Patents

Literature

30results about How to "Easy hemming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

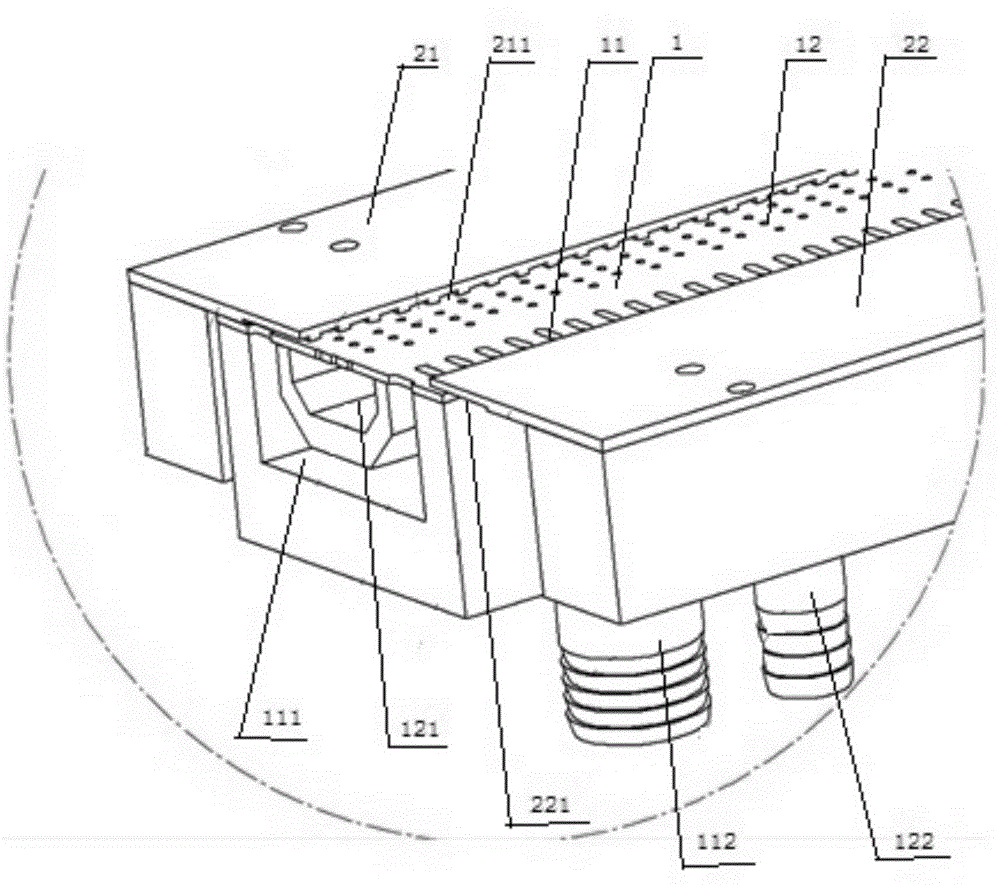

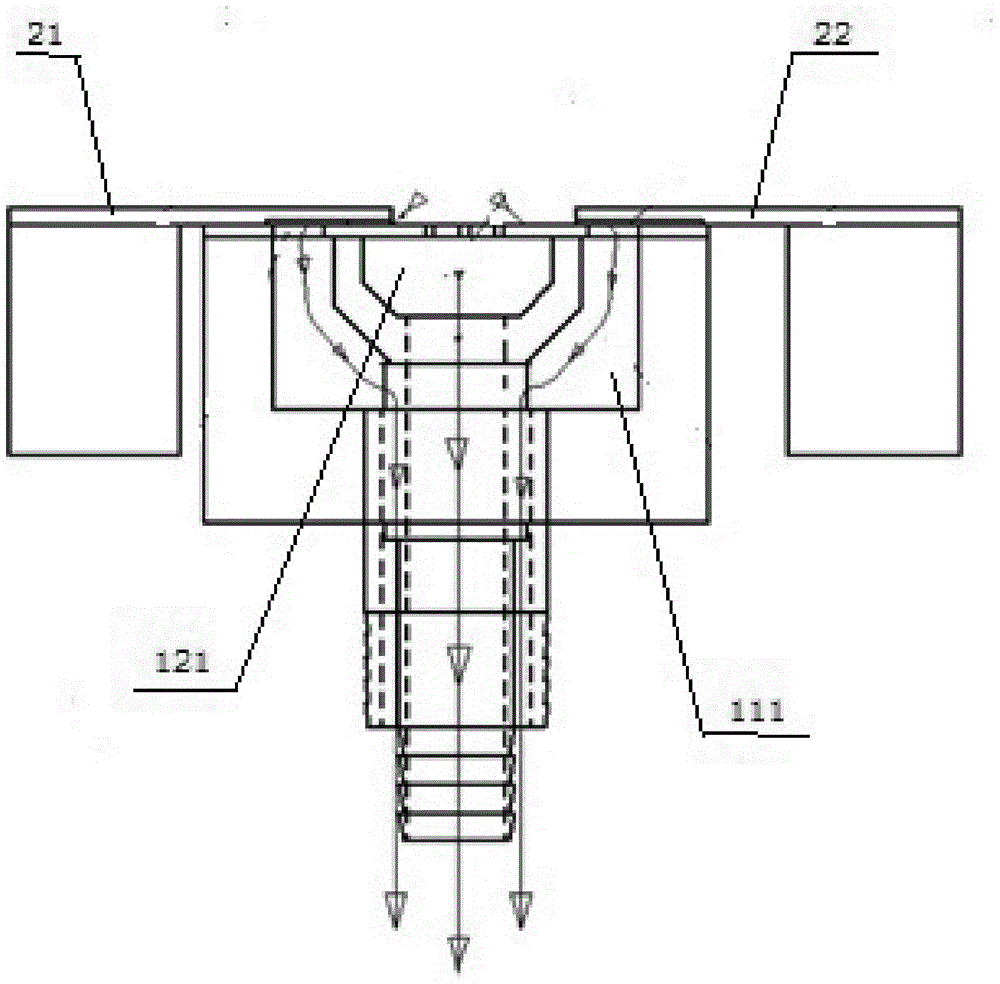

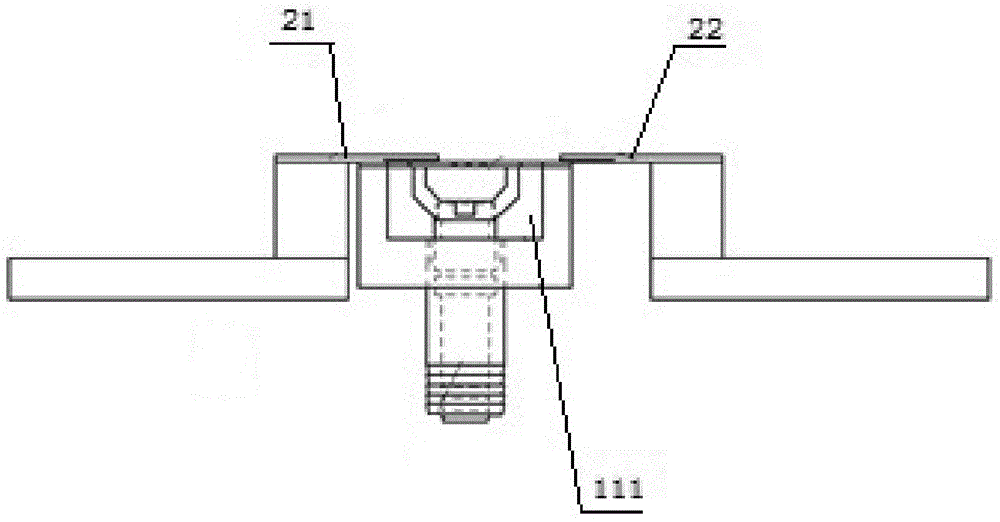

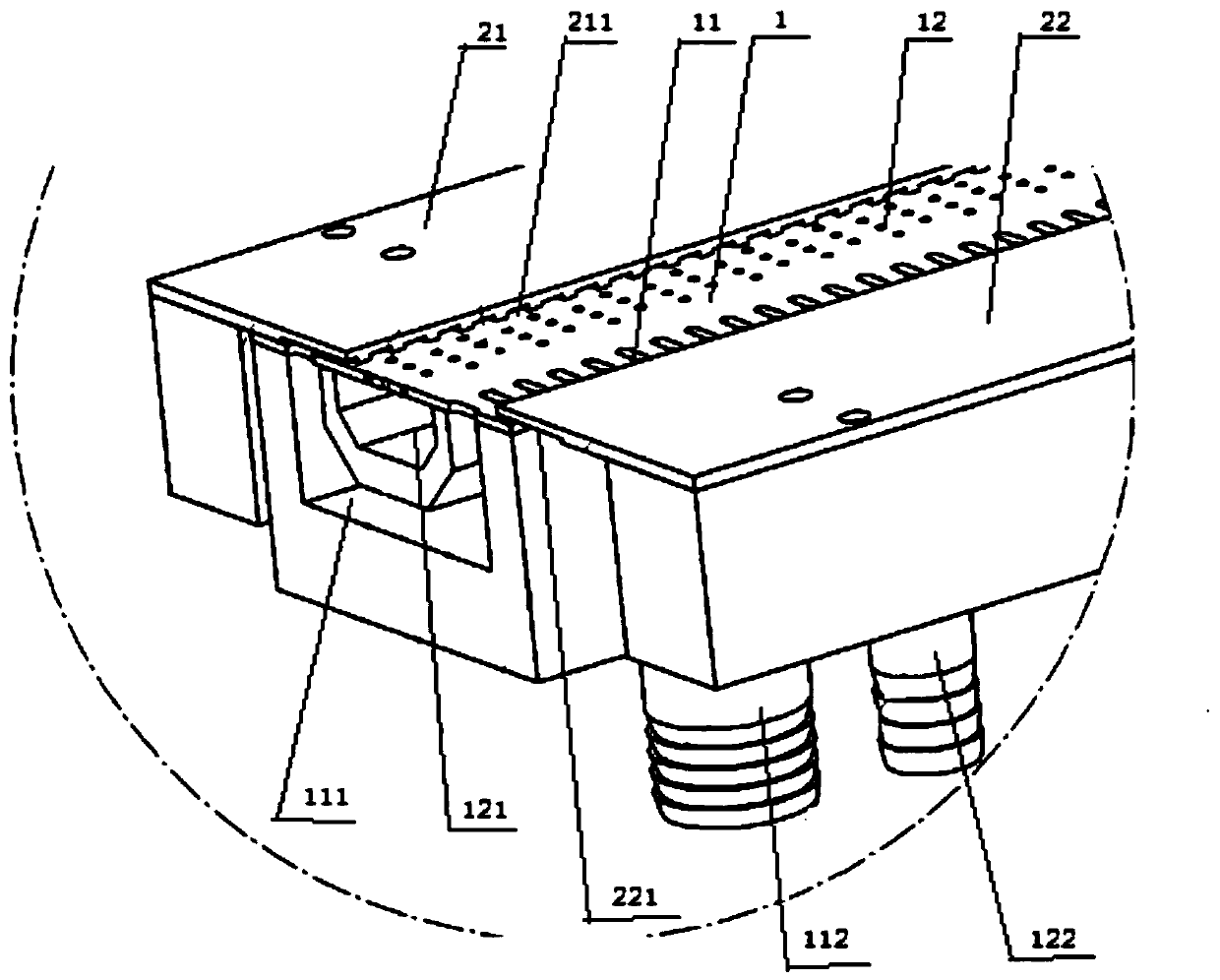

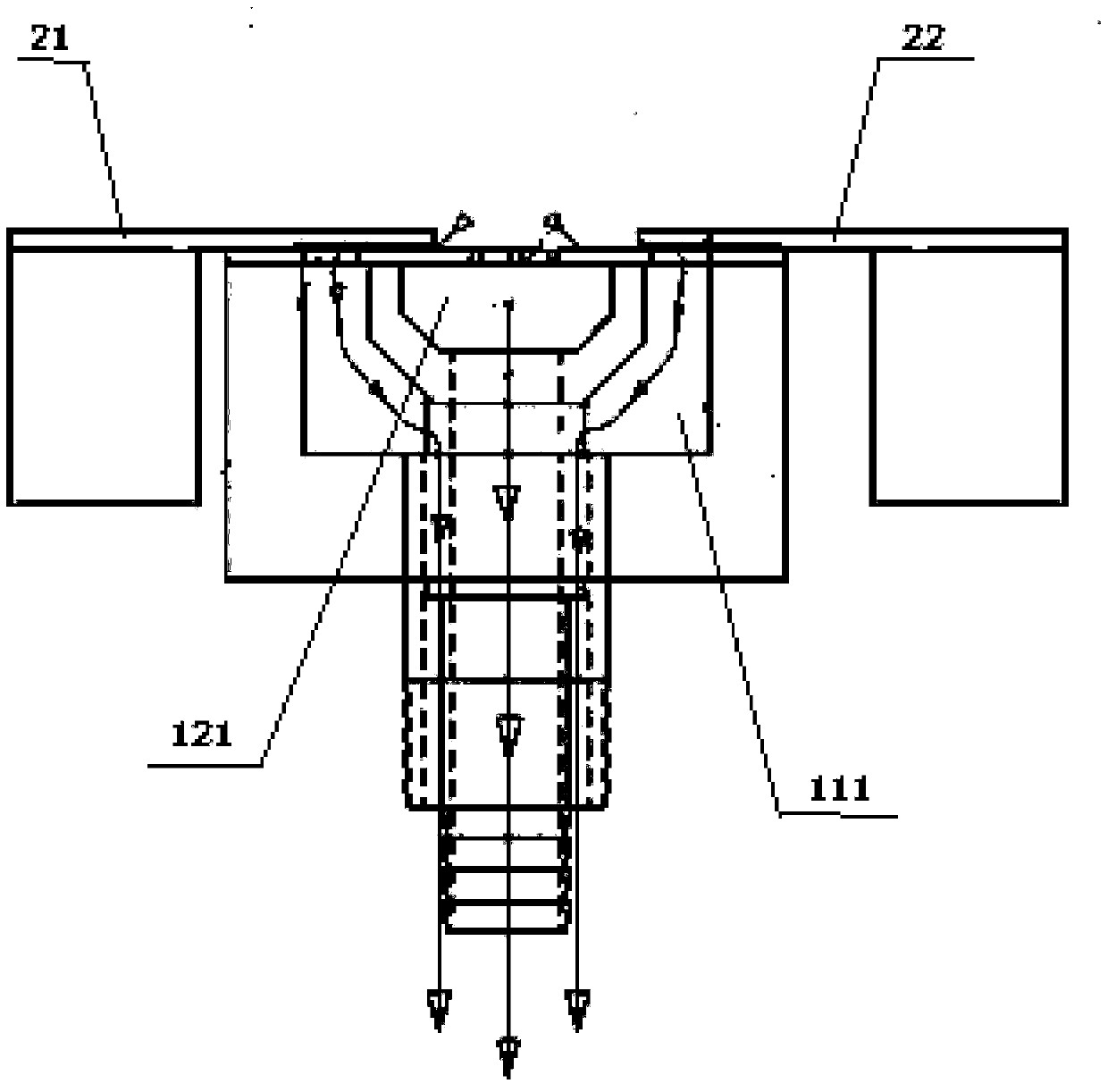

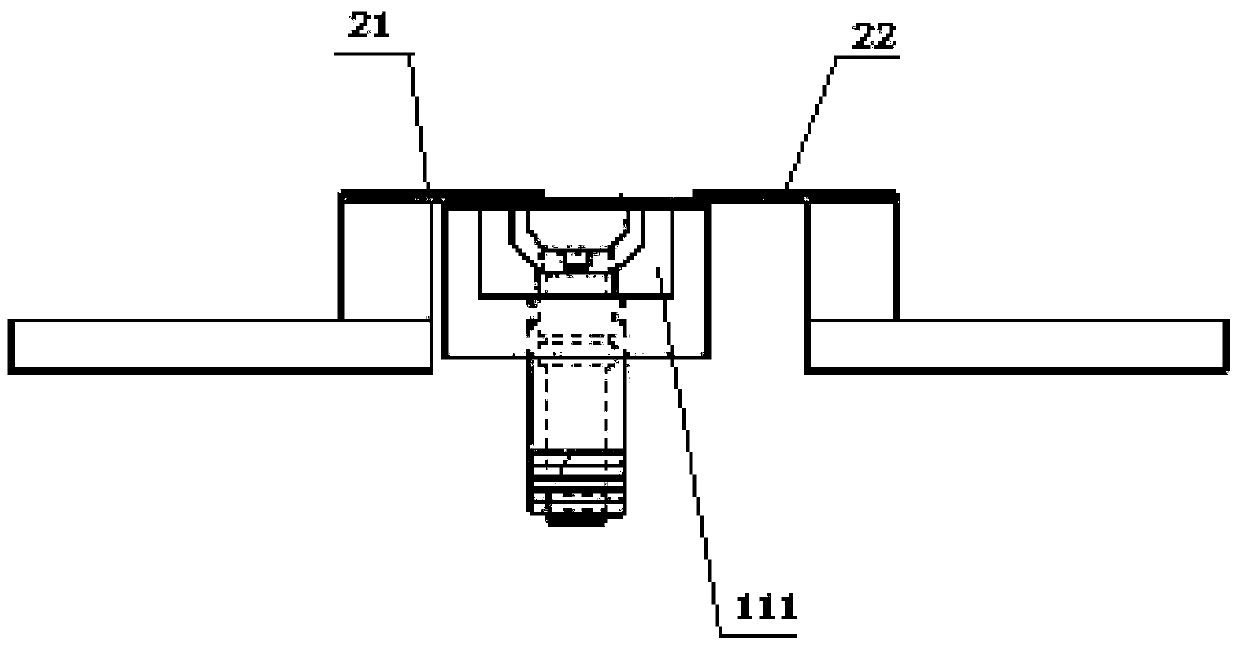

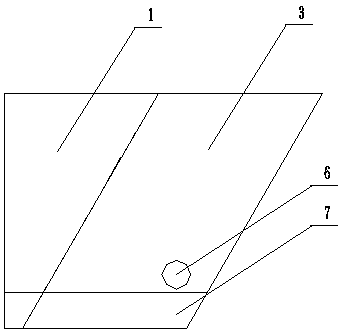

Fabric folding mechanism

The invention relates to a fabric folding mechanism which can be used for flanging one edge, two edges and a plurality of edges. The fabric folding mechanism comprises a platform, the platform is provided with a side air draught through hole, the platform is provided with a cover plate which can cover the side air draught through hole, the lower surface of the cover plate is provided with a groove, the opening of the groove faces to and covers the side air draught through hole, one edge of the cover plate is close to the center of the platform, another edge being symmetric with the edge is relatively far away from the center of the platform, one end of the groove extends to the edge of the cover plate close to the center of the platform, a side air draught chamber being in communication with the side air draught through hole is disposed under the platform, and the side air draught chamber is connected to an air draught device. The cover plate having the groove in the lower surface is added to the platform having the hole, lower air draught is changed into side air draught, edges of fabrics can be folded, the fabrics close to the groove of the edge of the cover plate can be vertical to form a flanging, the flanging with width being less than 3mm of fabrics can be normally machined, positioning is easy, and the fabrics hardly rebound and deform.

Owner:中山市阿米达机电设备有限公司

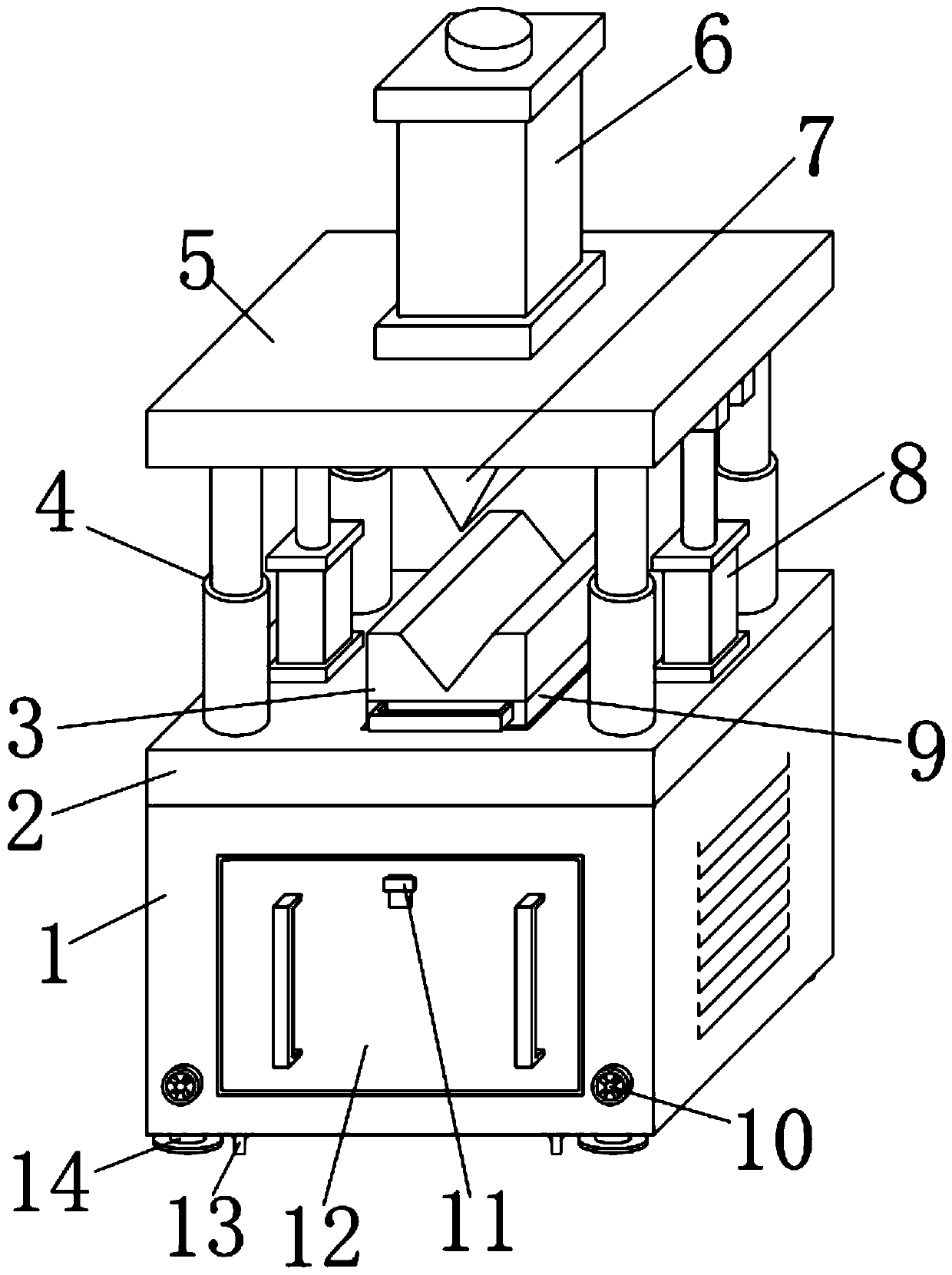

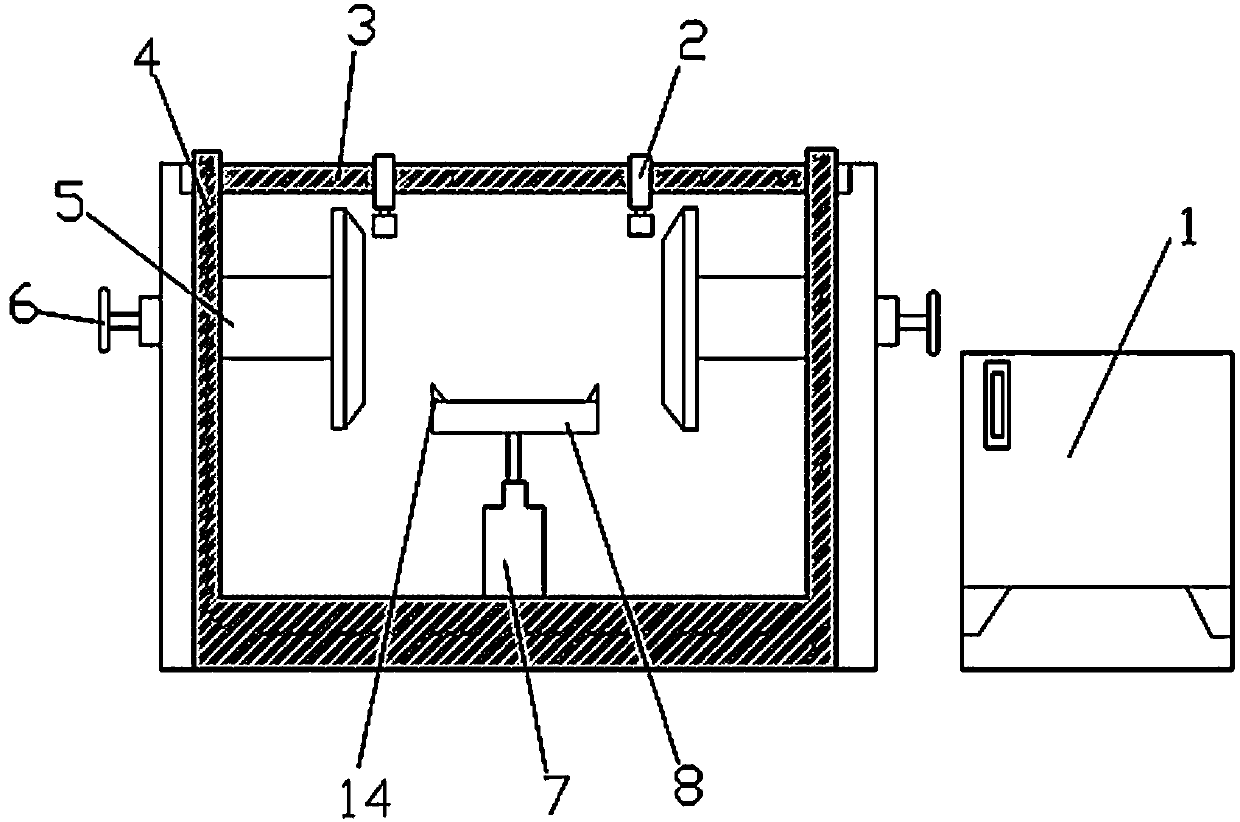

Refrigerator stamped part edge folding and forming device

InactiveCN111482500AEasy HemmingReduce manufacturing costShaping toolsPortable framesIceboxStructural engineering

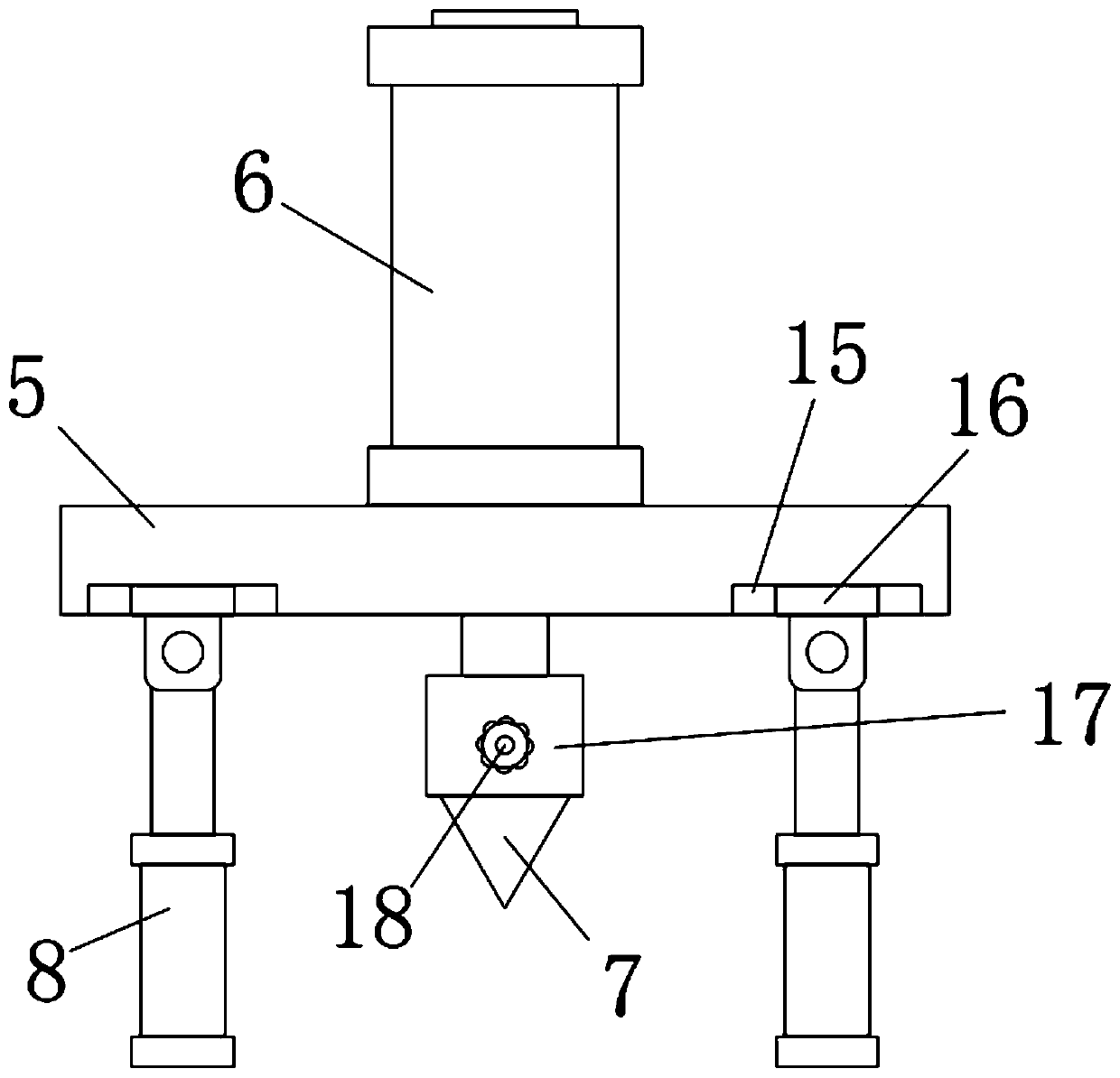

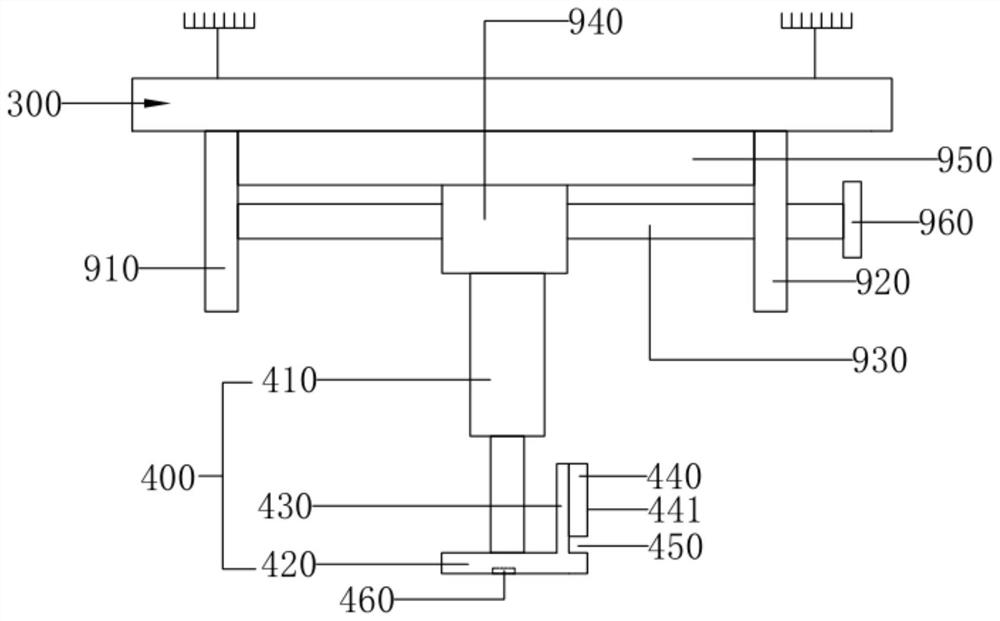

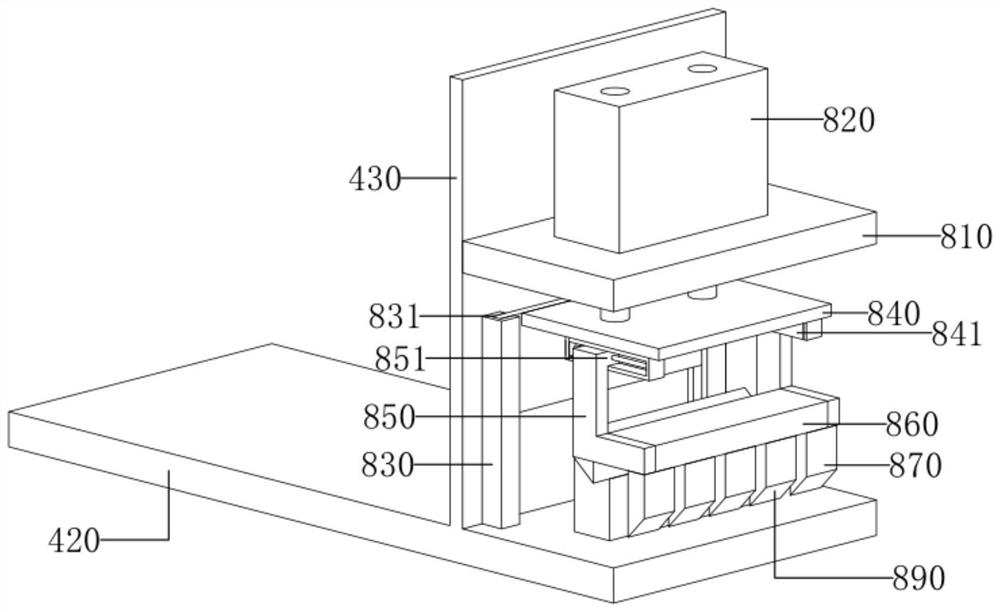

The invention discloses a refrigerator stamped part edge folding and forming device. The refrigerator stamped part edge folding and forming device comprises a base, and the upper surface of the base is fixedly connected with a workbench through bolts. The upper surface of the workbench is fixedly connected with guide columns, and a top plate is arranged at the upper ends of the guide columns. Thetwo ends of the upper surface of the workbench are fixedly connected with adjusting oil cylinders through bolts, and piston rods at the output ends of the adjusting oil cylinders are rotationally connected with adjusting sliding blocks. Adjusting sliding grooves are formed in the lower surface of the top plate, and the adjusting sliding blocks are slidably mounted in the adjusting sliding grooves.According to the refrigerator stamped part edge folding and forming device, by designing the adjusting oil cylinders and the guide columns, when different refrigerator stamped parts are subjected toedge folding, the rotating angle of the top plate jacked by the adjusting oil cylinders can be adjusted according to needs, guide supporting is carried out through the guide columns, and the angle ofan edge folding lower mold connected with the lower end of a stamping oil cylinder changes; and therefore the refrigerator stamped parts are subjected to edge folding better, a specific forming devicedoes not need to be prepared, and the refrigerator stamped part production cost is reduced.

Owner:CHUZHOU XINKANGDA METAL PROD

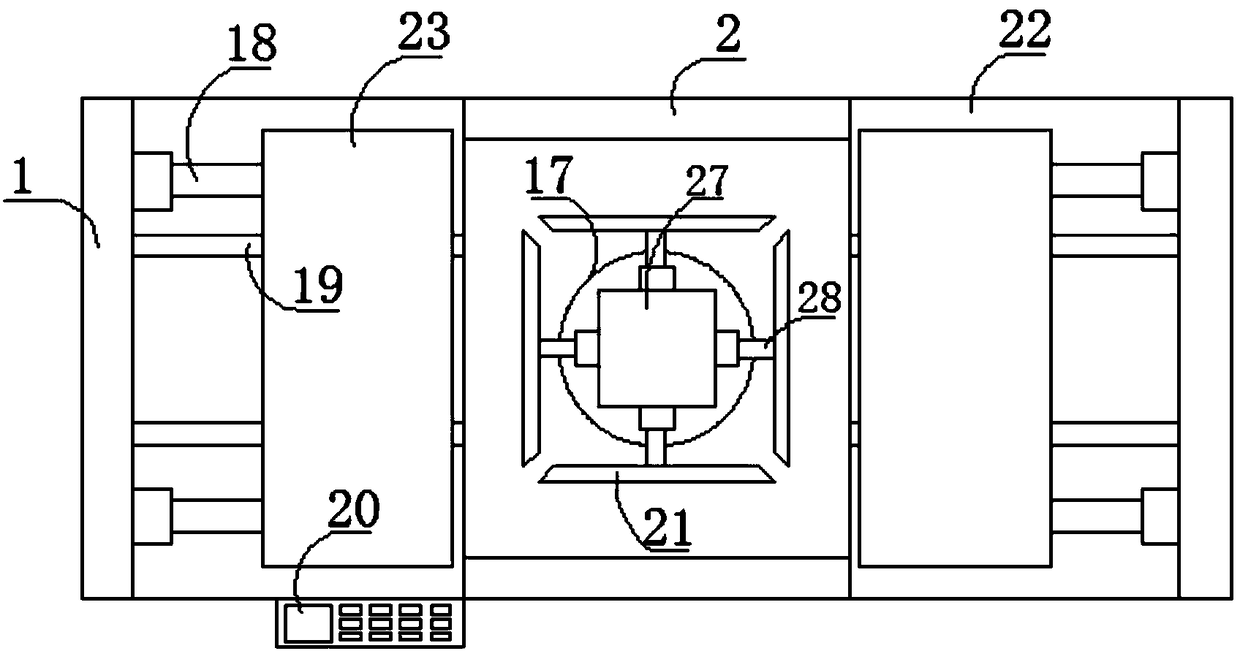

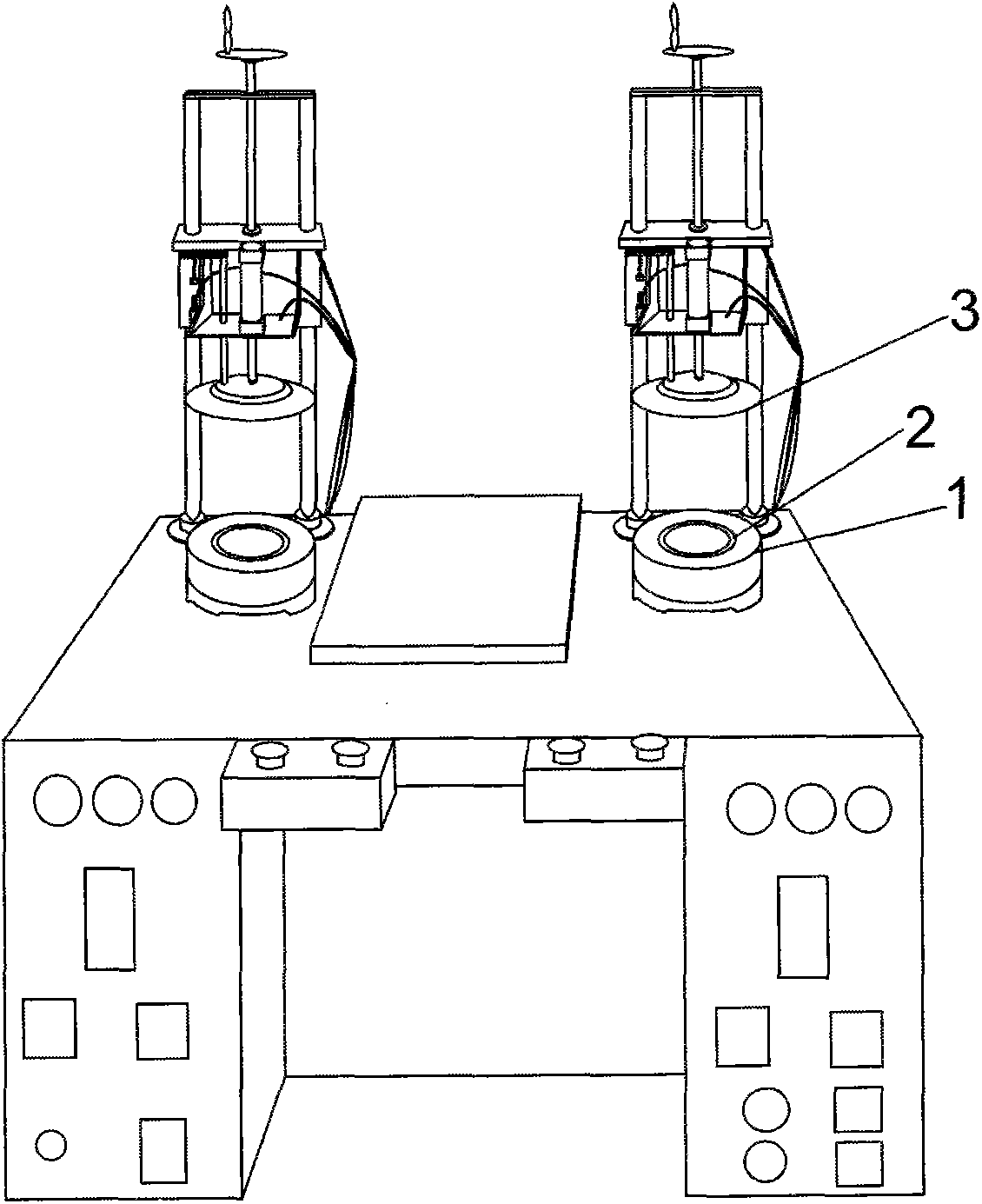

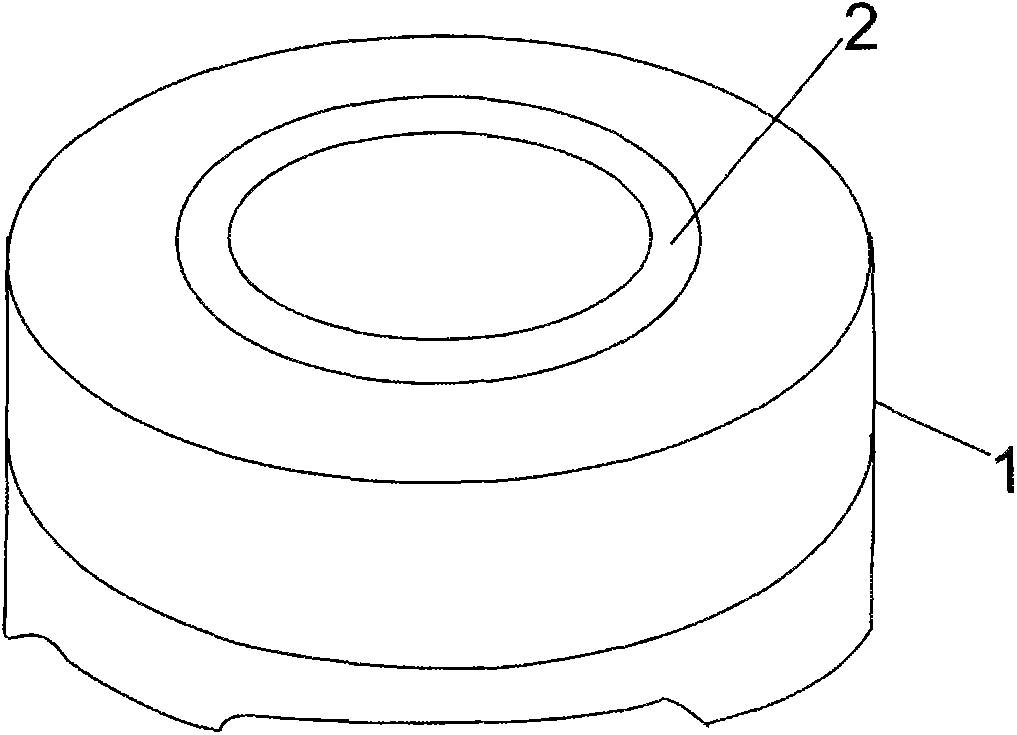

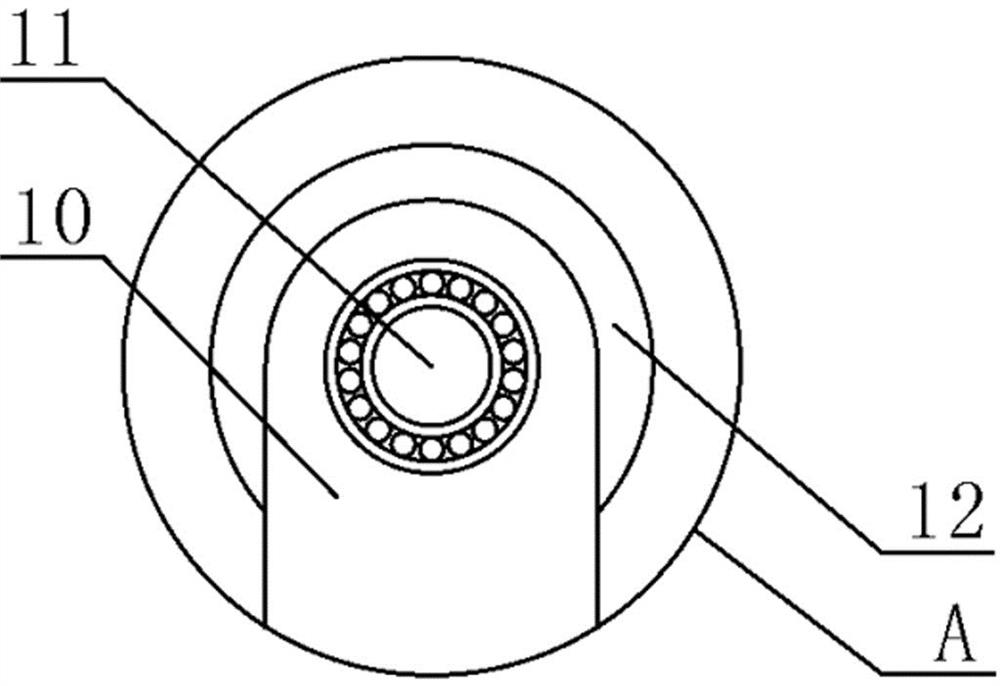

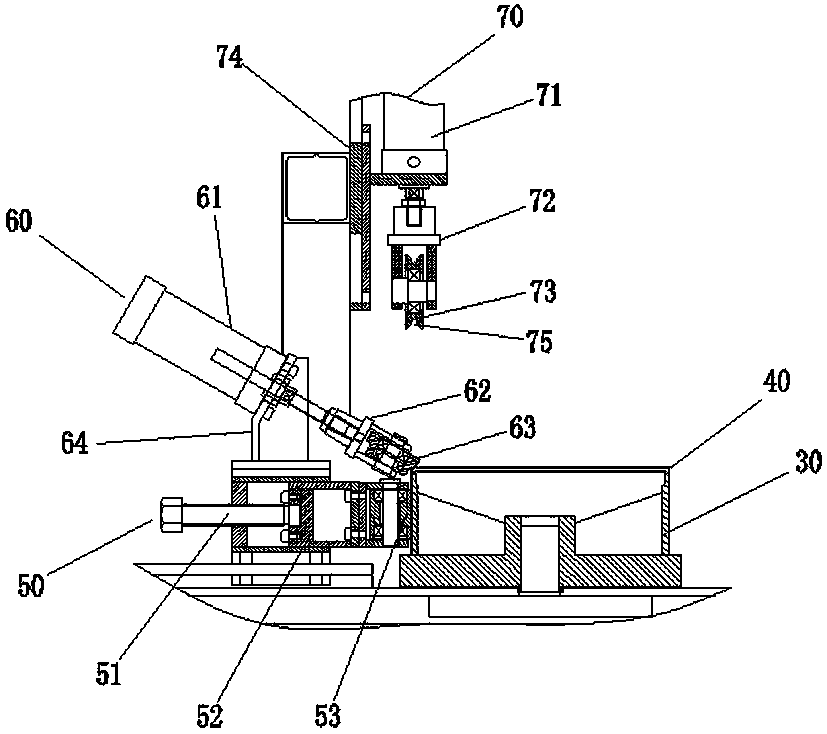

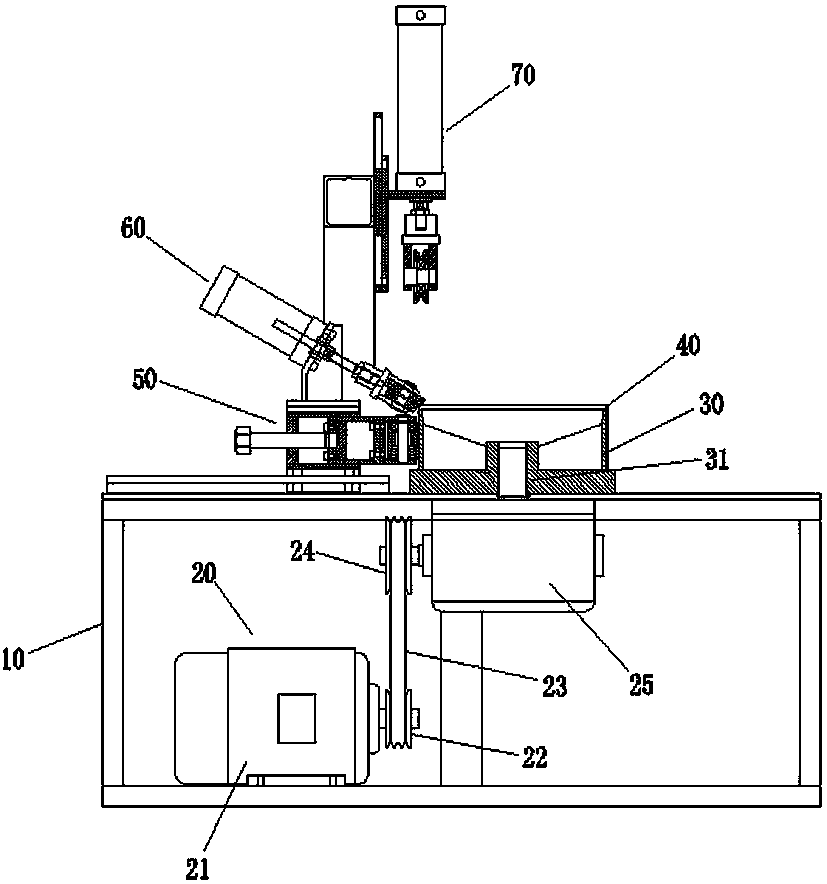

Steel ring edge folding machine

ActiveCN106391801ACheap compositionSimple structureMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

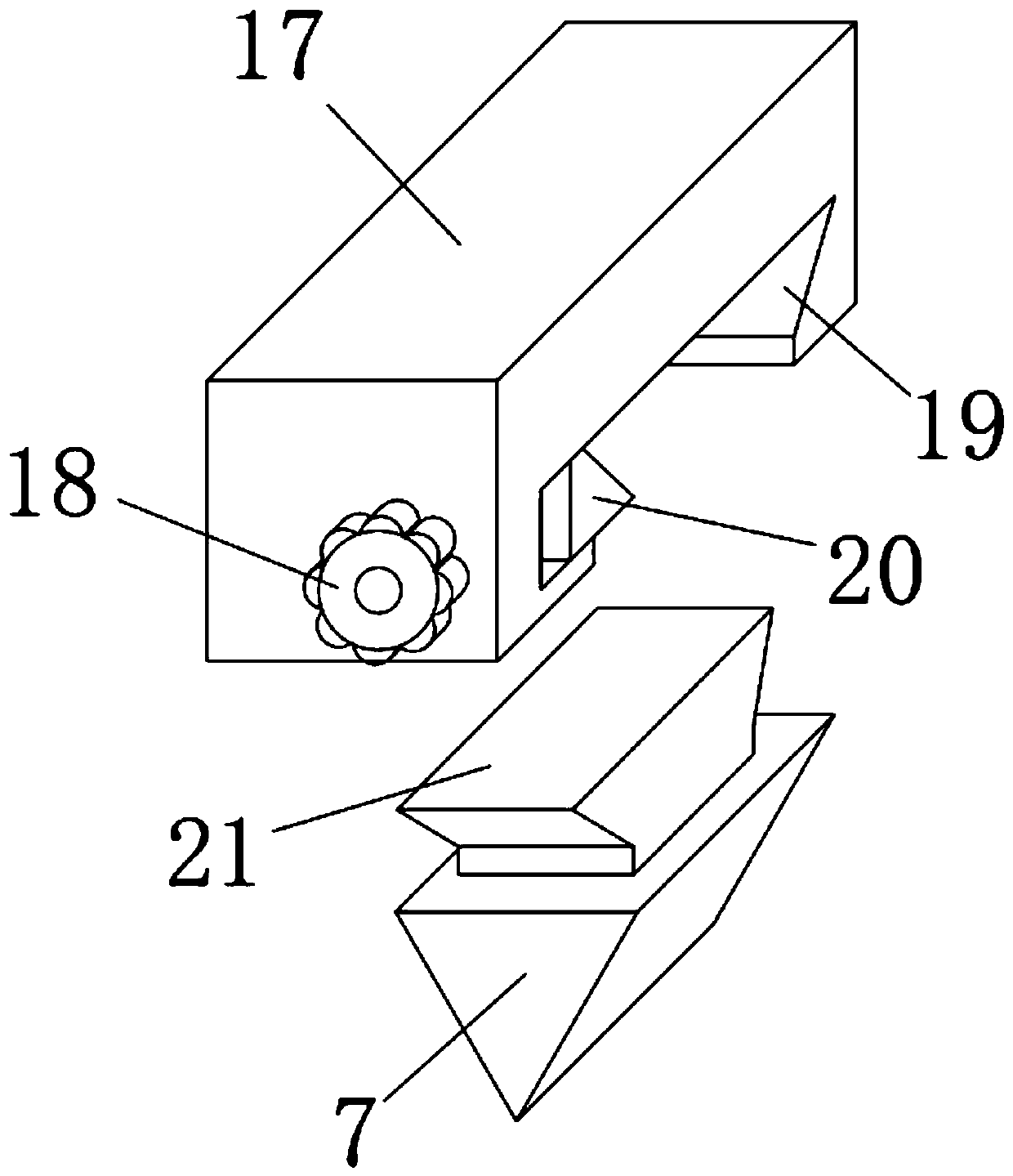

The invention discloses a steel ring edge folding machine which comprises a rack. The rack is internally provided with a transmission mechanism. The rack is provided with a locating core model for being in cup joint with a steel ring, an edge folding mechanism for rolling and pressing the steel ring and an arc pressing mechanism for downwards pressing the steel ring. The mandrel of the locating core model is connected with the transmission mechanism and driven by the transmission mechanism to rotate. The external circumference of the locating core model is in cup joint with the steel ring. One side of the locating core model is provided with the edge folding mechanism for applying force to the top end of the steel ring in an inclined mode from top to bottom, and the edge folding mechanism makes the top end of the steel ring form an inwards-folded edge. The arc pressing mechanism for downwards applying force to the inwards-folded edge at the top end of the steel ring is arranged above the locating core model and makes the inwards-folded edge form a downward arc groove by moving downwards. The steel ring edge folding machine has the advantages of being simple in structure, convenient to fabricate, low in cost, good in edge folding effect and arc pressing effect, not prone to breakage and the like.

Owner:广东鑫隆管业有限公司

Sealed opening edge folding device used for carton processing

InactiveCN108656623AEasy HemmingEasy to fixBox making operationsPaper-makingHydraulic cylinderCarton

The invention discloses a sealed opening edge folding device used for carton processing. The sealed opening edge folding device comprises a fixed base. Storage boxes are symmetrically arranged on thetwo sides of the inner portion of the fixed base. The inner portions of the two storage boxes are each fixedly connected with a second upper fixing plate through a second electric telescopic rod. Second lower fixing plates are installed on the lower portions in the two storage boxes correspondingly. Supporting stand columns are symmetrically installed on the top of each storage box. A storage tankis arranged between every two corresponding supporting stand columns. According to the sealed opening edge folding device, the four side walls of a fixing column are fixedly connected with edge folding plates through fourth electric telescopic rods correspondingly, the elongation length of every two opposite fourth electric telescopic rods can be regulated according to sizes of cartons, and edgefolding can be conveniently conducted on carton sealed openings of different sizes; and meanwhile, a hydraulic cylinder and a telescopic rod are arranged below a rotation cylinder used for rotating the fixing column, the height of the fixing column can be regulated through the hydraulic cylinder and the telescopic rod, and the cartons of different lengths can be conveniently fixed.

Owner:邱福祥

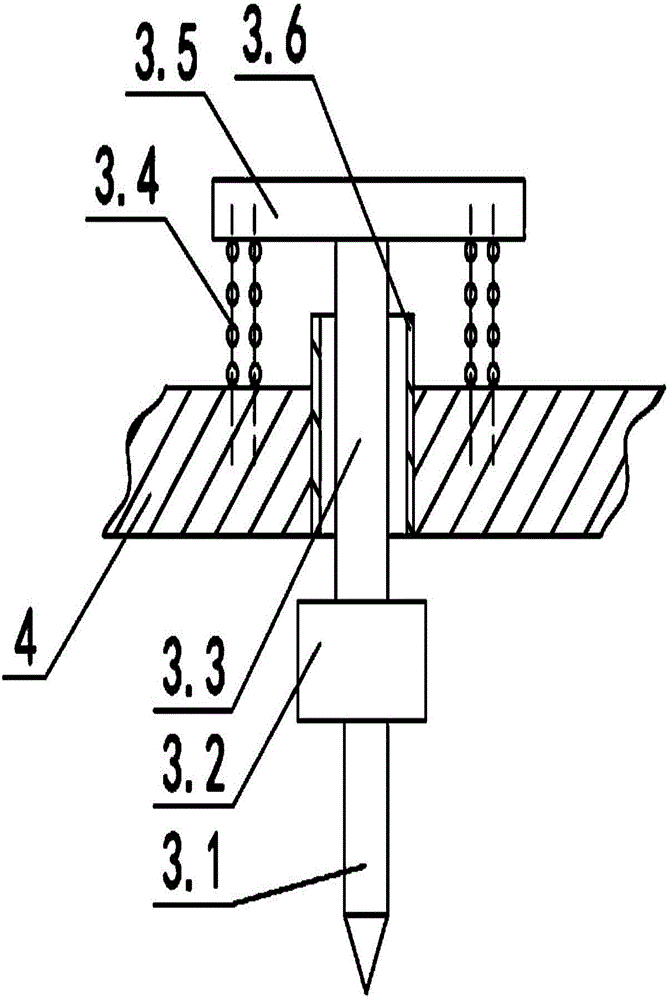

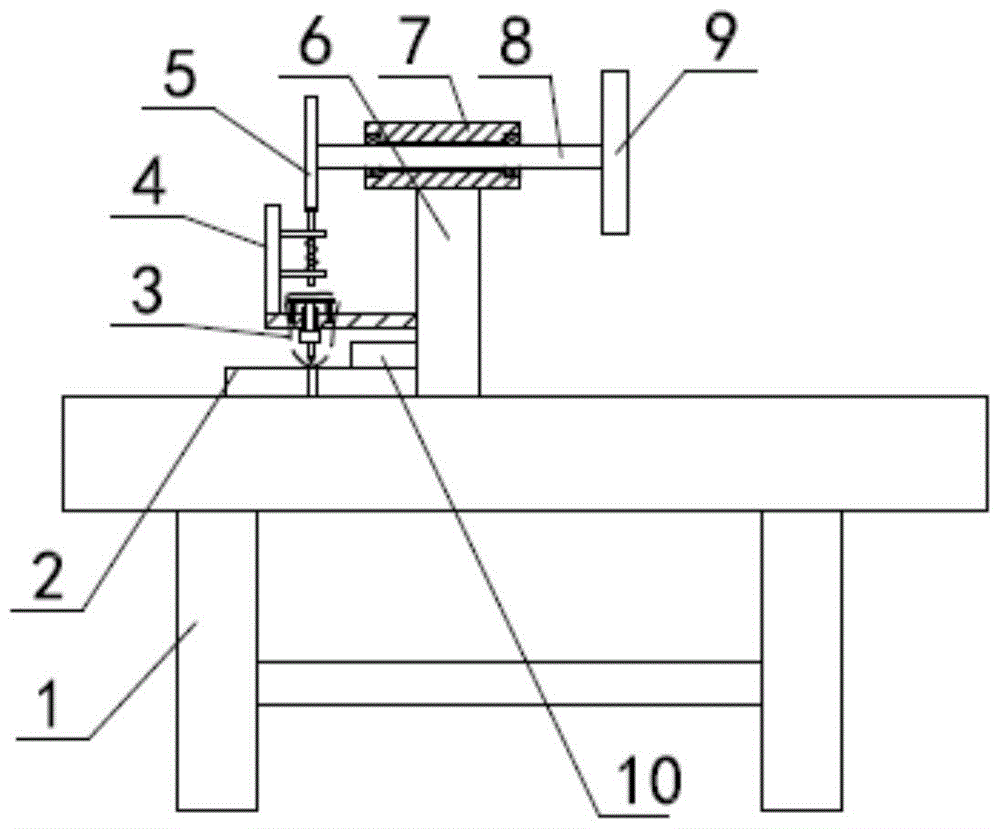

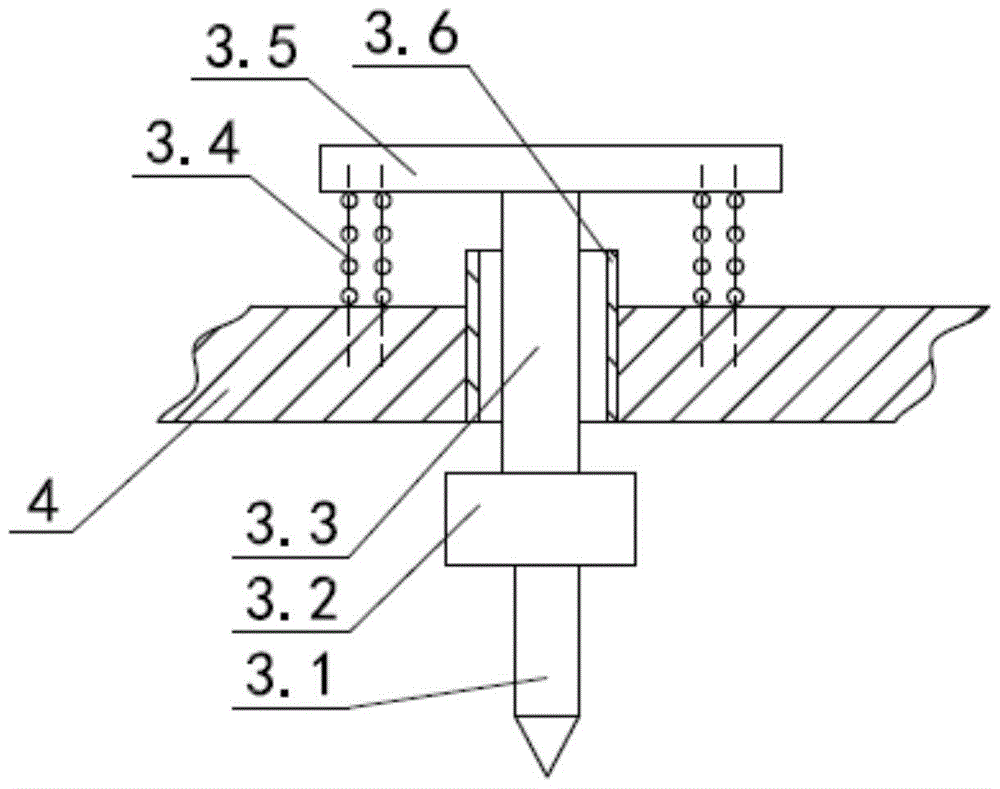

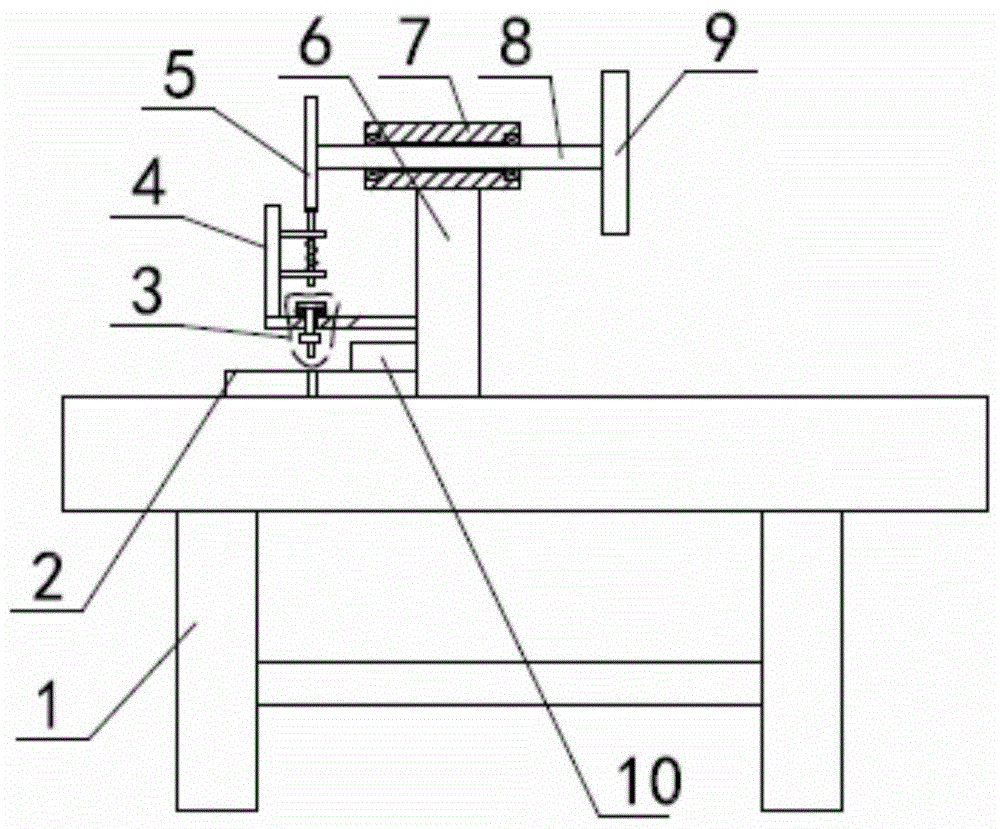

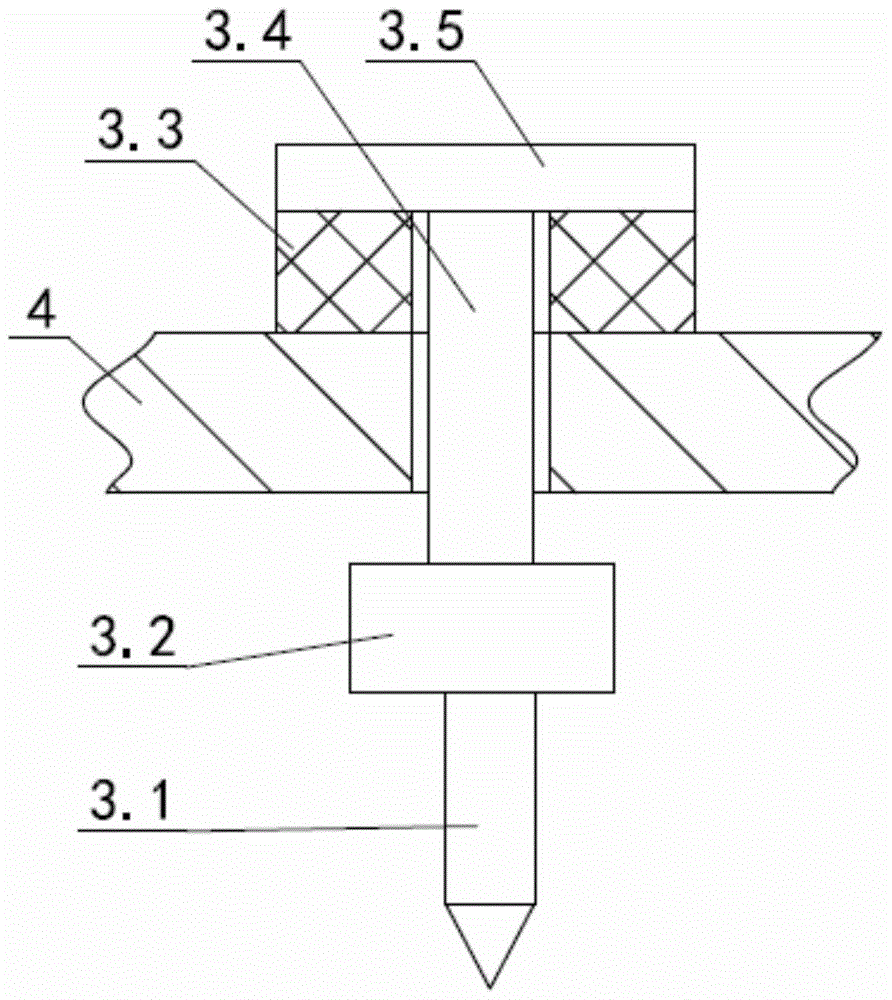

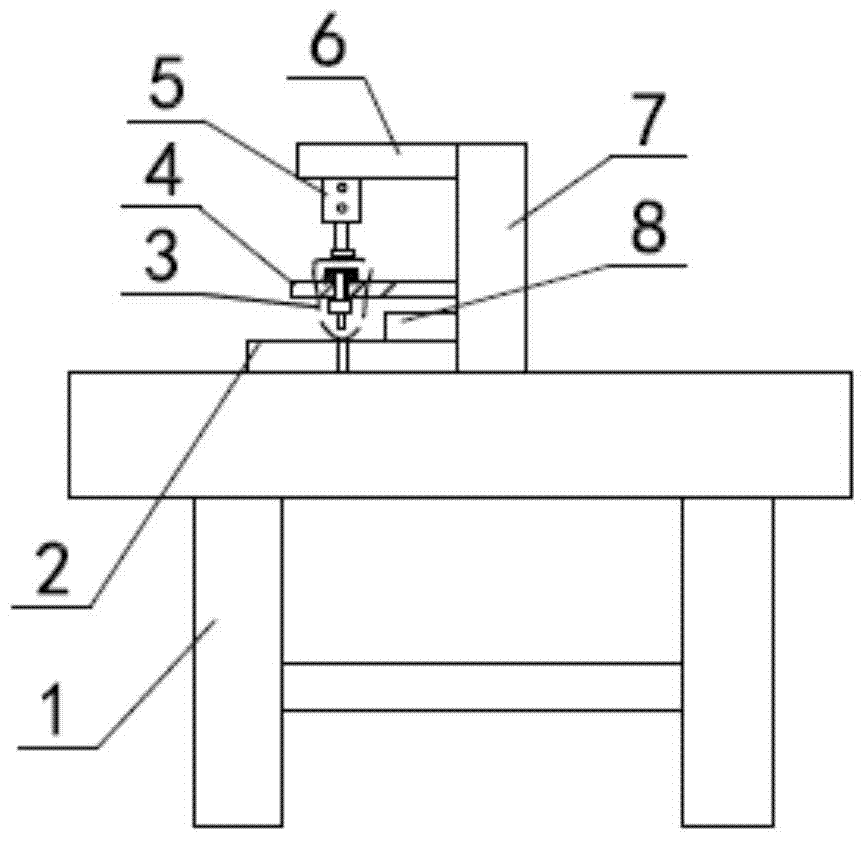

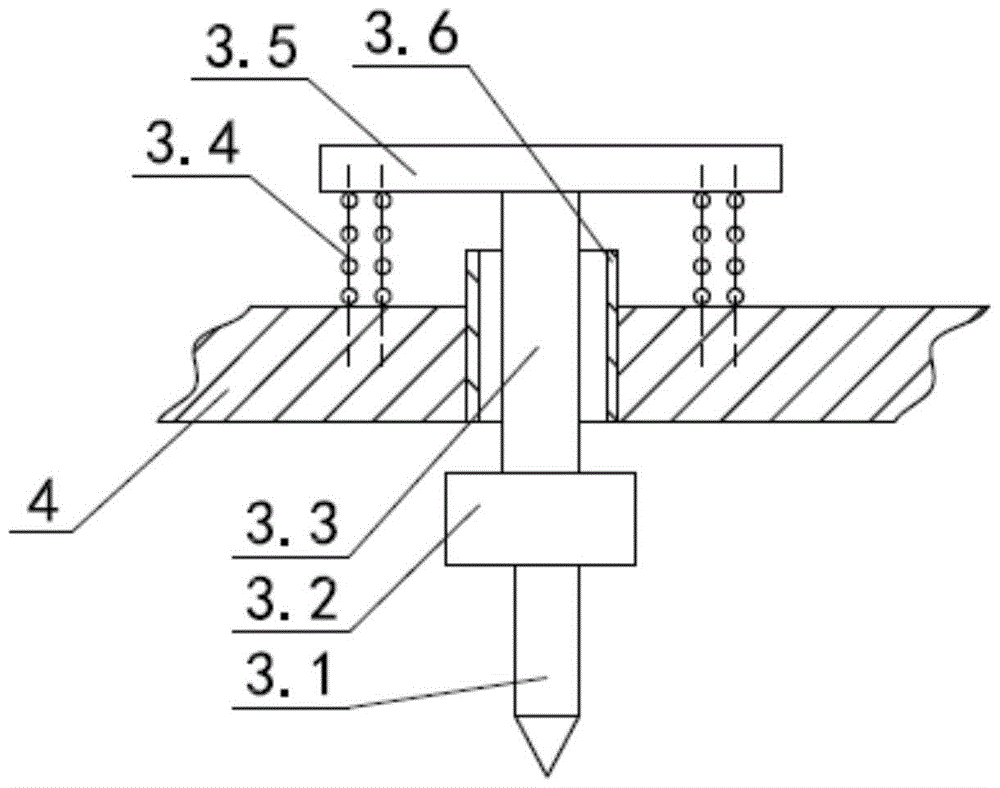

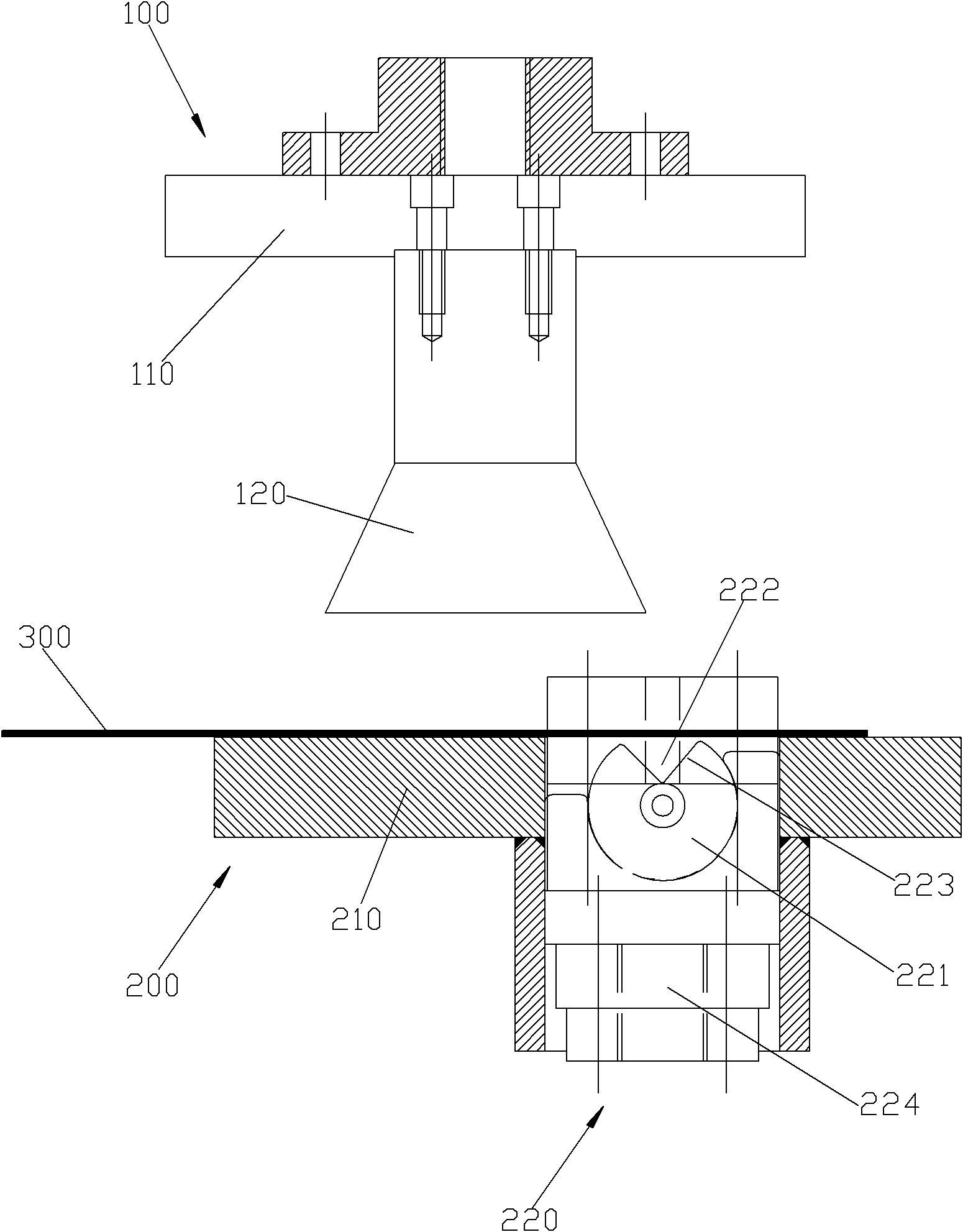

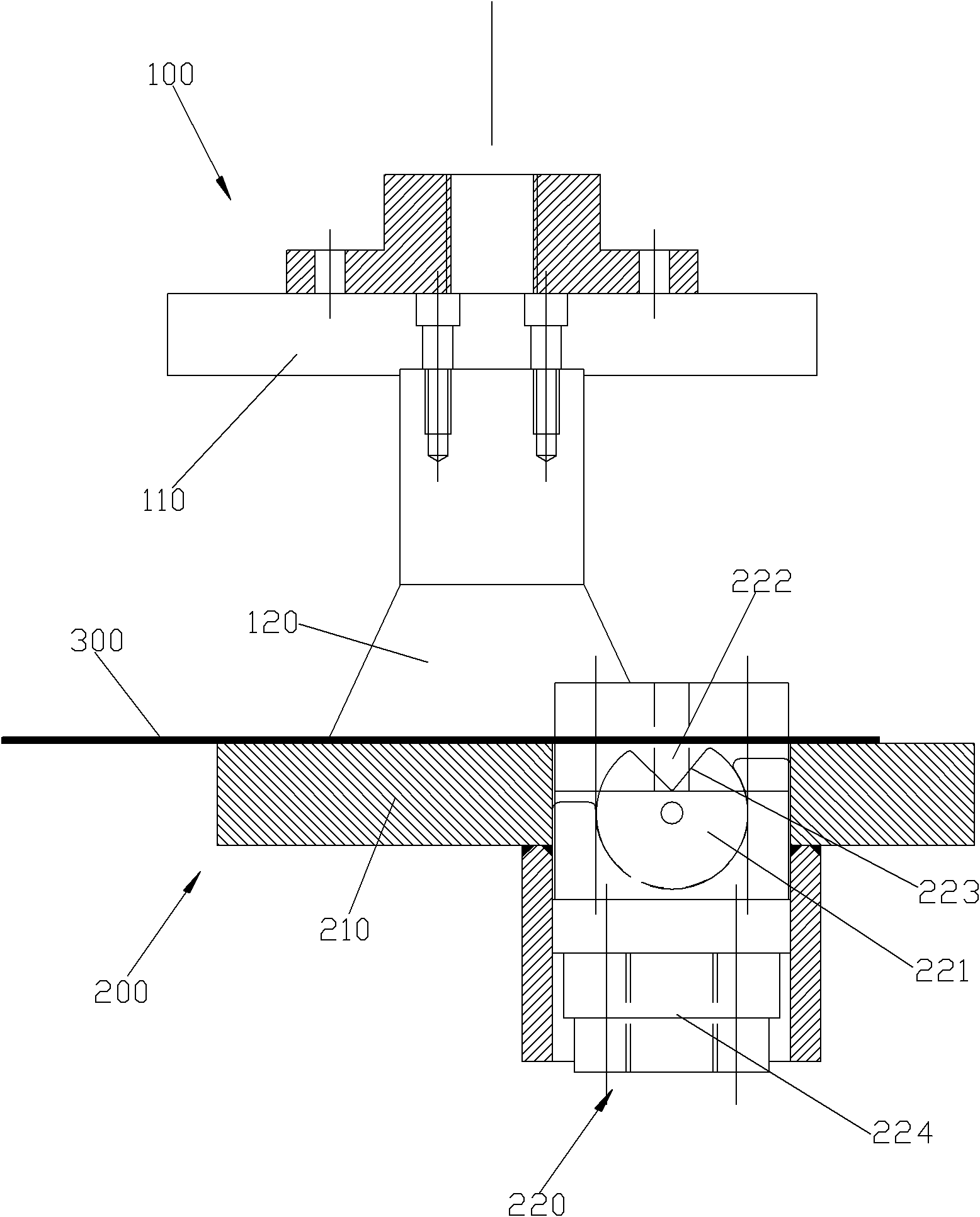

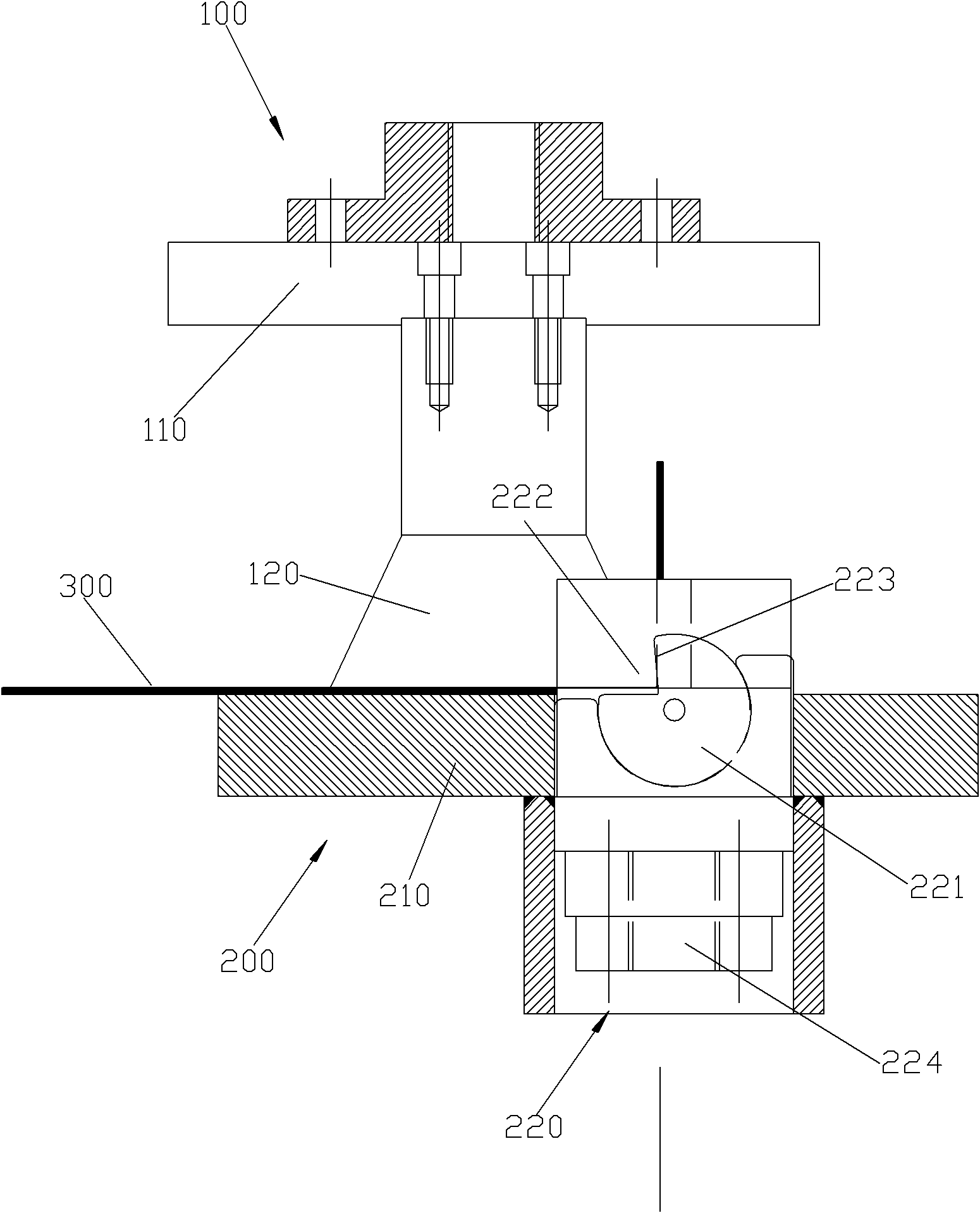

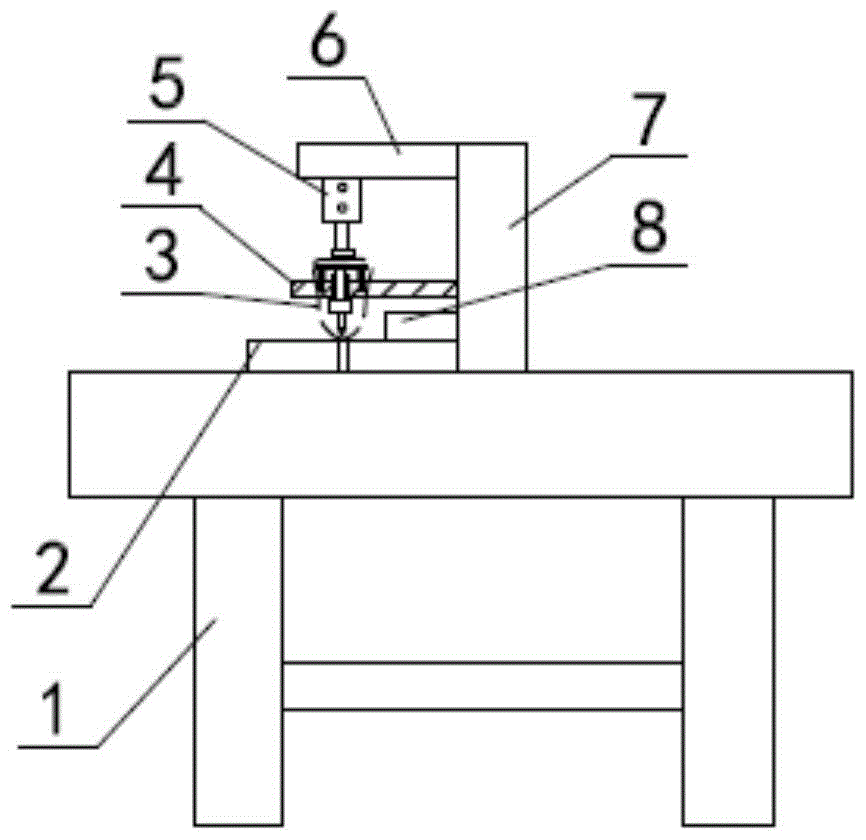

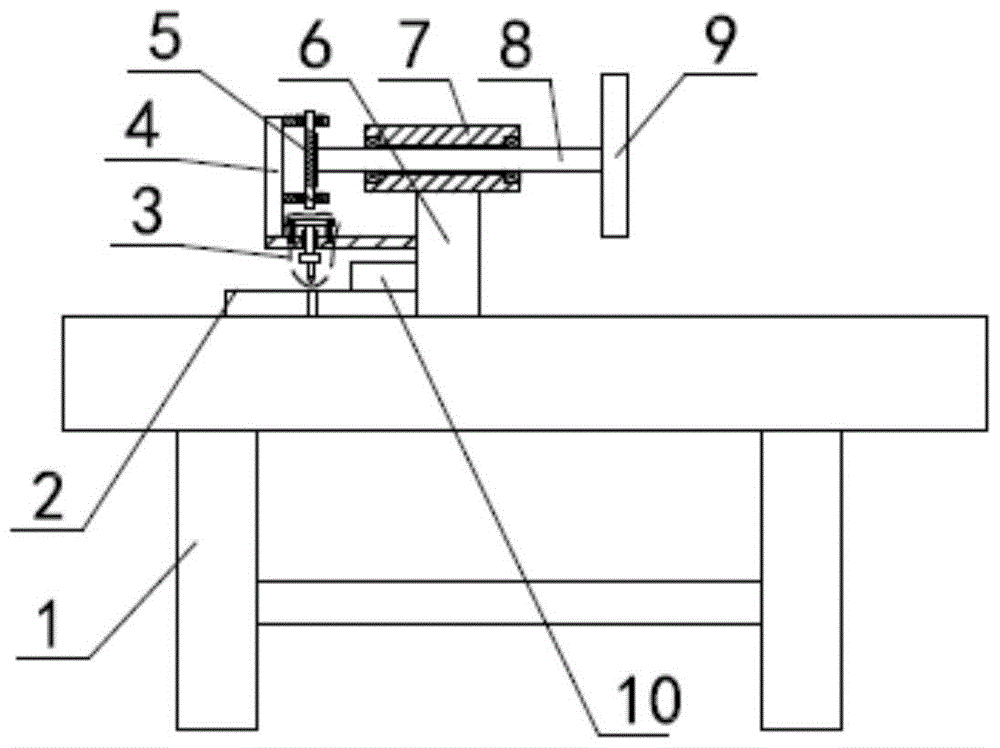

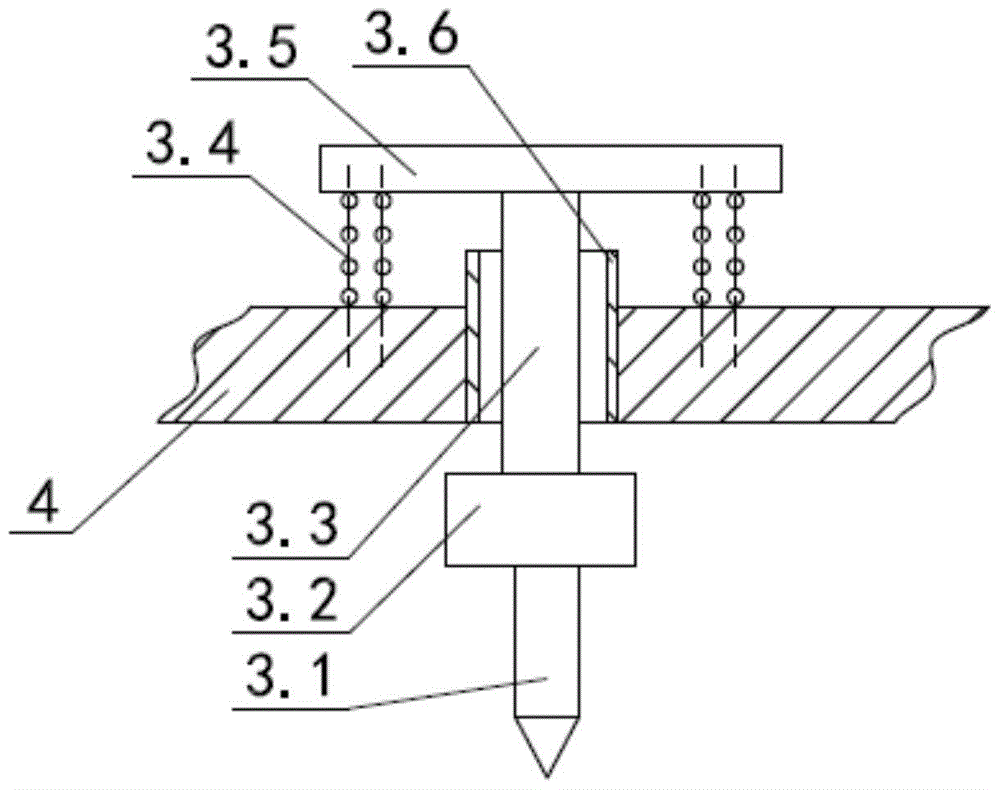

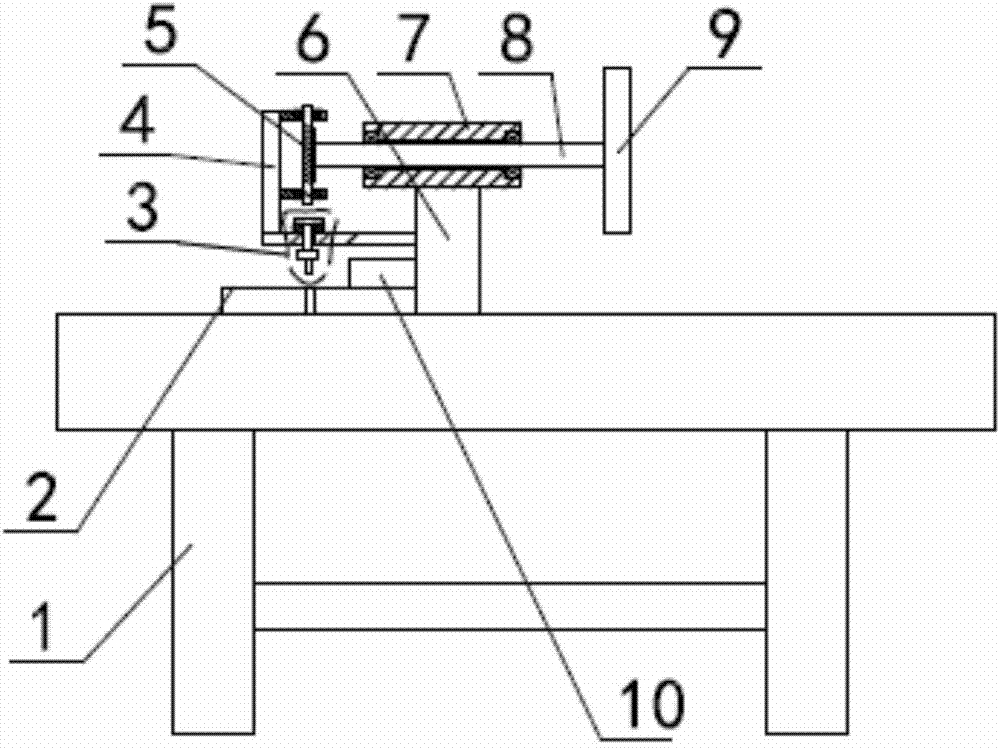

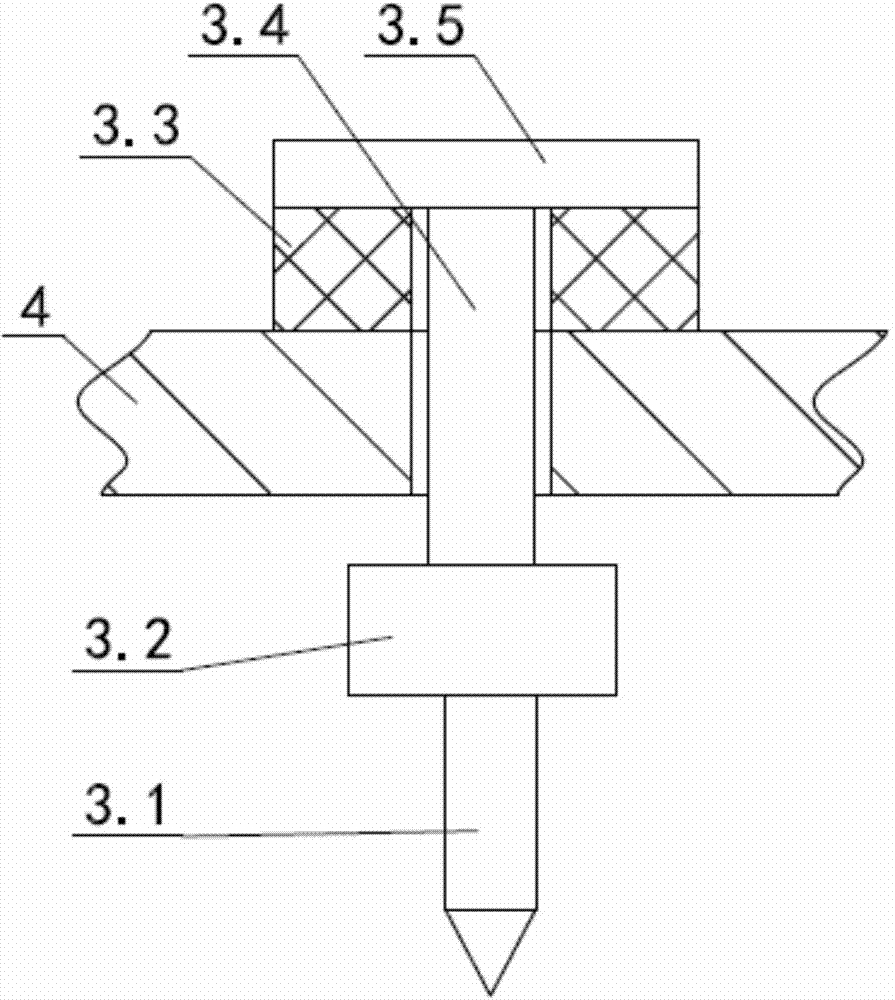

Limiting and edge folding mechanism for battery shell

InactiveCN106807815ASimple structureEasy to operateAssembling battery machinesMetal-working feeding devicesEngineeringPower transmission

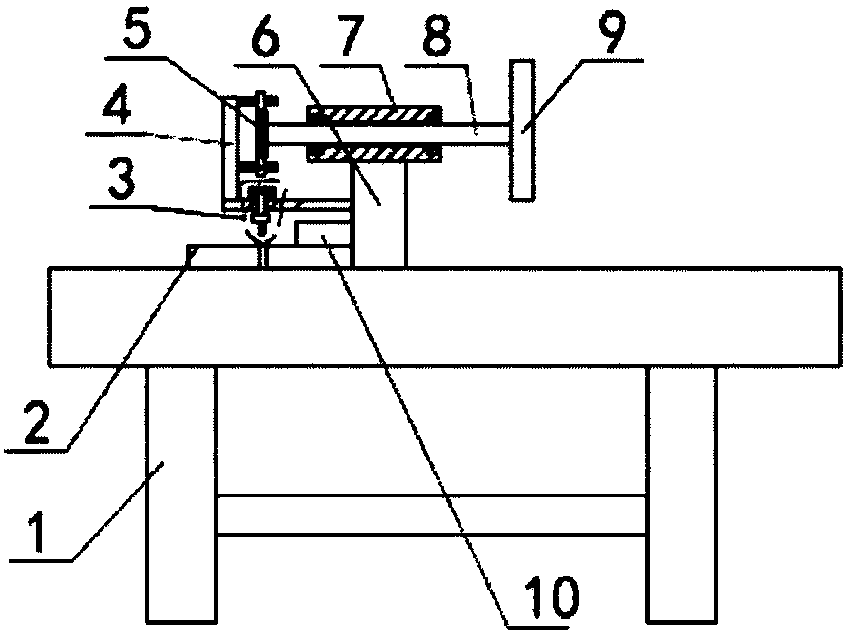

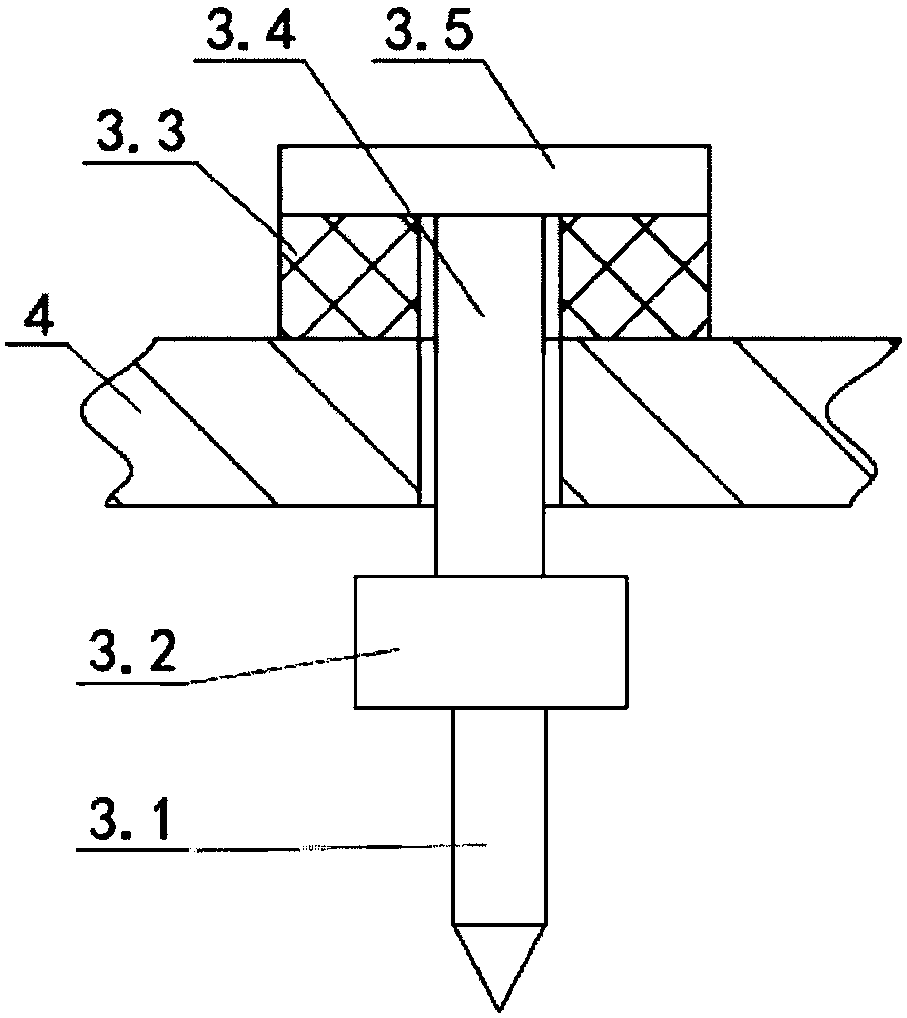

The invention relates to a limiting and edge folding mechanism for a battery shell, and belongs to the technical field of edge folding of the battery shells. The limiting and edge folding mechanism for the battery shell comprises a worktable on which a bottom die is mounted, wherein a mounting column on which a sleeve is mounted is fixed to the worktable section at the right side of the bottom die; a rotating shaft is horizontally mounted through the sleeve, and a handle plate is mounted at the right end of the rotating shaft; an edge folding returning mechanism for folding an edge is arranged right above the bottom die, and the edge folding returning mechanism comprises a mounting bracket, an edge folding cutter, and a transmission rod which can move up and down; the edge folding cutter is mounted at the lower end of a transmission rod through a cutter seat, and a returning plate is fixed at the upper end of the transmission rod; springs are mounted between the returning plate sections at the left side and the right side of the transmission rod and the mounting bracket; a worm and gear mechanism for power transmission is arranged between the transmission rod and the rotating shaft; a limiting block is fixed to the bottom die section at the right side of the edge folding cutter through a bolt. The limiting and edge folding mechanism for the battery shell is convenient to operate; the use cost and the repair cost can be effectively controlled while the production efficiency is ensured.

Owner:HEFEI LONGTUTEM INFORMATION TECH CO LTD

Blank pressing device with automatic adjusting function for processing pillow textile fabric

PendingCN114855405AImprove teleportation effectGood precisionFabric breaking/softeningTextile selvedgesFiberElectric machinery

The invention discloses an edge pressing device with an automatic adjusting function for pillow textile fabric processing, which comprises a support plate, conveying rollers are movably mounted at two ends of the support plate, a motor is fixedly mounted at one end of each conveying roller, a conveying belt movably sleeves the outer side of each conveying roller, and two telescopic rods are fixedly mounted at the top of the support plate. Supporting rollers are movably installed on the opposite sides of the top ends of the two telescopic rods. Through the arranged conveying belt, burrs on the two sides of the textile fabric are extruded and cut by a cutting ring and a cutting disc, then the burrs on the two sides of the textile fabric are cut off, airflow is sucked into the cut-off burrs through a first air pump under the action of a suction pipe, and the cut-off burrs enter a box body through flow guiding of an output pipe; and air flow is exhausted from the other side under limiting air flow in the box body, and burr fibers wrapped by the air flow are limited on the metal net plates on the inner sides of the clamping block sets, so that the burr fibers are conveniently collected, the cut burr fibers are conveniently recycled, and the overall using effect and environmental friendliness are conveniently improved.

Owner:江苏千瑞纺织科技有限公司

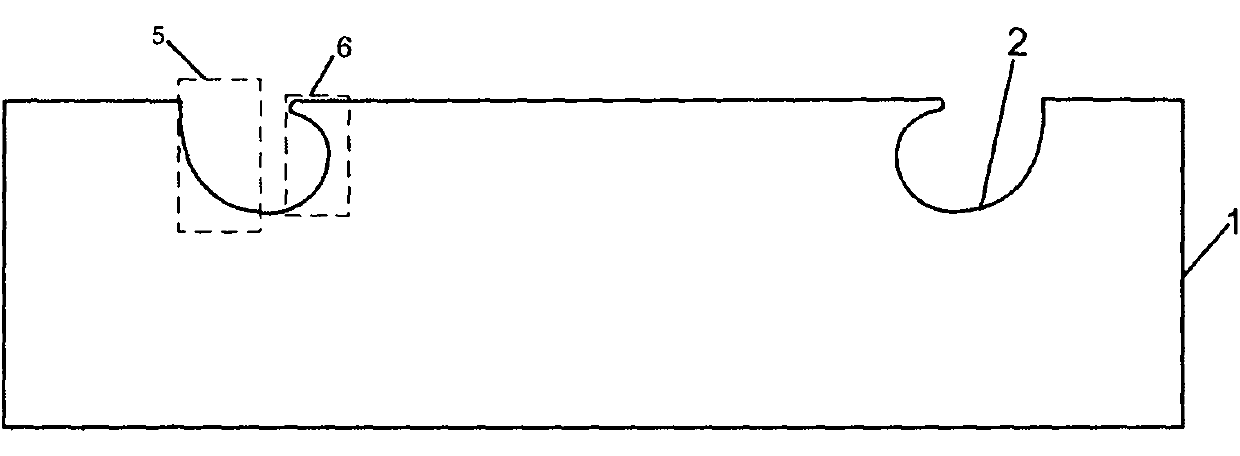

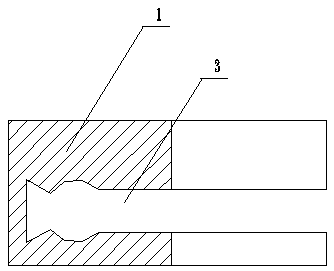

Improved cylinder curling machine

The invention discloses an improved cylinder curling machine which comprises an upper mould and a lower mould, wherein an annular groove is formed in the upper surface of the lower mould. The improved cylinder curling machine is characterized in that the annular groove comprises a half U-shaped groove I and a U-shaped groove II; the half U-shaped groove I is upwards opened, and the U-shaped groove II is horizontally opened; the bottom of the half U-shaped groove I is connected with the lower side wall of the U-shaped groove II in a smooth transition way. According to the improved cylinder curling machine, PVC (Polyvinyl Chloride) of a pipe socket can be easily curled when bearing very small upper mould pressure through a unique rabbet design; the time and labor conservation and the low scrap rate are achieved; a rabbet is in a U-shaped groove structure which is horizontally opened when ascending from a bottom, and the mouth part of a PVC product can be overturned and then attached to the inner wall of the PVC product when the bottom of the rabbet is very large, so that the curling is successful.

Owner:ANQING LIXIANG IND & TRADE

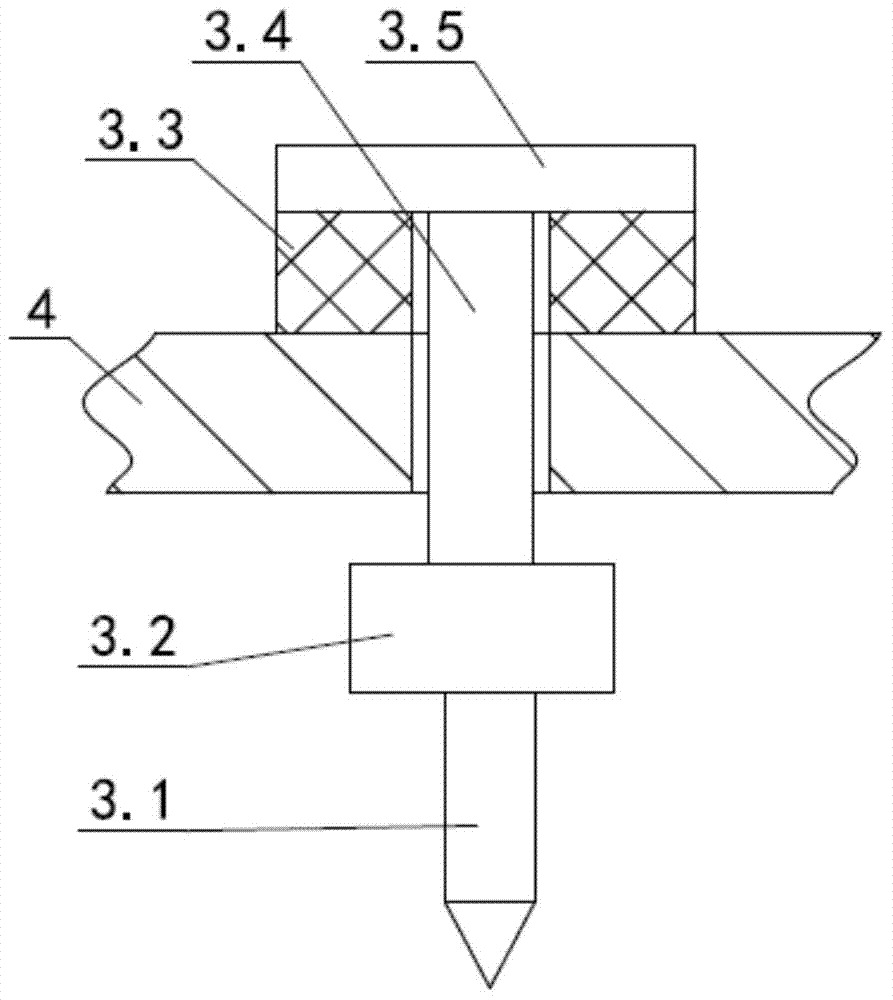

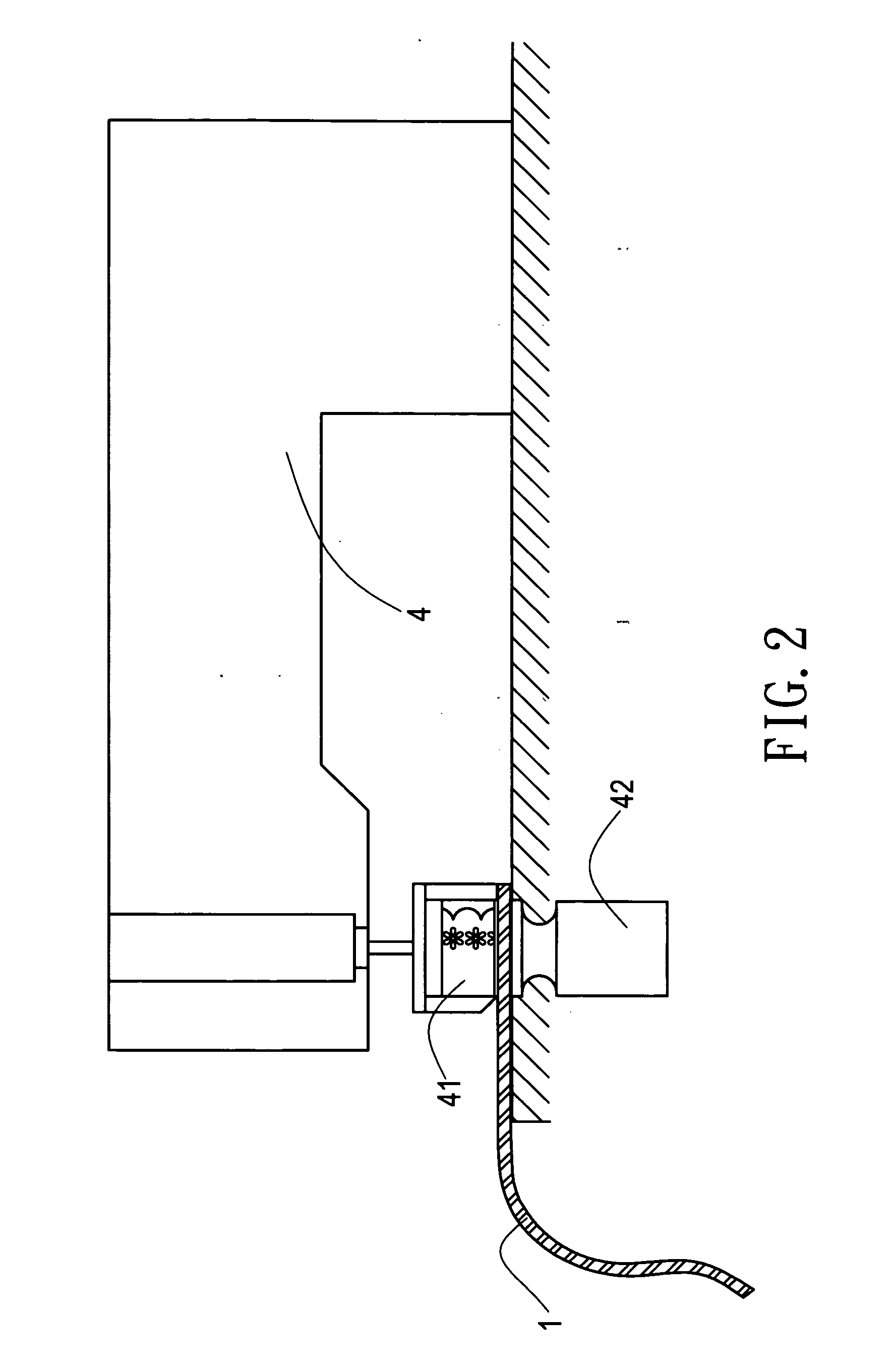

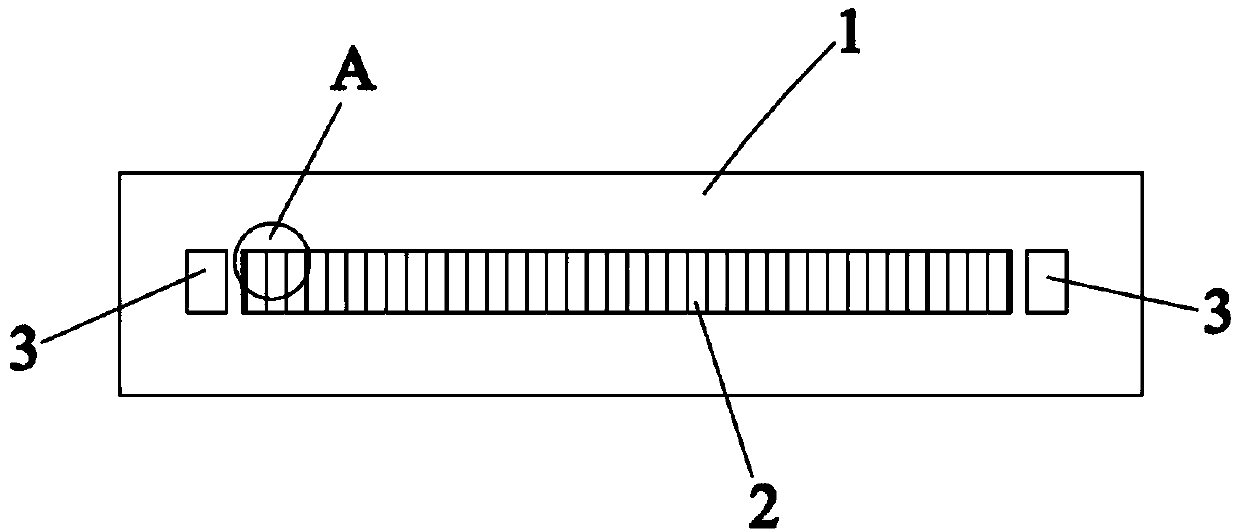

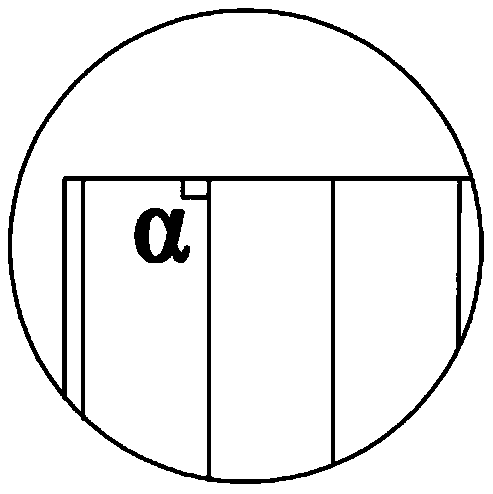

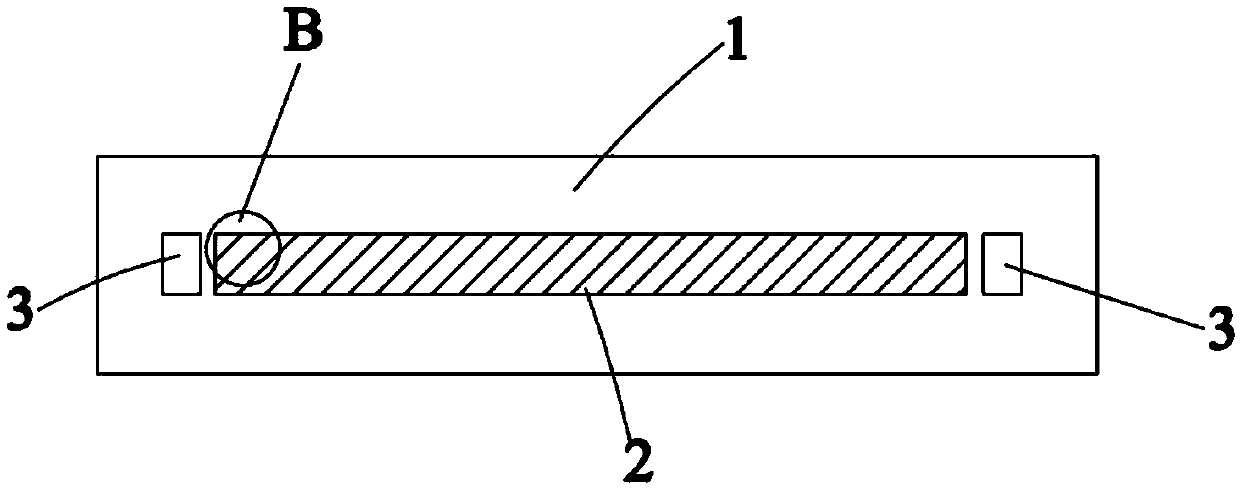

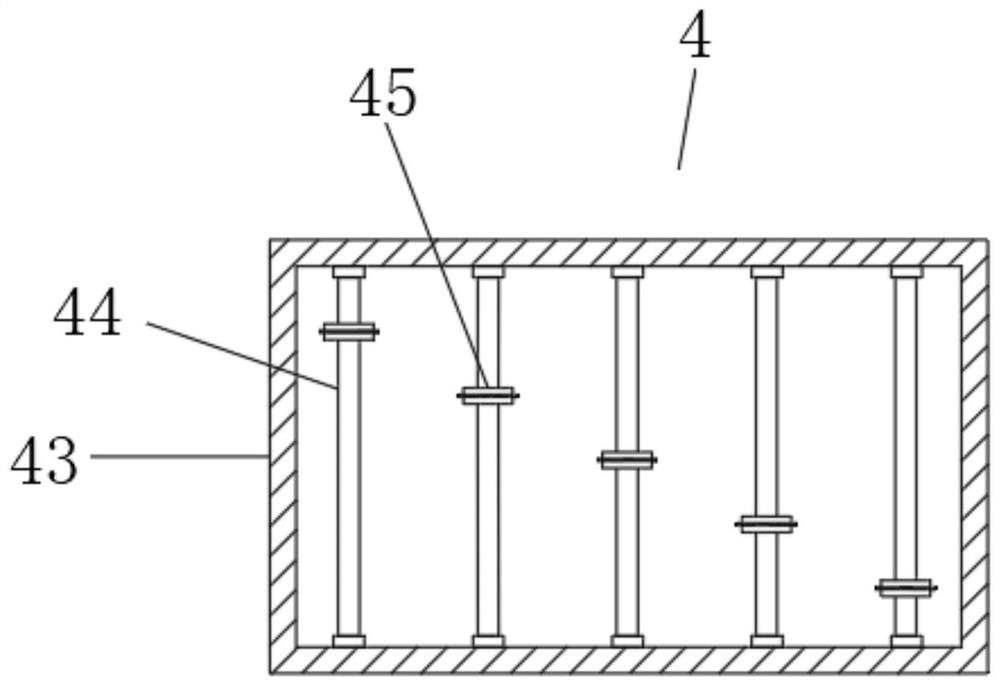

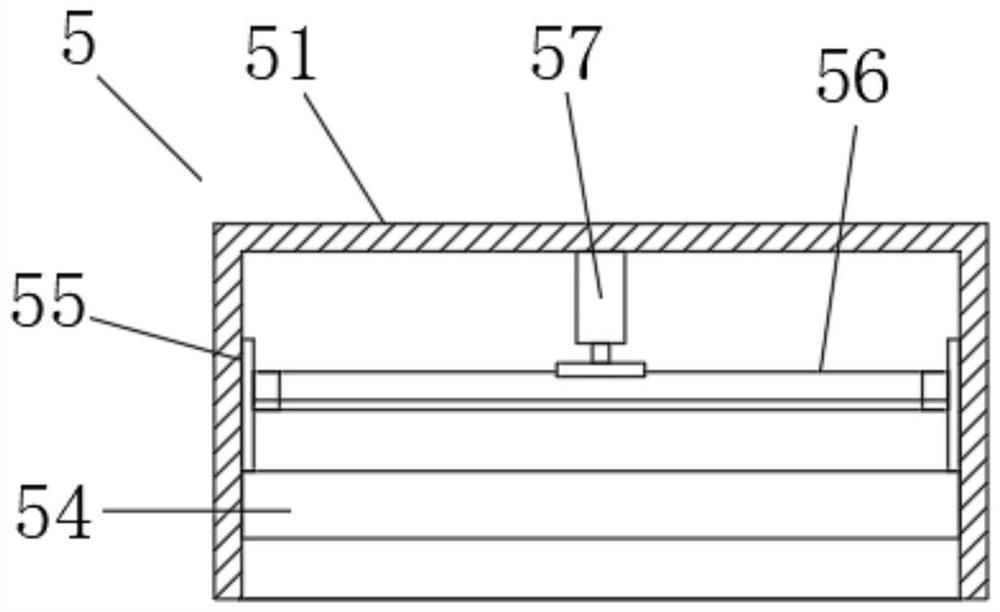

Fabric Hemming Mechanism

The invention relates to a fabric folding mechanism which can be used for flanging one edge, two edges and a plurality of edges. The fabric folding mechanism comprises a platform, the platform is provided with a side air draught through hole, the platform is provided with a cover plate which can cover the side air draught through hole, the lower surface of the cover plate is provided with a groove, the opening of the groove faces to and covers the side air draught through hole, one edge of the cover plate is close to the center of the platform, another edge being symmetric with the edge is relatively far away from the center of the platform, one end of the groove extends to the edge of the cover plate close to the center of the platform, a side air draught chamber being in communication with the side air draught through hole is disposed under the platform, and the side air draught chamber is connected to an air draught device. The cover plate having the groove in the lower surface is added to the platform having the hole, lower air draught is changed into side air draught, edges of fabrics can be folded, the fabrics close to the groove of the edge of the cover plate can be vertical to form a flanging, the flanging with width being less than 3mm of fabrics can be normally machined, positioning is easy, and the fabrics hardly rebound and deform.

Owner:中山市阿米达机电设备有限公司

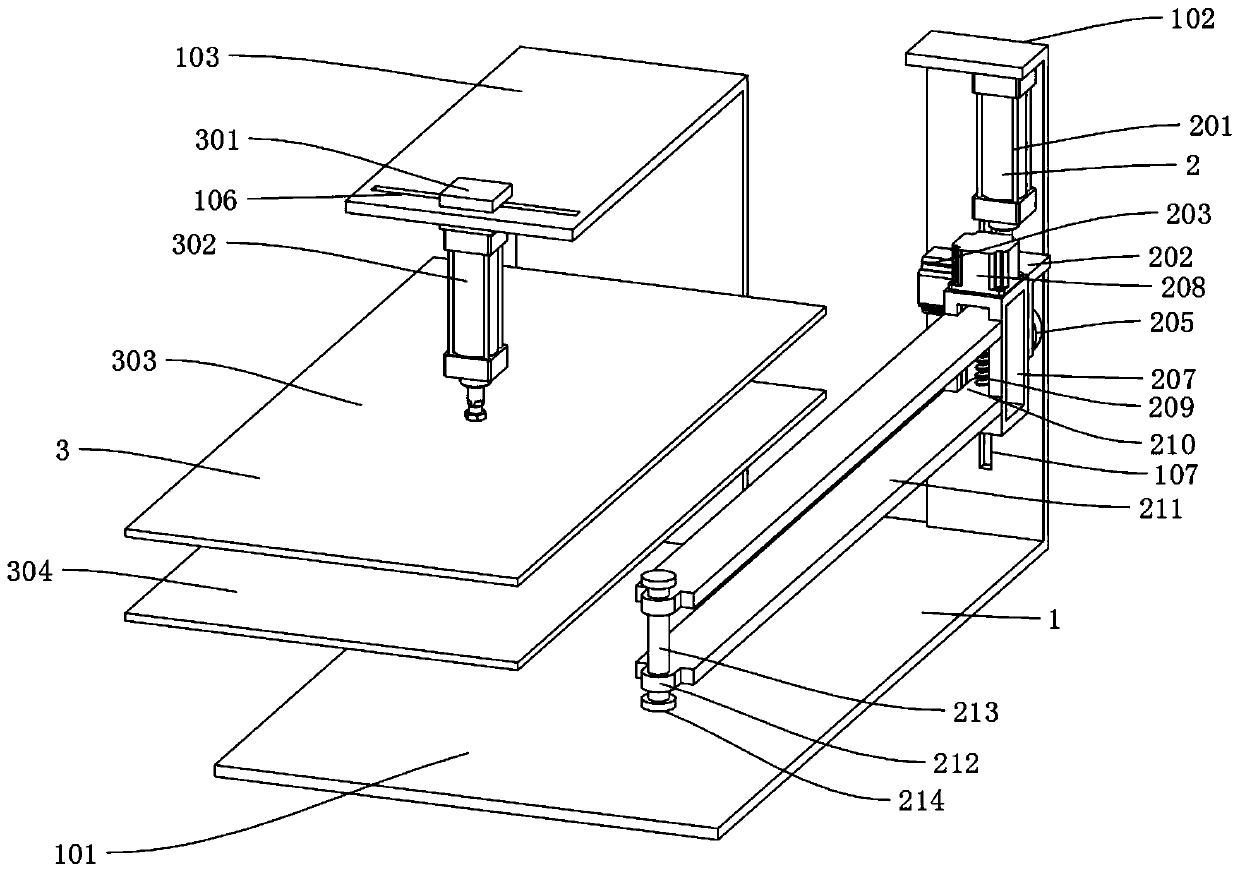

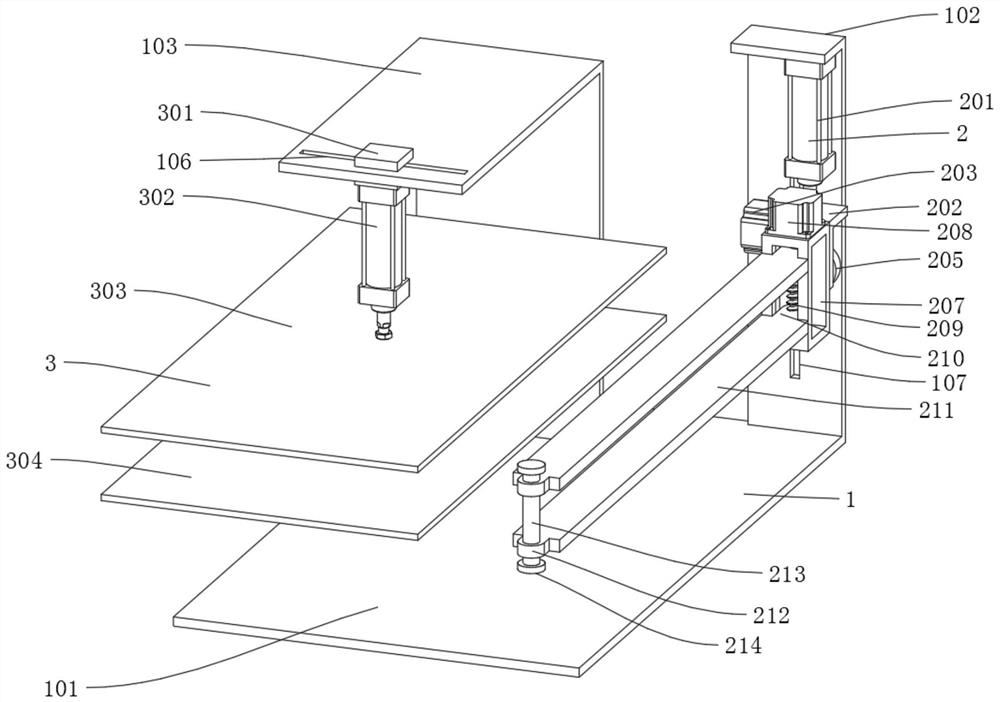

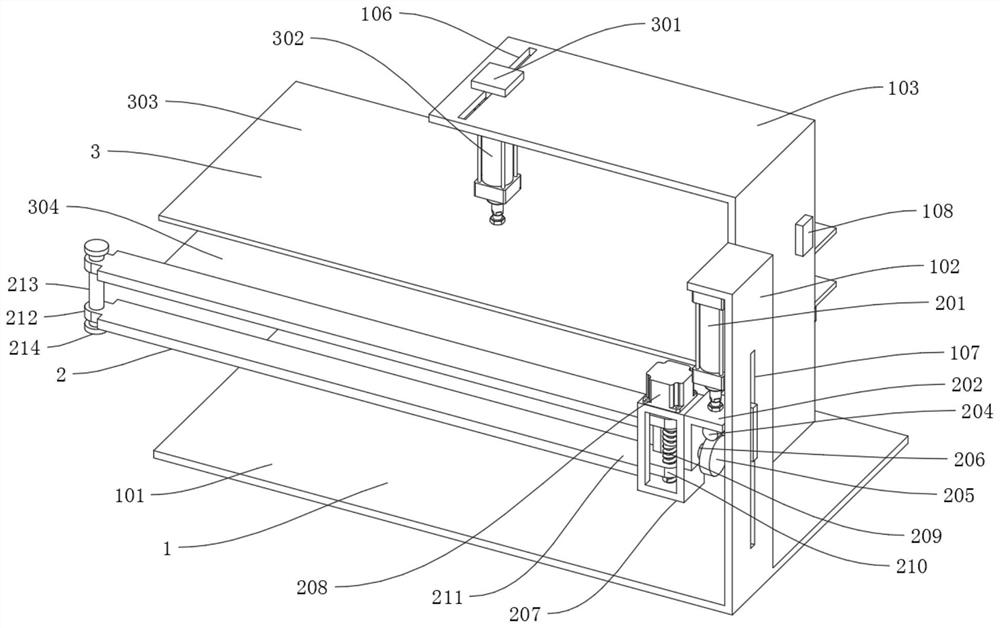

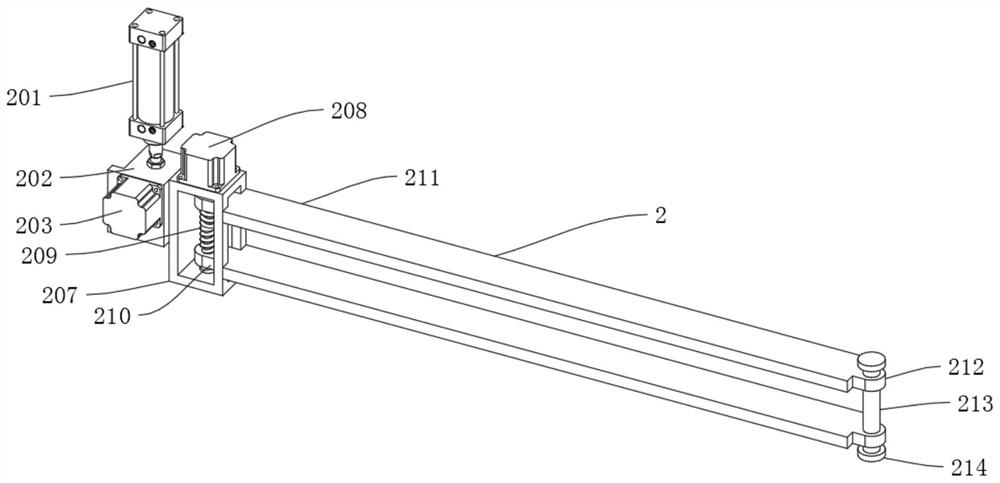

Easy-to-use folding tool for aluminum bracket of smart carbon skateboard and method of use thereof

ActiveCN111185532BEasy HemmingReduce labor intensityPower current collectorsElectric machineFixed frame

The invention discloses an easy-to-use intelligent carbon skateboard aluminum bracket folding tool, which includes a bottom plate, a first electric push rod is arranged at one end of the top surface of the bottom plate, a support plate is arranged above the top surface of one end of the bottom plate, and support rollers are distributed on the top surface of the bottom plate. Both ends of each supporting roller are rotatably connected with bearing plates, both sides of the middle part of the top surface of the bottom plate are rotatably connected with rotating shafts, and the middle part of the top surface of the bottom plate is provided with a rotating motor, and each rotating shaft is connected with the rotating motor through transmission. The top is fixedly connected to the moving plate, each moving plate is provided with a support tray, the other end of the bottom plate is provided with a mounting plate on the top side, the middle part of the bottom surface of the mounting plate is fixed with a second electric push rod, and the movable end of the second electric push rod The connecting plate is fixedly connected, the bottom surfaces of both ends of the connecting plate are fixedly connected with fixed frames, and each fixed frame is rotatably connected with an extrusion roller. The invention has a simple structure, is convenient to use, and effectively improves the processing efficiency.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

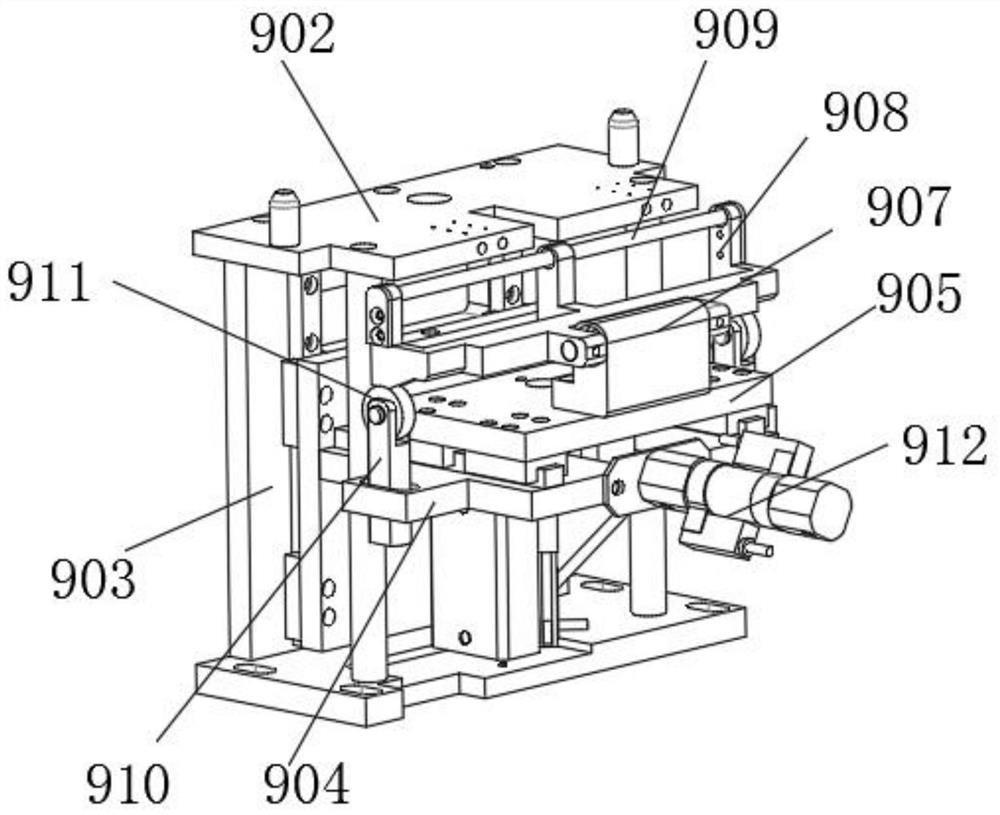

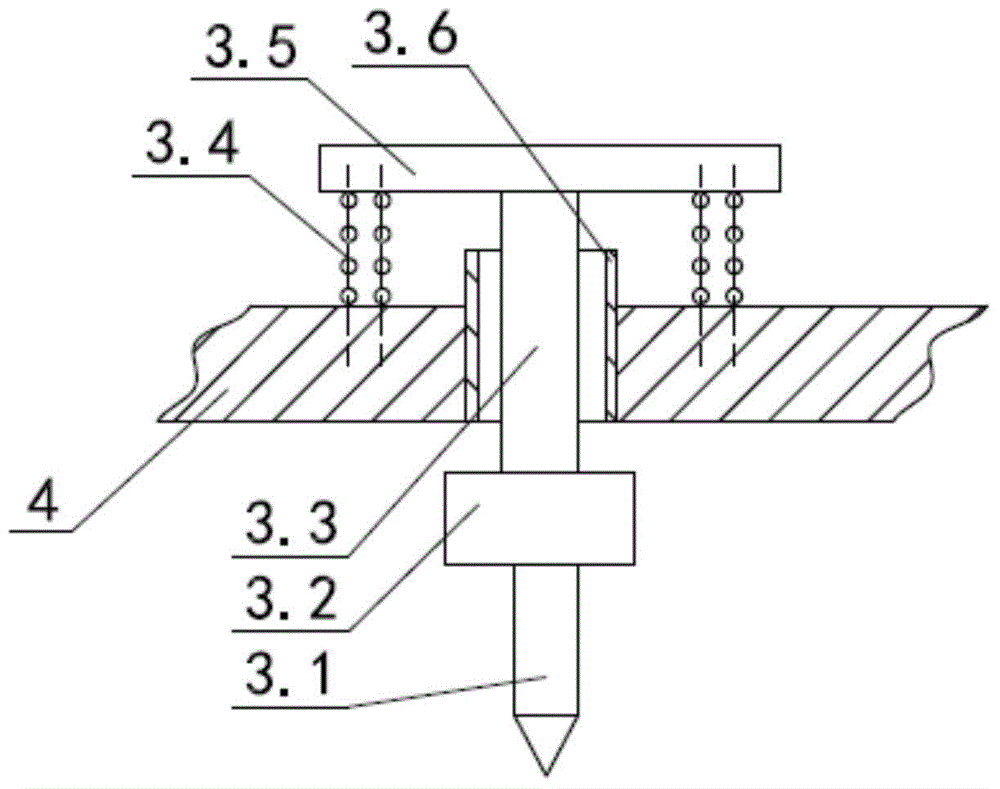

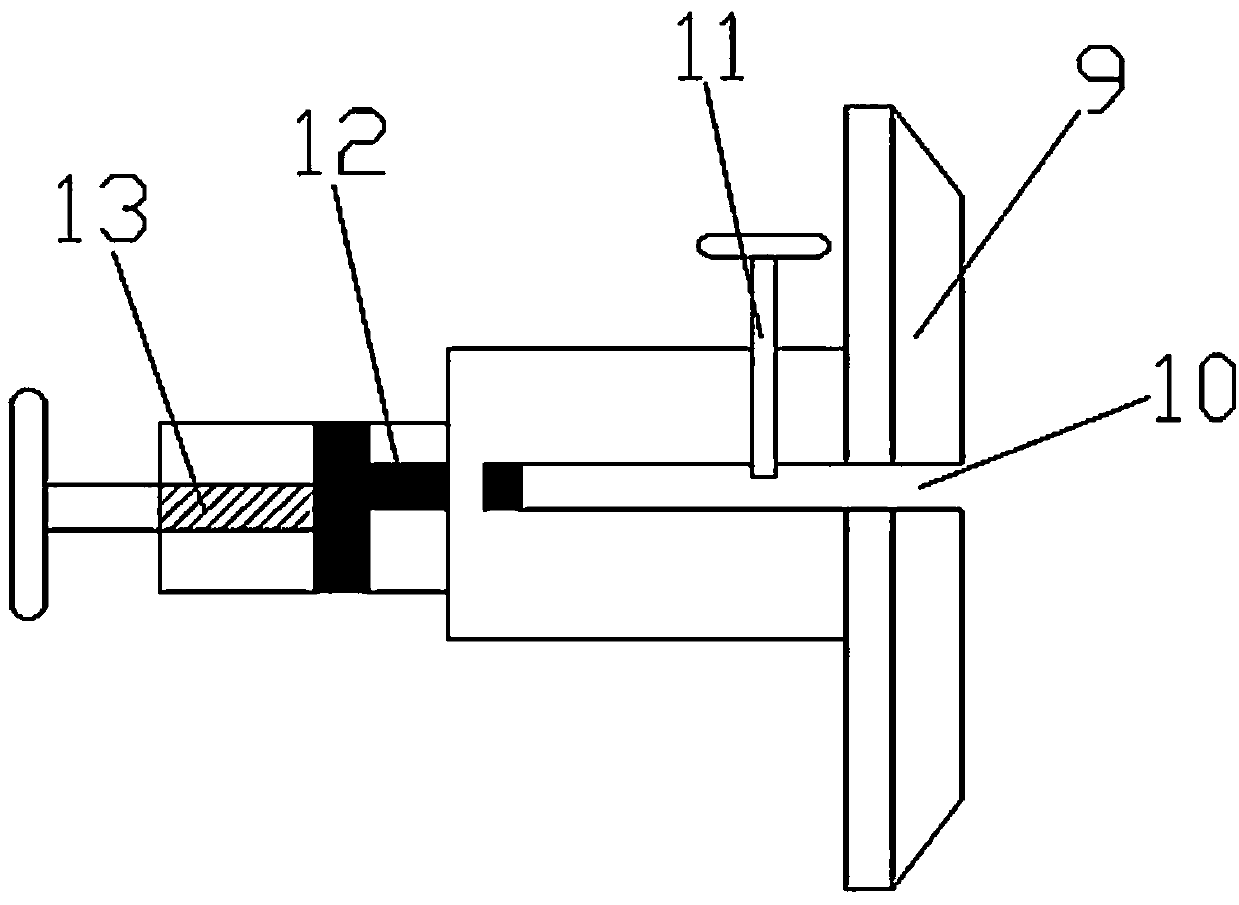

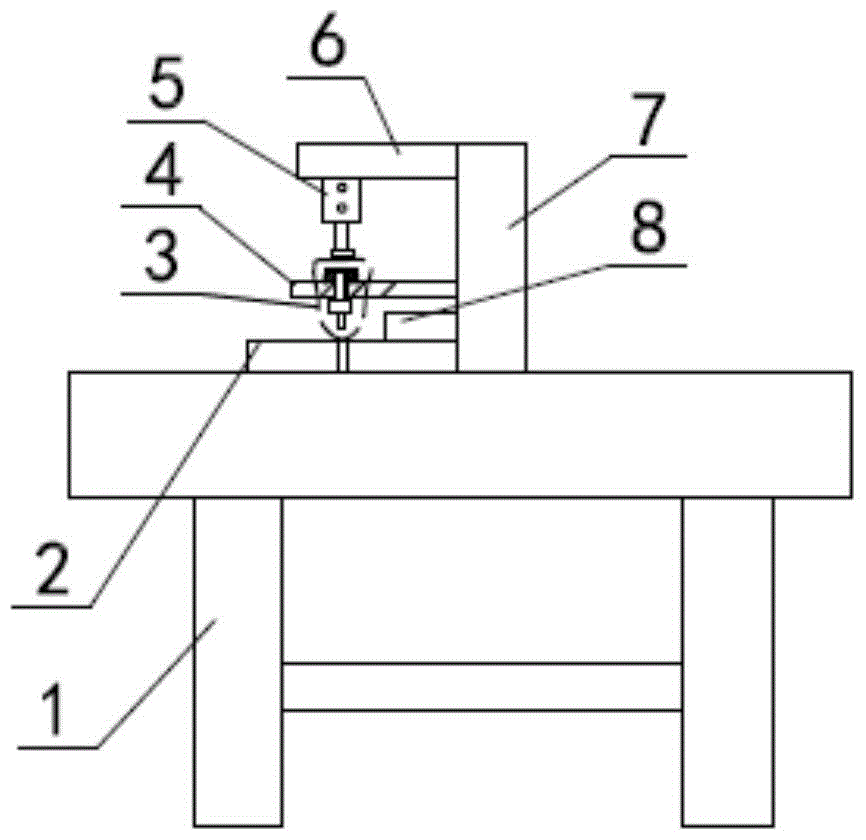

Cam type limit folding mechanism for battery case

InactiveCN104852079BEasy hemmingControl the cost of useFinal product manufactureSecondary cells manufactureEngineeringCam

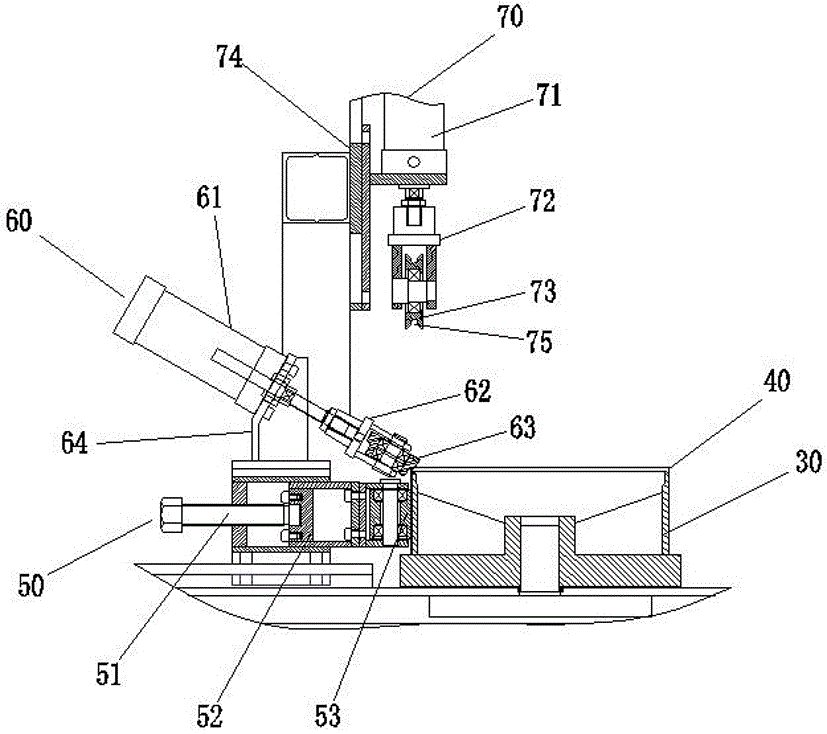

The invention relates to a cam-type limit folding mechanism for a battery case, which belongs to the technical field of battery case folding, and includes a workbench, on which a bottom mold is installed, and on the workbench on the right side of the bottom mold is fixed a mounting There is a casing installed on the installation column, and a rotating shaft is installed at the level of the casing, and a handle plate is installed at the right end of the rotating shaft. The mechanism includes a mounting bracket, a hemming knife and a transmission rod that moves up and down. The hemming knife is installed on the lower end of the transmission rod through the knife seat, and a reset plate is fixed on the upper end of the transmission rod. A spring is installed between them, a cam mechanism for power transmission is arranged between the transmission rod and the rotating shaft, and the limit block is fixed by bolts on the bottom mold on the right side of the hemming knife. The invention is convenient to operate, and effectively controls the use cost and the maintenance cost while ensuring the production efficiency.

Owner:黄建业

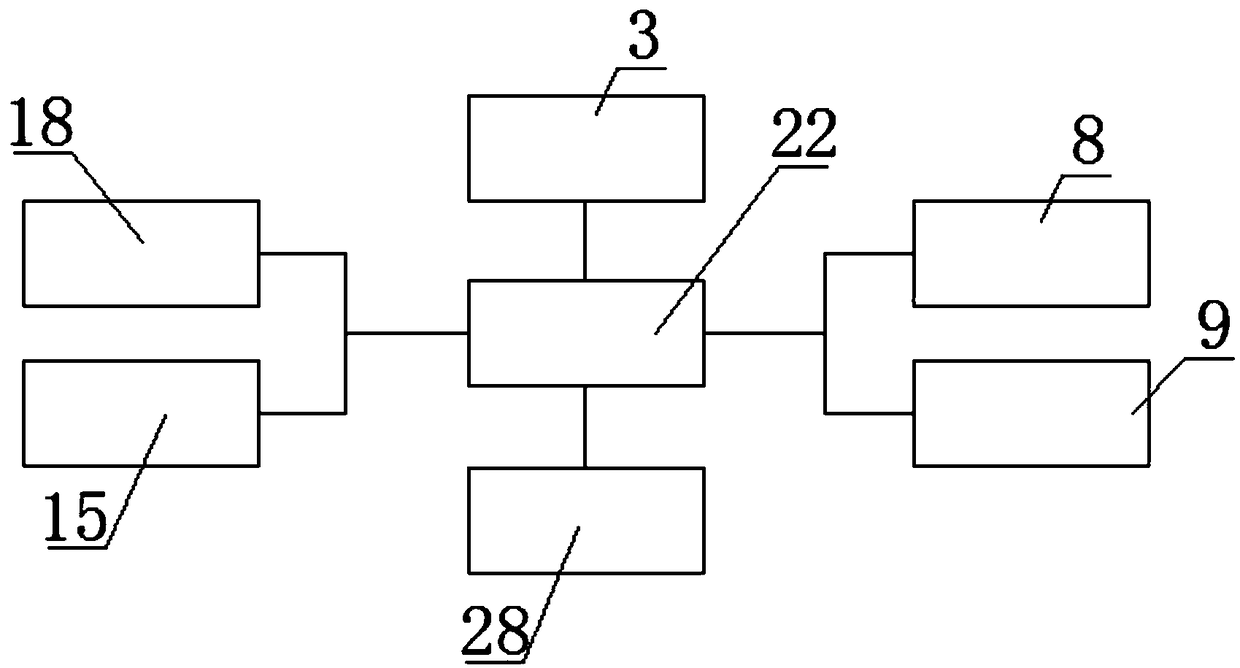

Flanging machine for power distribution cabinet manufacturing and using method thereof

ActiveCN110883156AEasy to set upEasy to useMetal-working feeding devicesPositioning devicesManufacturing engineeringControl switch

The invention discloses a flanging machine for power distribution cabinet manufacturing and a using method thereof. The flanging machine comprises a supporting mechanism, wherein the supporting mechanism comprises a bottom plate, a first supporting plate, a second supporting plate, a third supporting plate and a first sliding groove, the first supporting plate is welded to the upper end of the bottom plate, a third sliding groove is vertically formed in the first supporting plate, the second supporting plate is arranged on one side of the first supporting plate, a second sliding groove is horizontally formed in the top of the second supporting plate, a control switch is installed at the rear end of the second supporting plate, the third supporting plate is welded to the front end of the second supporting plate, the first sliding groove is formed in the third supporting plate, and a flanging mechanism used for flanging raw materials of a power distribution cabinet is arranged on the supporting mechanism. According to the flanging machine, the flanging mechanism is adopted, so that the flanging machine can adapt to the thicknesses of different raw materials, the flanging angle can beconveniently set, and therefore the use is more convenient; and a clamping mechanism is adopted, so that the raw materials can be clamped, the flanging mechanism can better flange the raw materials,the raw materials can be driven to move, and therefore the length of the flanging can be conveniently changed.

Owner:广州市顺承电气设备有限公司

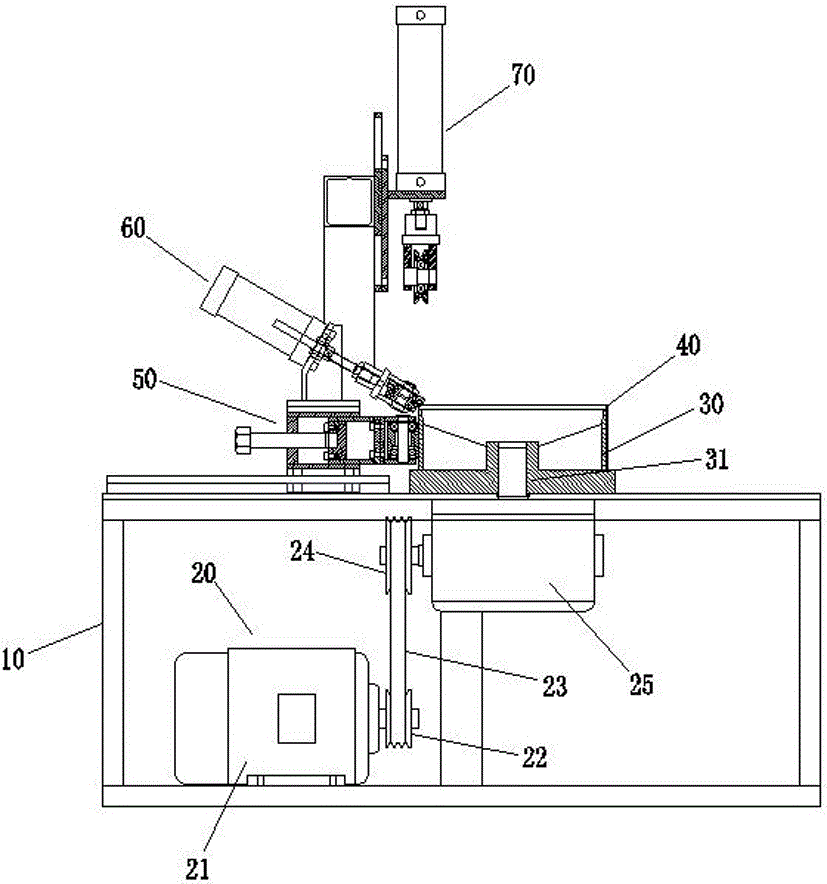

A device for cutting, folding and ironing soft packaging lithium batteries

ActiveCN111293238BReduce labor intensityAvoid complicated stepsFinal product manufactureSmall-sized cells cases/jacketsStructural engineeringBattery cell

Owner:安徽风驰新能源科技股份有限公司

Cam type limit folding mechanism for battery case

InactiveCN104868150BEasy hemmingControl the cost of useMetal-working feeding devicesFinal product manufactureEngineeringCam

The invention relates to a cam-type limit folding mechanism for battery casings, belonging to the technical field of battery casing hemming. There is an installation column, a casing is installed on the installation column, a rotating shaft is installed horizontally in the casing, a handle plate is installed on the right end of the rotating shaft, a mounting bracket is fixed on the installation column, and a corresponding bottom mold is provided directly above it for The hemming reset mechanism of hemming, the hemming reset mechanism includes a hemming knife and a transmission rod that moves up and down. A rubber block is installed between the reset plate on the side and the installation bracket, a cam mechanism for power transmission is arranged between the transmission rod and the rotating shaft, and the limit block is fixed by bolts on the bottom mold on the right side of the folding knife. The present invention effectively controls the use cost and the maintenance cost while ensuring the production efficiency.

Owner:艾炜杰

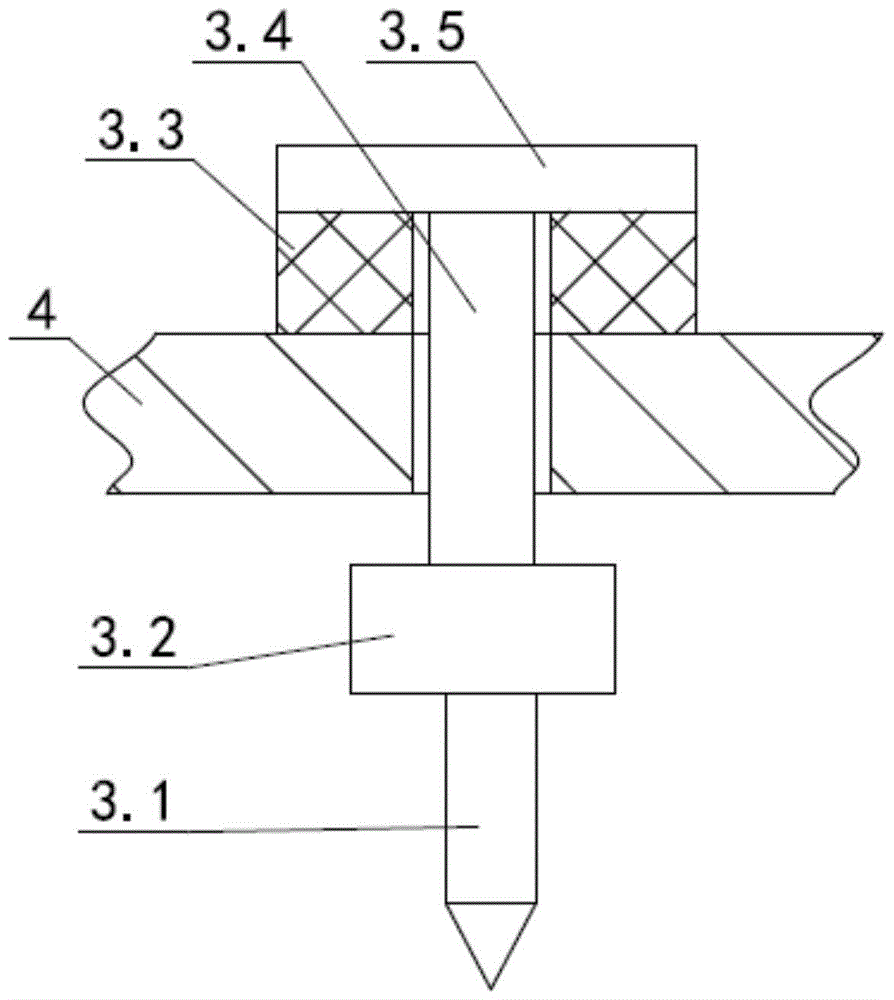

Cylinder type limiting flanging mechanism for battery shell

The invention relates to a cylinder type limiting flanging mechanism for a battery shell, and belongs to the technical field of battery shell flanging. The cylinder type limiting flanging mechanism comprises a workbench, wherein a bottom die for flanging is arranged on the workbench; a mounting post is vertically fixed on the workbench on the right side of the bottom die; a mounting plate is horizontally fixed on the left side wall of the mounting post; a mounting bracket is fixed on the mounting post; a flanging reset mechanism for flanging is arranged over the bottom die corresponding to the bottom die; the flanging reset mechanism comprises a flanging knife and a transmission rod moving up and down; a cylinder for driving the transmission rod to move downwards is vertically arranged over the transmission rod; and a limiting block is fixed on the bottom die on the right side of the flanging knife through a bolt. The cylinder type limiting flanging mechanism is convenient to operate. The use cost and maintenance cost are controlled effectively while the production efficiency is ensured.

Owner:徐州永固电力设备有限公司

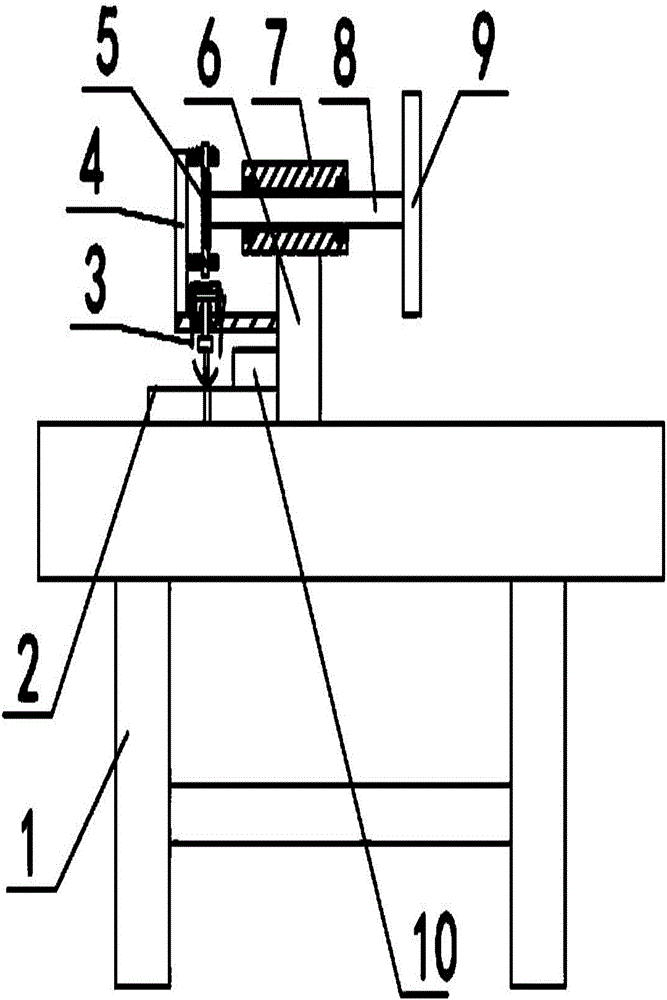

Battery case limiting and flanging mechanism

InactiveCN104868151ASimple structureEasy to operateAssembling battery machinesMetal-working feeding devicesAgricultural engineeringKnife holder

The invention relates to a battery case limiting and flanging mechanism, and belongs to the technical field of battery case flanging. The battery case limiting and flanging mechanism comprises a workbench, wherein a bottom die is mounted on the workbench; a mounting column is fixedly arranged on the workbench on the right side of the bottom die; a bushing is mounted on the mounting column; a rotating shaft horizontally penetrates through the bushing; a wheel handle is mounted at the right end of the rotating shaft; a flanging reset mechanism used for flanging is correspondingly arranged right above the bottom die; the flanging reset mechanism comprises a mounting bracket, a flanging knife and a transmission rod which moves up and down; the flanging knife is mounted at the lower end of the transmission rod through a knife holder; a reset plate is fixedly arranged at the upper end of the transmission rod; springs are mounted between the reset plate and the mounting bracket and on the left and right sides of the transmission rod; a worm and gear mechanism used for power transmission is arranged between the transmission rod and the rotating shaft; and a limiting block is fixedly arranged on the bottom die on the right side of the flanging knife through a bolt. The battery case limiting and flanging mechanism is convenient to operate, and has the advantage of effectively controlling the using cost and the maintenance cost while ensuring the production efficiency.

Owner:白翠贞

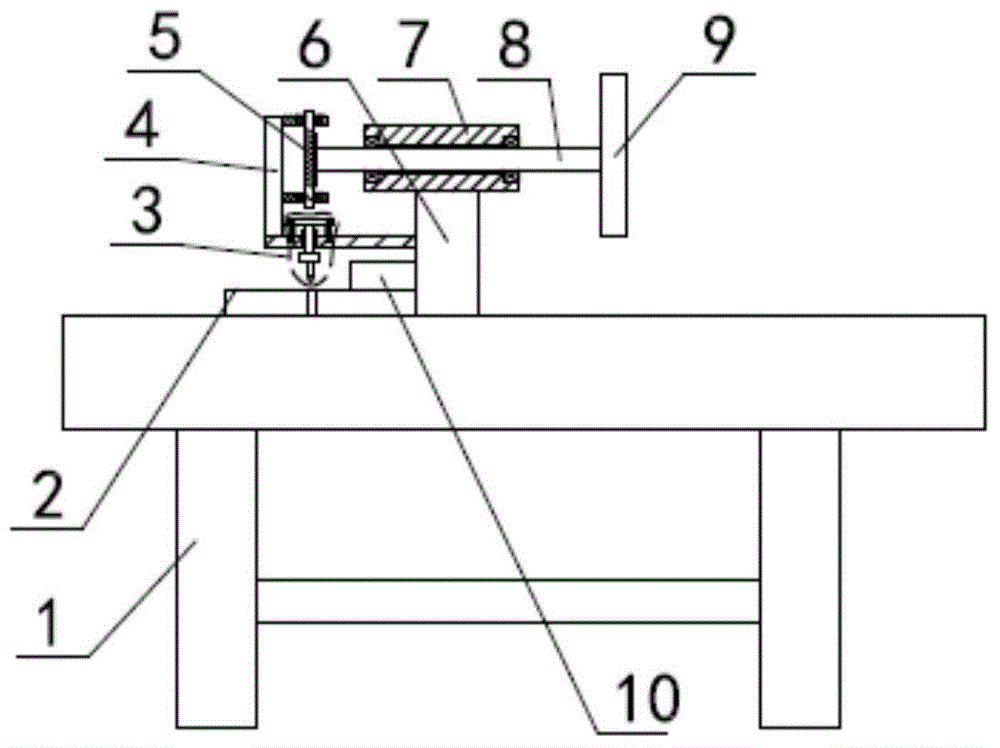

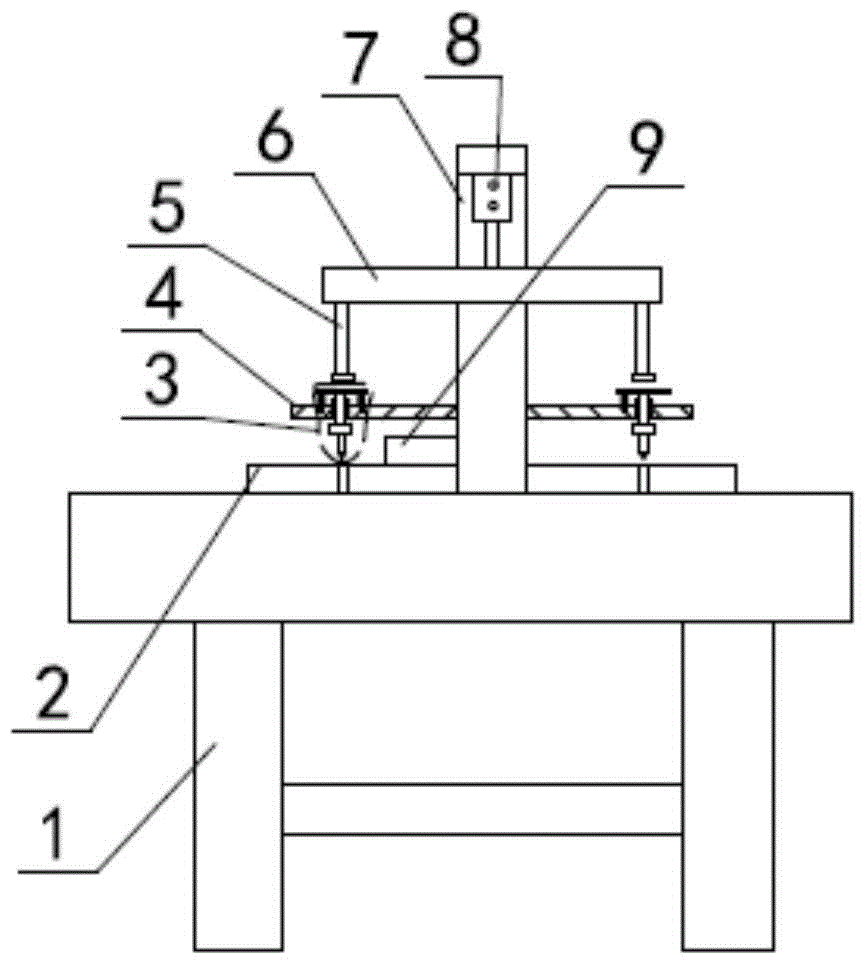

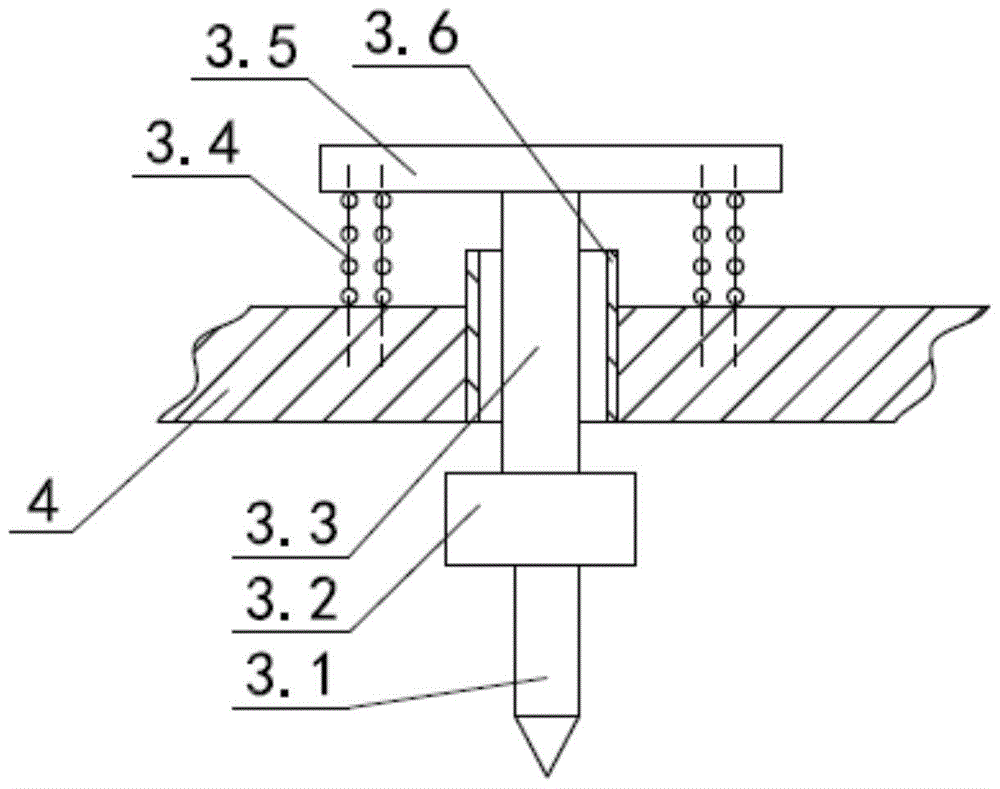

Cylinder type limit double folding mechanism for battery case

ActiveCN104852082BSimple structureEasy to operateFinal product manufacturePrimary cellsEngineeringCylinder block

The invention relates to a cylinder-type limiting double-folding mechanism for a battery case, which belongs to the technical field of battery case folding. Corresponding to each bottom mold is provided with a hemming reset mechanism directly above it for hemming. The hemming resetting mechanism includes a mounting bracket fixed on the mounting column, a hemming knife and a transmission rod that moves up and down. The upper part is vertically provided with a push rod for the downward movement of the transmission rod. The two push rods are fixed on the top plate. The top plate and the mounting column are connected by sliding up and down. Fixed on the installation column, the piston rod of the cylinder is connected with the top plate, and the limit block is fixed by bolts on the bottom mold between the hemming knife and the installation column. The invention is convenient to operate, and effectively controls the use cost and the maintenance cost while ensuring the production efficiency.

Owner:NANTONG NAIWEITE POWER SUPPLY CO LTD

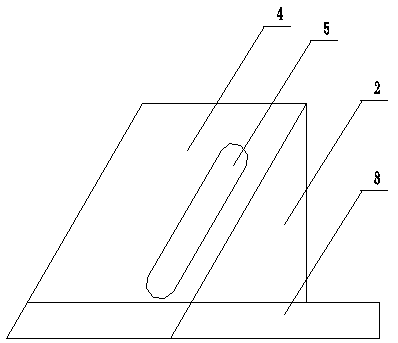

Folding machine for manufacturing power distribution cabinet and method of use thereof

ActiveCN110883156BEasy to set upEasy to useMetal-working feeding devicesPositioning devicesStructural engineeringControl switch

The invention discloses an edge folding machine used for the manufacture of power distribution cabinets and a method of using the same. The support plate 1 is welded, the support plate 1 is vertically formed with a chute 3, the support plate 1 is provided with the support plate 2 on one side, and the top of the support plate 2 is horizontally formed with a chute. Second, a control switch is installed at the rear end of the second support plate, the support plate three is welded on the front end of the support plate two, and the chute one is formed on the support plate three, and the support mechanism is provided with a The hemming mechanism for folding the raw materials of the power distribution cabinet. The invention adopts a folding mechanism, so that it can adapt to the thickness of different raw materials and can easily set the folding angle, so it is more convenient to use, and adopts a clamping mechanism, so that the raw materials can be clamped so that the folding mechanism can be better folded, and It can drive the displacement of the raw material, so it is convenient to change the length of the folded edge.

Owner:广州市顺承电气设备有限公司

Rotating shaft type turnover flanging method and flanging machine

Owner:XIAMEN ZHENGLIMING METALLURGICAL MACHINERY

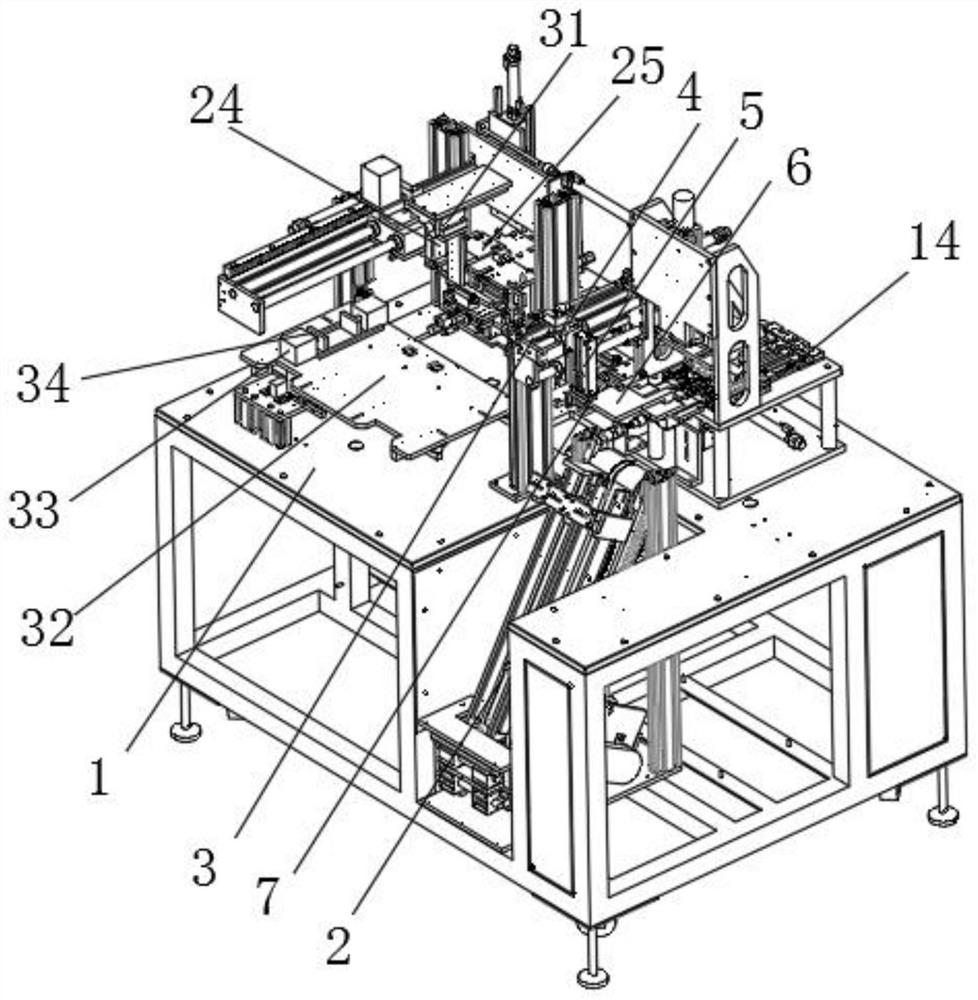

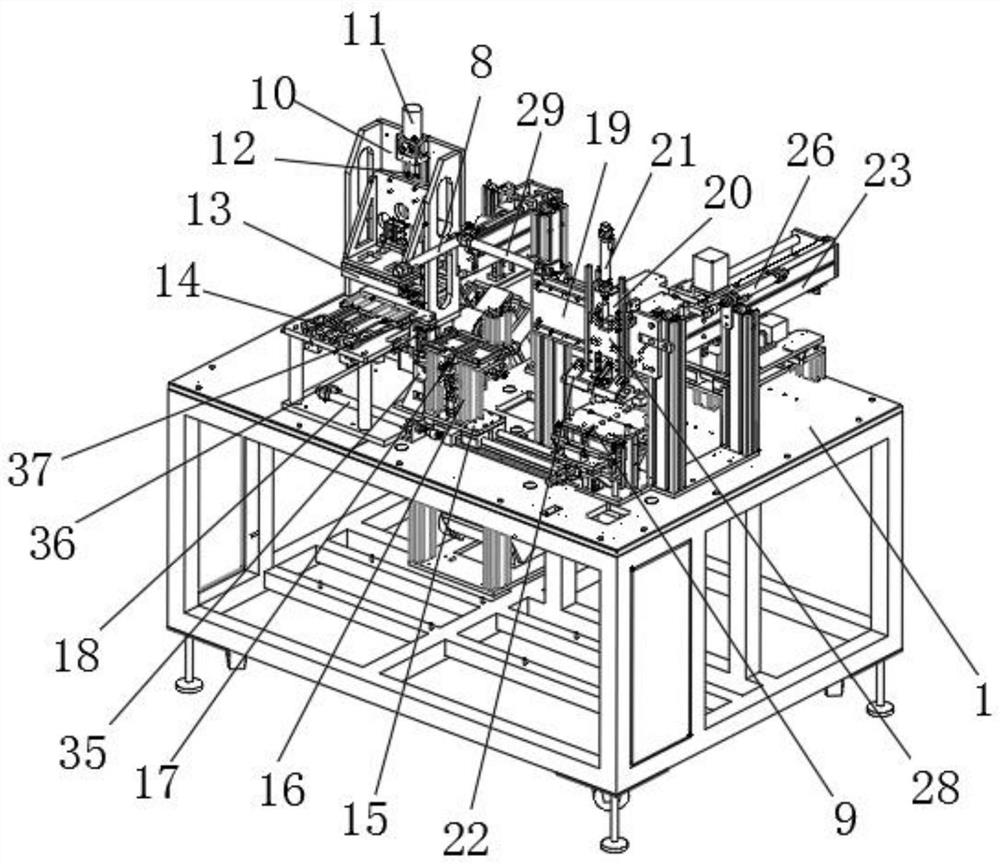

Edge folding mechanism of carton packaging machine

The invention relates to an edge folding mechanism of a carton packaging machine, which belongs to the technical field of carton processing equipment and comprises a conveying assembly, and a horizontal processing platform is arranged at the discharging end of the conveying assembly; a mounting frame is arranged above the machining platform, and a pressing and holding assembly for horizontally pressing and holding the conveyed corrugated board is arranged on the mounting frame. A mounting platform is arranged at the end, away from the conveying assembly, of the machining platform. A primary edge folding assembly for carrying out primary edge folding on the pressed corrugated board is arranged between the processing platform and the mounting platform; a secondary edge folding assembly for carrying out secondary edge folding on the corrugated board subjected to primary edge folding is arranged on the mounting platform; and an indentation assembly for applying indentation and / or cutting on the pressed and held corrugated board is arranged on the upper side of the pressing and holding assembly and located on the side close to the mounting platform. By the adoption of the technical scheme, edge folding and indentation are integrated, it can be guaranteed that edge folding traces and indentation are unified in the edge folding process, and the carton yield after the edge folding procedure is improved.

Owner:天长市天翔包装有限公司

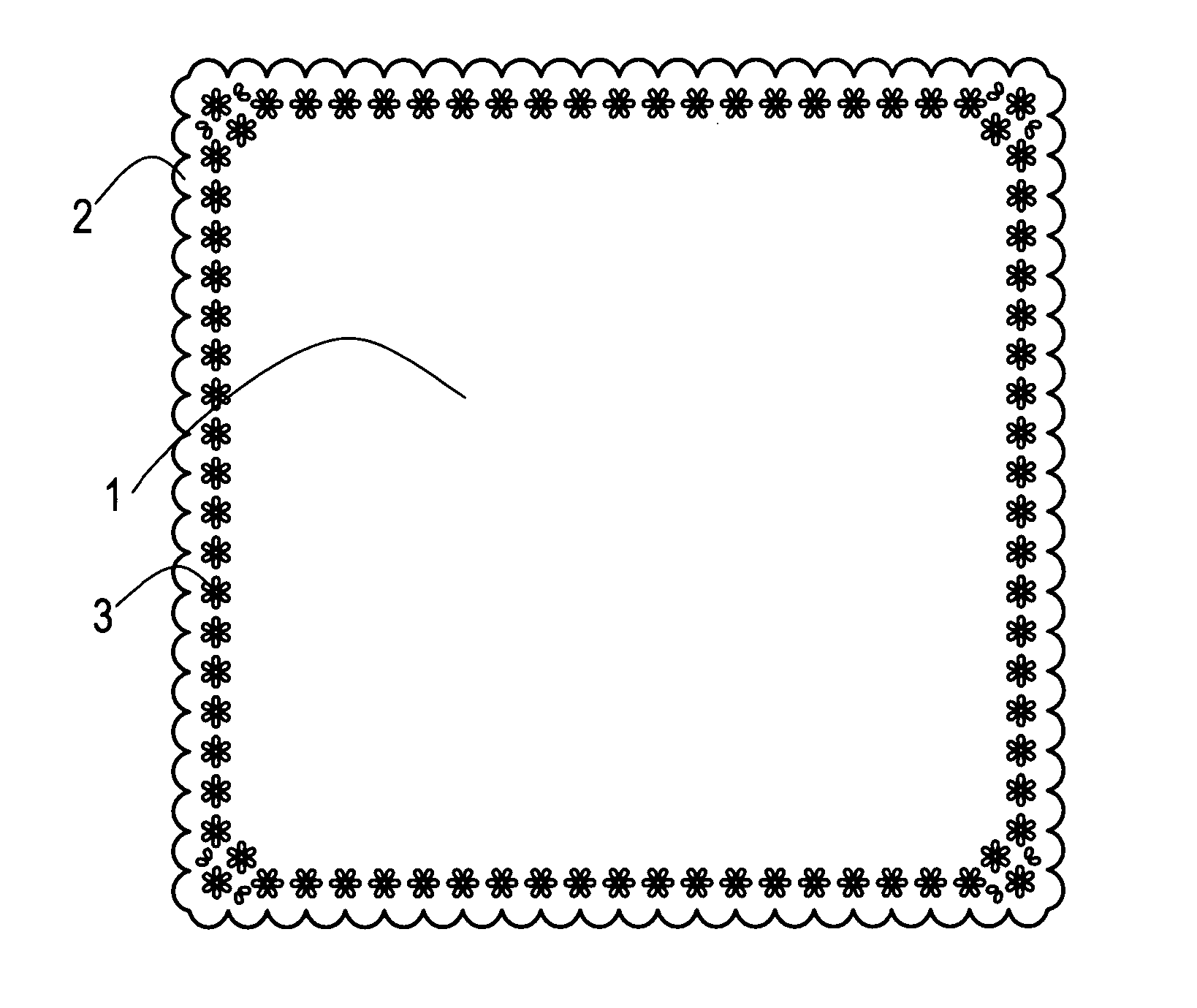

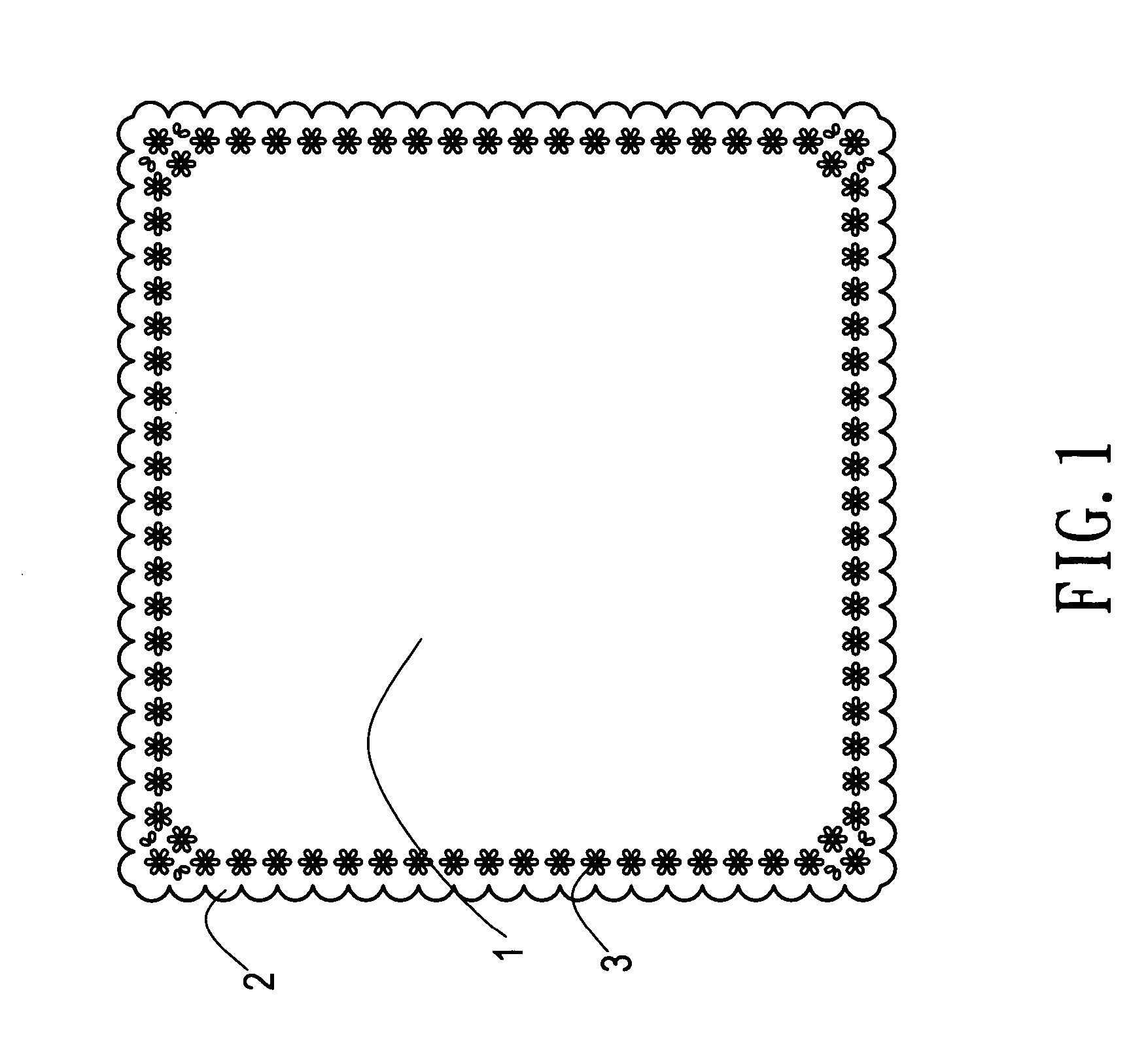

Structure of napkin having laces and method for making the same

A structure of napkin having laces and the method for making the same, comprising a napkin body made by fabric and used for wiping when dining, hemmed edges made on the periphery of the napkin body by an embossing and hemming means, and special geometric motifs arranged by many holes and patterns distributed in predetermined positions over the napkin body. With the above structure, a variety of geometric motifs can be embossed on the napkin body without folding the edges of the napkin body and increasing the thickness thereof. Thus, the hemmed edges can be easily made.

Owner:MEDTECS INT CORP +1

Head and soft roll lithium ion battery package method by employing same

InactiveCN109560220AEffective extrusionAvoid influenceFinal product manufactureSmall-sized cells cases/jacketsState of artEngineering

The invention belongs to the technical field of lithium ion battery production, and particularly relates to a head. Te head comprises a base, a head main body installed on the base and limit blocks located at two ends of the head main body, and the package surface of the head main body is provided with wave teeth or mesh teeth. The present invention further provides a soft roll lithium ion batterypackage method by employing the same. The method comprises the following steps of: the step 1, employing the head to perform primary package of a soft roll lithium ion battery to form a seal region having raised grains or mesh patterns; and the step 2, employing a conventional flat head to perform secondary package of the lithium ion battery to form a flat seal region. Compared to the prior art,the head can generate seal with raised grains or mesh patterns to effectively squeeze out electrolyte in the seal region to the two sides of the seal region so as to ensure the package effect.

Owner:HUNAN LIFANG NEW ENERGY SCI & TECH

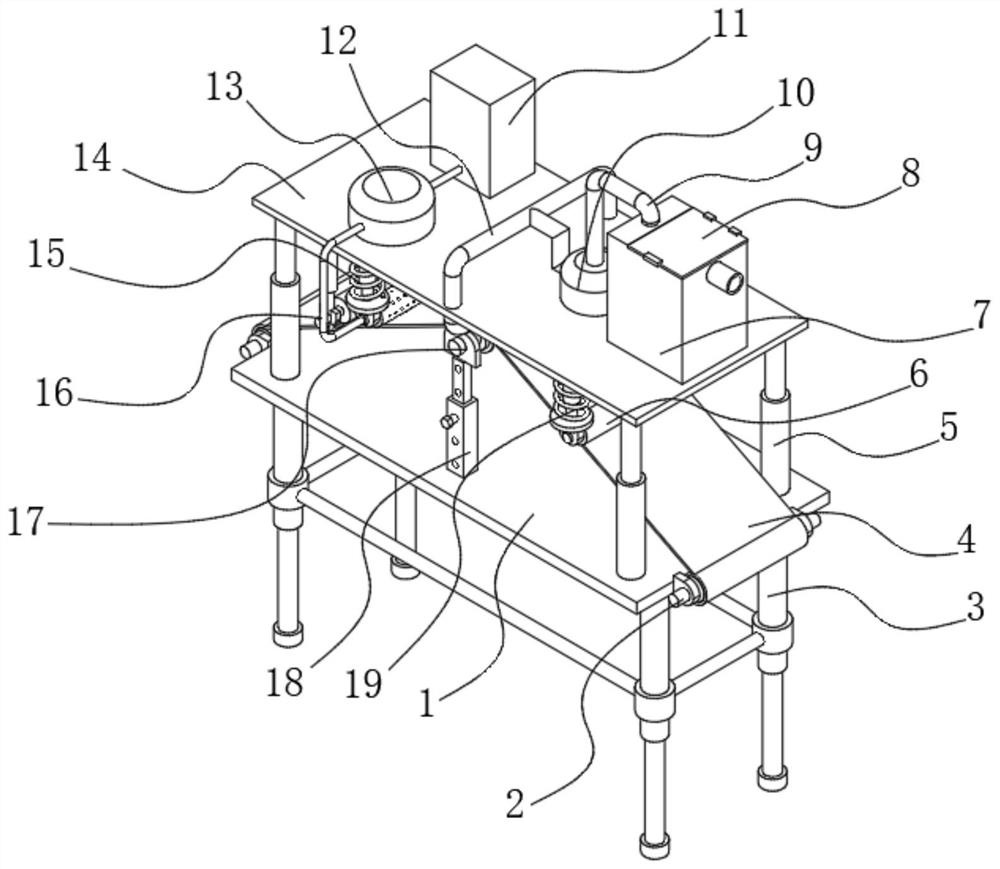

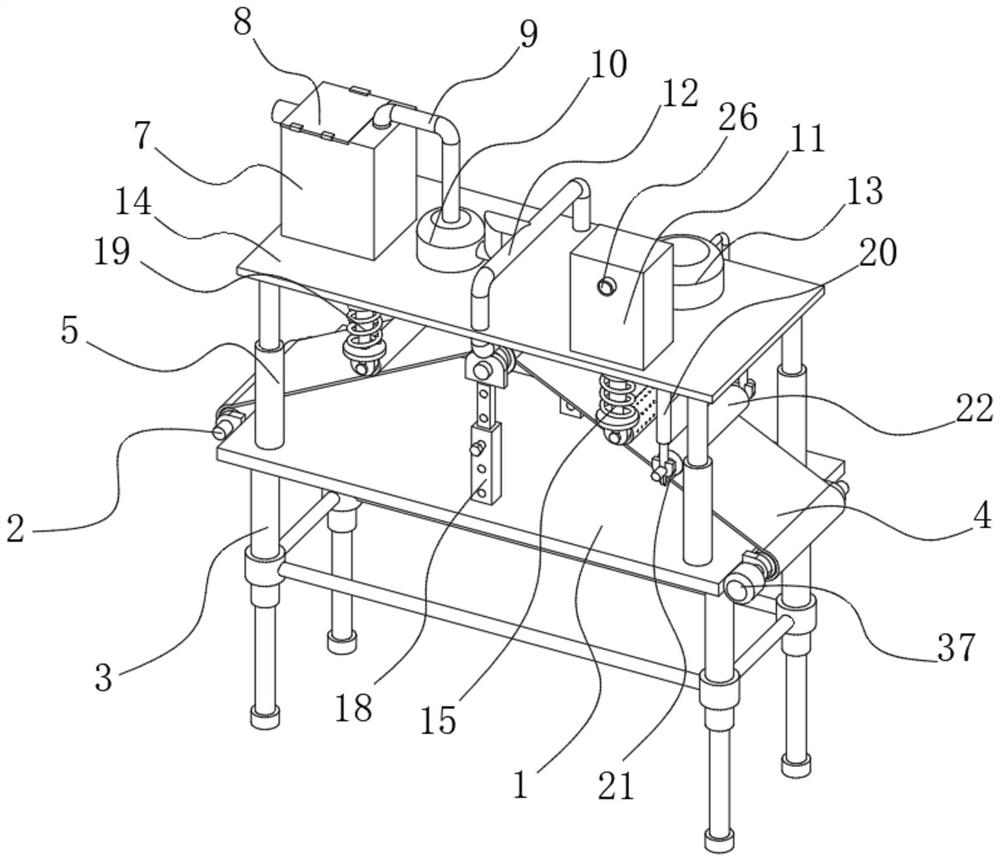

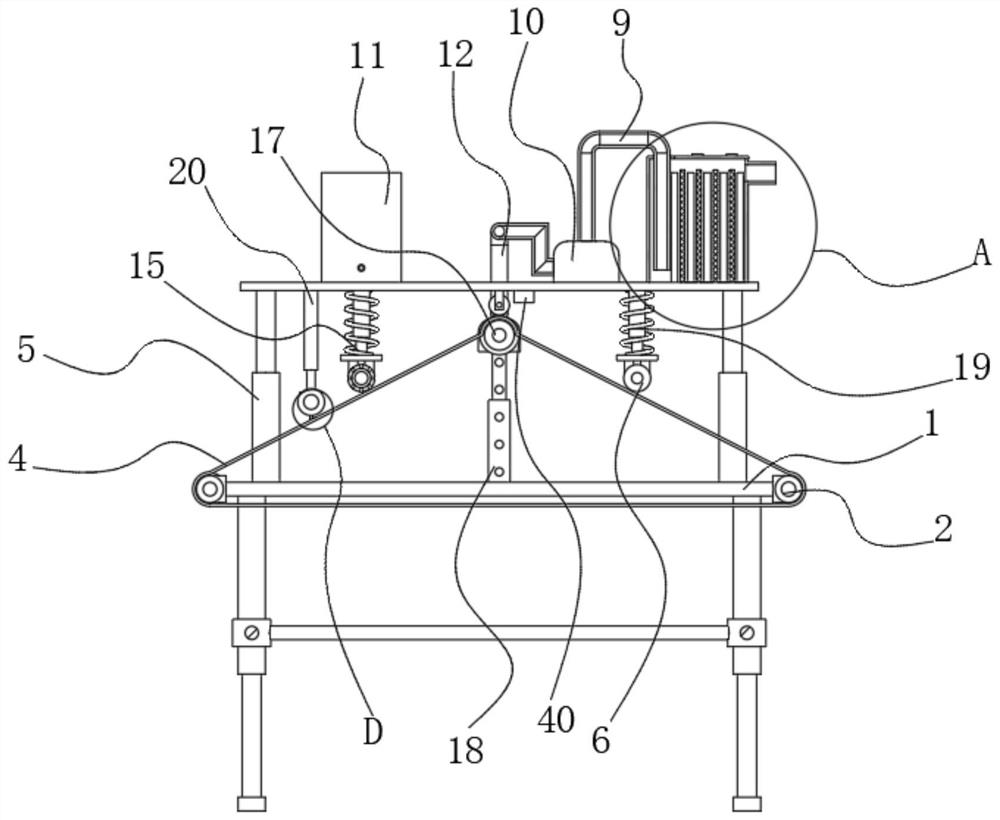

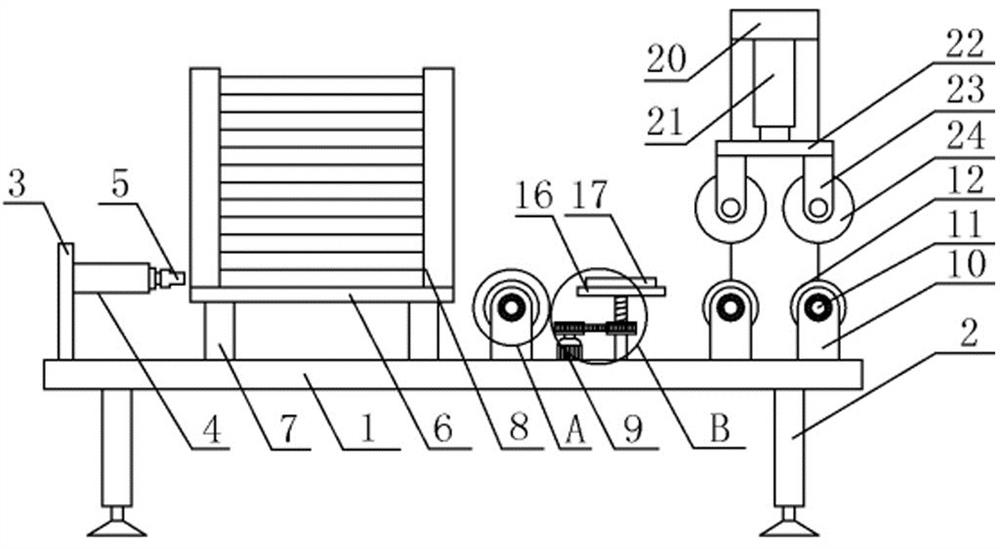

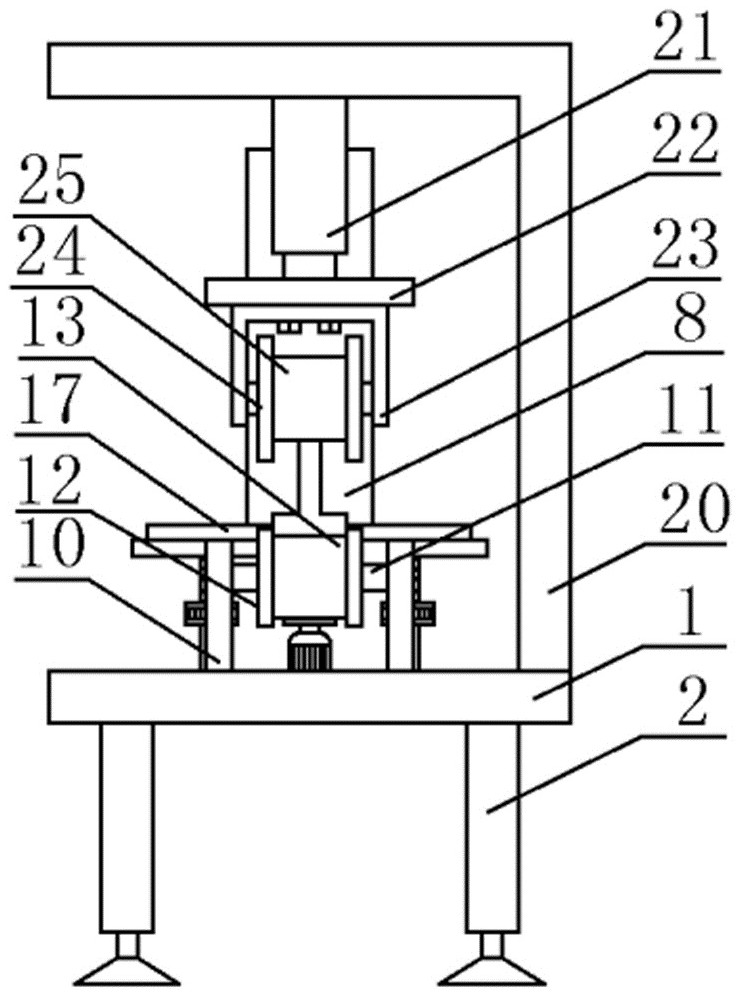

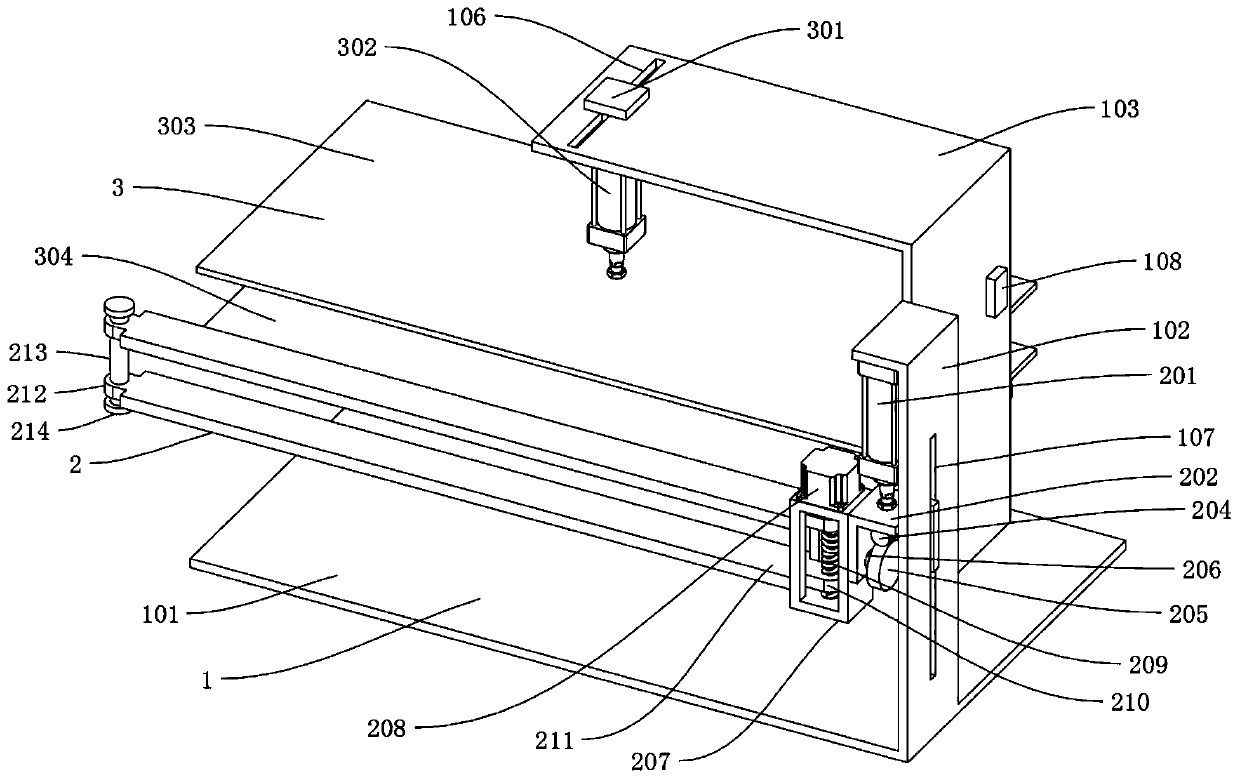

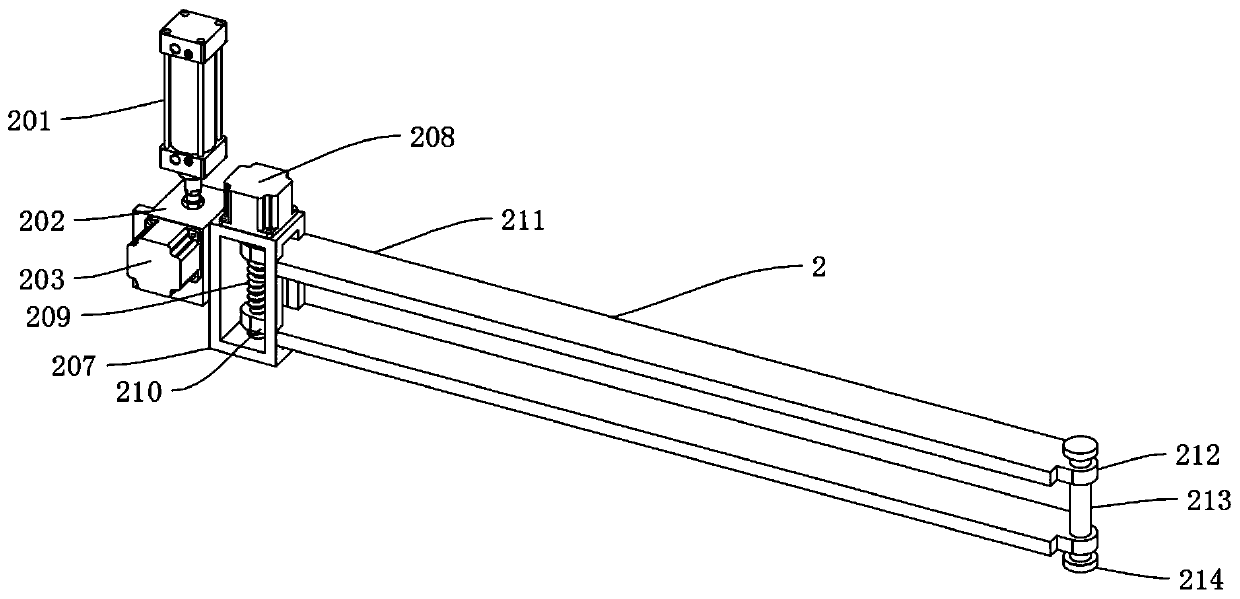

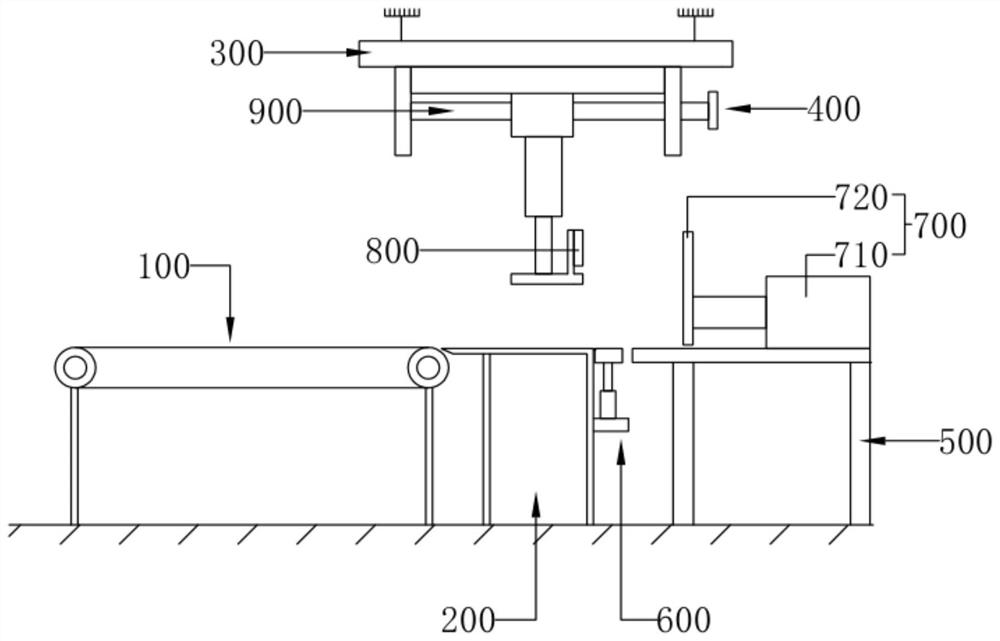

Full-automatic air pipe pressing production line

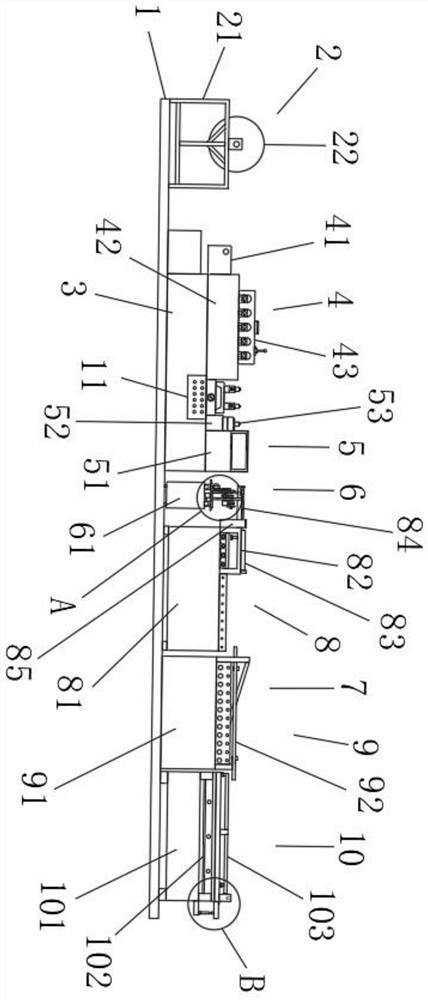

InactiveCN112935825AEasy to moveEasy hemmingOther manufacturing equipments/toolsProduction lineStructural engineering

The invention discloses a full-automatic air pipe pressing production line which comprises a bottom plate. An unwinding mechanism is arranged at one end of the top of the bottom plate; a first base is fixedly connected to the end, away from the unwinding mechanism, of the top of the bottom plate; a creasing mechanism is arranged at one end of the top of the first base; a cutting-off mechanism is arranged at the end, away from the creasing mechanism, of the top of the first base; and a single-side edge changing mechanism is arranged at the top of the bottom plate and located at the side, away from the first base, of the cutting-off mechanism. The full-automatic air pipe pressing production line provided by the invention has the beneficial effects that a crease can be better and conveniently pressed on an iron sheet, so that the iron sheet can be conveniently folded in half to form an air pipe in the later stage; and the iron sheet can be better and conveniently cut into a specified shape, the edge of the iron sheet can be better and conveniently folded, the iron sheet can be better and conveniently driven to move, and one side of the iron sheet can be better and conveniently bent by 90 degrees, so that the iron sheet can be conveniently matched with other faces in size when being folded in half in the later stage, and time and labor are saved.

Owner:风通动力环境科技(成都)有限公司

Folding machine for machining cable bridge frame

InactiveCN107597896ACompact structureIncrease productivityMetal-working feeding devicesPositioning devicesAgricultural engineering

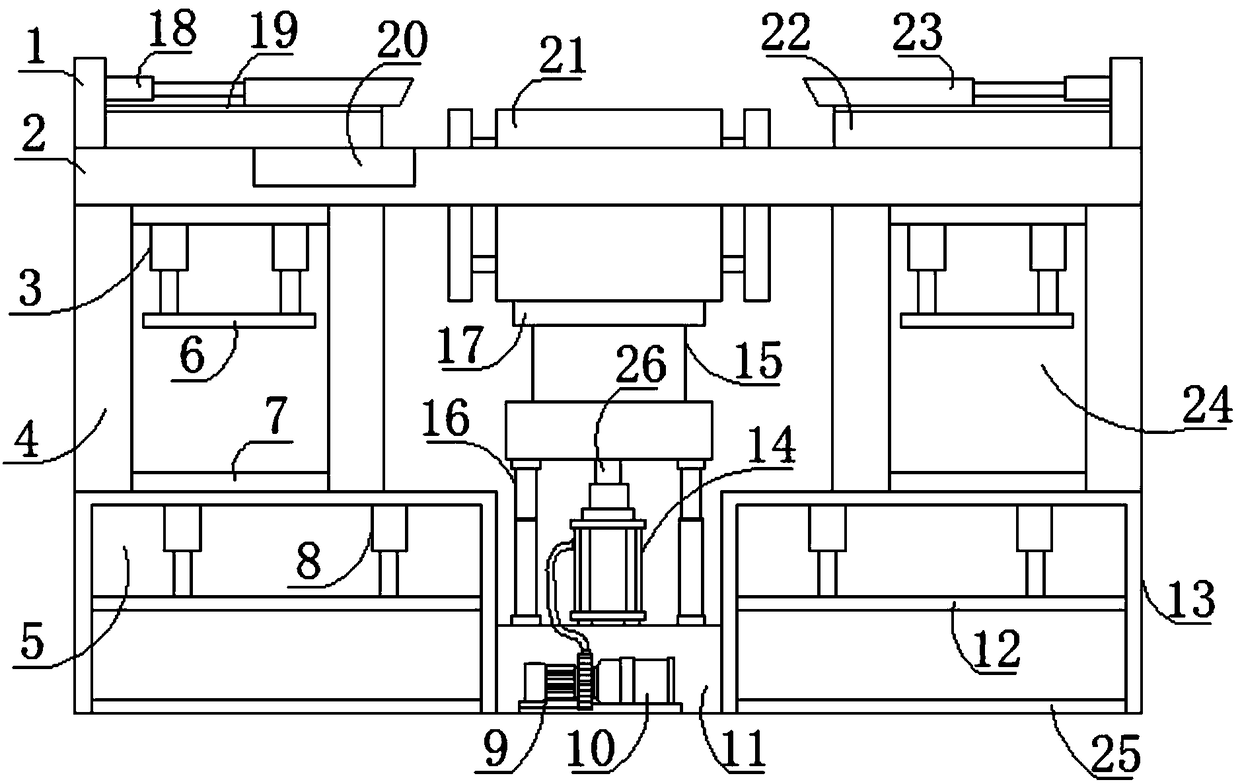

The invention discloses a folding machine for machining a cable bridge frame. The folding machine includes a hydraulic station, laser positioning devices, a crossbeam, a rack, plate fixing devices, alimiting device, a hydraulic ejector rod and a folding platform. The crossbeam is fixedly arranged on the rack. The two laser positioning devices are arranged on the crossbeam. The plate fixing devices are symmetrically arranged on the two sides of the rack. The limiting device is arranged on the plate fixing devices. The hydraulic ejector rod is arranged at the bottom of the rack and located between the two plate fixing devices. The folding platform is arranged on the hydraulic ejector rod. The hydraulic station is arranged independently and connected with the hydraulic ejector rod. The folding machine for machining the cable bridge frame is simple and compact in structure, can achieve once folding machining on the cable bridge frame, and greatly improves the production efficiency of thecable bridge frame.

Owner:江苏昊昱科技咨询有限公司

A dovetail ball type movable lug

The invention relates to a dovetail spherical movable lifting lug. The dovetail spherical movable lifting lug comprises an upper movable lifting lug and a lower movable lifting lug; one side of the upper movable lifting lug is an inclined face, a vertically through dovetail groove is formed in one side of the inclined face of the upper movable lifting lug, one side of the lower movable lifting lugis also an inclined face, the inclined face of the lower movable lifting lug and the inclined face of the upper movable lifting lug are in mirror symmetry, a convex dovetail consistent with the inclined angle of the inclined face of the lower movable lifting lug is arranged on one side of the inclined face of the lower movable lifting lug, and a sliding groove consistent with the inclined angle of the dovetail is formed in the dovetail. The dovetail of the lower movable lifting lug is arranged in the dovetail groove of the upper movable lifting lug, a positioning pin is fixed to the upper movable lifting lug, and the positioning pin penetrates the dovetail groove and the sliding groove in the dovetail. The upper movable lifting lug can slide in the range defined by the positioning pin andthe sliding groove along the convex dovetail of the lower movable lifting lug. Through the lifting lug, the problem that most steel furniture, box cabinets and door folding sides are not thorough, the surface is not flat, and the size is lack of standardization is solved.

Owner:扬州四星工业自动化设备有限公司

Cylinder type limit folding mechanism for battery case

Owner:徐州永固电力设备有限公司

Cylinder type limit folding mechanism for battery case

ActiveCN104852088BEasy hemmingEasy to seeFinal product manufactureElectrolyte accumulators manufactureEngineeringLeft wall

The invention relates to a cylinder-type limit folding mechanism for a battery case, which belongs to the technical field of battery case folding, and includes a workbench, on which a bottom mold is installed, and on the workbench on the right side of the bottom mold is fixed a mounting Column, the installation plate is fixed on the left side wall of the installation column, and the corresponding bottom mold is provided with a folding reset mechanism for folding directly above it, and the folding reset mechanism includes a mounting bracket, a folding knife and a transmission rod for moving up and down , the hemming knife is installed on the lower end of the transmission rod through the knife seat, a reset plate is fixed on the upper end of the transmission rod, springs are installed between the reset plates on the left and right sides of the transmission rod and the mounting bracket, and vertically above the transmission rod there is a The cylinder that the drive rod moves downward is fixed with a limit block by bolts on the bottom mold on the right side of the hemming knife. The invention is convenient to operate, and effectively controls the use cost and the maintenance cost while ensuring the production efficiency.

Owner:南通鼎鑫电池有限公司

Limiting folding mechanism for battery shell

The invention relates to a limiting folding mechanism for a battery shell, and belongs to the technical field of battery shell folding. The limiting folding mechanism comprises a workbench. A bottom die is installed on the workbench, an installation column is fixed to the workbench and located on the right side of the bottom die, a casing pipe is horizontally installed on the installation column,a rotating shaft horizontally penetrates in the casing pipe, a handle disc used for rotation is installed at the right end of the rotating shaft, an installation support is fixed to the installation column, a folding reset mechanism used for folding is arranged over the bottom die correspondingly and comprises a folding knife and a transmission rod which does up-down motion, a worm and gear mechanism used for power transmission is arranged between the transmission rod and the rotating shaft, and a limiting block is fixed to the bottom die through a bolt and located on the right side of the folding knife. By means of the limiting folding mechanism, operation is convenient, the production efficiency is ensured, and meanwhile the using cost and the maintenance cost are effectively controlled.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

A steel ring folding machine

ActiveCN106391801BCheap compositionSimple structureMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention discloses a steel ring edge folding machine which comprises a rack. The rack is internally provided with a transmission mechanism. The rack is provided with a locating core model for being in cup joint with a steel ring, an edge folding mechanism for rolling and pressing the steel ring and an arc pressing mechanism for downwards pressing the steel ring. The mandrel of the locating core model is connected with the transmission mechanism and driven by the transmission mechanism to rotate. The external circumference of the locating core model is in cup joint with the steel ring. One side of the locating core model is provided with the edge folding mechanism for applying force to the top end of the steel ring in an inclined mode from top to bottom, and the edge folding mechanism makes the top end of the steel ring form an inwards-folded edge. The arc pressing mechanism for downwards applying force to the inwards-folded edge at the top end of the steel ring is arranged above the locating core model and makes the inwards-folded edge form a downward arc groove by moving downwards. The steel ring edge folding machine has the advantages of being simple in structure, convenient to fabricate, low in cost, good in edge folding effect and arc pressing effect, not prone to breakage and the like.

Owner:广东鑫隆管业有限公司

Battery shell limit folding mechanism

InactiveCN104868151BSimple structureEasy to operateAssembling battery machinesMetal-working feeding devicesEngineeringWorkbench

The invention relates to a limit folding mechanism for a battery case, belonging to the technical field of battery case folding, which includes a workbench, a bottom mold is installed on the workbench, and a mounting column is fixed on the workbench on the right side of the bottom mold. A casing is installed on the column, and a rotating shaft is installed at the level of the casing, and a handle plate is installed at the right end of the rotating shaft. Bracket, hemming knife and transmission rod for moving up and down, the hemming knife is installed on the lower end of the transmission rod through the knife seat, a reset plate is fixed on the upper end of the transmission rod, and a The spring is provided with a worm and gear mechanism for power transmission between the transmission rod and the rotating shaft, and the limit block is fixed by bolts on the bottom mold on the right side of the hemming knife. The invention is convenient to operate, and effectively controls the use cost and the maintenance cost while ensuring the production efficiency.

Owner:白翠贞

Limiting edge folding mechanism for battery shell

The invention relates to a limiting edge folding mechanism for a battery shell, and belongs to the technical field of edge folding of battery shells. The mechanism comprises a working table, wherein a bottom mold is mounted on the working table; a mounting column is fixed on the working table at the right side of the bottom mold; a bushing is horizontally mounted on the mounting column, and is horizontally inserted with a rotating shaft; a handle disc for rotating is mounted at the right end of the rotating shaft; a mounting bracket is fixed on the mounting column; an edge folding return mechanism for edge folding is arranged rightly above the bottom mold corresponding to the bottom mold, and comprises an edge folding knife and a transmission rod for vertically moving; a worm and gear mechanism for power transmission is arranged between the transmission rod and the rotating shaft; and a limiting block is fixed on the bottom mold at the right side of the edge folding knife through a bolt. As the mechanism is convenient to operate, the use cost and the maintenance cost are effectively controlled while guaranteeing the production efficiency.

Owner:GUANGDONG YINGYEDA ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com