Patents

Literature

60results about How to "Good for long-term storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-hydrophobic coating, super-hydrophobic coating layer as well as preparation method and application of super-hydrophobic coating layer

InactiveCN109370418AStrong adhesionIncreased durabilityLiquid surface applicatorsAntifouling/underwater paintsAcrylic resinHydrophobic silica

The invention discloses a super-hydrophobic coating, a super-hydrophobic coating layer as well as a preparation method and application of the super-hydrophobic coating layer, relating to the technicalfield of hydrophobic materials. The preparation method comprises the following steps: adding ammonia water and silicate ester into an alcohol solvent, stirring for reaction, and aging, so as to obtain dispersion liquid of silicon dioxide nano-particles; adding a low-surface-energy fluoride-free organic matter into the dispersion liquid of the silicon dioxide nano-particles, so as to obtain super-hydrophobic silicon dioxide functional nano-liquid; mixing organic silicon resin, acrylic resin, nylon powder, barium sulfate powder, a diluent and a dispersing agent, so as to prepare a primer coating; adding a curing agent into the primer coating, coating the surface of a base material with the primer coating, so as to obtain a primer; and spraying the super-hydrophobic silicon dioxide functional nano-liquid to the surface of the primer, and drying, so as to obtain the super-hydrophobic coating layer. By coating the surface of glass, metal, ceramic or plastic with the super-hydrophobic coating layer, the hydrophobic and anti-pollution properties of the material are improved.

Owner:武汉疏能新材料有限公司

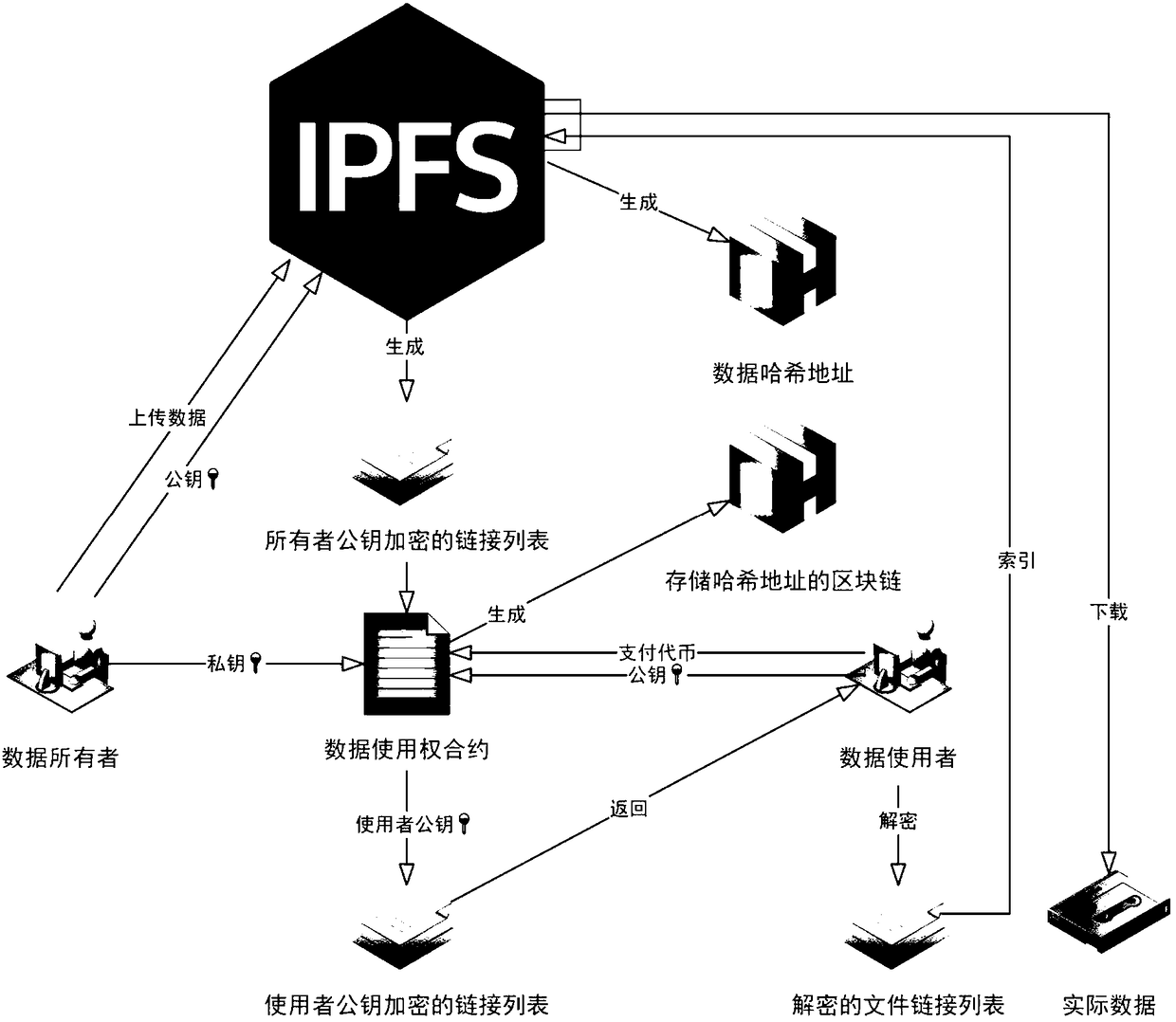

Method and equipment for medical image data decentralized management based on block chain

ActiveCN109243583AHigh transparencyGood for long term storageDigital data protectionMedical imagesFile systemSmart contract

The invention relates to a method for medical image data decentralized management based on a block chain. The data owning end uploads the owned medical image data stores the medical image data as an interstellar file system (IPFS) file, the hash value for the medical image data is taken and the link list file in the IPFS is encrypted by using the public key of the data owning end; the data accesscontract uses the private key of the data owning end to decrypt the encrypted link list file in the step according to the smart contract, and when the data use end transmits the data use end public key information and the payment tokens to the data access contract to request for obtaining the medical image data, the data access contract uses the user public key to encrypt the decrypted link list file again to be transmitted to the data use end and also generates the block chain storing the hash address; and the data use end performs decryption operation through the data use end private key toobtain the link list file and retrieves the interstellar file system to obtain the actual medical image data.

Owner:上海全景医学影像诊断中心有限公司

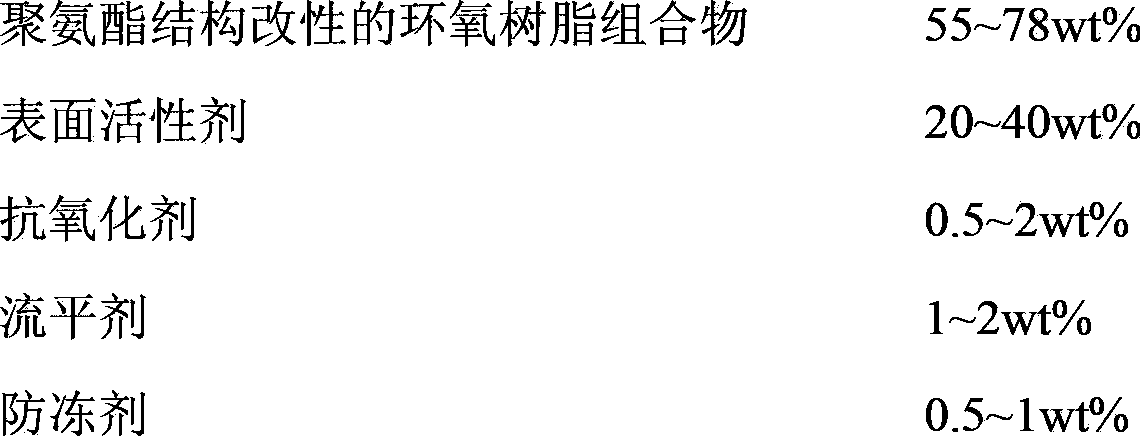

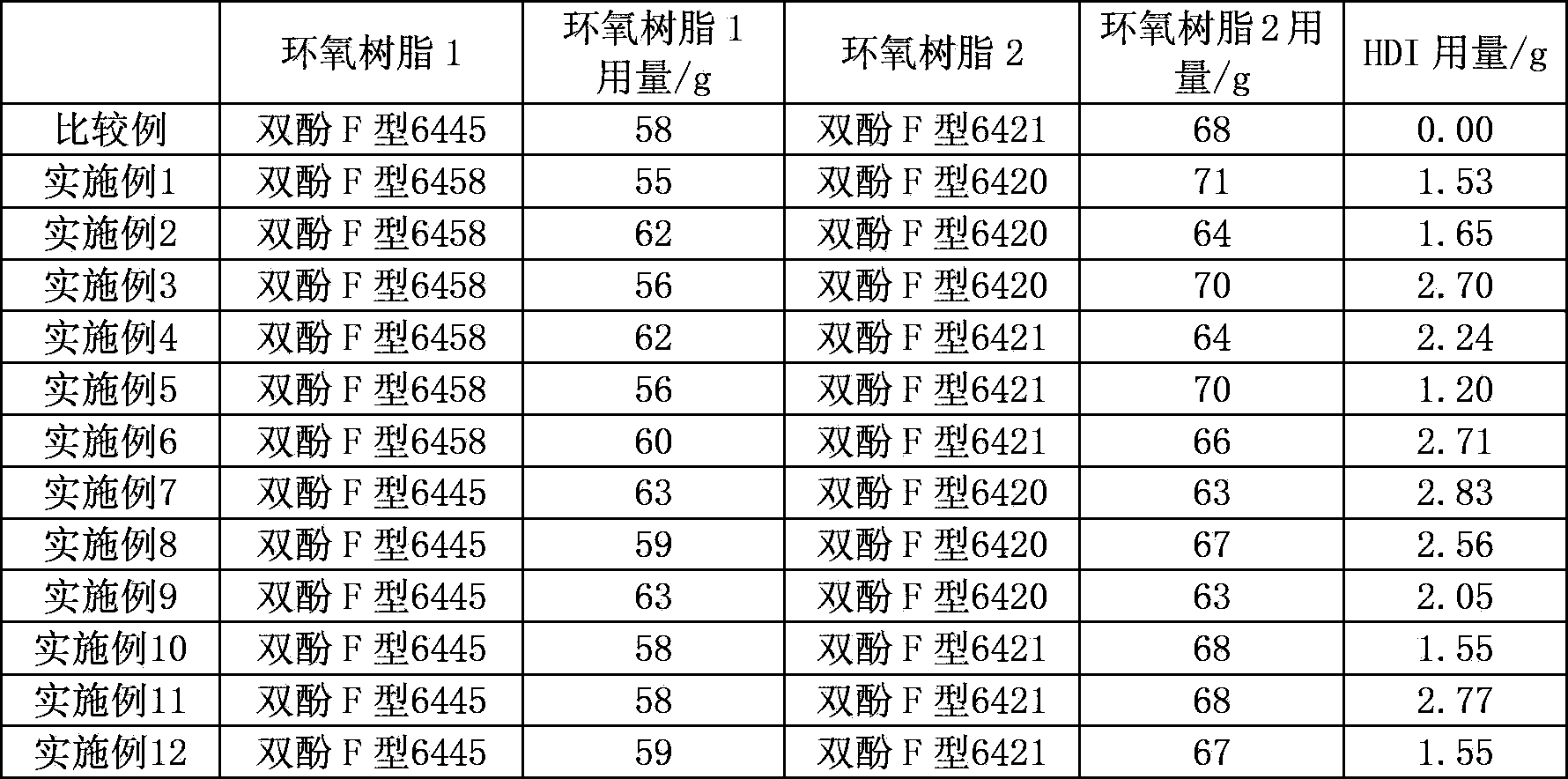

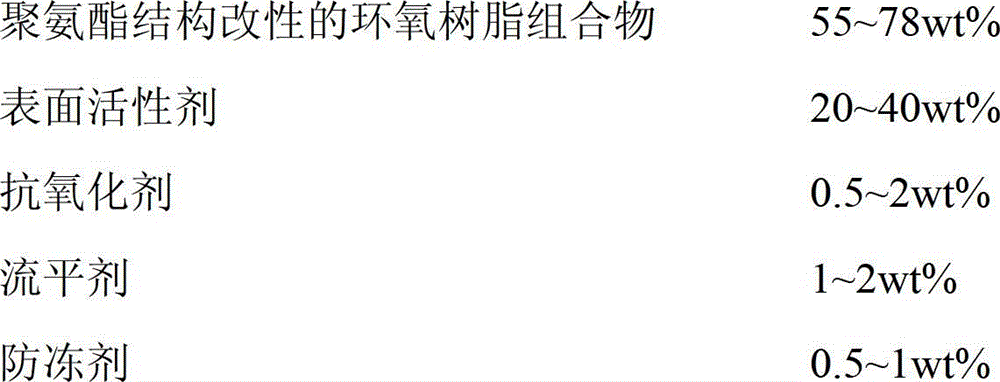

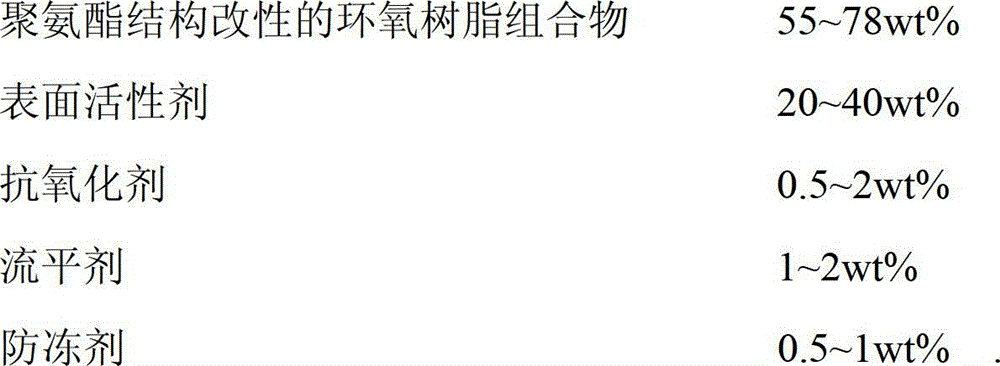

Epoxy-based carbon fiber sizing agent emulsion, its preparation method and its application

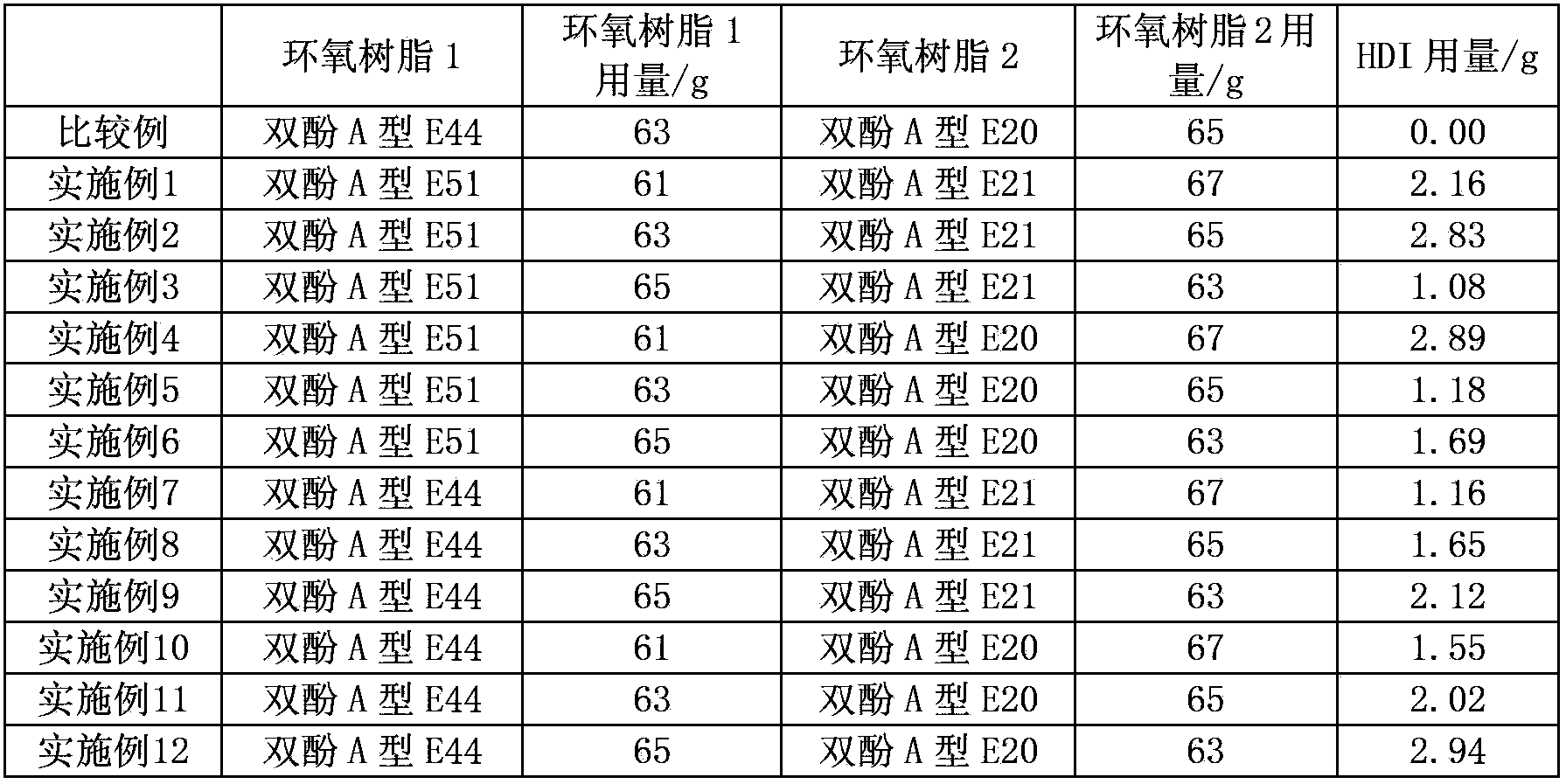

The invention relates to an epoxy-based carbon fiber sizing agent emulsion, which comprises the following components: 55-78wt% of polyurethane structure-modified epoxy resin composition, 20-30wt% of surfactant, 0.5-2wt% of anti-oxidant, 1-2wt% of levelling agent and 0.5-1wt% of antifreezing agent. A preparation method comprises the following steps: pumping a bisphenol F epoxy resin reactant under vacuum, dehydrating until no bubbles can be generated, adding an isocyanate reactant to prepare an epoxy resin composition; mixing and homogenizing the surfactant and the anti-oxidant in a reaction vessel according to the above material fraction; and then gradually adding deionized water, a levelling agent and an antifreezing agent to prepare the sizing agent emulsion. The carbon fiber from the epoxy-based carbon fiber sizing agent emulsion has good convergence, wear resistance and toughness, the sizing agent resin has good chemical stability, and is in favor of long-term storage and quality guaranteeing of sizing carbon fiber; the preparation method has the advantages of simple technology and easy operation, the reaction raw material has the advantages of convenient source and low cost, and the epoxy-based carbon fiber sizing agent emulsion is in favor of realization of industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

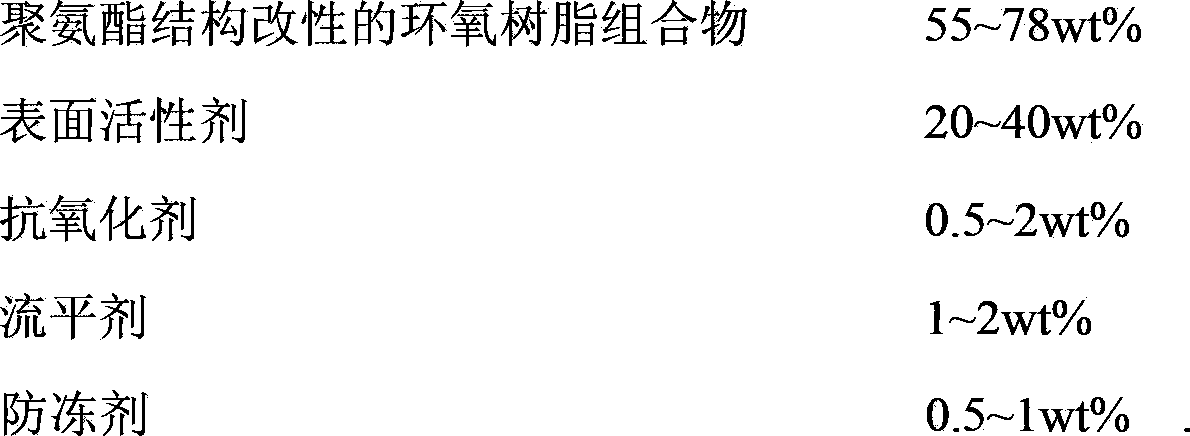

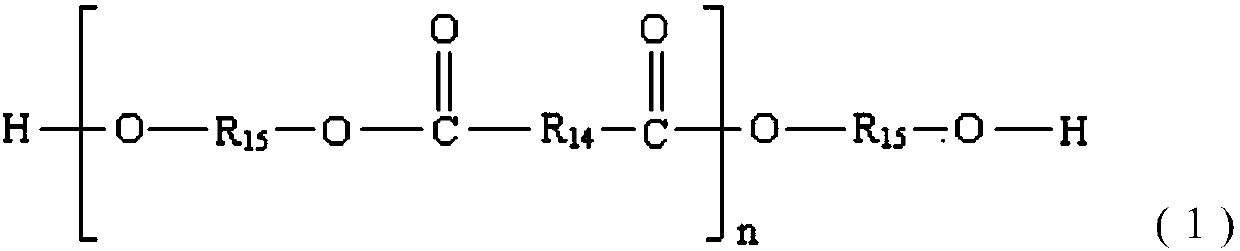

Polyurethane structure modified epoxy resin sizing agent emulsion, and preparation and application

The invention relates to a polyurethane structure modified epoxy resin sizing agent emulsion, which comprises the following ingredients: 55-78wt% of polyurethane structure modified epoxy resin composition, 20-40wt% of surfactant, 0.5-2wt% of anti-oxidant, 1-2wt% of levelling agent and 0.5-1wt% of antifreezing agent. The preparation method comprises the following steps: performing vacuum-pumping and dehydrating the bisphenol A epoxy resin to the condition that no bubbles can be generated, cooling and adding isocyanate to prepare a epoxy resin composition; mixing a surfactant and an antioxidant are mixed and homogenized in a reaction vessel according to the above material fraction, then adding deionized water, a levelling agent and an antifreezing agent gradually to obtain the polyurethane structure modified epoxy resin sizing agent emulsion. The carbon fiber prepared by the polyurethane structure modified epoxy resin sizing agent emulsion has good convergence, wear resistance and toughness, the convergence and wear resistance are easily and freely adjusted through the isocyanate component; a cluster agent is not required at the anaphase of the carbon fiber sizing agent, and on-site secondary mixing is not required, the application stability is good, the carbon fiber pasting wellability is good, and the polyurethane structure modified epoxy resin sizing agent emulsion is benefit for industrial stabilization and production of carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid lutein and preparation method thereof

InactiveCN101124944AStrong stabilityGood for long-term storageAnimal feeding stuffAccessory food factorsAbsorption rateChemistry

Owner:CHENGDU FENGLAN SCI & TECH

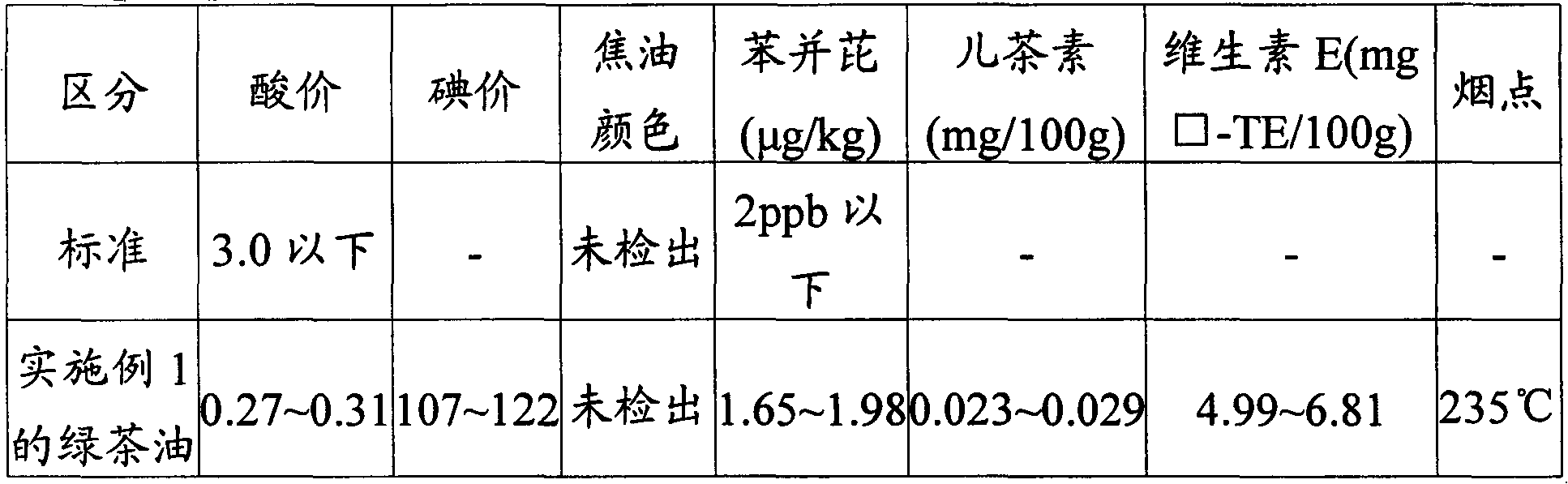

Edible oil comprising tea leaves and a process for the preparation therof

InactiveCN101874530AGood for long term storageDelayed acidificationPre-extraction tea treatmentTea extractionEdible oilAdditive ingredient

The invention provides an edible oil comprising tea leaves and a process for the preparation thereof. The edible oil comprising tea leaves comprises a tea leaves extract extracted using the edible oil as the medium. The invention also provides a process for the preparation thereof and a weight reduction food comprising the edible oil. The edible oil comprising tea leaves comprises high-proportion tea leaves fat-soluble components, especially tocopherol, when keeping the good taste, the edible oil is prepared using very simple method and the food containing the edible oil is also used as the weight reduction food.

Owner:BOSUNG GREEN TEA & TECH

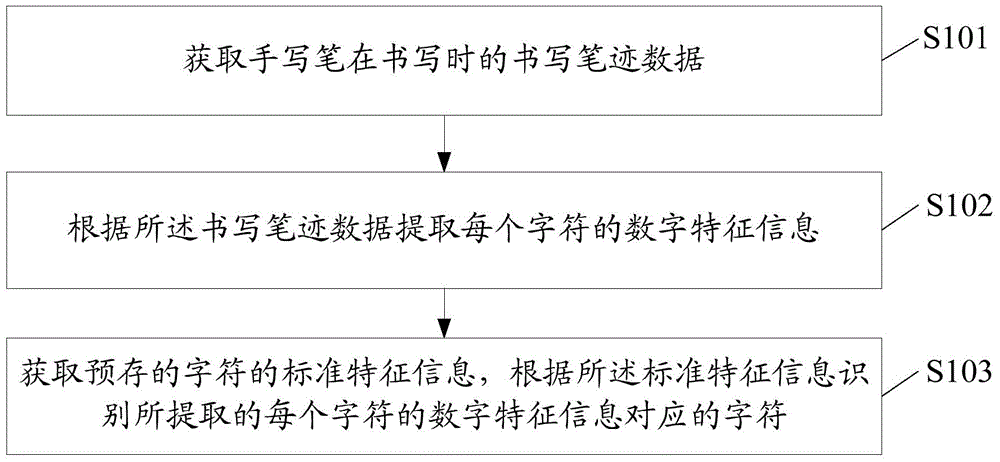

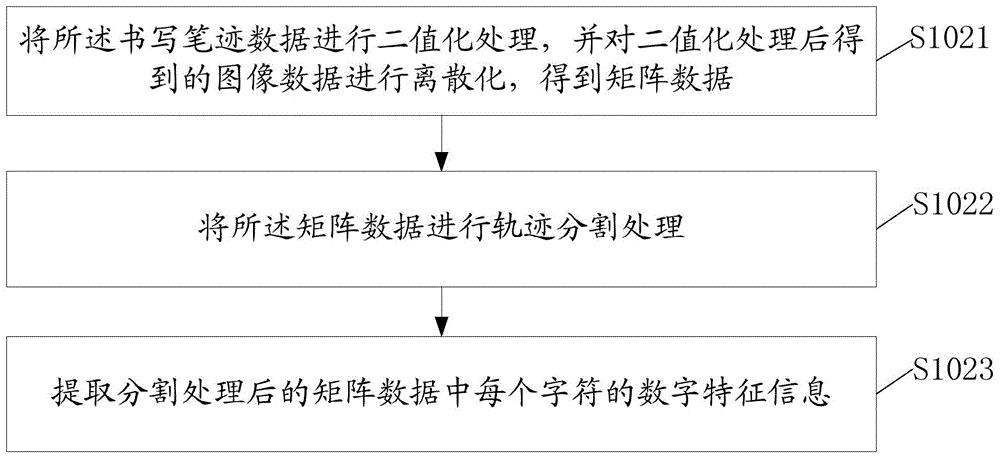

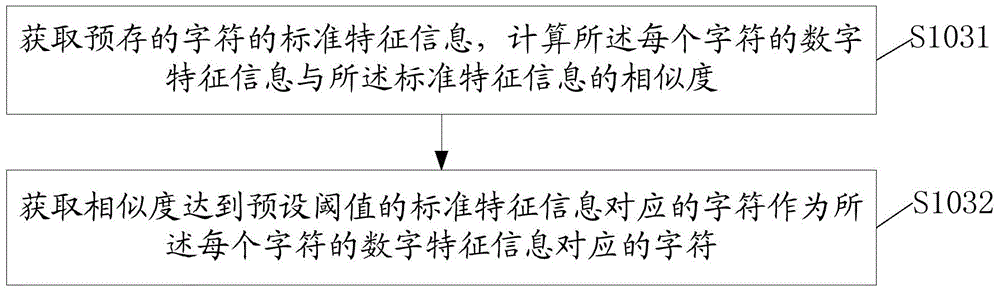

Character recognition method and stylus

InactiveCN104899560AGood for long term storageConvenient queryDigital ink recognitionCharacter recognitionHandwriting

The present invention discloses a character recognition method and a stylus. The character recognition method comprises the following steps of: acquiring handwriting data of the stylus in the writing process; according to the handwriting data, extracting numerical characteristic information of each character; and acquiring standard characteristic information of pre-stored characters, and according to the standard characteristic information, recognizing characters corresponding to the extracted numerical characteristic information of each character. According to the character recognition method and the stylus, electronization of paper documents can be implemented; long-term storage of written contents is facilitated and subsequent inquiry is convenient; the written contents are not required to input into intelligent terminals such as a computer and the like in a manual mode, so that input workload is greatly reduced.

Owner:NUBIA TECHNOLOGY CO LTD

Process for storing cut flowers of peony and Chinese herbaceous peony for long time

ActiveCN102365935ASolve the problems of short storage period and poor storage process effectExtended storage timeDead plant preservationFloral handlingPaeonia albifloraCut flowers

Owner:HENAN UNIV OF SCI & TECH

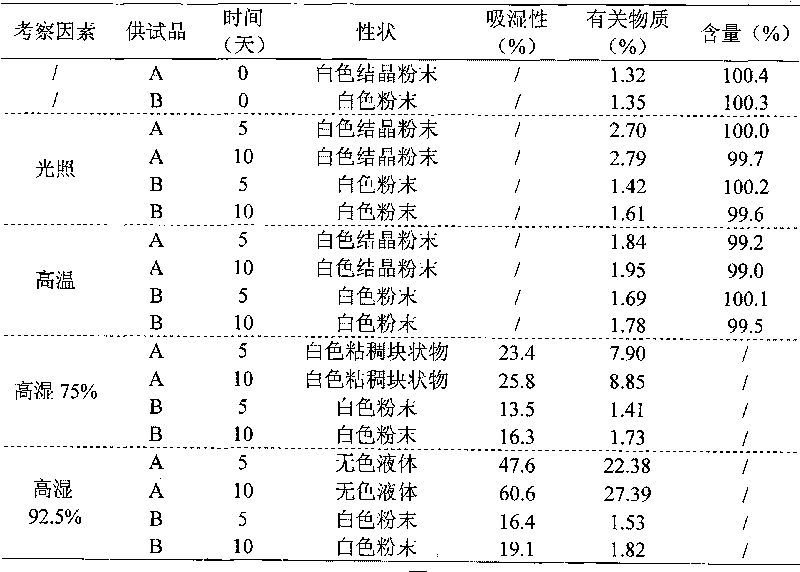

Two crystal forms of azilsartan and preparation method thereof

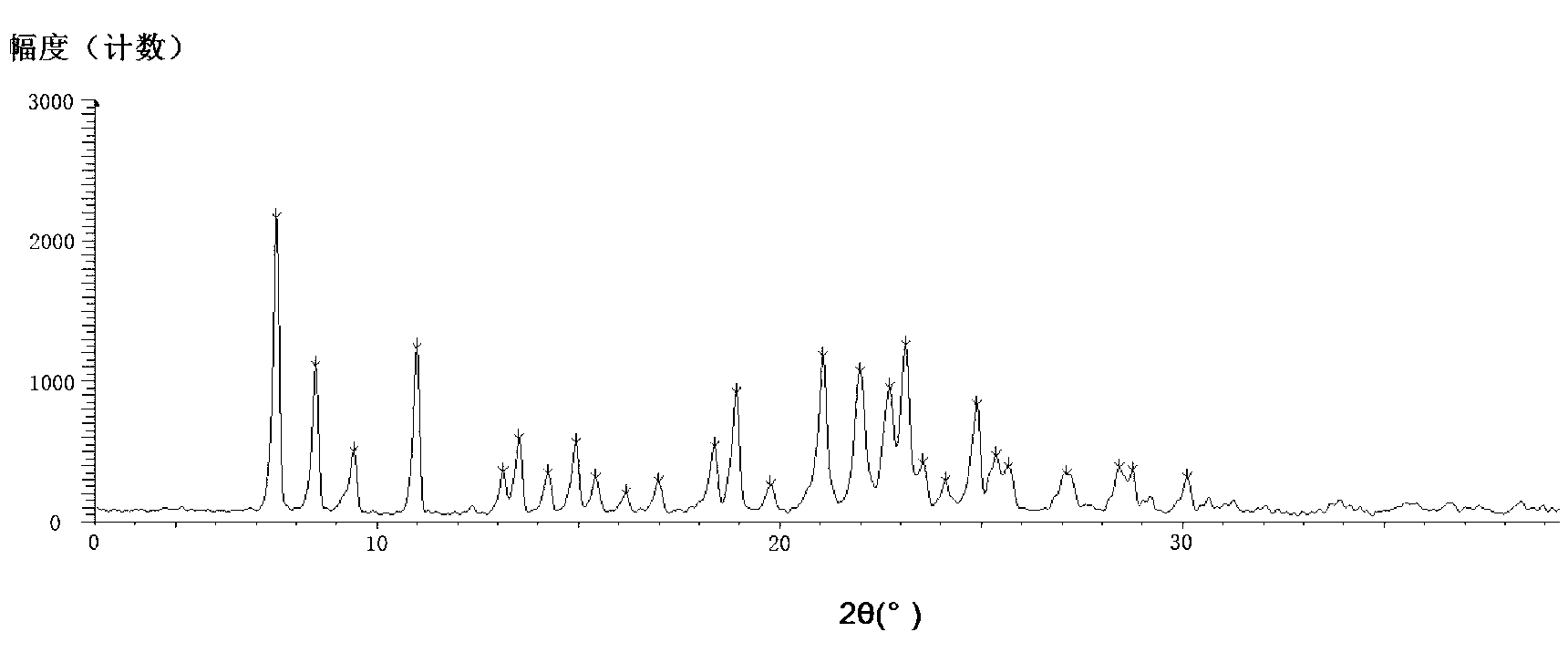

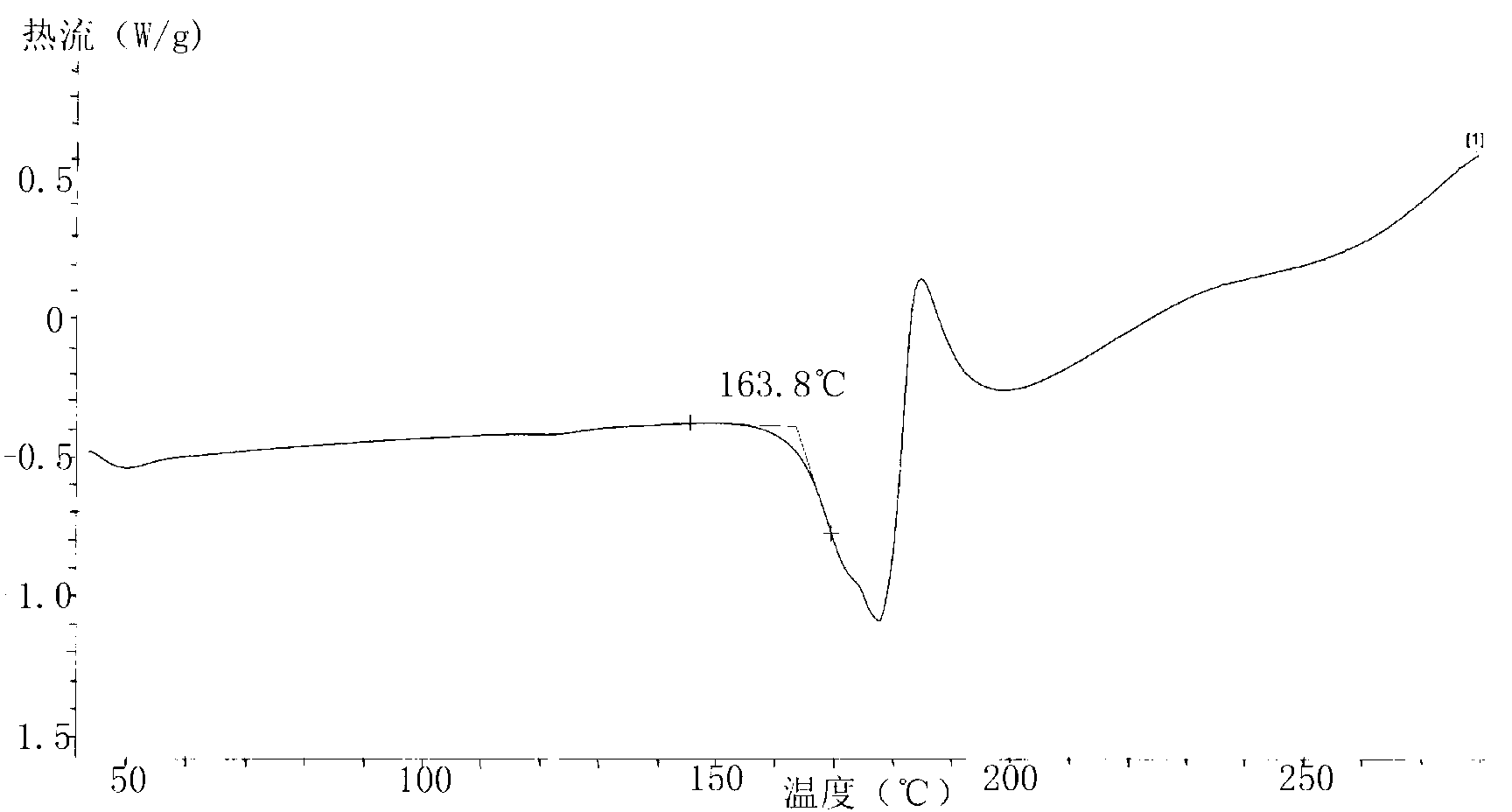

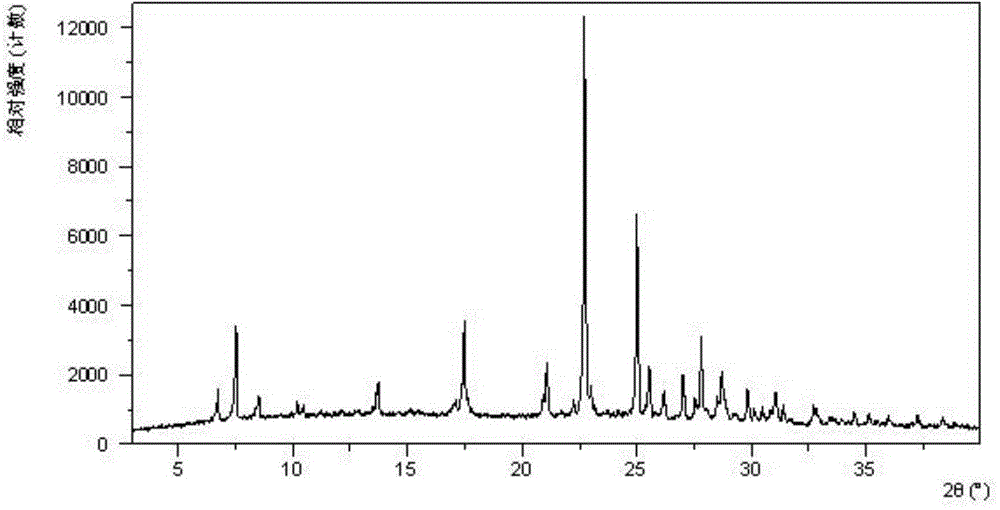

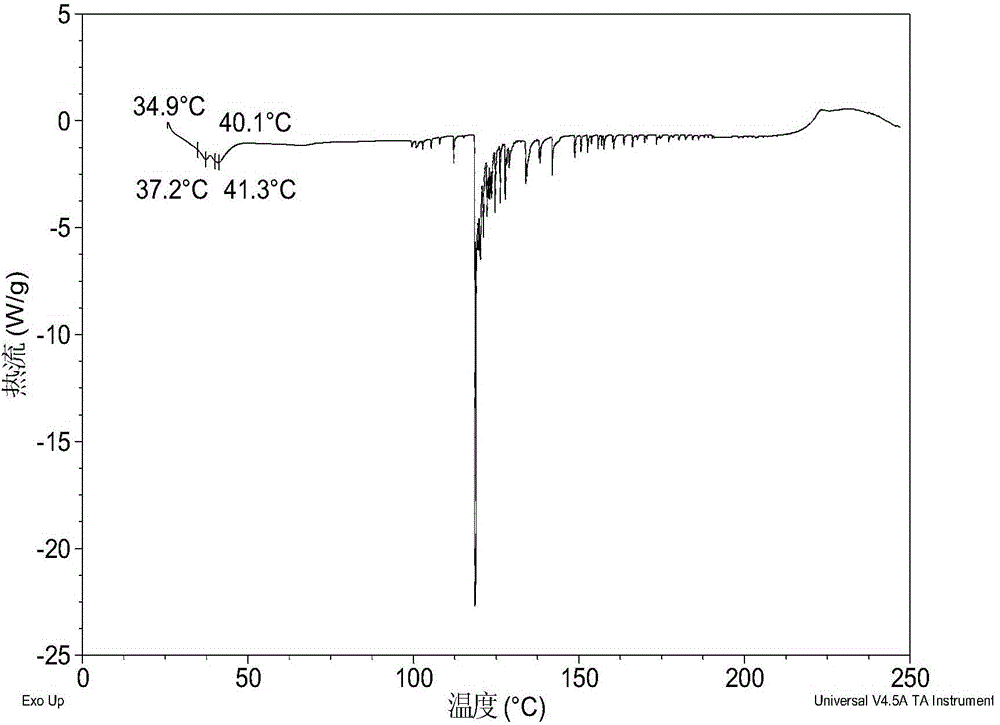

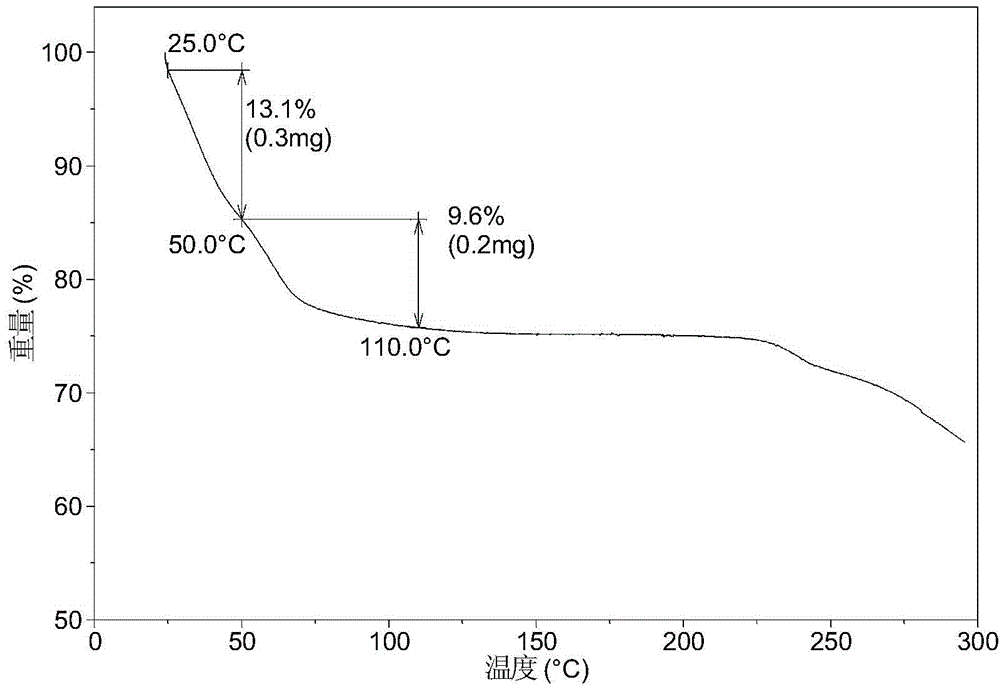

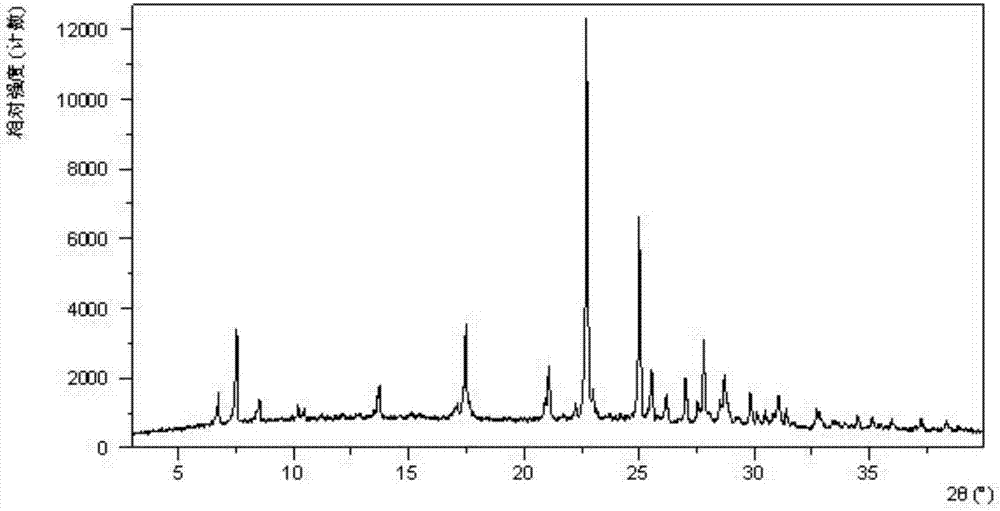

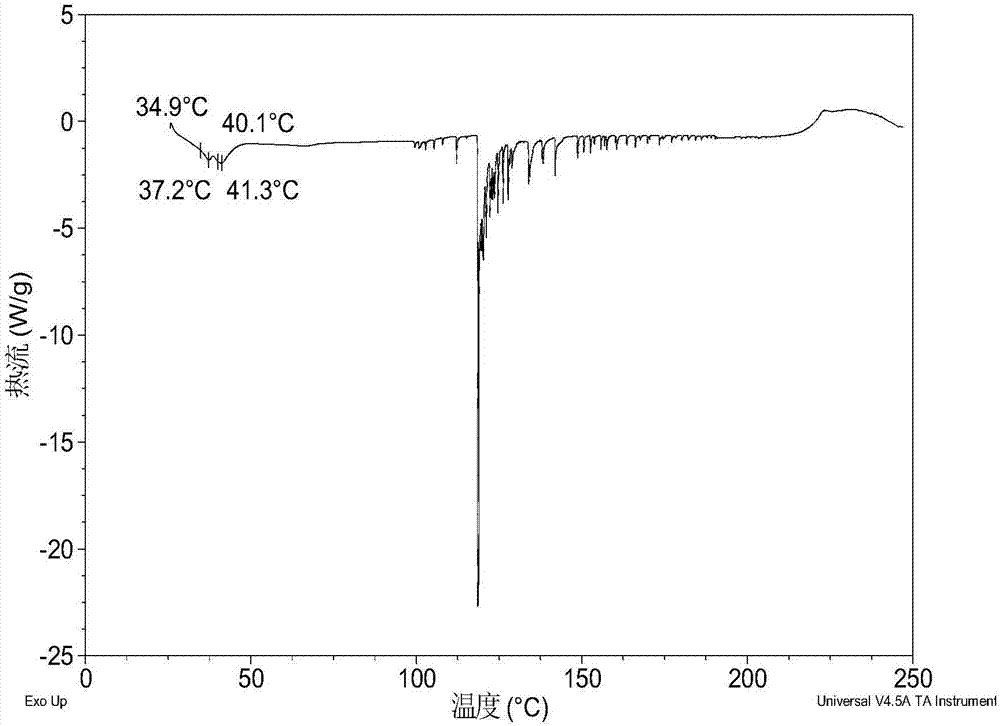

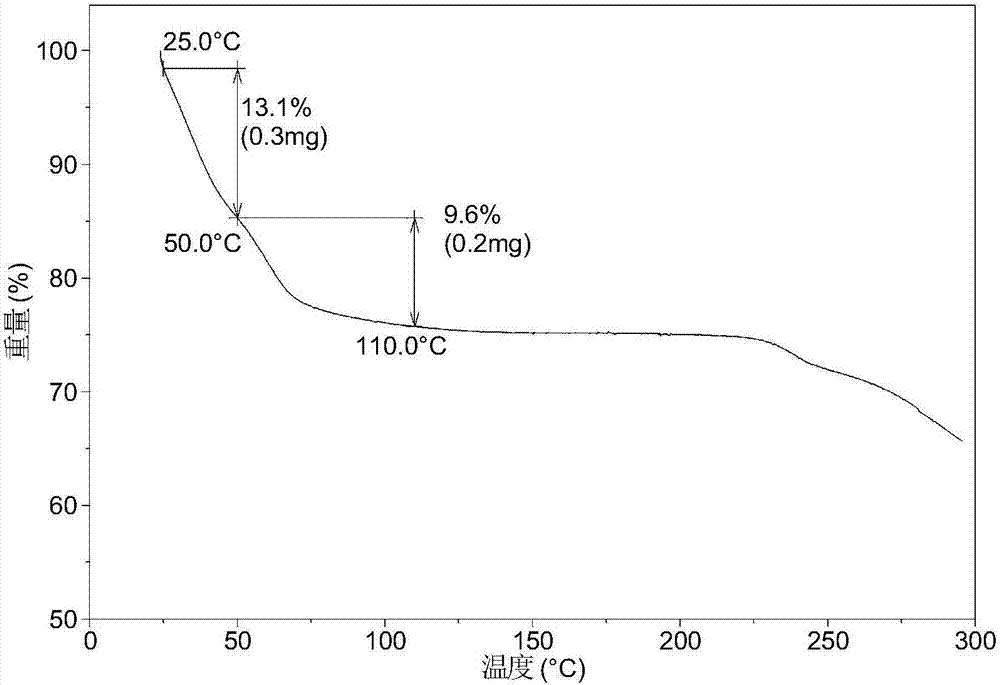

InactiveCN103319473AGood for long term storageGood liquidityOrganic chemistryChemical technologyPowder diffraction

The invention belongs to the technical field of medicinal chemistry, and particularly relates to two crystal forms of azilsartan and a preparation method thereof. For the crystal form B of the azilsartan, in a X-ray powder diffraction pattern, 2theta has characteristic peaks near 7.46 degrees, 8.43 degrees, 9.38 degrees, 10.96 degrees, 18.90 degrees, 21.06 degrees, 21.98 degrees, 22.71 degrees, 23.11 degrees and 24.89 degrees. For the crystal form C, in the X-ray powder diffraction pattern, 2theta has characteristic peaks near 9.52 degrees, 11.64 degrees, 13.51 degrees, 20.85 degrees, 21.83 degrees, 22.40 degrees, 23.44 degrees, 25.17 degrees, 26.17 degrees and 29.06 degrees. The crystal form B and crystal form C of the azilsartan have better stability and fluidity and are beneficial to long-time storage.

Owner:HEFEI IND PHARMA INST

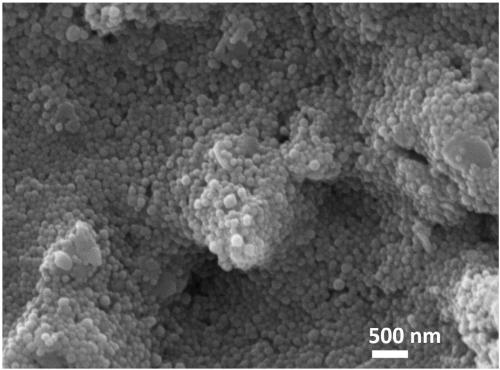

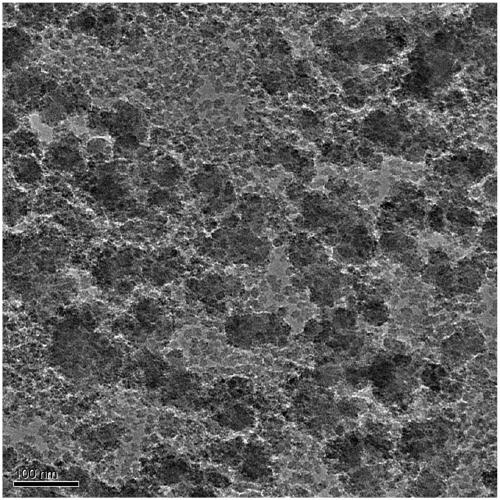

Preparation method of superamphiphobic SiO2 nano functional solution and application

ActiveCN109181537AGood dispersionSimple processAntifouling/underwater paintsPaints with biocidesAlcoholSio2 nanoparticle

The invention discloses a preparation method of a superamphiphobic SiO2 nano functional solution and relates to the technical field of hydrophobic materials. The preparation method comprises the following steps: adding an alkaline catalyst and silicate ester into an alcohol solvent, and stirring, reacting and ageing the mixture to prepare a SiO2 nanoparticle dispersion solution; and adding a fluorine-containing organic matter with low surface energy to react and modify to prepare the superamphiphobic SiO2 nano functional solution. The preparation method is simple in process, controllable in reaction, low in cost and good in dispersibility of the functional solution and has important social and economical value in industrial popularization, production and application. The invention also provides the application of the superamphiphobic SiO2 nano functional solution. The superamphiphobic SiO2 nano functional solution can be coated to various base materials such as glass, plastics, ceramics or metals by way of spraying, brush-spraying, dip-coating and the like to form a superamphiphobic film; the static contact angle of the surface of the superamphiphobic film and water can reach 168.4degrees, the rolling angle is as low as 1.5 degrees, the static contact angle of the surface of the superamphiphobic film and vacuum pump oil can reach 154.4 degrees, and the rolling angle is 7.8 degrees. The superamphiphobic SiO2 nano functional solution shows a very good superamphiphobic function.

Owner:武汉疏能新材料有限公司

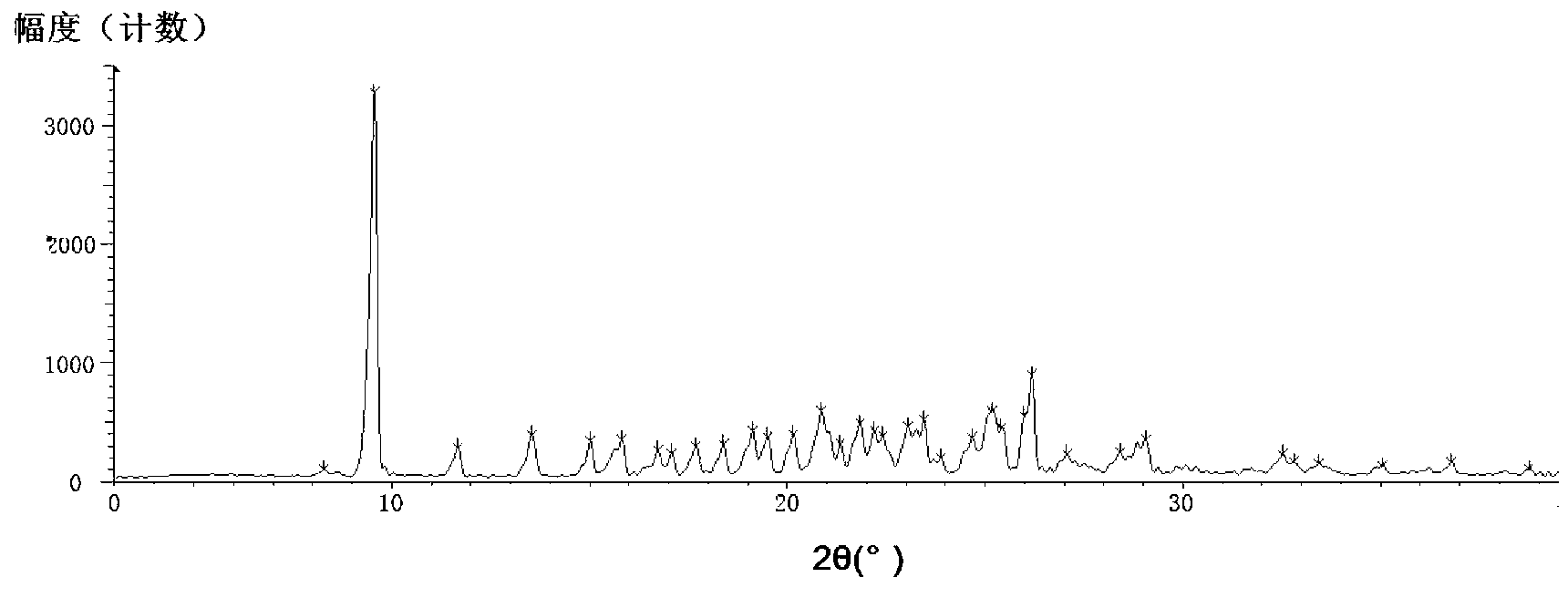

New crystal forms of sodium 2-(5-bro-4-(4-cyclopropylnaphthalene-1- yl)-4H-1,2,4-triazole-3-yl sulfenyl) acetate and preparation method thereof

InactiveCN104387333AGood stabilityGood for long-term storageOrganic chemistry methodsBromineChemistry

The invention relates to four novel crystal forms of 2-(5-bromine-4(4-cyclopropyl naphthaline)-1-yl)-4H-1,2,4-triazole-3-yl-sulfenyl) sodium acetate. The invention also provides a preparation method for the novel crystal forms of 2-(5-bromine-4(4-cyclopropyl naphthaline)-1-yl)-4H-1,2,4-triazole-3-yl-sulfenyl) sodium acetate.

Owner:CRYSTAL PHARMATECH CO LTD +1

Novel green grape antistaling agent

InactiveCN1537436AAvoid injuryPrevent bleachingFruit and vegetables preservationProduct gasChinese patent

An antistaling agent for green grape is prepared from the durable antistaling agent of grape (described in the Chinese patent whose application number is 01137211.7), oxidant, alkaline substance and gas absorbent through respectively shaping and proportional mixing. It can keep the active concentration of SO2 in packing container for green grape.

Owner:XINJIANG UNIVERSITY

Nutrient fast-food convenient food and preparation method thereof

The invention discloses nutrient fast-food convenient food and a preparation method thereof. The nutrient fast-food convenient food is characterized by being prepared from the following raw materials of 200-300 parts of semen juglandis, 10-20 parts of currant, 40-60 parts of carrot, 80-120 parts of pumpkin, 40-60 parts of kelp, 200-300 parts of Chinese yam, 80-120 parts of potato, 40-60 parts of millet flour, 40-60 parts of corn flour, 80-120 parts of whole meal flour, 40-60 parts of sweet potato flour, 40-60 parts of high-quality unshelled peanut meal, 80-120 parts of brown sugar, 10-30 parts of sesame and 140-160 parts of soybean oil. The nutrient fast-food convenient food provided by the invention is full of nutrients and is safe, so that the balance supply of the nutrition for a human body can be realized; effective health care and rehabilitation effects on the human body can be realized; the human body can easily absorb; the storage time is long; the requirements on various celluloses by the human body can be improved; and the nutrient fast-food convenient food is beneficial to protection and improvement of digestive health.

Owner:于才民

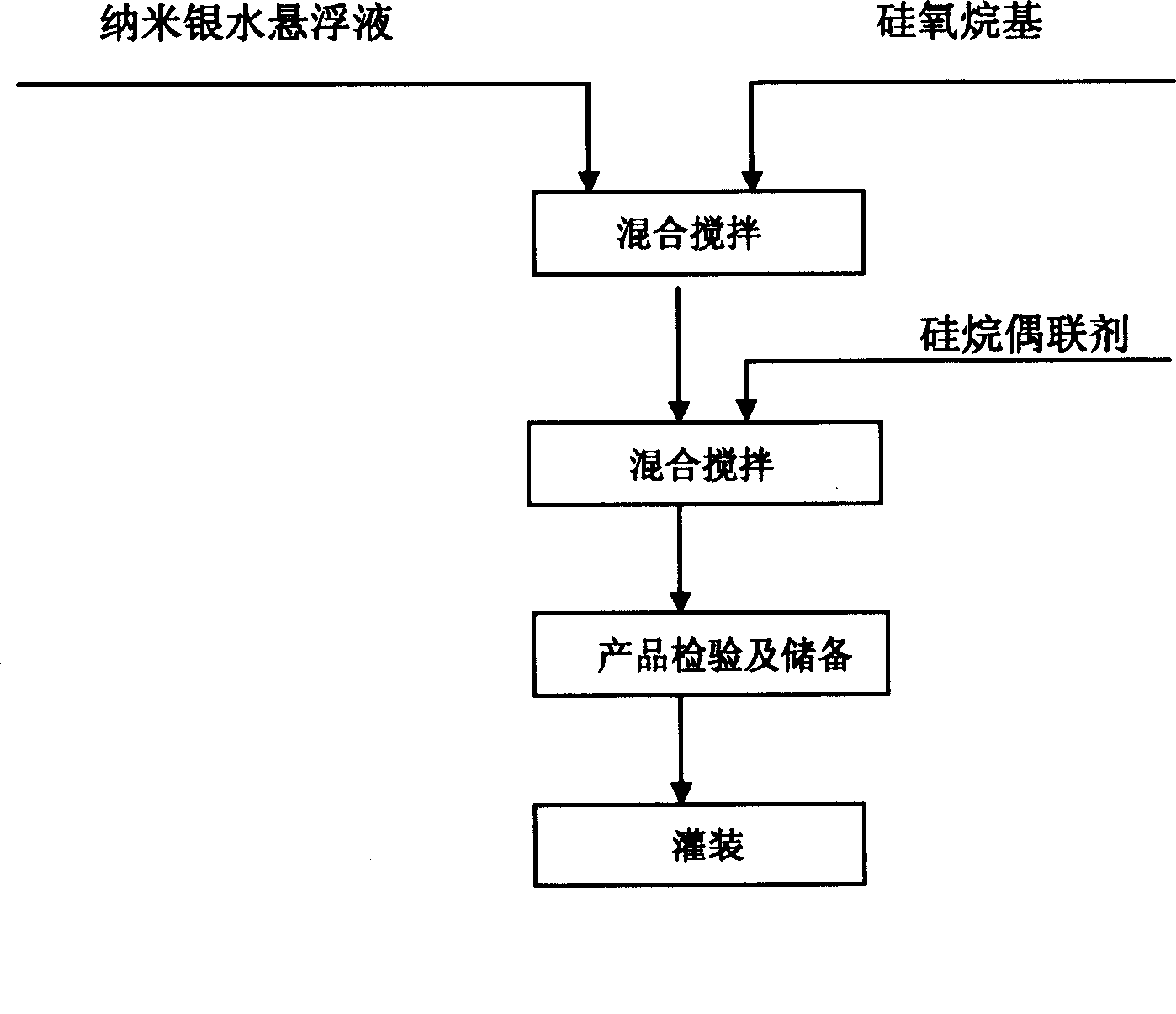

Nano silver calligraphy and painting protecting solution and preparation thereof

InactiveCN101481891AWill not change the original appearanceAvoid harmPaper/cardboardSilanesPrimary color

The invention relates to a nano-silver calligraphy, painting and ancient book protection solution. The protection solution is made from the following components by mass percentage: 10-1000ppm of nano-silver, 0.5-20% of silicane and 0-20% of a silane coupler. The mixed liquid is obtained by the following steps: filling nano-silver water suspension into a stirring and heating container; adding siloxane and the silane coupler by the weight proportion successively within 10-20min; mixing and stirring for 10-180min to obtain a novel mixed solution. Xuan paper, calligraphy and painting, as well as ancient books which are treated by the product can be dampproof, antibacterial, antimildew and anti-pollution for a long time, thus keeping primary colors of the calligraphy and painting and maintaining original artistic reality sense of the Xuan paper of the calligraphy and painting.

Owner:张宝荣

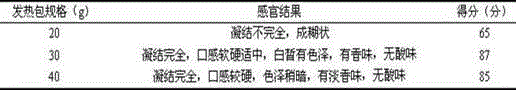

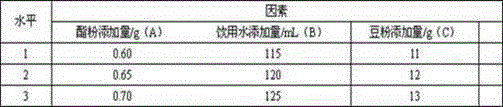

Manufacturing method of instant tofu pudding

InactiveCN106260012AImprove automationEasy to standardize productionCheese manufactureFood scienceGluconic acidMaterials science

The invention discloses a manufacturing method of an instant tofu pudding. Raw materials including soybeans, gluconic acid-delta-lactone, preparing drinking water and a heating bag are required. According to the method, tofu pudding powder is made based on conventional processing technology, the consumption of gluconic acid-delta-lactone, preparing drinking water and tofu pudding powder is optimized, and a tofu pudding powder bag, a gluconic acid-delta-lactone bag and preparing drinking water are heated with the heating bag during consumption. The manufactured tofu pudding is balanced in nutrition, and through the design of a self-heating heating bag, the convenience in a real sense is achieved.

Owner:SICHUAN AGRI UNIV

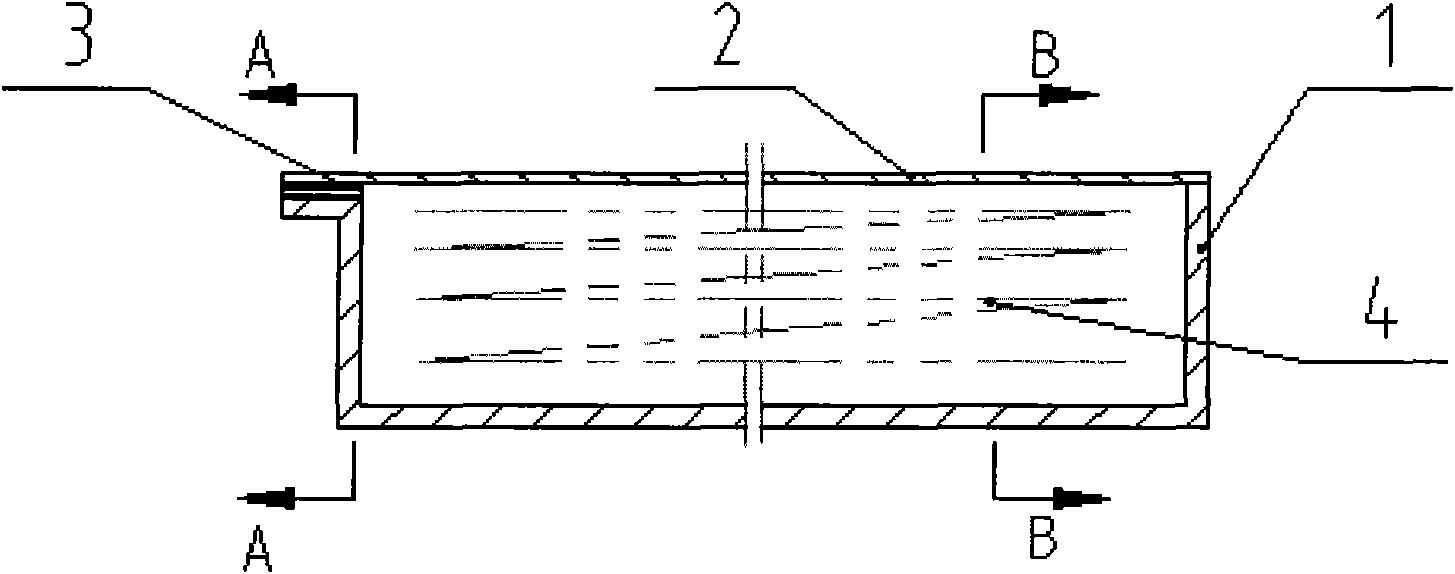

Dry cargo storage device and control method thereof

ActiveCN105996846AImprove storage qualityGood for long-term storageSeed preservation by dryingKitchen equipmentAutomotive engineeringSupport plane

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

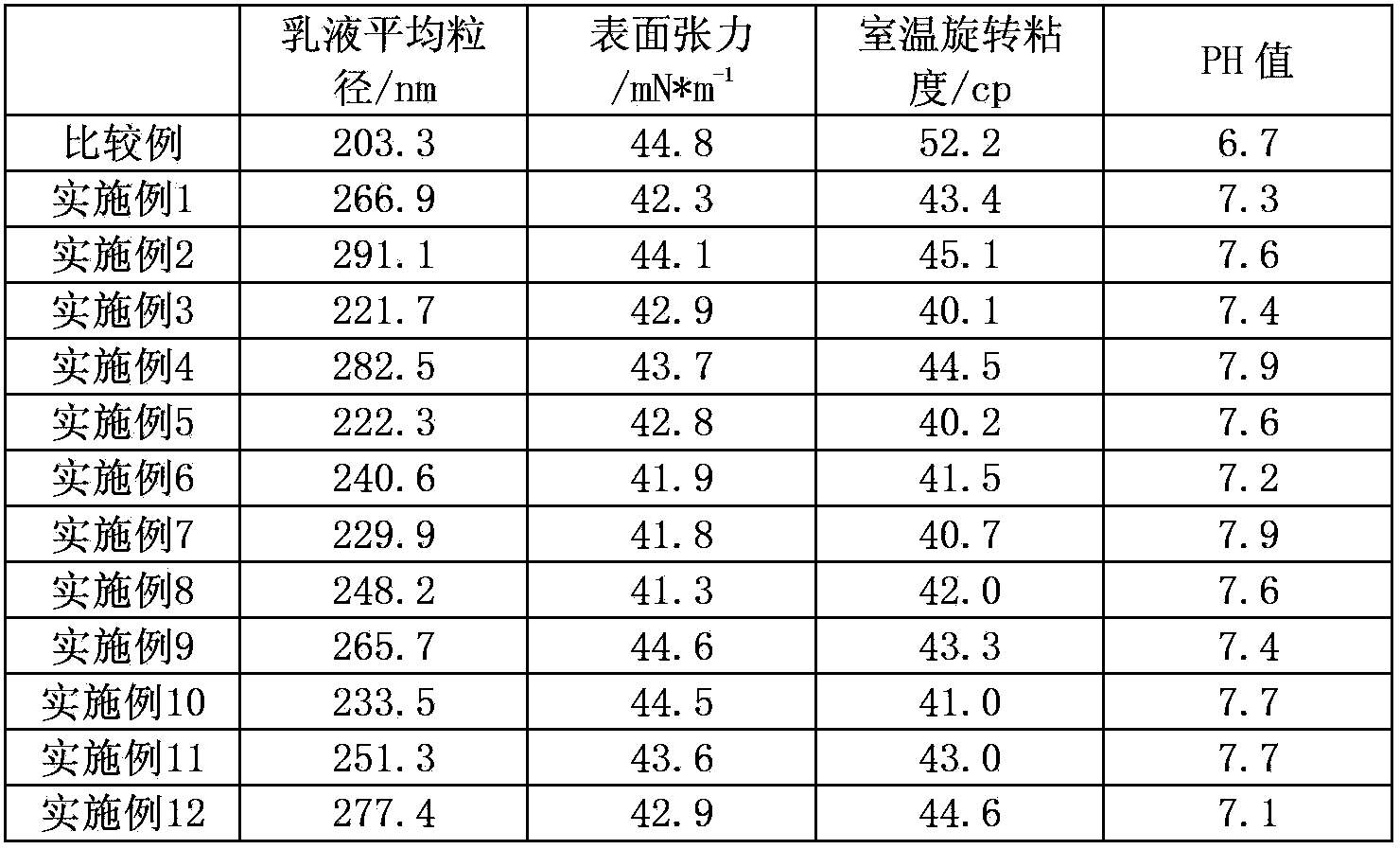

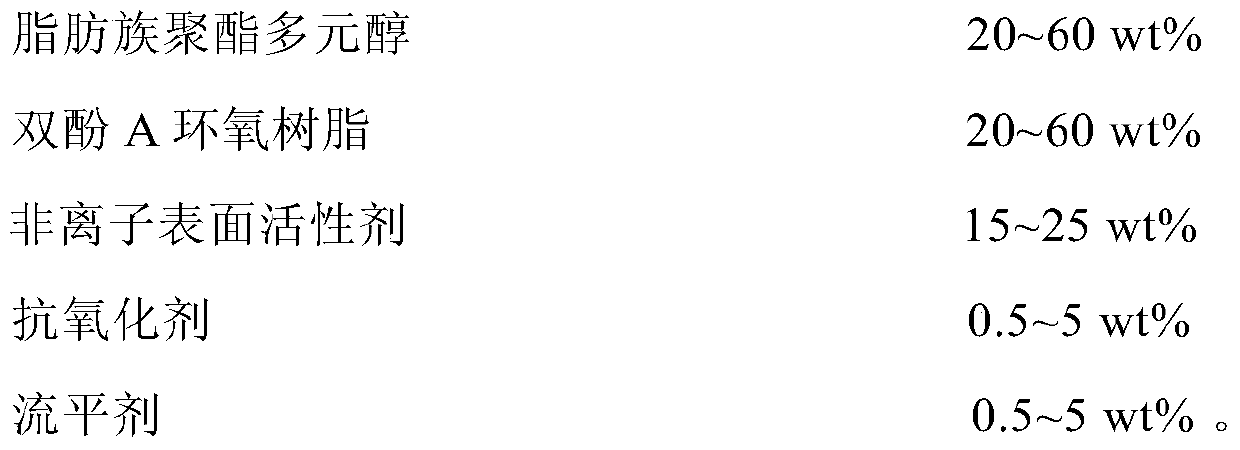

Carbon fiber composite emulsion sizing agent with low surface tension and high particle size stability and preparation method thereof

The invention discloses a carbon fiber composite emulsion sizing agent with low surface tension and high particle diameter stability. , 15-25% non-ionic surfactant, 0.5-2.5% antioxidant, 0.5-2.5% leveling agent, the preparation process includes (1) resin mixing, (2) adding additives, (3) adding deionization water and other steps. The solid content of the sizing agent emulsion prepared by the present invention is 30-60%, the pH of the emulsion is 7.0-9.0, the average particle diameter of the emulsion is 100-300nm, the particle diameter change rate is <15%, the surface tension of the emulsion is <35mN / m, and the prepared sizing agent The emulsion has high stability, can be stored for a long time, has strong ability to soak and absorb carbon fiber, and has good online sizing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound coarse grain fine dried noodles convenient to eat

InactiveCN104171930AImprove healthy living standardsGood for long term storageFood thermal treatmentFood preparationChemistryScrew speed

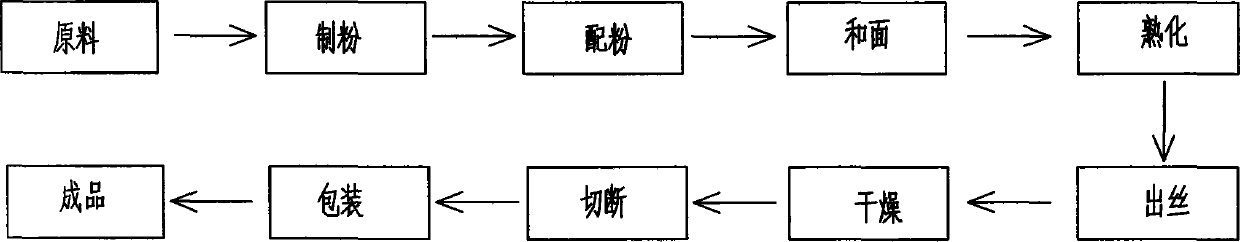

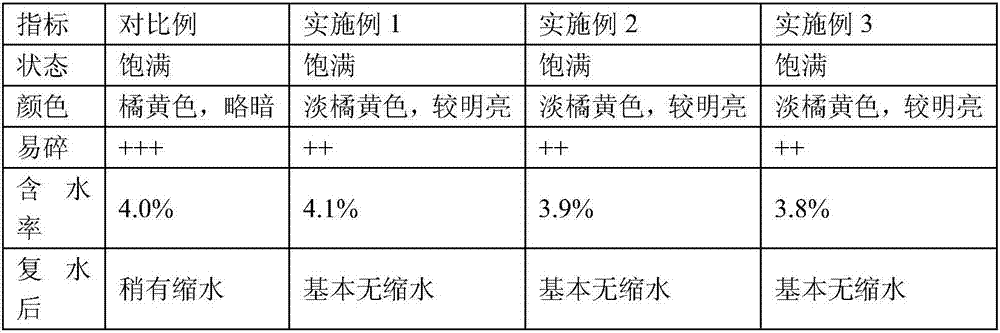

The invention discloses compound coarse grain fine dried noodles convenient to eat. The compound coarse grain fine dried noodles are prepared by the following steps: performing flour blending on corn flour, buckwheat flour and yam flour according to a weight part ratio of 50: 40: 10, adding a proper amount of salt and water, and performing flour milling; performing flour blending; kneading dough; curing, namely under the condition that the temperature of a jacket is controlled to be 70-80 DEG C at the front part, 120-130 DEG C in the middle and 140-150 DEG C at the rear part, the screw speed is controlled to be 62-72r / min and the working pressure is controlled to be 3-4kg / cm<2>, extruding and curing coarse noodles; discharging, namely under the condition that the temperature of the jacket is controlled to be 120-150 DEG C, the screw speed is controlled to be 62-72r / min and the working pressure is controlled to be 5-6kg / cm<2>, extruding to form thin noodles; drying; cutting off; packaging. According to the compound coarse grain fine dried noodles, a preparation process of extruding and quickly curing once and continuously extruding for forming twice is adopted, additives and other grain powder do not need to be added in a production process, and the compound coarse grain fine dried noodles keep the inherent taste and nutrition of corns, buckwheat and yams; the compound coarse grain fine dried noodles refer to boiling-free instant foods and are good in curing property, high in toughness, continuous, non-pasted after being repeatedly boiled, fine and smooth in mouth feel, chewy and fragrant.

Owner:HENAN JINLONG FLOUR IND

Cordyceps militaris storing method

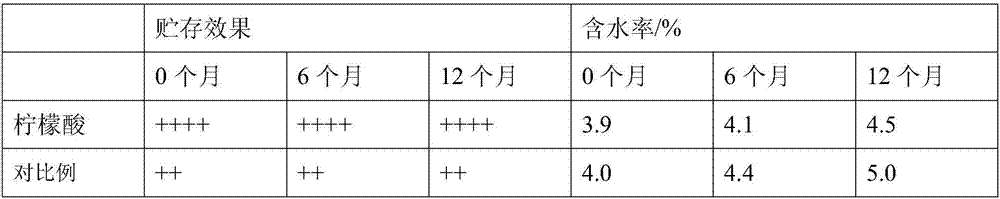

InactiveCN107028074AReduce friabilityGood for long-term storageClimate change adaptationFood preservationCordycepsVacuum pressure

The invention relates to a cordyceps militaris storing method. The cordyceps militaris storing method comprises the following steps of soaking cordyceps militaris in a citric acid aqueous solution for shaping, performing drainage, spreading the drained cordyceps militaris in a material plate, loading the material plate in a material box of a vacuum freeze drying machine, and when material precooling temperature reaches to minus 40-minus 50 DEG C, maintaining the temperature for 2.0-2.5 hours; performing vacuumizing, when vacuum pressure is reduced to 50Pa or below, beginning to raise temperature, continuing vacuumizing, after the temperature of a material bin rises to 35 DEG C, turning off the equipment, and taking out dried cordyceps militaris so as to obtain freeze-dried cordyceps militaris; and when the freeze-dried cordyceps militaris is eaten, soaking the freeze-dried cordyceps militaris with water for 20-30 minutes so as to obtain freshly eaten cordyceps militaris. After pretreatment through citric acid immersion liquid, dried finished products is low in the frangible degree, long-time storage is facilitated, the dried finished products do not mildew or deteriorate and are not eaten by worms, and the tissue structure and the appearance shape of the dried finished products are well preserved. The rehydration effect of the cordyceps militaris is the best, after rehydration, the immersion juice is golden and clear, the color and the appearance state of cordyceps militaris bodies are similar with those of fresh cordyceps militaris, and the dried finished products can be used as dishes on a dining table to be eaten.

Owner:辽宁省微生物科学研究院

Milky tea solid beverage prepared from ultra-micro broadleaf holly leaf powder and preparation method thereof

InactiveCN106615148AReduced stabilityReduce or avoid lossMilk preparationPre-extraction tea treatmentAdditive ingredientDry ice

The invention provides a milky tea solid beverage prepared from ultra-micro broadleaf holly leaf powder. The milky tea solid beverage contains the ultra-micro broadleaf holly leaf powder, milk powder and soluble soybean polysaccharide. According to the invention, the prepared ultra-micro broadleaf holly leaf powder, milk powder and soluble soybean polysaccharide are prepared into a solid fruit tea under a specific condition. The integrated innovations of the technique according to the invention are as follows: the tea leaf raw material is refrigerated and treated with dry ice, so that the loss of the thermal sensitive nutritional ingredients in the tea leaves caused by the thermodynamic effect in an ultra-micro smashing process can be reduced or avoided; the dry ice is remained in the pores of the ultra-micro broadleaf holly leaf powder grains, so that the tea powder can be stored for a long time; the soluble soybean polysaccharide and the high-pressure homogenizing treatment are beneficial to the stability of the solid beverage in a brewing process; different from the tea soup or tea juice extracted from the tea leaves as raw material, the ultra-micro tea powder is directly used for preparing the milky tea, so that the nutritional ingredients in the tea leaves can be fully maintained, and meanwhile, the extraction process is reduced, so that the production cost is lowered.

Owner:HUBEI UNIV OF TECH

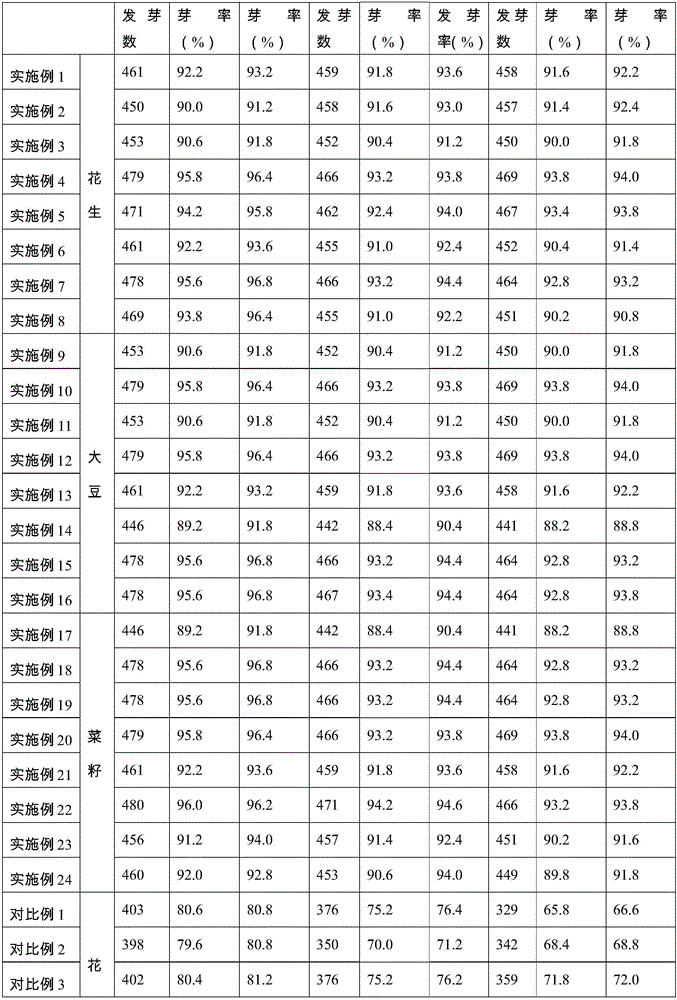

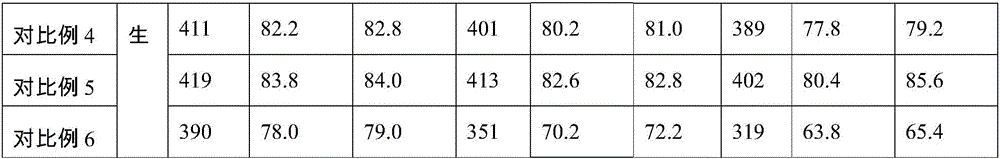

Crop seed storage agent and storage method

ActiveCN106076292AKeep dryStrong water absorptionAgriculture tools and machinesGas treatmentSuper absorbentChloride

The invention relates to the field of seed storage and discloses a crop seed storage agent and a storage method. The storage agent is prepared from at least two kinds of calcium oxide, calcium chloride and super absorbent resin. The storage agent is applied to seed storage, the vitality can be kept well, and the germination rate is 90% or above when seeds are storage for 2 years or longer. The crop seed storage method is simple in process and low in cost.

Owner:JIANGXI ACAD OF AGRI SCI

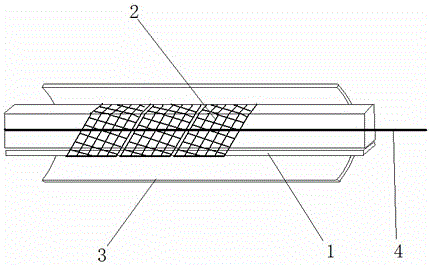

Package of single transposition winding

InactiveCN106005740ATo dissipate heatWear resistancePackagingStructural engineeringMechanical engineering

The invention discloses a package of a single transposition winding. The package of the single transposition winding comprises a spacing strip which is of a belt shaped structure and arranged at the bottom part of the transposition winding, wherein the spacing strip is arranged along the length direction of the transposition winding; net wrapping belts are arranged around the transposition winding and the spacing strip in a manner of obliquely coiling and wrapping the peripheries of the transposition winding and the spacing strip; a protecting belt is arranged at the outer parts of the net wrapping belts in a manner of obliquely coiling and wrapping the peripheries of the net wrapping belts; a tearing line is arranged between the net wrapping belts and the protecting belt along the length direction of the transposition winding; one head of the tearing line is arranged at the outer part of the package. Compared with the prior art, the package of the single transposition winding has the advantages that the transposition winding is packed through the spacing strip, the net wrapping belts and the protecting belt, so that the transposition winding is insulated, radiating, damp-proof and durable, and as a result, the transposition winding can be coiled with each other and stored for a long time; in addition, the transposition winding is conveniently transported in outdoor, and moreover, the potential risk in the use of the transposition winding can be avoided.

Owner:SUZHOU SHENGBAIWEI PACKAGE EQUIP

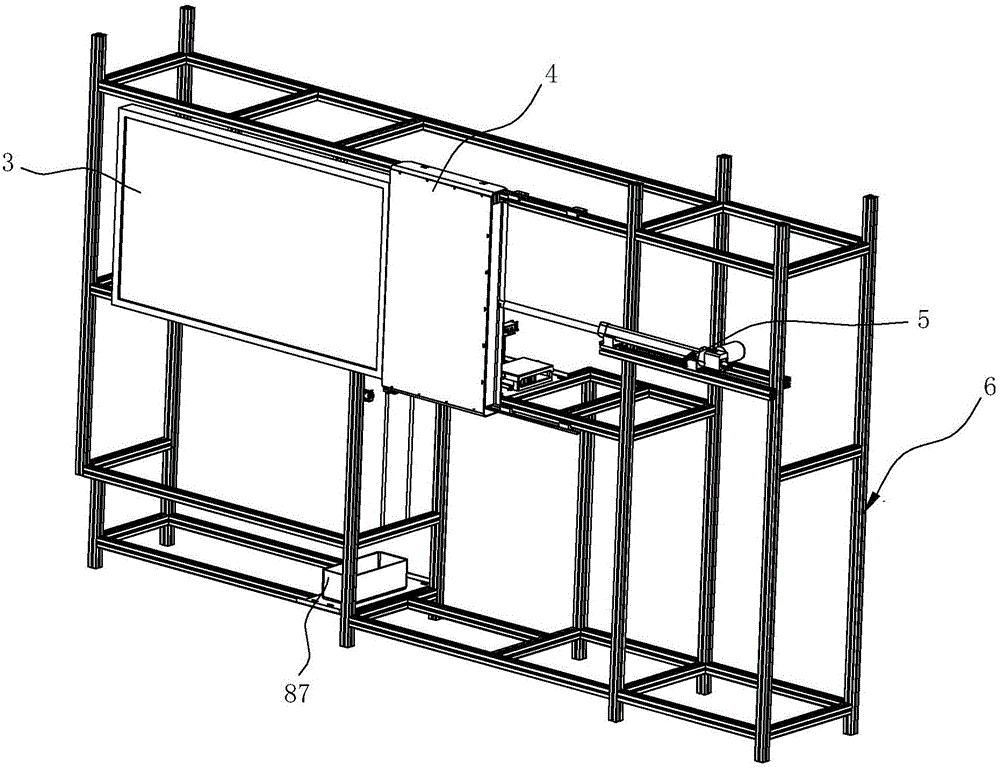

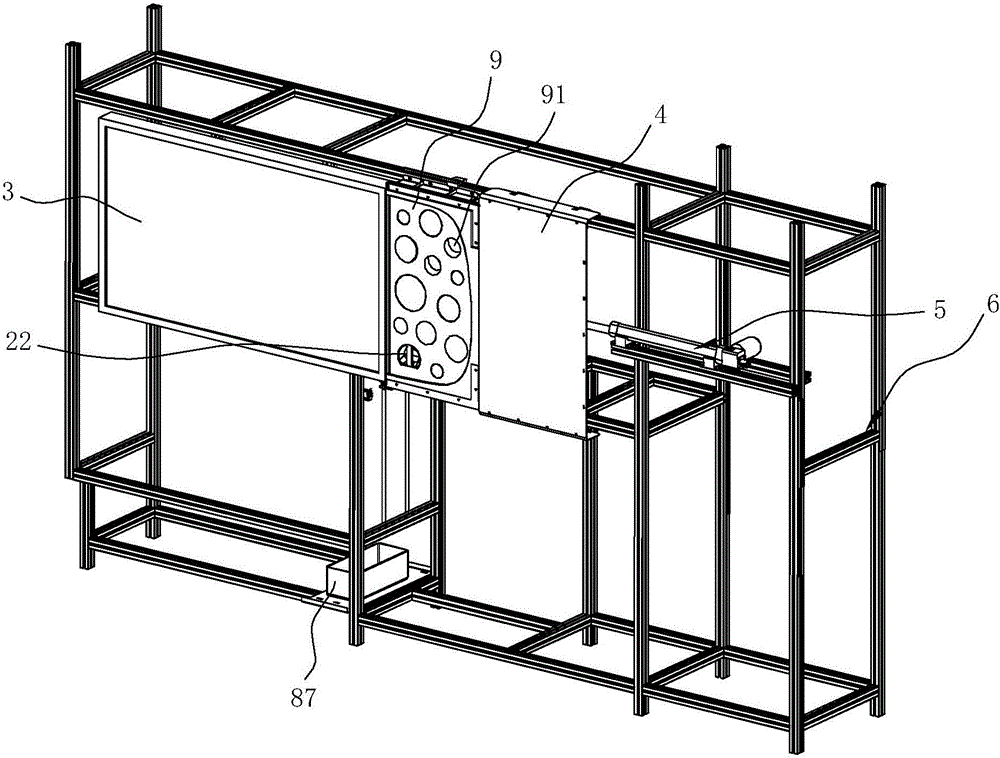

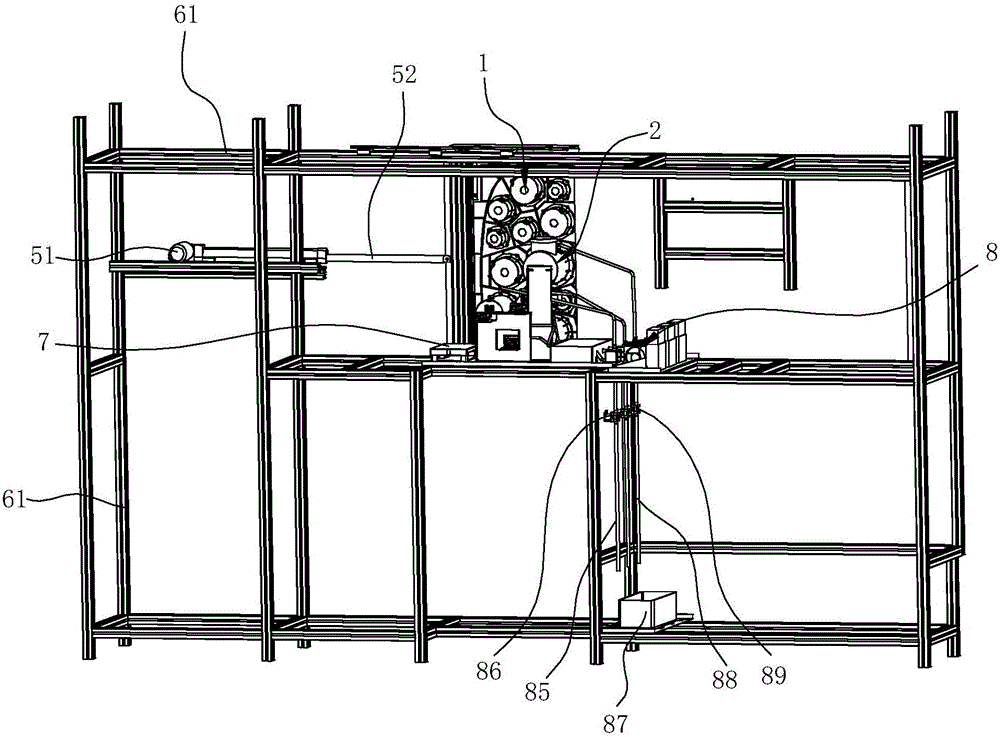

Method and device capable of continuously providing sampling carrier

ActiveCN101571457ANot easy to be pollutedGood for long term storageDispensing apparatusWithdrawing sample devicesWipe samplingEngineering

The invention provides a method and a device capable of continuously providing a sampling carrier, which are used for a hand-held wiping sampler. In the invention, the sampling carrier is manufactured into a long-strip shape, is folded into a layer shape according to certain length and sealed into a storage box, wherein one end of the storage box is provided with an outlet. A sampling carrier box is arranged on a special sampler, is pulled out for proper length to be fixed on a wiping surface when sampling, and a sample part is cut off for detection after the sampling. The continuous sampling carrier can keep straight and cannot be polluted in the processes of storage and application, is capable of sampling for multiple times by one-step mounting, simplifies the wiping sampling operation and improves the service efficiency of an ionic migration spectrometer.

Owner:NUCTECH CO LTD

Wolfberry, jujube and Nitraria sibirica Pall compound solid beverage and making method thereof

InactiveCN106213105AGood for long term storageSweet tasteFood ingredient as mouthfeel improving agentNutrientMenstruations

The invention discloses a wolfberry, jujube and Nitraria sibirica Pall compound solid beverage and a making method thereof. According to the solid beverage, wolfberry, jujubes and Nitraria sibirica Pall serve as main raw materials, and the beverage is made through the processes of impurity removal, cleaning, blanching, pulping, extraction, homogenization, spray drying and the like. The mass ratio of wolfberry to jujubes to Nitraria sibirica Pall is (2-4):4:(3-5). Nutrients in the raw materials can be fully dissolved out easily by effectively removing objectionable odor of the raw materials through 100 DEG C blanching treatment and conducting extraction at 80-90 DEG C after raw material pulping. Particles of the beverage are fine and easy to dissolve, are beige pink and sweet in taste, and have the strong fragrance of jujubes and Nitraria sibirica Pall. The solid beverage is convenient to carry and use and extremely high in nutritional value, has the effects of improving immunity, resisting ageing, invigorating the stomach and regulating menstruation and the like, and can regulate existing sub-health conditions, dysmenorrheal, anemia and other symptoms of females.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Solid fruit tea beverage prepared from superfine broadleaf holly leaf powder and preparation method thereof

InactiveCN106665993AGood for long-term storageReduce or avoid lossTea substituesAdditive ingredientDry ice

The invention provides a solid fruit tea beverage prepared from superfine broadleaf holly leaf powder and a preparation method thereof. The solid fruit tea beverage comprises the following components: the superfine broadleaf holly leaf powder, fruit powder and soluble soybean polysaccharide. According to the invention, the prepared superfine broadleaf holly leaf powder, the fruit powder and the soluble soybean polysaccharide are prepared into the solid fruit tea beverage under a specific condition. The integrated innovation of the technology according to the invention is as follows: the tea leaf raw material is refrigerated and treated with dry ice, so that the loss of thermal sensitive nutritional ingredients in the tea leaves under the thermodynamic effect in a superfine grinding process can be reduced or avoided; the dry ice is left in the pores of the fine tea powder grain, so that the long-term storage of the tea powder is benefited; the soluble soybean polysaccharide and the high-pressure homogeneous treatment are beneficial to the stability of the solid beverage in the brewing process; different from the technique of extracting tea soup or tea juice as the raw material from the tea leaves, the technique directly utilizes the superfine tea powder to develop the fruit tea, so that the nutritional ingredients in the tea leaves are fully maintained; and extracting process links are reduced, so that the production cost is lowered.

Owner:HUBEI UNIV OF TECH

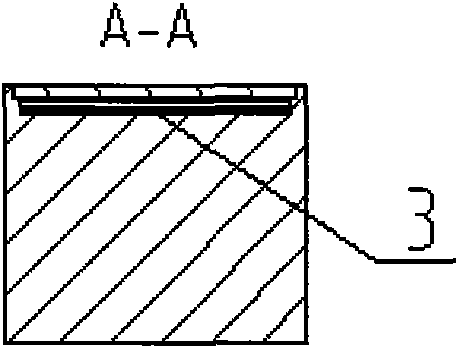

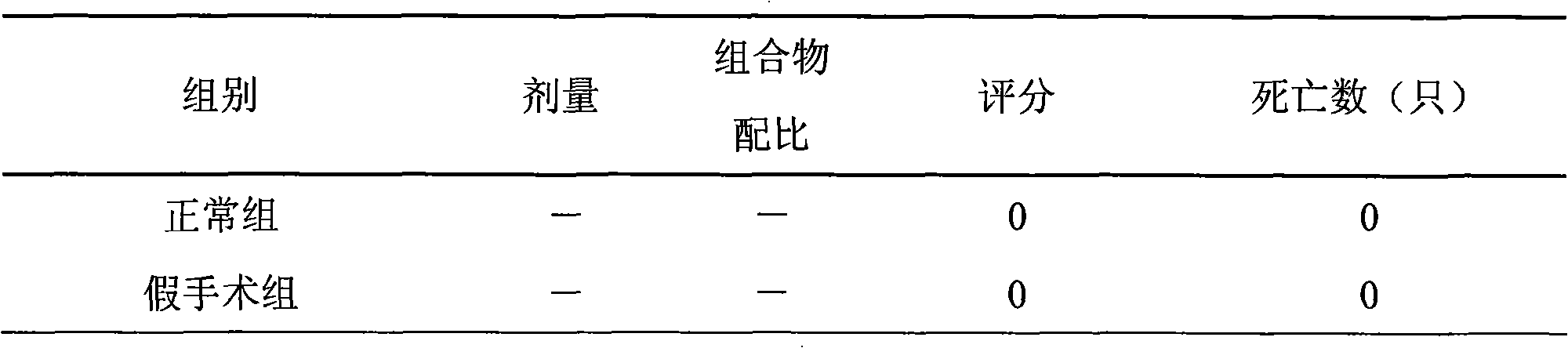

Composition of sodium ozagrel and polyethylene glycol and preparation method thereof

InactiveCN101780072AImprove effectivenessImprove in vivo stabilityOrganic active ingredientsPowder deliverySodium bicarbonateMANNITOL/SORBITOL

The invention discloses a composition of sodium ozagrel and polyethylene glycol and a preparation method thereof, belonging to the medical technical field. The weight ratio of sodium ozagrel to polyethylene glycol in the pharmaceutical composition is 1:0.002-0.1. Injections can be prepared by using the pharmaceutical composition and auxiliary material which is acceptable in pharmacy and the auxiliary material is selected from one or more of lactose, mannitol, sorbitol, dextran, citric acid-sodium citrate and sodium bicarbonate-sodium carbonate. The pharmaceutical composition is used to cure dyskinesia associated with acute thrombotic infarction and cerebral infarction.

Owner:BEIJING SIHUAN PHARMA +1

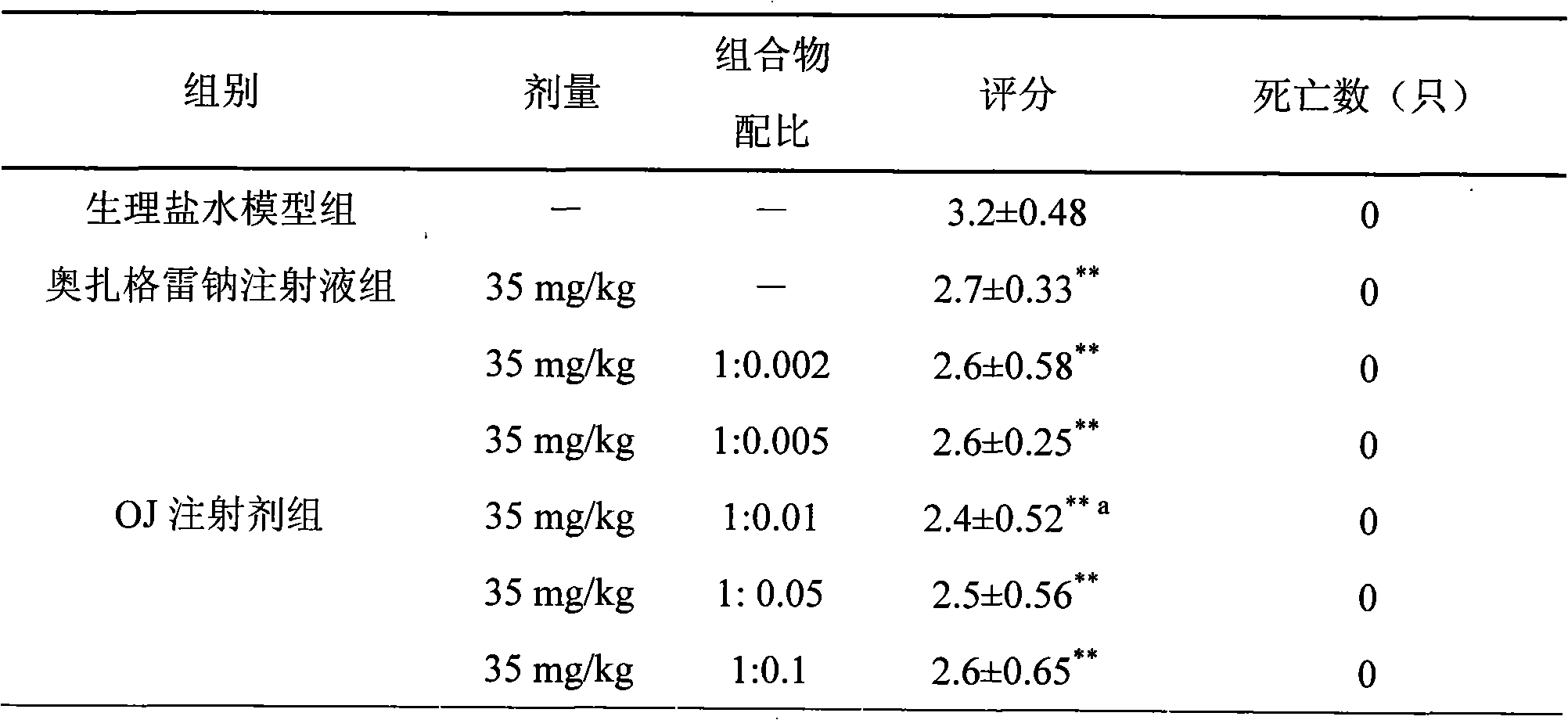

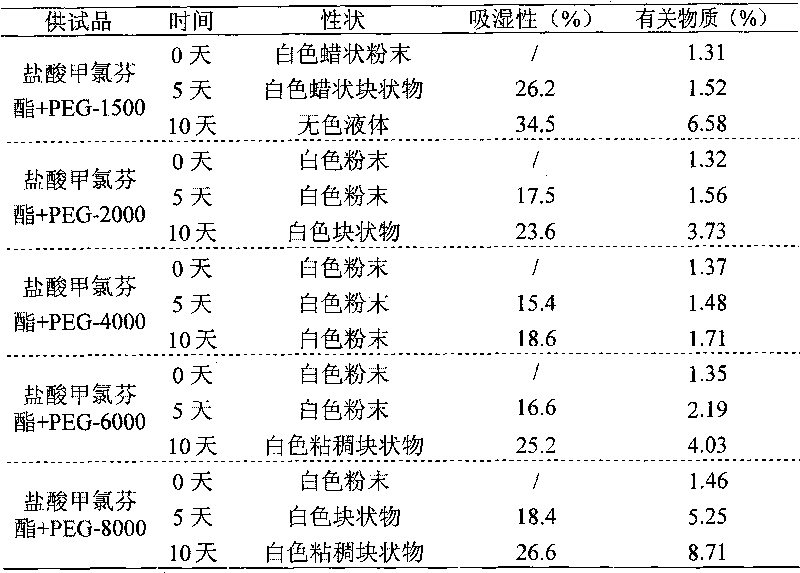

Drug composition of meclofenoxate hydrochloride and polyethylene glycol and preparation method thereof

InactiveCN101756952AImprove securityImprove stabilityOrganic active ingredientsNervous disorderPolyethylene glycolMeclofenoxate Hydrochloride

Owner:HAINAN SIHUAN PHARMA +1

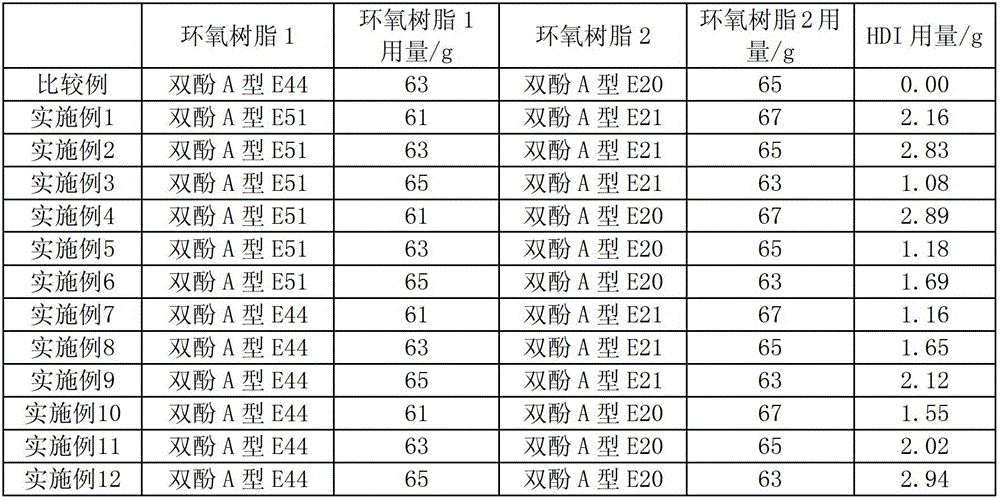

Polyurethane structure-modified epoxy resin sizing agent emulsion and its preparation and application

The invention relates to a polyurethane structure modified epoxy resin sizing agent emulsion, which comprises the following ingredients: 55-78wt% of polyurethane structure modified epoxy resin composition, 20-40wt% of surfactant, 0.5-2wt% of anti-oxidant, 1-2wt% of levelling agent and 0.5-1wt% of antifreezing agent. The preparation method comprises the following steps: performing vacuum-pumping and dehydrating the bisphenol A epoxy resin to the condition that no bubbles can be generated, cooling and adding isocyanate to prepare a epoxy resin composition; mixing a surfactant and an antioxidant are mixed and homogenized in a reaction vessel according to the above material fraction, then adding deionized water, a levelling agent and an antifreezing agent gradually to obtain the polyurethane structure modified epoxy resin sizing agent emulsion. The carbon fiber prepared by the polyurethane structure modified epoxy resin sizing agent emulsion has good convergence, wear resistance and toughness, the convergence and wear resistance are easily and freely adjusted through the isocyanate component; a cluster agent is not required at the anaphase of the carbon fiber sizing agent, and on-site secondary mixing is not required, the application stability is good, the carbon fiber pasting wellability is good, and the polyurethane structure modified epoxy resin sizing agent emulsion is benefit for industrial stabilization and production of carbon fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid fruit tea drink made of ultramicro yellow tea powder and making method of solid fruit tea drink

InactiveCN106665945AReduced stabilityReduce or avoid lossPre-extraction tea treatmentAdditive ingredientDry ice

The invention provides a solid fruit tea drink made of ultramicro yellow tea powder and a making method of the solid fruit tea drink. The solid fruit tea drink comprises components, namely, ultramicro yellow tea powder, fruit powder and soluble soybean polysaccharide. The making method comprises a step of making the solid fruit tea from the ultramicro yellow tea powder, the fruit powder and the soluble soybean polysaccharide under certain conditions. The process technique of the solid fruit tea drink is integrated and innovative, that is, a tea leaf raw material is refrigerated and treated with dry ice, so that consumption of heat-sensitive nutrient components in tea leaves by thermal action in the ultramicro crushing process can be reduced or avoided; the dry ice is retained in pore cavities of ultramicro yellow tea powder particles, so that the tea powder can be preserved for a long time; due to high-pressure homogenization treatment on the soluble soybean polysaccharide, the stability of the solid drink in the brewing process can be facilitated; different from a method that a tea decoction or tea juice is extracted from the tea leaves as raw materials, the making method directly adopts the ultramicro yellow tea powder to develop the fruit tea, so that the nutrient components in the tea leaves can be completely retained, extraction process procedures can be reduced, and thus the production cost can be lowered.

Owner:HUBEI UNIV OF TECH

Crystal form of sodium salt of lesinurad and preparation method thereof

InactiveCN106883190AGood for long-term storageImprove stabilityOrganic active ingredientsOrganic chemistry methodsLesinuradCost Controls

The invention relates to a crystal form of a sodium salt of lesinarad and a preparation method thereof. The crystal form provided by the invention is good in stability and facilitates the long-term storage of chemicals. Moreover, the preparation method is simple in operation, good in repeatability, capable of facilitating the cost control in the industrialized production and extremely high in economic value.

Owner:CRYSTAL PHARMATECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com