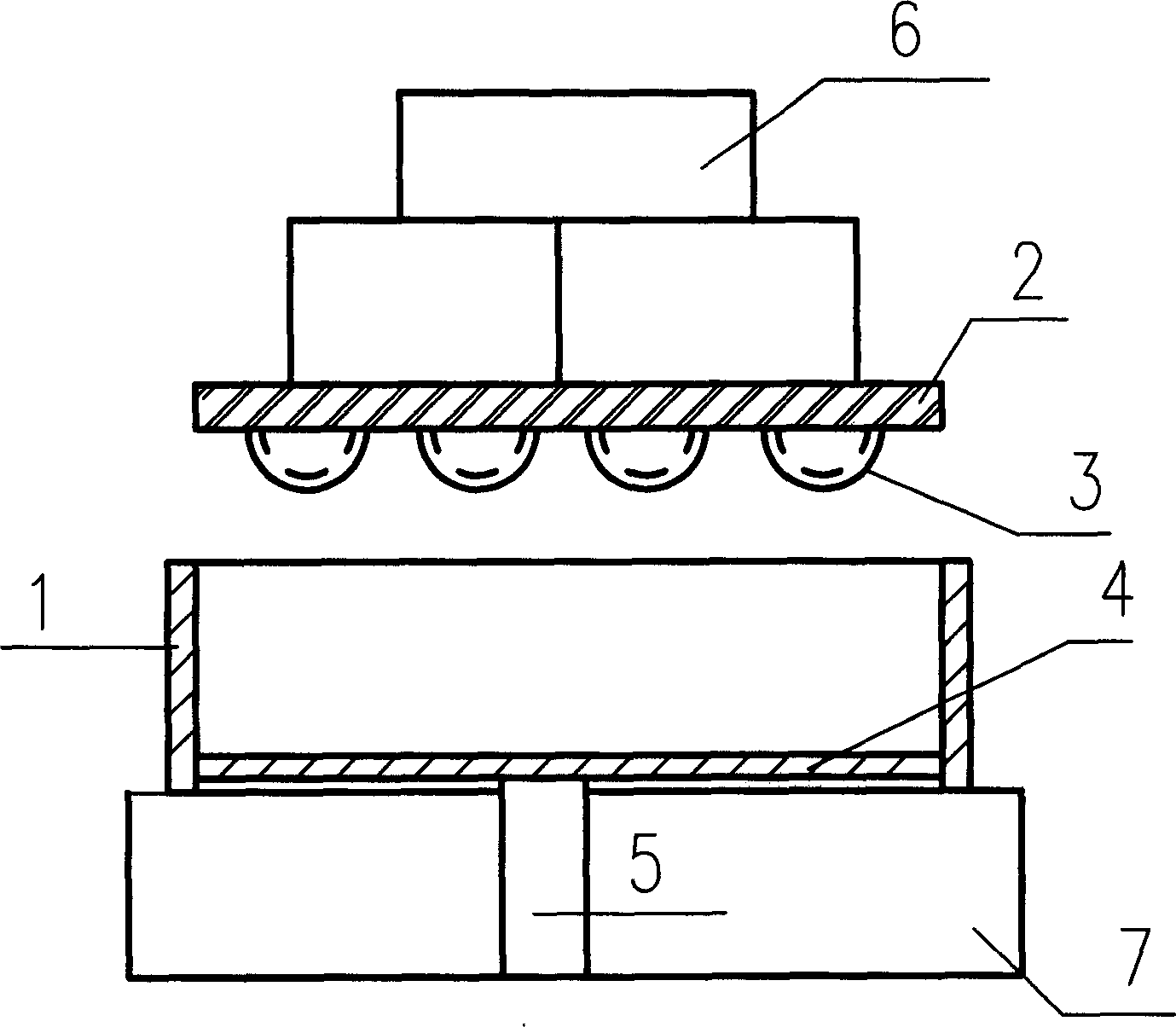

Air-entraining thermal insulation board and its producing method and special forming device

A molding device and insulation board technology, applied in insulation, building components, layered products, etc., can solve the problems of low thermal resistance, low compressive strength, complex production process, etc., and achieve good heat insulation performance and no noise pollution , the effect of good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Example 1: Proportioning without fly ash

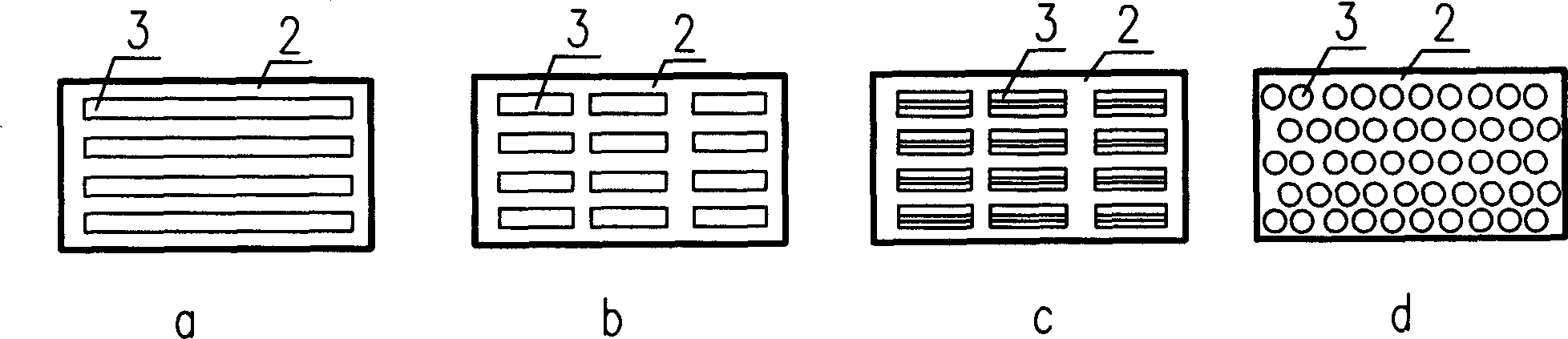

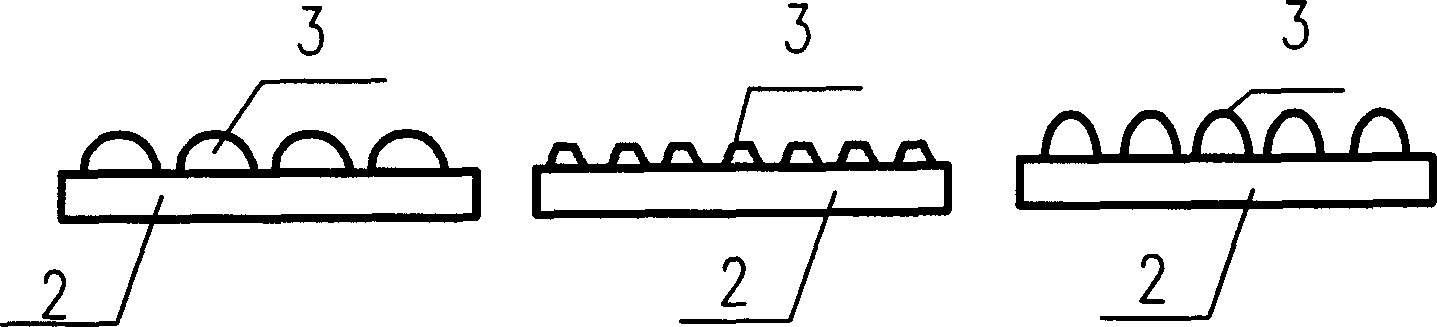

[0034] 325 Ordinary Portland cement 190kg; bulk density is 80kg / m 3 Perlite 126kg, water 200kg, 107 glue 10kg, the ratio of the cumulative length of the closed air section horizontal projection to the board width is 60%, the ratio of air volume to the volume of the whole board is 26%, and the dry bulk density of the finished product is 316kg / m 3 , The thermal conductivity is 0.083W / (m·k), and the compressive strength is 0.9MPa.

example 2

[0035] Example 2: Proportioning without fly ash

[0036] 325 Ordinary Portland cement 150kg; bulk density is 80kg / m 3 Perlite 126kg, water 165kg, 107 glue 10kg, the ratio of the cumulative length of the closed air section horizontal projection to the board width is 80%, the ratio of the air volume to the whole board volume is 34%, and the dry bulk density of the finished product is 276kg / m 3 , The thermal conductivity is 0.075W / (m·k), and the compressive strength is 0.6MPa.

example 3

[0037]Example 3: Contain a certain proportion of fly ash

[0038] 325 Ordinary Portland cement 150kg, fly ash 40kg, bulk density 80kg / m 3 Perlite 126kg, water 170kg, 107 glue 10kg, the ratio of the cumulative length of the closed air section horizontal projection to the board width is 80%, the ratio of the air volume to the whole board volume is 34%, and the finished product dry bulk density is 316kg / m 3 , The thermal conductivity is 0.083W / (m·k), and the compressive strength is 0.83MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com