Super-hydrophobic coating, super-hydrophobic coating layer as well as preparation method and application of super-hydrophobic coating layer

A super-hydrophobic coating and super-hydrophobic technology, applied in the direction of anti-fouling/underwater coatings, coatings, and devices for coating liquid on the surface, can solve the problem of insufficient adhesion between coatings and substrates and affect coating products Durability and other issues, to achieve the effect of wide application range and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

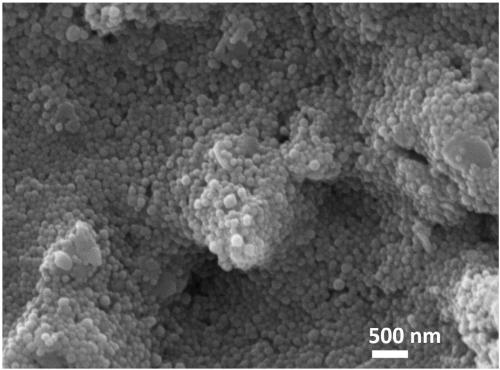

Image

Examples

preparation example Construction

[0050] The embodiment of the present invention also relates to a method for preparing a superhydrophobic coating, comprising the following steps:

[0051] 1) Add ammonia water and silicate to an alcohol solvent, stir, react, and age to prepare a dispersion of silica nanoparticles; add low surface energy fluorine-free to the dispersion of silica nanoparticles Organic matter, prepared super-hydrophobic silica nano-functional liquid. Wherein, the alcoholic solvent is one or more of ethanol, methanol, and isopropanol. The volume ratio of the ammonia water to the alcohol solvent is between 1:5 and 1:20. The silicate is one or both of tetrabutyl orthosilicate and tetraethyl orthosilicate. The aging time is 1-7 days. The low surface energy fluorine-free organics include methyltriethoxysilane, methyltrimethoxysilane, polydimethylsiloxane, propyltrimethoxysilane, octyltriethoxysilane, hexamethoxysilane One or more of disilazane, dodecyltrimethoxysilane, dodecyltriethoxysilane, hexa...

Embodiment 1

[0057] Embodiment 1: the preparation method of superhydrophobic coating

[0058] (1) Preparation of superhydrophobic silica nanoparticles functional liquid: add 5.5ml of concentrated ammonia water to 50ml of methanol, heat up to 40°C, then add 8ml of tetrabutyl orthosilicate, stir for 3h, cool to room temperature, and age 1 day. In the stirring state, add 10ml of hexamethyldisilazane to the above dispersion system, and react for 4 hours to obtain the superhydrophobic silica nano-functional liquid.

[0059] (2) Preparation of primer: Mix silicone resin, acrylic resin, nylon powder, barium sulfate powder, ethyl acetate, and polyacrylate, and stir and disperse at high speed at room temperature to obtain primer coating. The mass percentages of the above components are: silicone resin:acrylic resin:barium sulfate powder:ethyl acetate:polyacrylate:nylon powder=50:10:20:10:3:7.

[0060] (3) Preparation of superhydrophobic coating: add isocyanate to the primer prepared in step (2) u...

Embodiment 2

[0061] Embodiment 2: the preparation method of superhydrophobic coating

[0062] (1) Preparation of superhydrophobic silica nanoparticle functional liquid: add 5.5ml of concentrated ammonia water to 50ml of ethanol, heat up to 40°C, then add 8ml of tetraethyl orthosilicate, stir for 3h, cool to room temperature, and age 1 day. In the stirring state, add 10 ml of methyltriethoxysilane to the above dispersion system, and react for 4 hours to obtain the superhydrophobic silica nano-functional liquid.

[0063] (2) Preparation of primer: Mix silicone resin, acrylic resin, nylon powder, barium sulfate powder, butyl acetate, and polyacrylate, and stir and disperse at high speed at room temperature to obtain primer coating. The mass percentages of the above components are: silicone resin: acrylic resin: barium sulfate powder: butyl acetate: polyacrylate: nylon powder = 50:10:20:10:3:7.

[0064] (3) Preparation of superhydrophobic coating: add isocyanate to the primer prepared in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com