Modified polypropylene hot melt adhesive and preparation method thereof

A technology of polypropylene and hot melt adhesives, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problem of affecting the bonding strength of multi-layer barrier materials, the fast cooling crystallization speed of modified polypropylene, Problems such as high melt index of polypropylene, to achieve the effect of prolonging the bonding time, avoiding deactivation and degradation, and slowing down the crystallization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

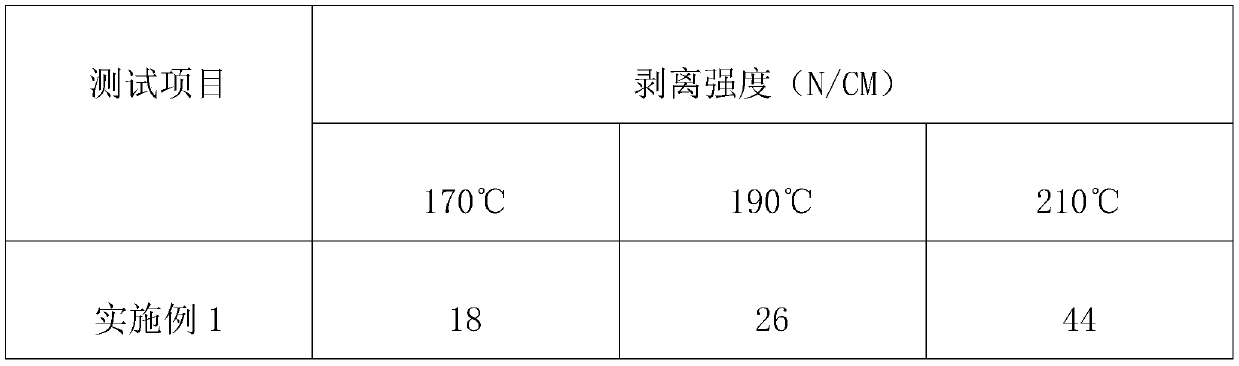

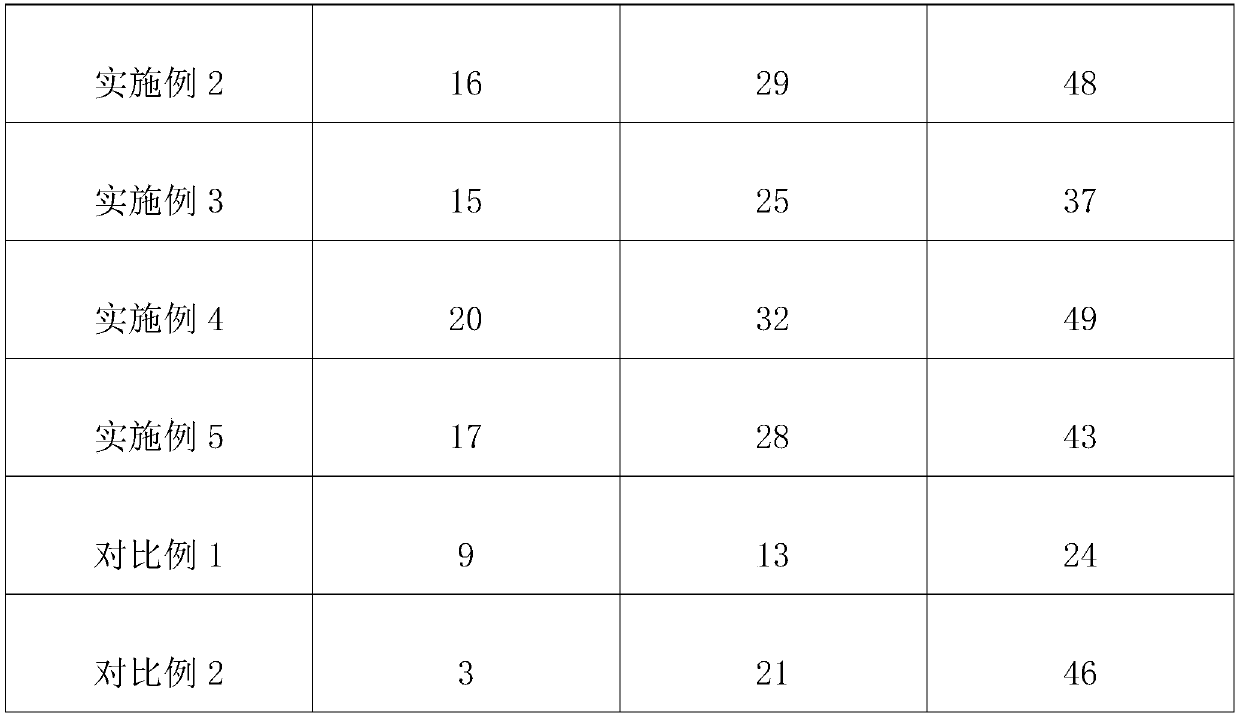

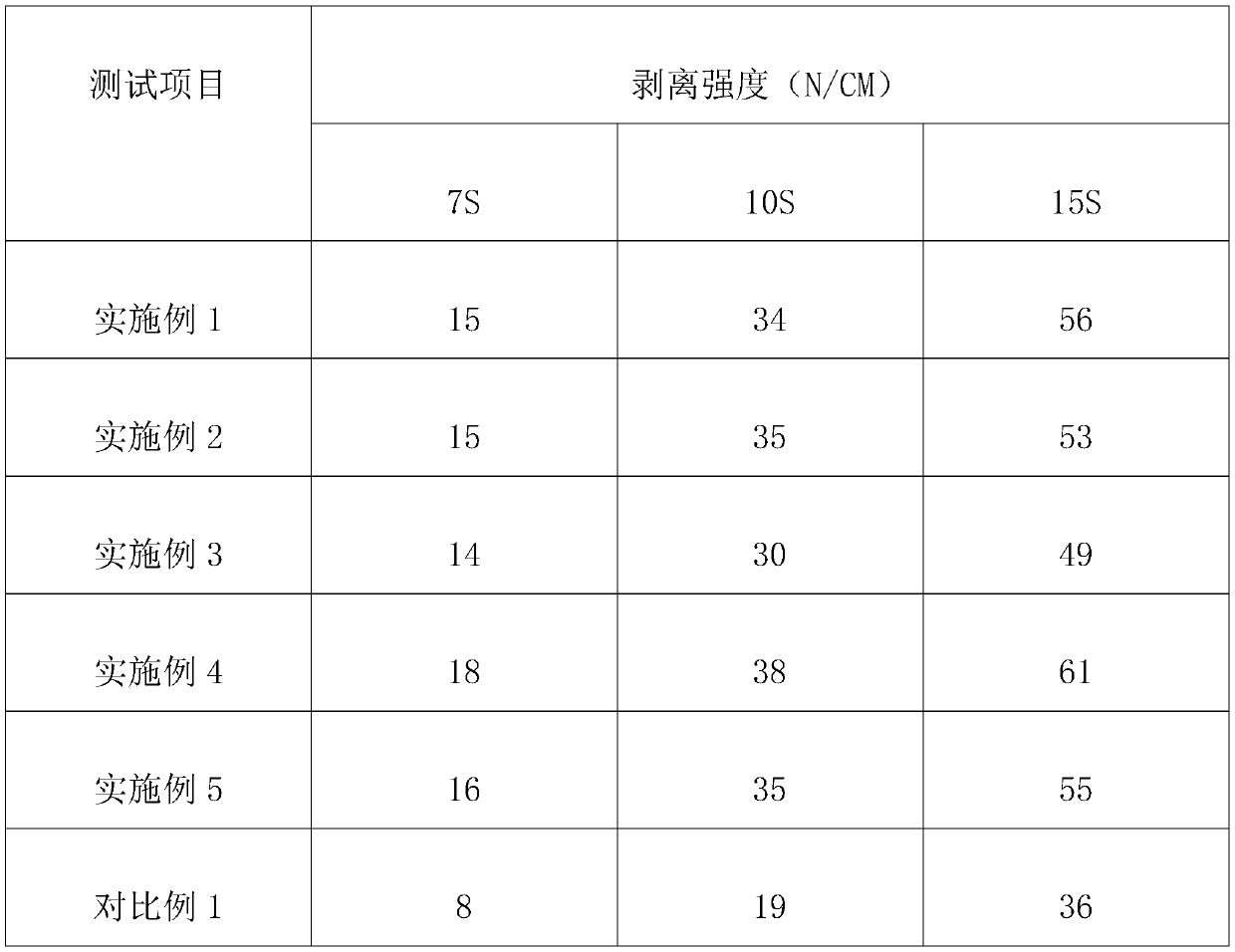

Examples

preparation example Construction

[0047] The preparation method of above-mentioned modified polypropylene hot-melt adhesive comprises the following steps:

[0048] Steps for preparing functionalized modified polypropylene: Mix the second random copolymerized polypropylene and the second ethylene-α-olefin copolymer uniformly, put them into a screw extruder, and the temperature of the mixing zone of the screw extruder is 130-200 °C, the temperature in the reaction zone is 150-230 °C, and the temperature in the termination zone is 150-220 °C; then add polar monomers, initiators, and modification additives, extrude and granulate, and obtain functionalized modified polypropylene;

[0049] The step of preparing the modified polypropylene hot melt adhesive: the functionalized modified polypropylene obtained in the step of preparing the functionalized modified polypropylene, the first random copolymerized polypropylene, the first ethylene-α-olefin copolymer and the antioxidant Put the agent into a screw extruder for m...

Embodiment 1

[0052] A preparation method of modified polypropylene hot-melt adhesive, is characterized in that, comprises the following steps:

[0053] The step of preparing functionalized modified polypropylene: the density of 80 parts is 0.90g / cm 3 , the second random copolymerized polypropylene with a melt index of 8g / 10min (230°C, 2.16kg) and 20 parts with a density of 0.88g / cm 3 The second ethylene-α-olefin copolymer with a melt index of 2g / 10min (190°C, 2.16kg) was added to the mixer, mixed for 5min, and the stirring speed was 1000r / min; then the uniformly stirred material was put into a φ65 twin-screw extruder In the extruder, the length-to-diameter ratio of the screw is 36:1, the temperature of the three reaction zones of the twin-screw extruder is 180°C, and the screw speed is 300 rpm. Add 2 parts of maleic anhydride, 0.3 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane and 1 part of styrene to the mixing zone of the extruder, and extrude to granulate. A functionalized modi...

Embodiment 2

[0058] A preparation method of modified polypropylene hot-melt adhesive, is characterized in that, comprises the following steps:

[0059] The step of preparing functionalized modified polypropylene: the density of 40 parts is 0.91g / cm 3 , the second random copolymerized polypropylene with a melt index of 2.5g / 10min (230°C, 2.16kg) and 60 parts with a density of 0.89g / cm 3 The second ethylene-α-olefin copolymer with a melt index of 8g / 10min (190°C, 2.16kg) was added to the mixer, mixed for 5min, and the stirring speed was 1000r / min; then the uniformly stirred material was put into a φ65 twin-screw extruder In the extruder, the length-to-diameter ratio of the screw is 36:1, the temperature of the three reaction zones of the twin-screw extruder is 190°C, and the screw speed is 250rpm. In the mixing zone of the extruder, 1 part of maleic acid, 0.1 part of tert-butylcumyl peroxide, and 0.5 part of p-methylstyrene were added by weighing, extruded and granulated to obtain functiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com