Modified vinyl acetate-acrylic emulsion adhesive with antibacterial function and preparation method thereof

A vinyl acetate-acrylate emulsion and adhesive technology, applied in the directions of monocarboxylic acid ester copolymer adhesive, adhesive type, resistance to vector-borne diseases, etc. Conducive to long-term storage, improved hydrolysis resistance, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

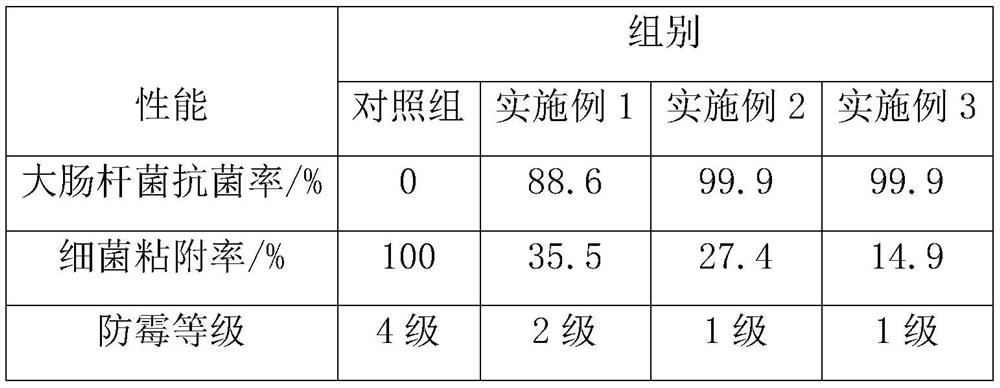

Examples

Embodiment 1

[0022] (1) Preparation of antibacterial monomer: at room temperature, react 10g of α-methyl-D-mannoside with 1.9g of isocyanoethyl methacrylate, take 50mL of dichloromethane as the reaction solvent, and react for 72h to obtain antibacterial monomer.

[0023] (2) Preparation of modified sorbitol: Dissolve 10g of sorbitol in 50mL of tetrahydrofuran or cyclohexane solution, then gradually add 1.2g of isocyanomethacrylate, stir and heat the reaction mixture, and react at 90°C for 24h The reaction mixture was stirred and heated.

[0024] (3) Preparation of modified vinegar-acrylic emulsion adhesive with antibacterial function: add 50mL deionized water and 5g polyvinyl alcohol to a four-necked flask with heating, electric stirring, condensation and nitrogen conduit, and heat to 70°C Continue to stir for 1 hour, then cool to 40°C, then add 0.1g of buffer solution, the buffer solution is an aqueous solution of sodium acetate and ferrous sulfate with a weight ratio of 1:2, then add 10...

Embodiment 2

[0026] 1) Preparation of antibacterial monomer: at room temperature, 15g of 4-isothiohydrophenyl-A-D-mannoside was reacted with 2.85g of isocyanoethyl methacrylate, and 100mL of dichloromethane was used as the reaction Solvent, reaction 72 to obtain antibacterial monomer h.

[0027] 2) Preparation of modified sorbitol: Dissolve 20g of sorbitol in 100mL of tetrahydrofuran or cyclohexane solution, then gradually add 2.4g of isocyanomethacrylate, stir and heat the reaction mixture, react at 90°C for 24h and stir and heat the reaction mixture.

[0028] 3) Preparation of modified vinegar-acrylic emulsion adhesive with antibacterial function: Add 100mL deionized water and 10g polyvinyl alcohol into a four-necked flask equipped with heating, electric stirring, condensation and nitrogen conduit, and heat it to 70°C Continue to stir for 2 hours, then cool to 50°C, then add 0.5g of buffer solution, the buffer solution is an aqueous solution of sodium acetate and ferrous sulfate with a ...

Embodiment 3

[0030] 1) Preparation of antibacterial monomer: at room temperature, 20g of 4-methylumbelliferyl α-D-mannopyranoside was reacted with 3.8g of isocyanoethyl methacrylate, and 150mL of dichloromethane was used as Reaction solvent, react for 72h to obtain antibacterial monomer.

[0031] 2) Preparation of modified sorbitol: Dissolve 30g of sorbitol in 150mL of tetrahydrofuran or cyclohexane solution, then gradually add 3.6g of isocyanomethacrylate, stir and heat the reaction mixture, react at 90°C for 24h and stir and heat the reaction mixture.

[0032]3) Preparation of modified vinegar-acrylic emulsion adhesive with antibacterial function: add 150mL deionized water and 15g polyvinyl alcohol to a four-necked flask equipped with heating, electric stirring, condensation and nitrogen conduit, and heat to 70 °C Continue to stir for 4 hours, then cool to 40°C, then add 0.3g of buffer solution, the buffer solution is an aqueous solution of sodium acetate and ferrous sulfate with a weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com