Flanging machine for power distribution cabinet manufacturing and using method thereof

A technology for power distribution cabinets and folding machines, which is applied to manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of inconvenient use, inconvenient adaptation to changing the angle of folding, and inconvenience to drive the displacement of raw materials, etc. Easy to set up, easy to use, easy to change the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

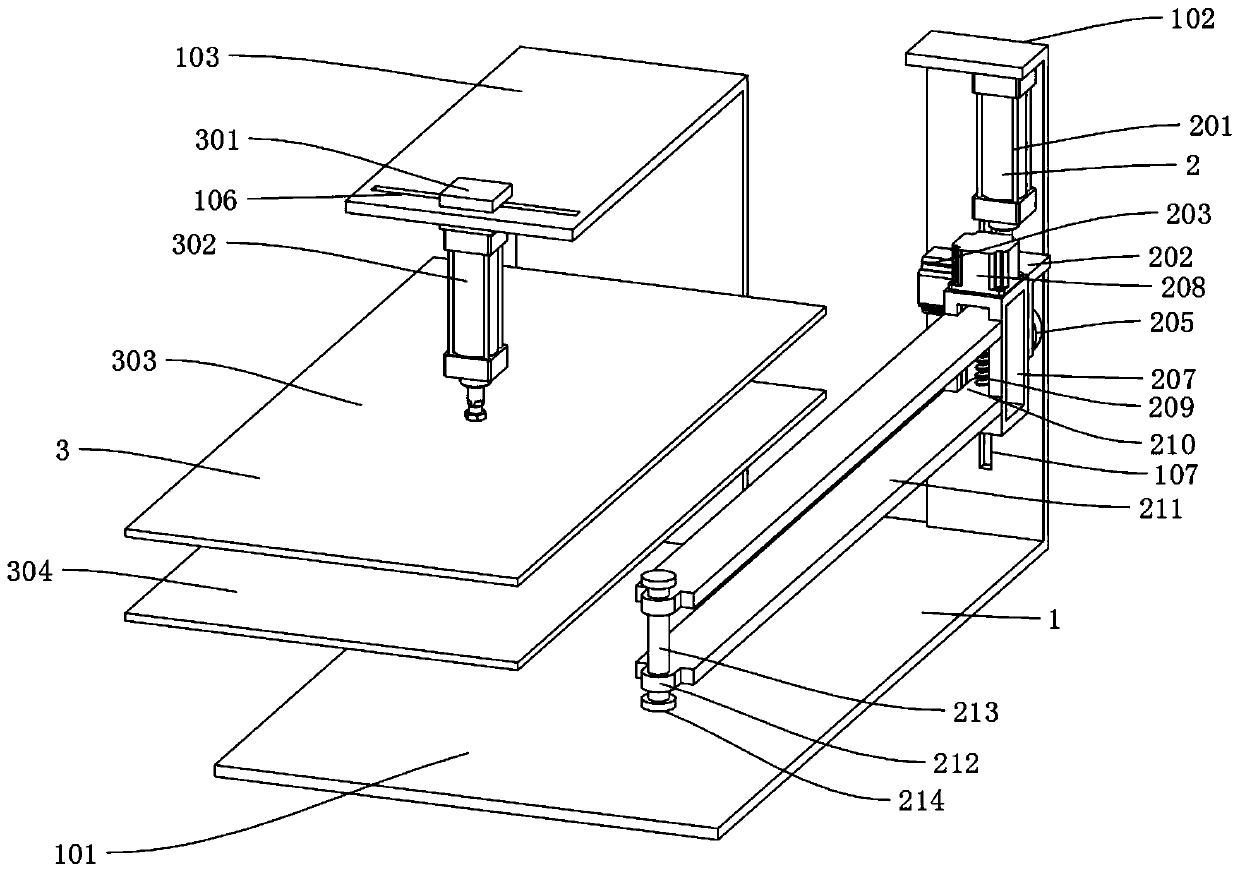

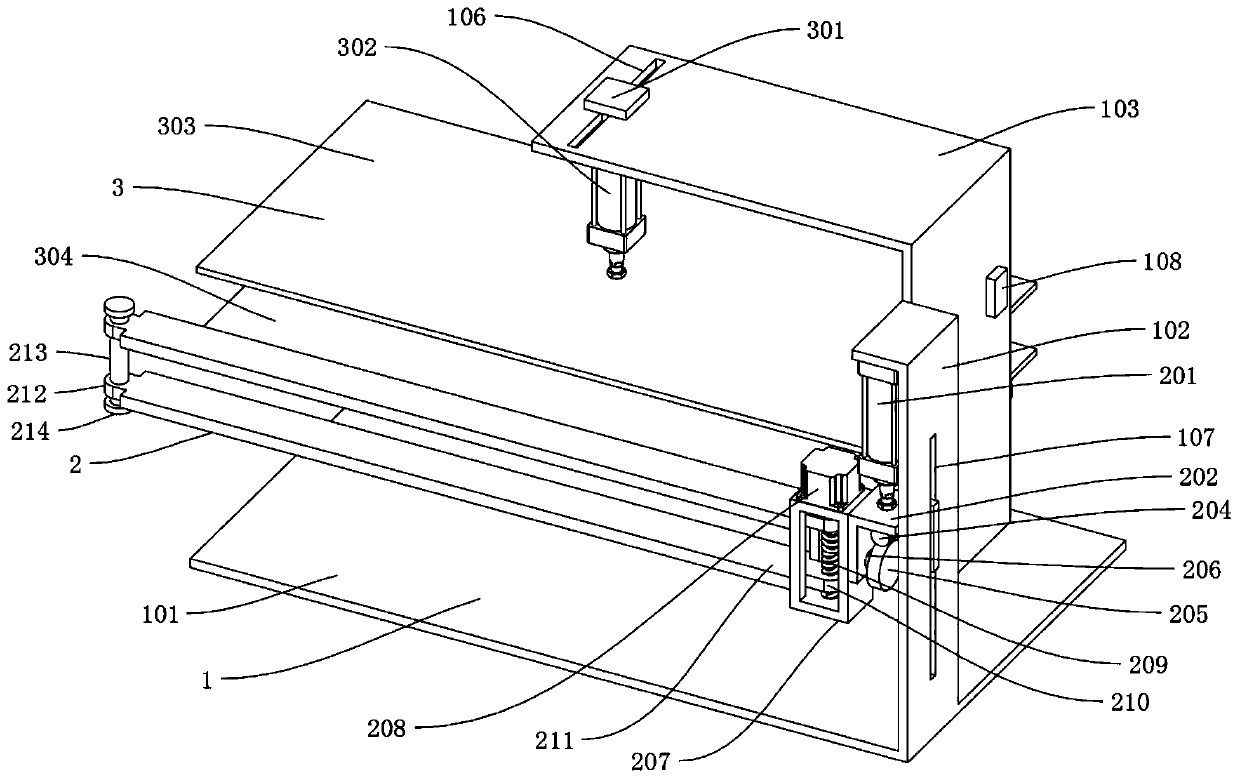

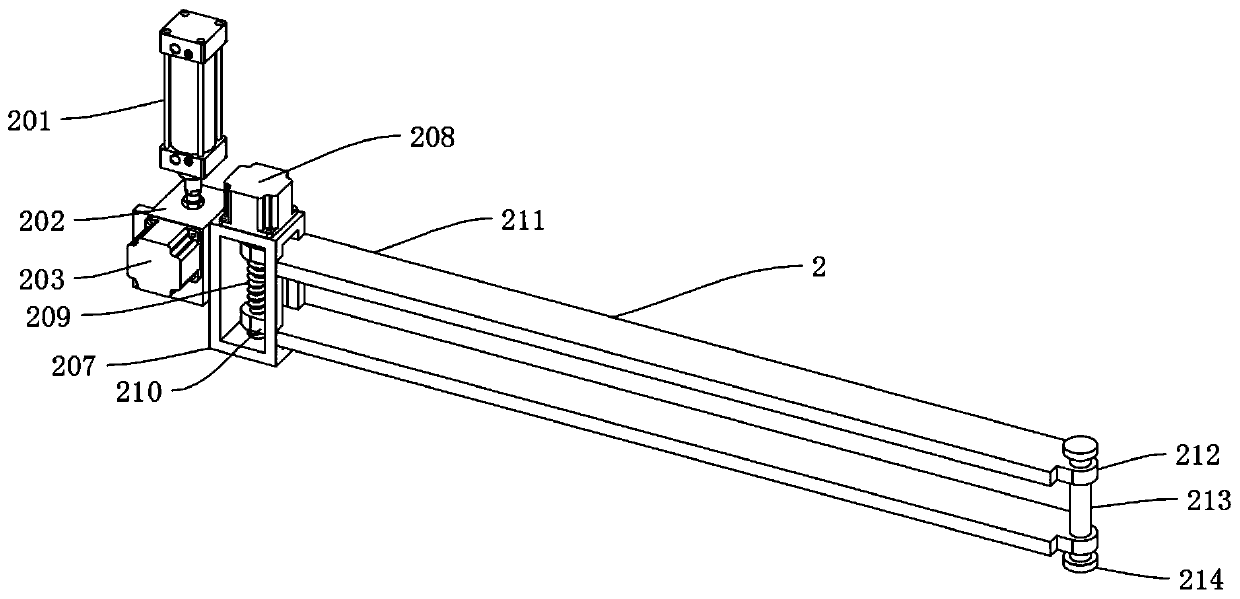

[0045] like Figure 1-Figure 7 As shown, the edge folding machine used for the manufacture of power distribution cabinets includes a support mechanism 1. The support mechanism 1 includes a bottom plate 101, a support plate 102, a support plate 2 103, a support plate 3 104, and a chute 105. The upper end of the bottom plate 101 is welded There is a support plate 102, and the support plate 102 is vertically formed with a chute 3 107, and one side of the support plate 102 is provided with a support plate 103, and the shape of the support plate 102 and the support plate 2 103 is "L" shape Support plate 1 102 and support plate 2 103 stably support the folding mechanism 2 and clamping mechanism 3, and the top of support plate 103 is horizontally formed with chute 2 106, which is used to facilitate the sliding of slider 301. The control switch 108 is installed at the rear end of the second board 103, the front end of the second board 103 is welded with the third board 104, the third ...

Embodiment 2

[0052] like Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the clamping mechanism 3 includes a slide block 301, a cylinder two 302, an upper splint 303, a lower splint 304, and a push plate 309, and the lower end of the slide block 301 is equipped with a cylinder two 302, and the cylinder The lower end of the second 302 is provided with an upper splint 303, the lower end of the upper splint 303 is provided with a lower splint 304, the lower splint 304 is slidingly connected with the upper end of the support plate 3 104, and the lower end of the lower splint 304 is welded with a push plate 309 near the rear side. The inner side of one 105 is slidingly connected with support plate three 104, and one side of push plate 309 is horizontally connected with cylinder three 308 by bolts, and the push plate 309 is fastened with cylinder three 308, and cylinder three 308 is connected with support plate three 104 by bolts, and the cylinder One 201, one mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com