3D printer for metal powder

A 3D printer and metal powder technology, applied in the direction of additive processing, etc., can solve the problems of manpower consumption, difficulty in monitoring the quality of powder coating, and lower product quality, and achieve the effects of saving manpower and material resources, simple and convenient handling, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

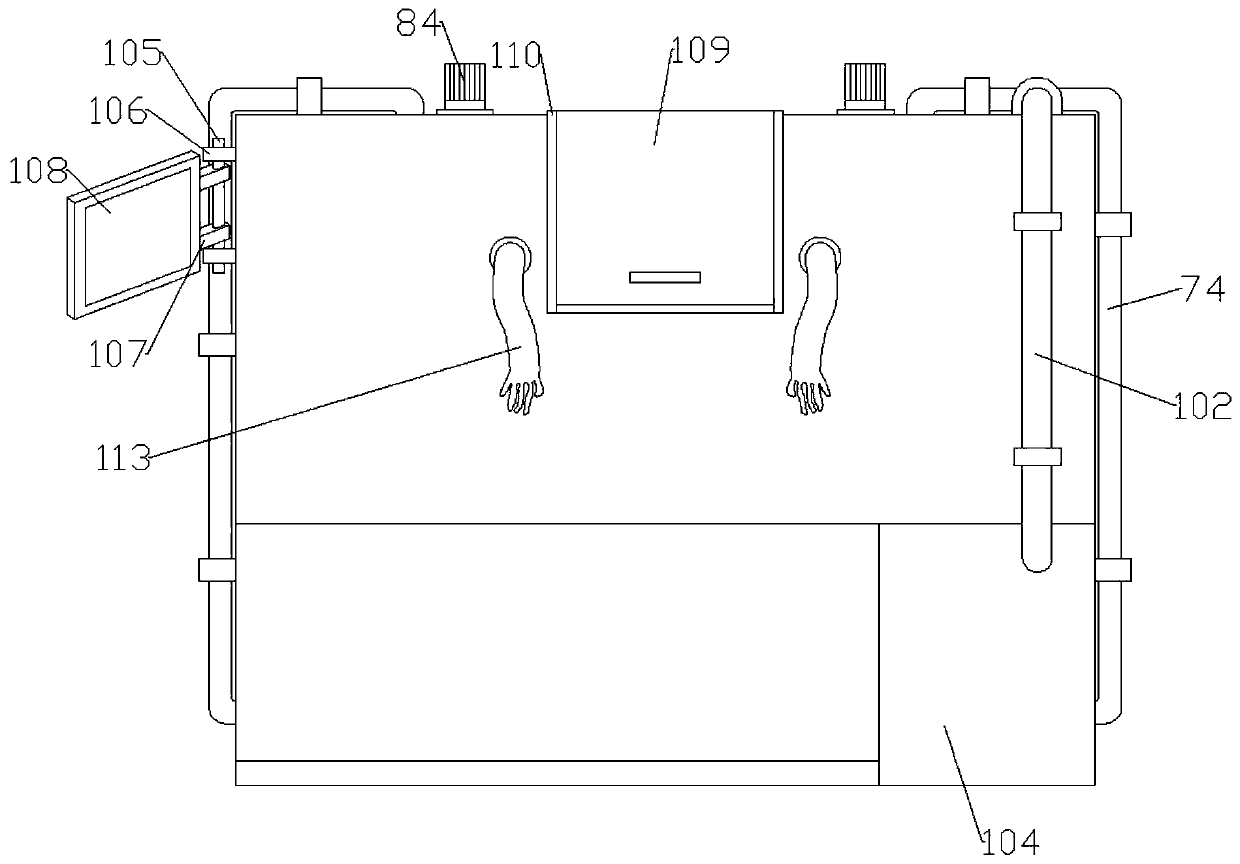

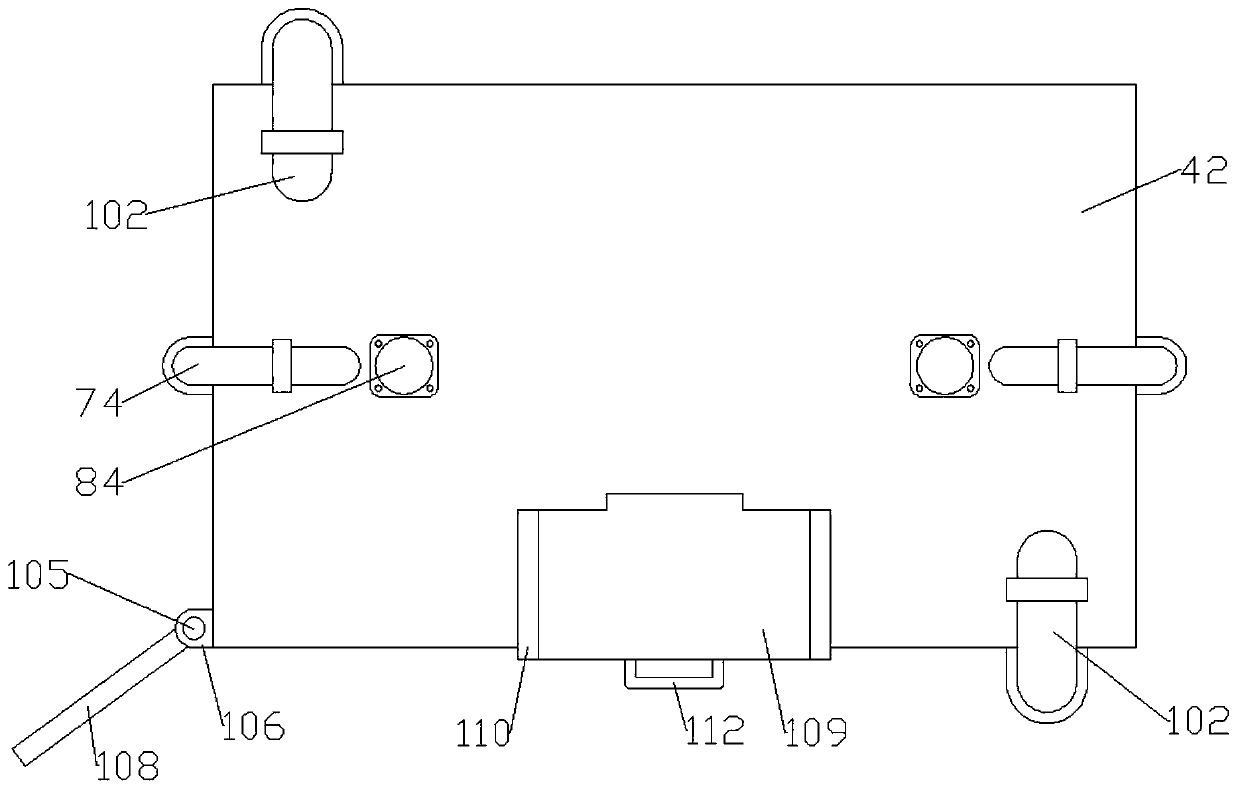

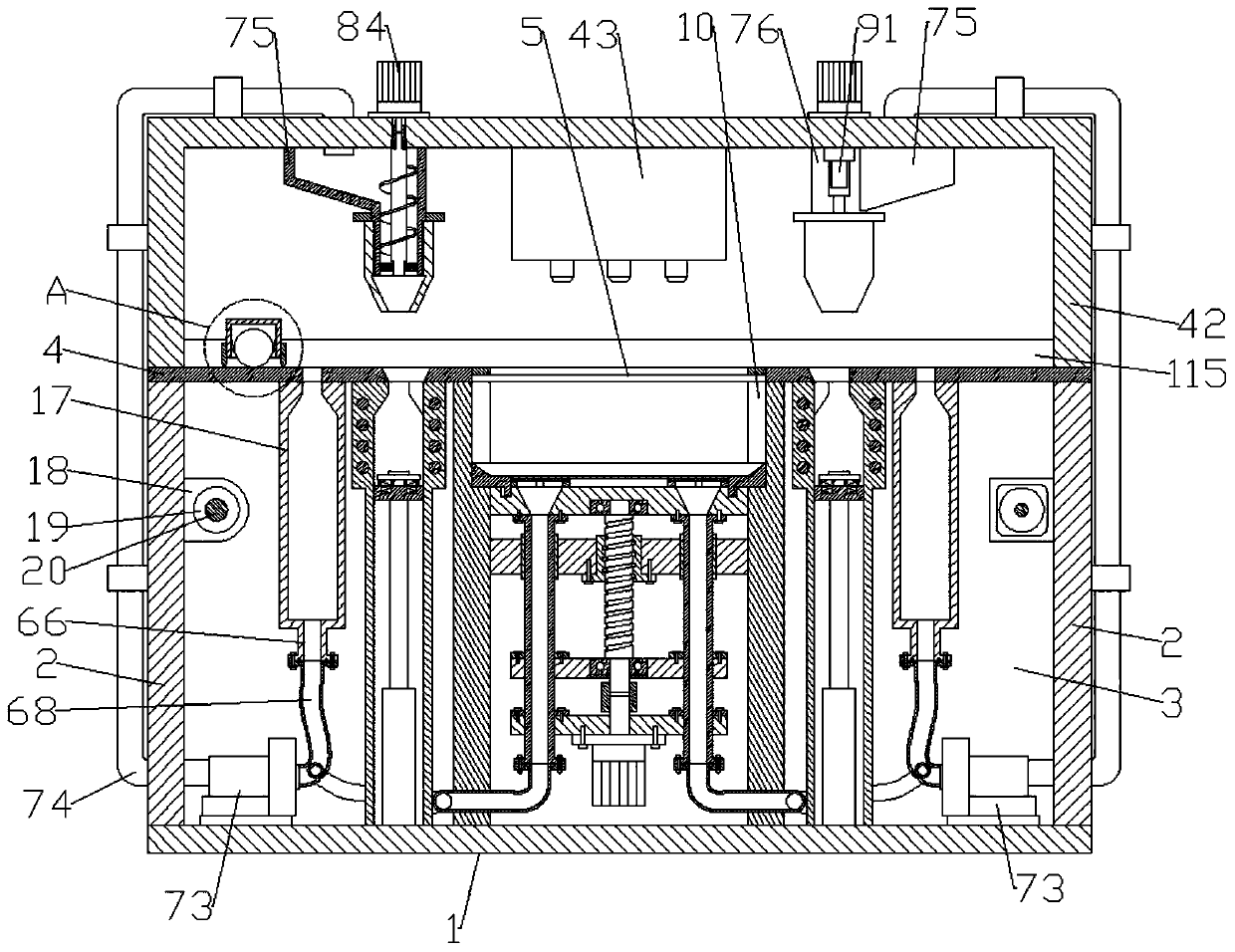

[0037] Refer to attached Figure 1-19: A metal powder 3D printer in this embodiment, comprising a base plate 1, the upper end of the base plate 1 is fixedly connected with the first support plate 2 on the left and right sides, and the upper side of the front and rear ends of the base plate 1 is fixedly connected with the second The support plate 3, the upper ends of the first support plate 2 and the second support plate 3 are fixedly connected with the operation plate 4, and the center position of the upper end of the operation plate 4 is provided with a processing groove 5, and the inner side of the upper end of the processing groove 5 is fixedly connected with the limit ring 120 , the left and right ends of the processing groove 5 are provided with powder outlet grooves 6 opened on the operation panel 4, and the left and right ends of the powder outlet groove 6 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com