Fabric folding mechanism

A fabric and edge technology, applied in the field of fabric hemming mechanisms, can solve the problems of short and difficult fabric folding, and achieve the effects of improving work efficiency, easy positioning, and convenient positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

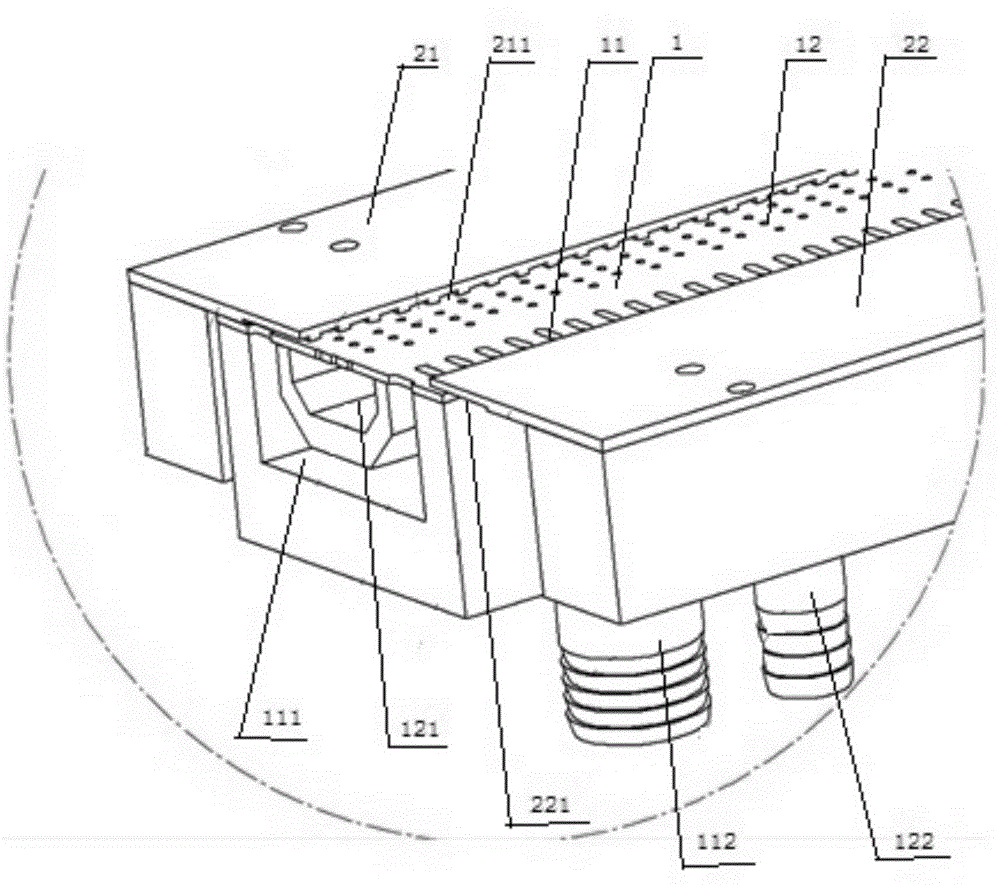

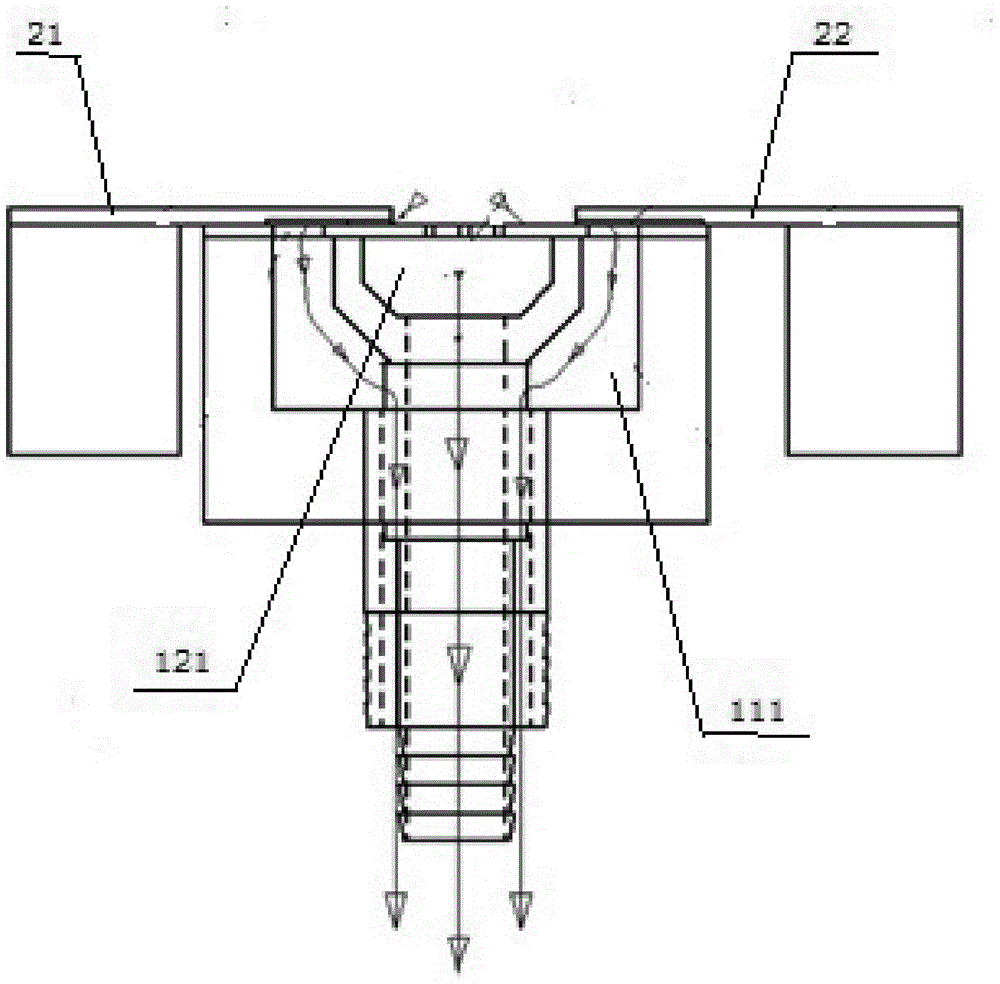

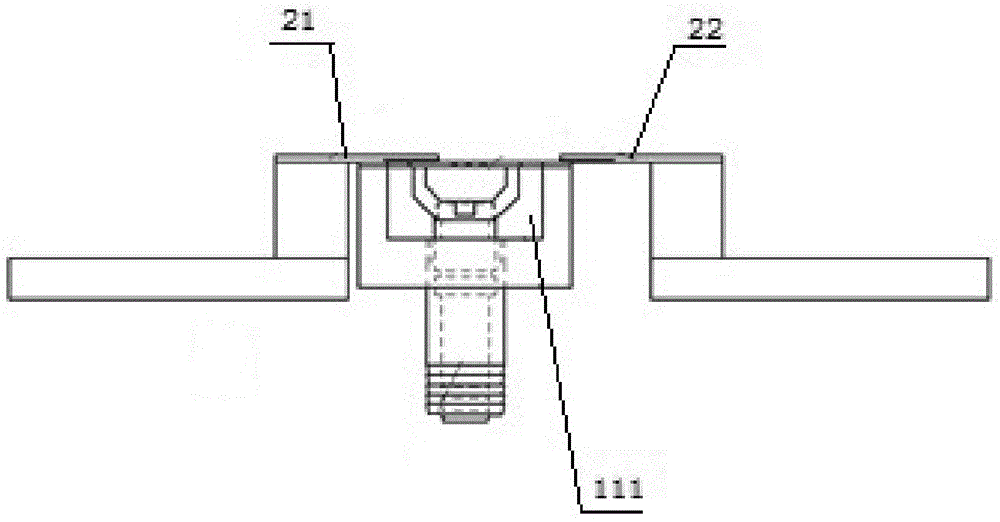

[0026] Such as figure 1 As shown, a fabric hemming mechanism includes a platform 1, and a side suction through hole 11 is provided on the platform 1, a cover plate capable of covering the side suction through hole 11 is provided on the platform 1, and a cover plate is provided on the lower surface of the cover plate. Groove, the notch of the groove faces the side suction through hole 11 and covers the side suction through hole 11. One edge of the cover plate is close to the center of the platform 1, and the symmetrical edge of the edge is relatively far away from the center of the platform 1. One end of the groove Extending to the edge of the cover plate close to the center of the platform 1, a side suction air chamber 111 communicating with the side suction through hole 11 is provided below the platform 1, and the side suction air chamber 111 is connected with a suction device.

Embodiment 2

[0028] Such as Figure 1-3 as well as Figure 6 As shown, it is the second embodiment of the present invention, a fabric hemming mechanism, including a platform 1, two rows of side suction through holes 11 on the left and right are symmetrically arranged on the platform 1, and a left cover is provided on the left row of side suction through holes 11 Plate 21, the right side suction through hole 11 is provided with a right cover 22, the lower surface of the left cover 21 is provided with a row of left grooves 211 corresponding to the left side suction through hole 11, each left One end of the groove 211 extends to the right edge of the left cover 21, the other end of the left groove 211 extends to the middle of the left cover 21, and the lower surface of the right cover 22 is provided with a row and a right row of side suction through holes 11. Corresponding to the right grooves 221, one end of each right groove 221 extends to the left edge of the right cover plate 22, and the...

Embodiment 3

[0040] Above-mentioned embodiment two is applicable to carry out hemming on both sides, as Figure 4 , 5 Shown, embodiment three also can design different hemming mechanisms according to different needs, take the sewing shirt pocket as example, generally mainly divide triangle, pentagon, circle and rectangular pocket, in the present embodiment, take circle pocket as For example, set the folding mechanism to three sides for folding (such as Figure 5 As shown) combined with the working principle of Embodiment 1, in the same way, 1. Precise positioning with cross laser lights in the suction cavity and the area where the garment pieces are placed. 3. The side suction is activated, and the edge of the pocket fabric is erected. 4. The down suction is changed to a strong suction, and the edge of the pocket fabric falls down, that is, the edge is folded. If the edge of the fabric is lower than 3mm and does not fall down automatically, it can be gently smoothed by hand. , as long as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com