Edge folding mechanism of carton packaging machine

A packaging machine and carton technology, which is applied in packaging, transportation, packaging, papermaking, etc., can solve the problems of defective products, waste of operator's physical strength and time, and easy deviation of folding position, etc., so as to reduce the occupied area , Guarantee the effect of hemming yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

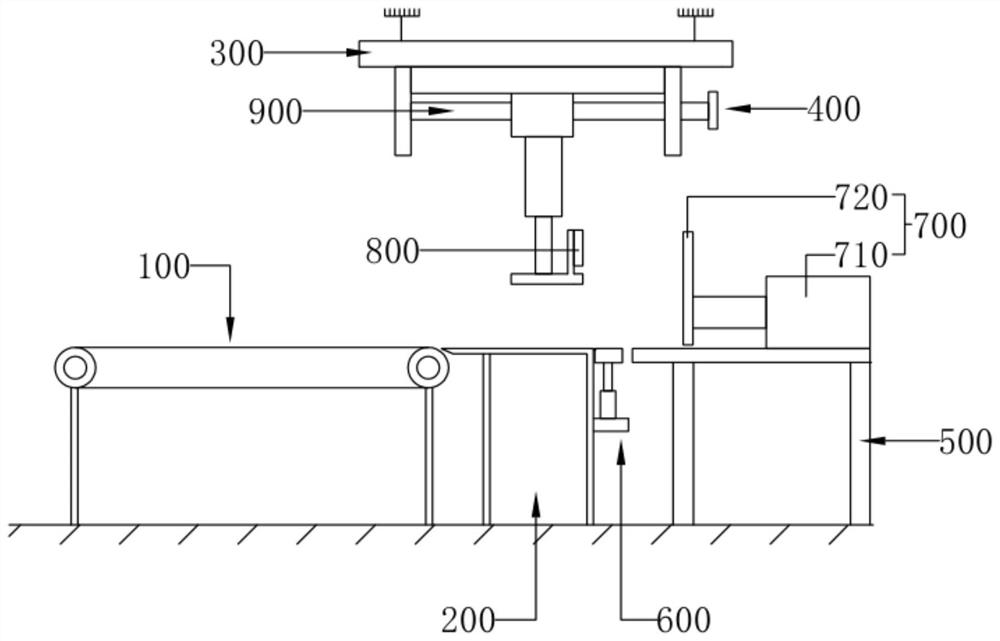

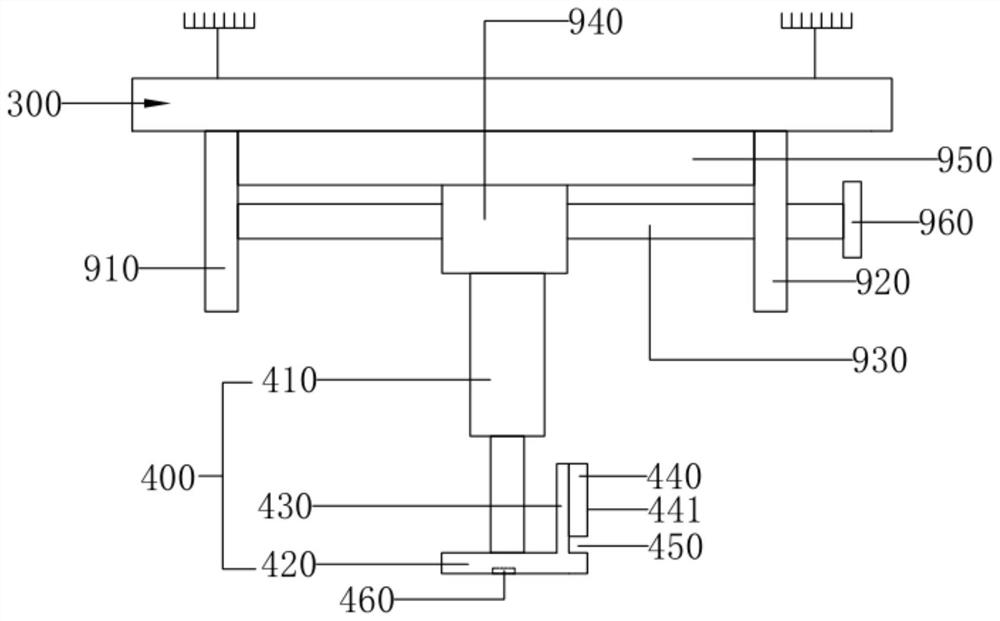

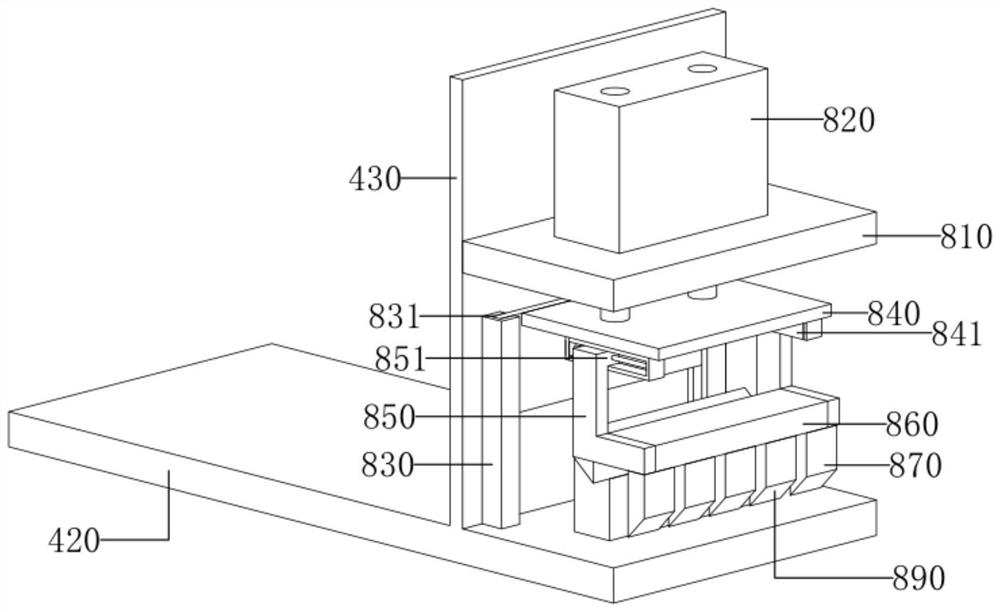

[0035] The invention provides a folding mechanism of a carton packaging machine, see Figure 1-Figure 5, including a conveying assembly 100, a horizontal processing platform 200 is provided at the feeding end of the conveying assembly 100; a mounting frame 300 is provided above the processing platform 200, and a horizontal pressing mechanism for conveying corrugated boards is provided on the mounting frame 300 The holding assembly 400; the processing platform 200 is provided with an installation platform 500 at the end away from the transmission assembly 100; the primary folding assembly 600 for preliminary folding of the pressed corrugated board is provided between the processing platform 200 and the installation platform 500; the installation platform 500 is provided with a secondary hemming assembly 700 for secondary hemming of the corrugated board after primary hemming; Creasing and / or cutting creasing assembly 800 . When folding the corrugated board, the corrugated board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com