Package of single transposition winding

A transposition line and single technology, applied in packaging and other directions, can solve the problems of unavoidable electric leakage of wires and cables, inability to prevent electric wires and cables from being easily damped, poor heat dissipation, etc., so as to avoid electric leakage, facilitate outdoor transportation, and prevent damp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

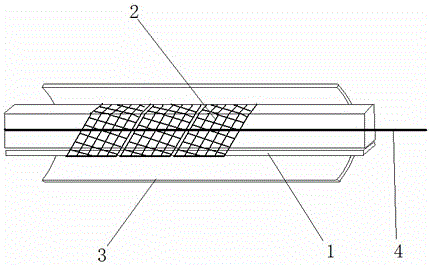

[0019] As shown in the figure, the packaging of a single transposition line of the present invention includes a pad 1 arranged at the bottom of the transposition line. The pad 1 is a belt-shaped structure, and the pad 1 is along the length direction of the transposition line. Set, the width of the spacer 1 is smaller than the width of the bottom of the transposition line, the spacer 1 is an insulating tape, when the transposition line is wound, the spacer 1 at the bottom of the transposition line is in contact with the upper part of the transposition line of the lower layer, It plays the role of isolation from the transposition line of the lower layer, avoiding electric leakage;

[0020] A net bag belt 2 is arranged around the transposition line and the pad strip 1, and the net bag belt 2 is obliquely wound and wrapped around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com