Equipment for safe power construction

A technology for electric power construction and equipment, applied in the installation of electrical components, cable accessories, cables, etc., can solve the problems of inability to install the insulation cover, damage the insulation cover, high heat of the insulation cover, etc., and achieve insulation performance, excellent insulation performance, The effect of fastening the wire connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

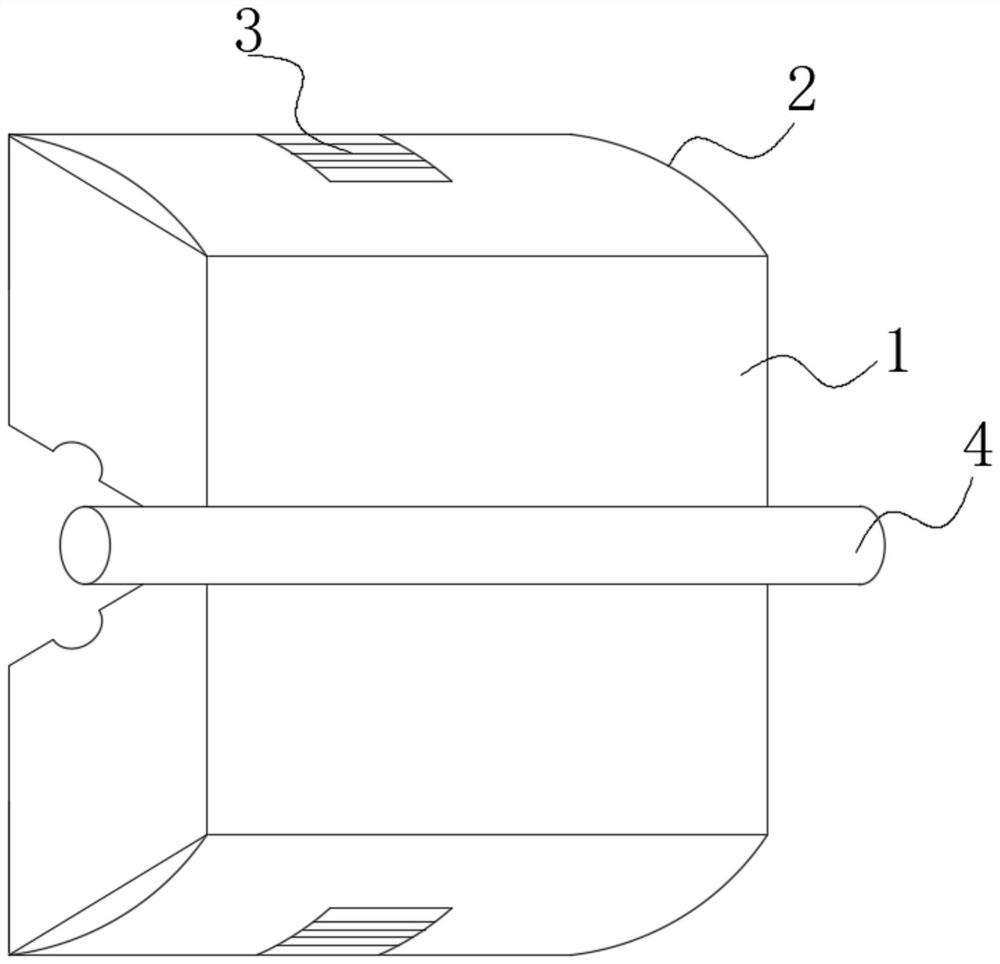

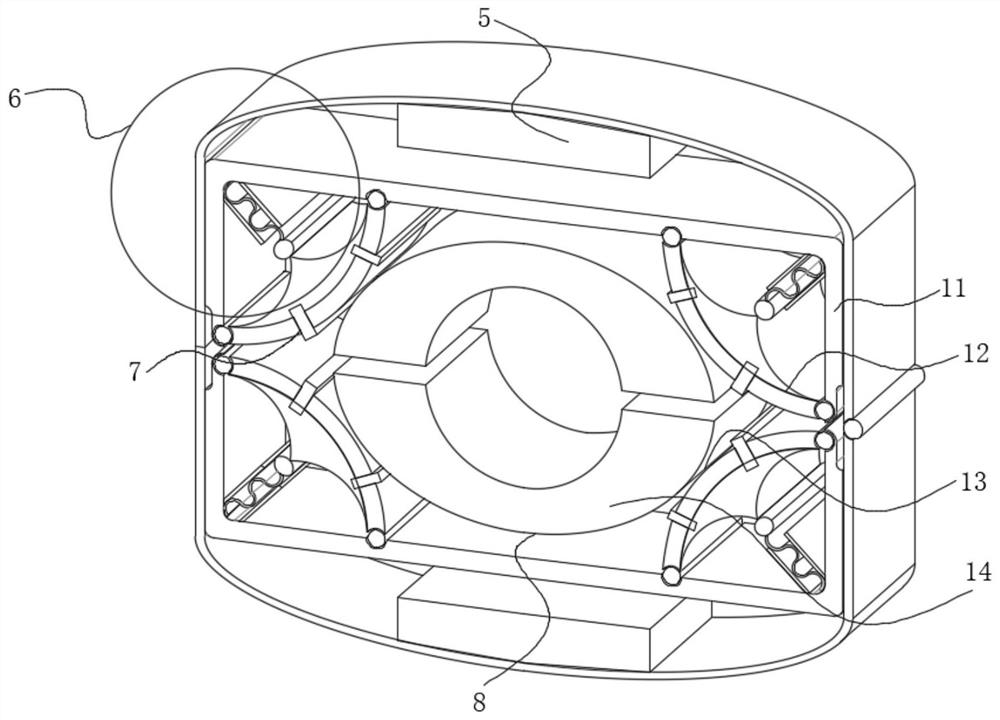

[0022] use Figure 1-Figure 7 A safe electrical construction device according to an embodiment of the present invention will be described as follows.

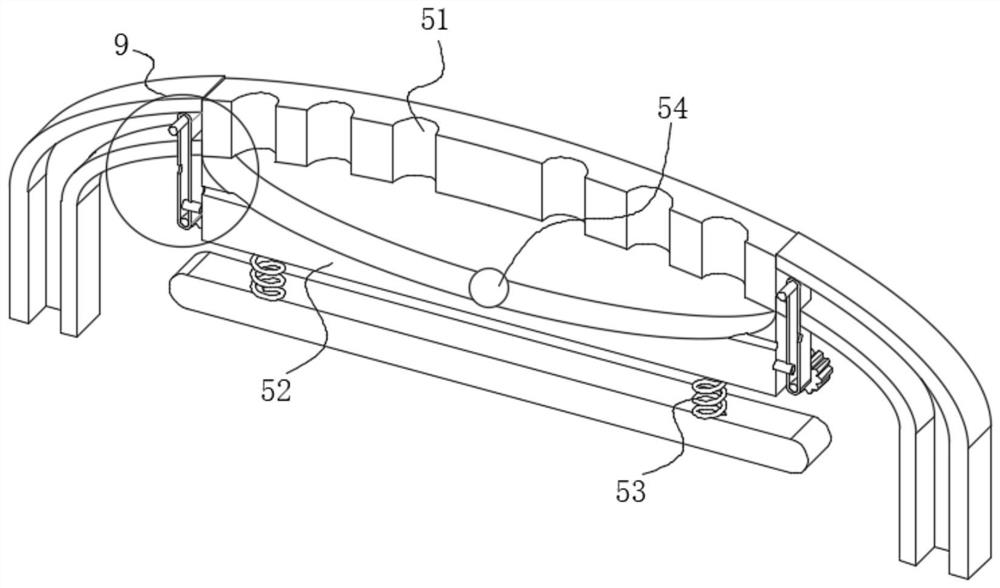

[0023] Such as Figure 1-Figure 7 As shown, a safe electric construction equipment according to the present invention includes a wire-wrapping clip 1, the top of the wire-wrapping clip 1 is fixedly connected with a water storage chamber 2, and the top of the water storage chamber 2 is provided with a water inlet 3. The lower surface of the wire wrapping clip 1 is rotatably connected with a rotating shaft 4. The wire wrapping clip 1 includes an insulating shell 11, the outer surface of the insulating shell 11 is fixedly connected with the inner wall of the wire wrapping clip 1, and the insulating shell The inner wall of 11 is rotatably connected with a side pressing arm 12, and both ends of the inner wall of the insulating shell 11 are fixedly connected with a limit support platform 8, and the top end of the limit support platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com