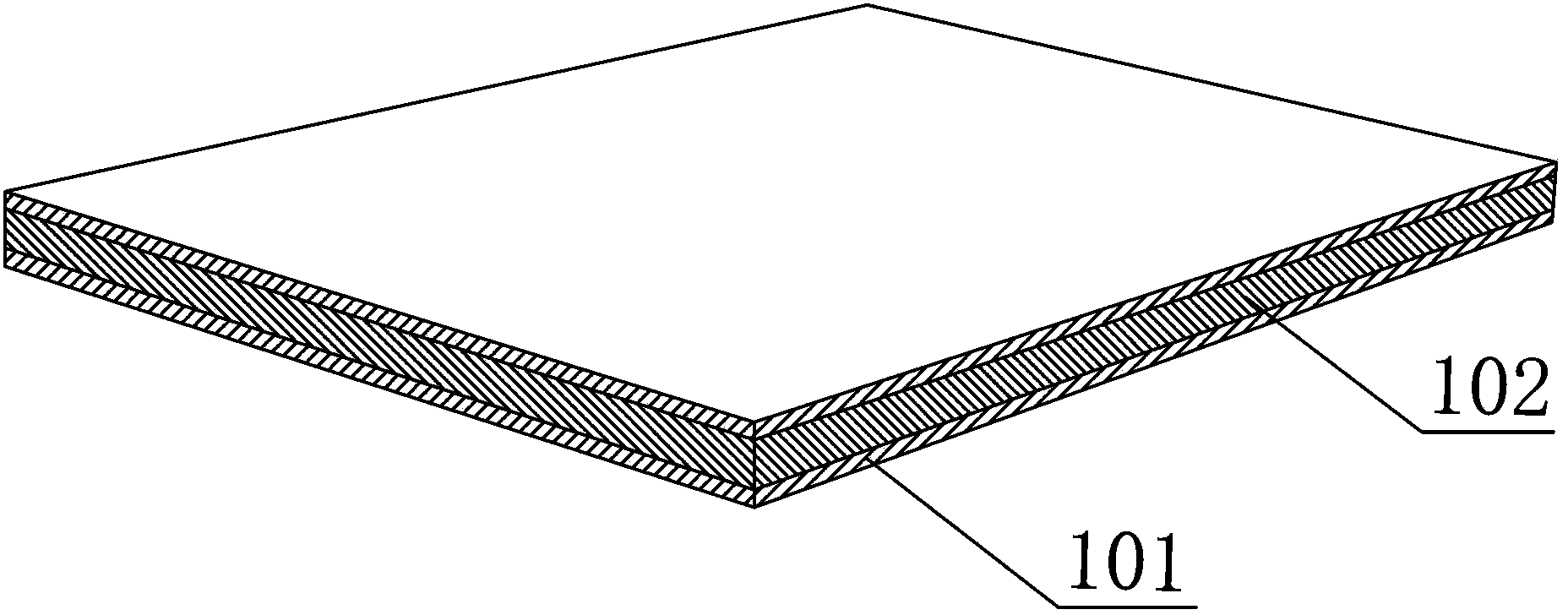

[0023] Since the fiberboard is composed of the first fiber layer 101 and the second fiber layer 102, the fiberboard may crack from the connection between the first fiber layer 101 and the second fiber layer 102 during long-term use. For this problem, optionally, the side walls of the first fiber layer 101 and the second fiber layer 102 are provided with a glue layer, so that the side walls of the first fiber layer 101 and the second fiber layer 102 can be bonded by the glue layer, Furthermore, the effect of closely bonding the entire first fiber layer 101 and the second fiber layer 102 is achieved, so as to solve the problem of cracking of the fiberboard.

[0024] The fiberboard of this embodiment sandwiches the second fiber layer 102 through the first fiber layer 101, so, in the process of specific setting, in order to make the first fiber layer 101 and the second fiber layer 102 can better realize Form an integral fiberboard, so in this embodiment, the first fiber layer 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com