Rubberized fabric material with polyester cotton lining and capable of preventing chemical penetration

An anti-chemical and inner lining technology, which is applied in the field of adhesive cloth materials that prevent chemical penetration, can solve problems such as poor bonding strength, impact on wearer's wearing comfort, and potential safety hazards of air tightness of protective clothing, so as to improve the bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

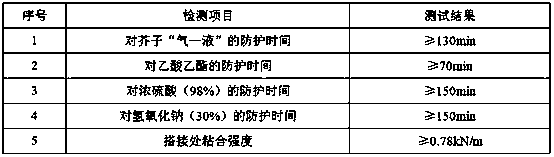

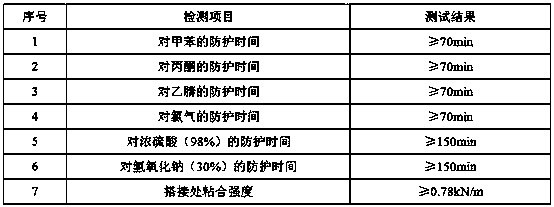

[0068] A kind of anti-chemical permeation tape material with polyester cotton lining, including base cloth (aramid fiber), the surface of both sides of the base cloth is coated with fluorine rubber layer and chlorinated butyl rubber layer respectively, and compounded on the outside of the fluorine rubber layer cotton cloth, such as figure 1 shown.

[0069] The specific preparation method is as follows:

[0070] (1) Preparation of fluororubber coating

[0071] 1.1. The proportion of each component of the fluororubber layer is as follows (1 kg per part):

[0072] Fluorine rubber 100 parts,

[0073] Bisphenol AF (molecular formula C 15 h 10 f 6 o 2 ) 2 copies,

[0074] BPP (fluorine rubber vulcanization accelerator) 1.0 parts,

[0075] Bis-2,5 (curing agent, formula C 16 h 34 o 4 ) 0.05 parts,

[0077] Magnesium oxide 5 parts,

[0078] 5 parts of permanent yellow;

[0079] 1.2. Mixing process of fluororubber layer:

[0080] The mix...

Embodiment 2

[0125] A kind of anti-chemical permeation tape material with polyester cotton lining, including base cloth (aramid fiber), the surface of both sides of the base cloth is coated with fluorine rubber layer and chlorinated butyl rubber layer respectively, and compounded on the outside of the fluorine rubber layer cotton cloth, such as figure 1 shown.

[0126] The specific preparation method is as follows:

[0127] (1) Preparation of fluororubber coating

[0128] 1.1. The proportion of each component of the fluororubber layer is as follows (10kg per part):

[0129] Fluorine rubber 100 parts,

[0130] Bisphenol AF 3.5 parts,

[0131] BPP 0.5 parts,

[0132] Double-2,5 0.1 parts,

[0134] Magnesium oxide 2 parts,

[0135] 10 parts of permanent yellow;

[0136] 1.2. Mixing process of fluororubber layer:

[0137] The mixing rubber material adopts an open rubber mixing machine with a roller speed ratio of 1:1.25. When mixing fluororubber, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com