Patents

Literature

88results about How to "Improve teleportation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

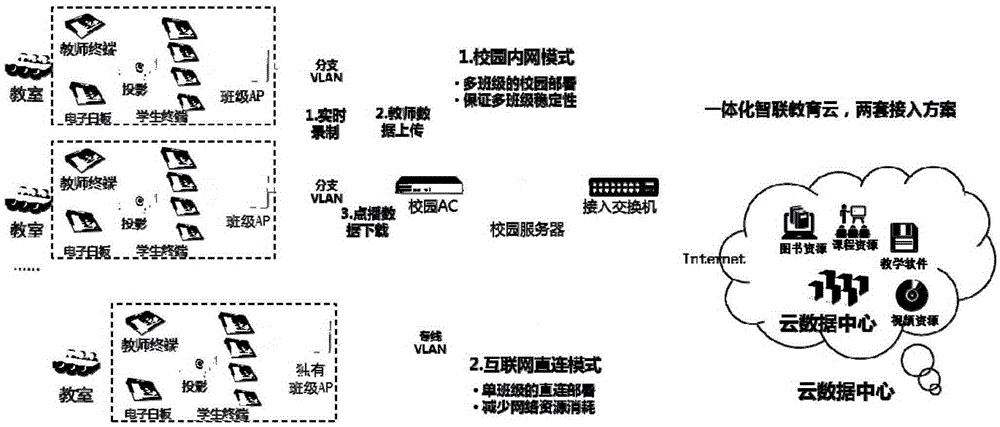

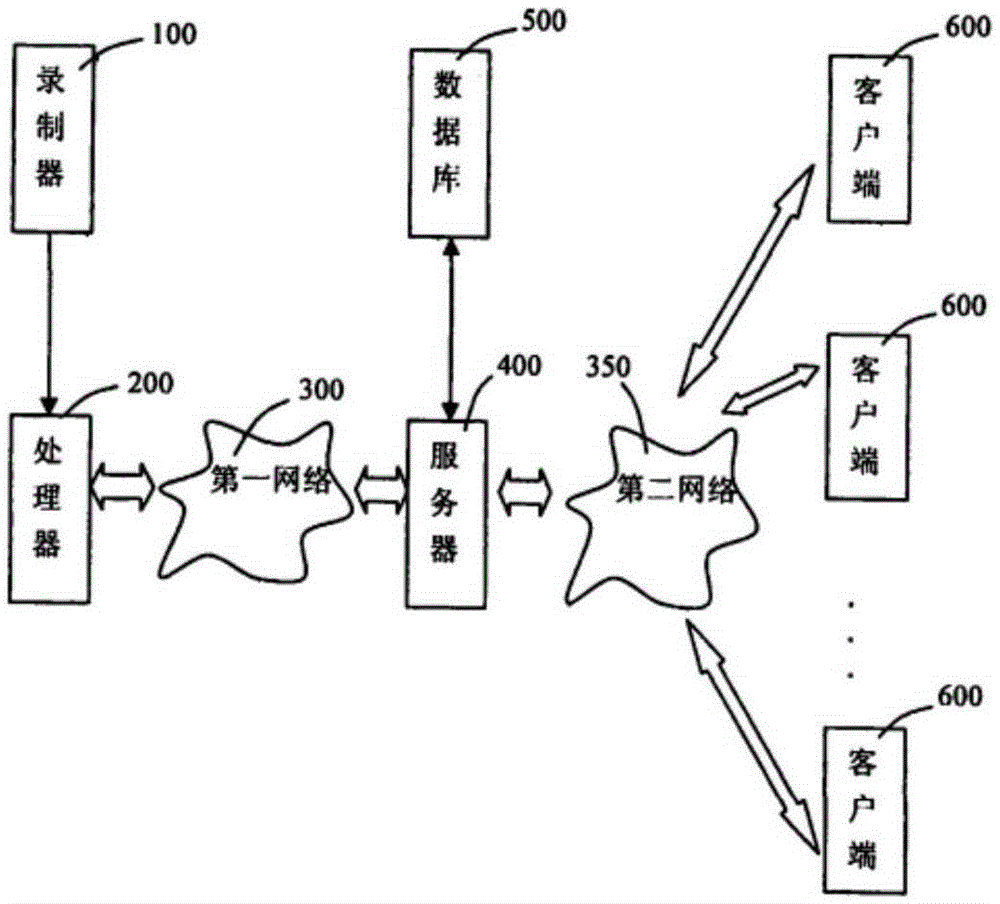

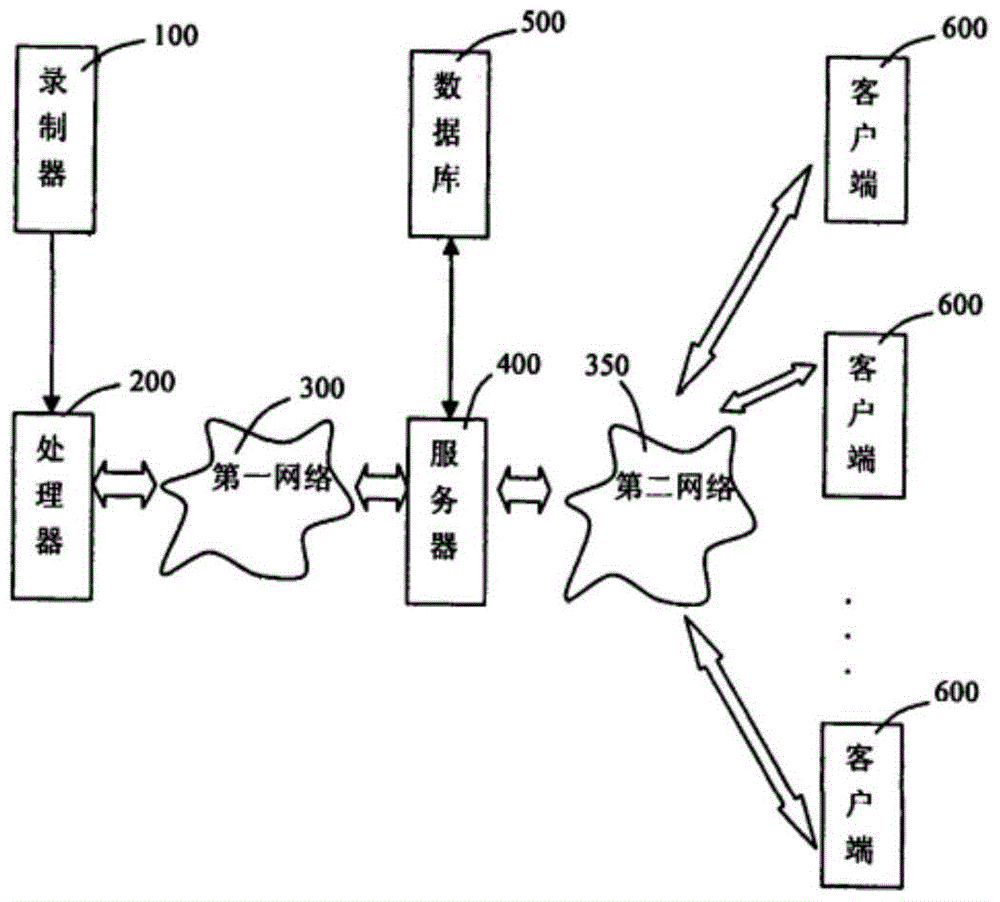

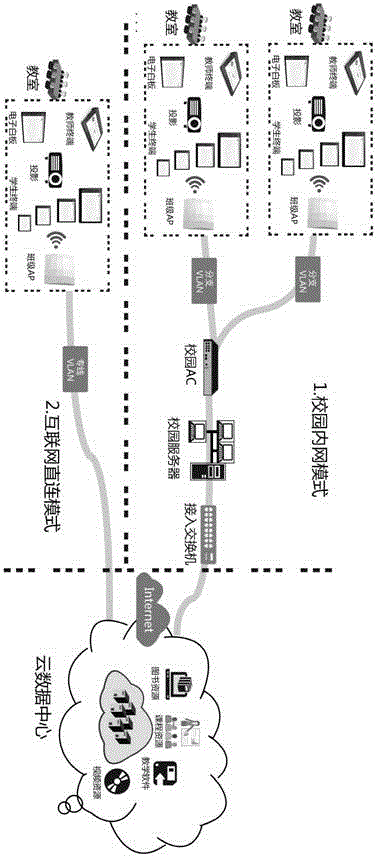

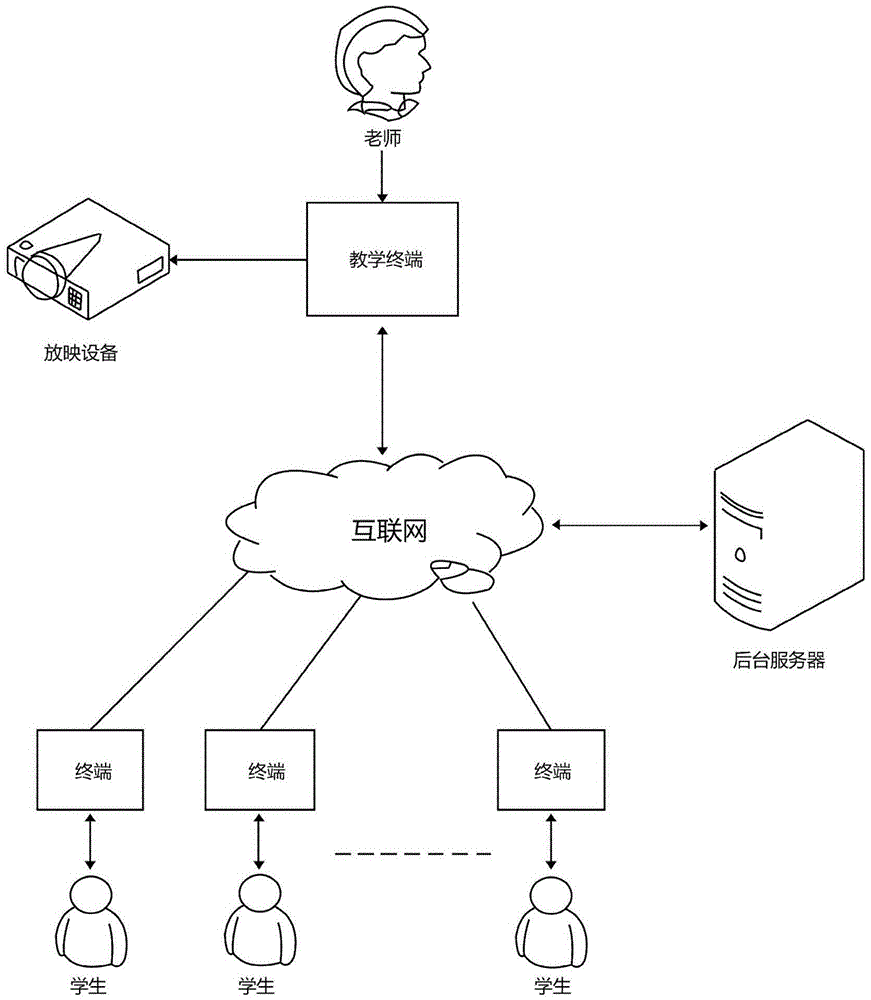

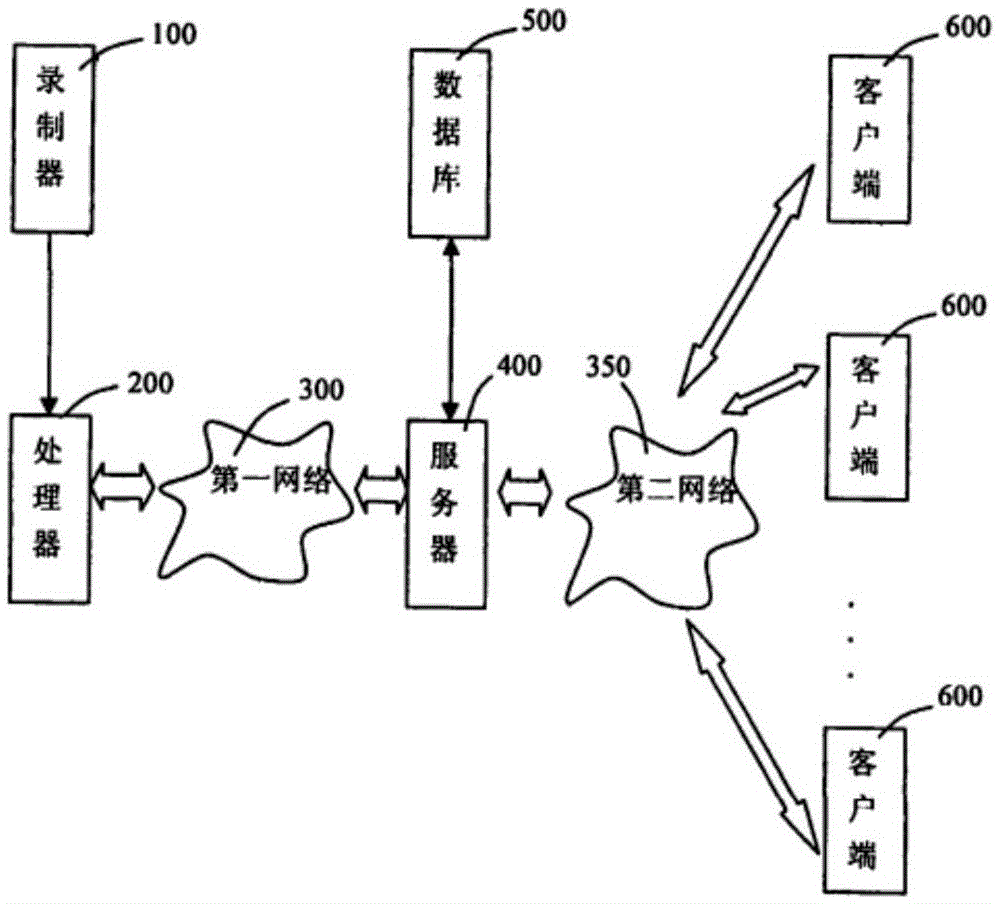

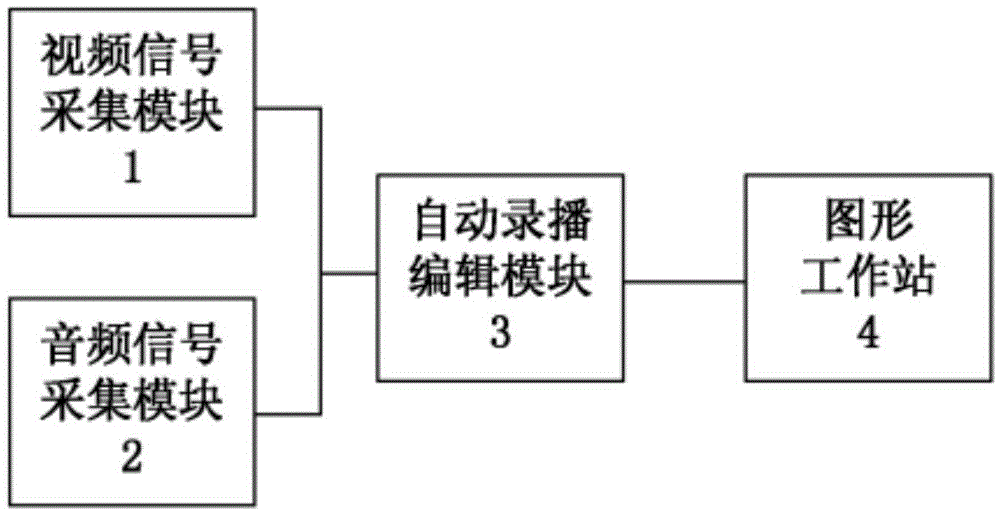

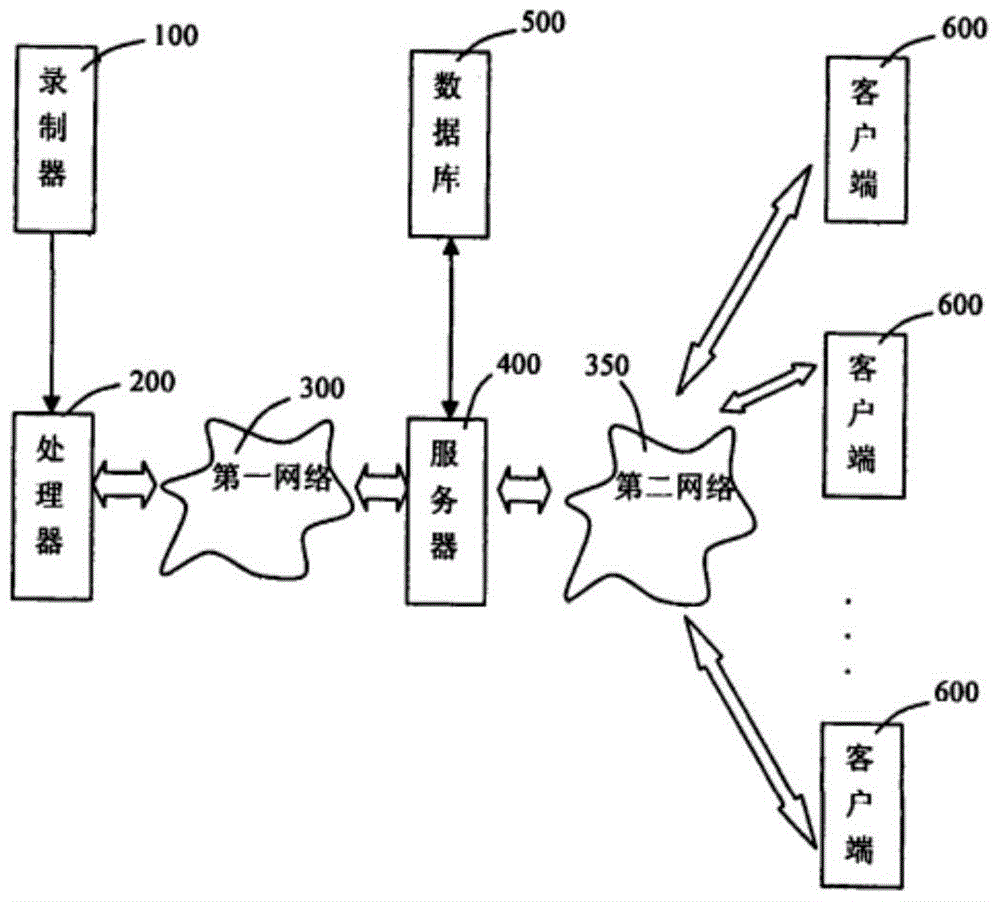

Network teaching method and system

ActiveCN105405325AImprove review efficiencyRealize intelligent judgmentElectrical appliancesData acquisitionComputer terminal

The invention provides a network teaching method and a system. The system comprises multiple user terminals and a server. The user terminals communicate with the server via the network. The method comprises a data acquisition step, a synchronous display step, a real-time recording step and a broadcasting and replaying step. In the data acquisition step, image data, application data and / or audio data in the network teaching processes are acquired and are used for synchronous display and real-time recording. In the synchronous display step, the acquired data are automatically synchronously displayed or transmitted on student user terminals. In the real-time recording step, the acquired data are separately stored into a database, so users can download the data. In the broadcasting and replaying step, according to the users' requests, the recorded and stored data are transmitted to the users and are combined and redisplay the teaching processes on the user terminals.

Owner:SHENZHEN EAGLESOUL TECH CO LTD

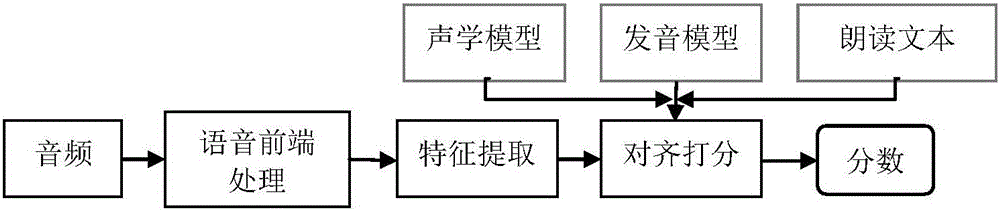

Network teaching method and system with voice recognition function

ActiveCN105681920AEncourage human pronunciation testsQuality improvementTelevision system detailsSpeech analysisSpoken languageSpeech identification

The invention provides a network teaching method and system. Double identity verification of face recognition and voice recognition is realized, the voice signal collection accuracy in a teaching process, an oral training process, a test process and an examination process are scored and assessed by a plurality of models, so that the assessment accuracy is improved, the network teaching is more autonomous and effective, and particularly in reading and listening and recitation teaching, the authenticity and effectiveness of learning can be improved by these functions of the system. By adopting the method provided by the invention, the face recognition is combined with the voice recognition, the user identity is checked before an oral test or system login of the user, and the user can be better encouraged to carry out a human voice test in a use process.

Owner:SHENZHEN EAGLESOUL EDUCATION SERVICE CO LTD

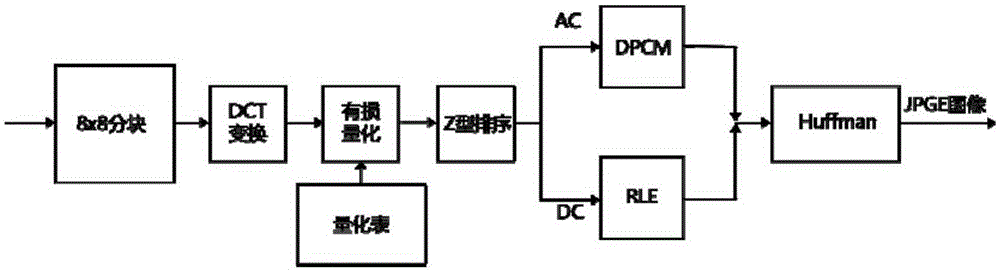

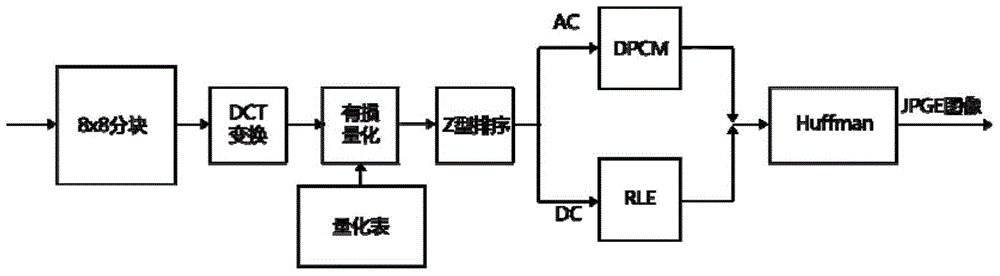

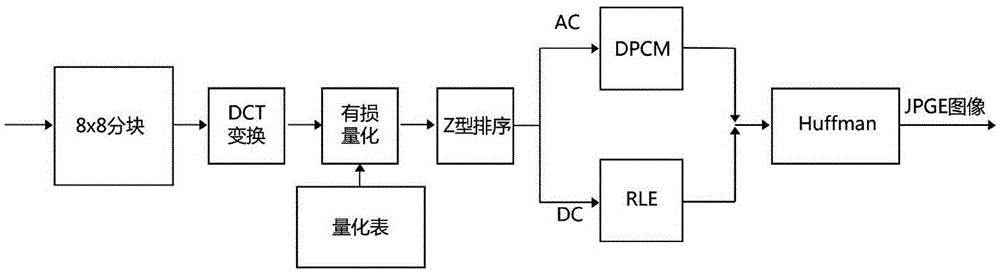

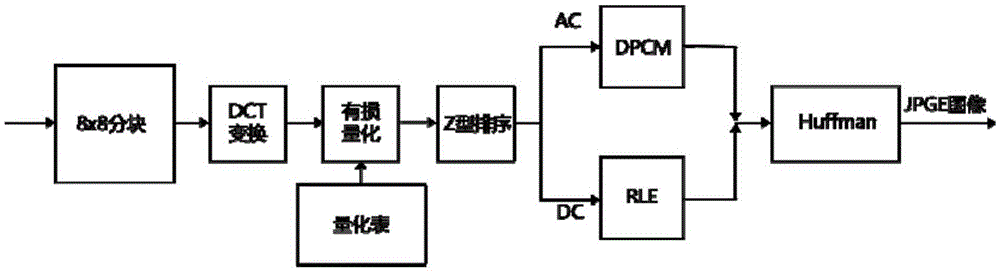

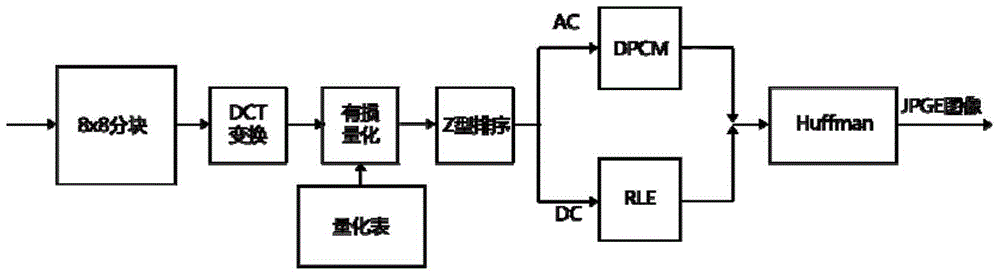

Synchronous display method and device of images

ActiveCN105491414AImprove review efficiencyRealize intelligent judgmentData processing applicationsDigital video signal modificationAcquired characteristicComputer graphics (images)

The invention provides a synchronous display method and device of images. Compression treatment is carried out through periodically capturing screen contents; the transmission capability can be realized at any time; the transmission effect is improved; and the transmission time can be shortened. The captured image contents can be quickly compared according to the feature values analyzed in the image compression process; the images are judged intelligently synchronously; the images are transmitted automatically synchronously without manual operation; the screen contents are prevented from being transmitted repeatedly; the storage pressure of a student user terminal is relieved; comprehensiveness of the contents is ensured; the screen image contents are marked and judged, the review efficiency of a student is improved, when the student reviews, the student can directly view the last few pages of blackboard-writings.

Owner:SHENZHEN EAGLESOUL TECH CO LTD

Network teaching method and system with voice assessment function

ActiveCN105578115ATroubleshoot slow evaluation performanceImprove accuracyTelevision system detailsData processing applicationsSpoken languageMulti language

The invention provides a network teaching method and system with a voice assessment function. According to the voice assessment method provided by the invention, a phoneme state of a voice is used for replacing a multi-Gaussian mixture model trained by a conventional Mel-frequency cepstral coefficient (MFCC), and a posterior probability and a zero-order Baum-Welch statistical magnitude are calculated according to the feature. A voice feature based on phonemes is extracted through a multi-language phoneme identifier. A feature based on multi-language extraction is complementary during catching of non-native pronunciation information, and a feature based on phoneme duration is effective in automatic native accent assessment. Finally, a fusion system is provided in the method, so that Spearman relevant coefficients of 0.5706 and 0.6089 are reached on a development set and a test set. As indicated by the relevant coefficients, the method provided by the invention is very accurate and effective in oral speech assessment.

Owner:SHENZHEN EAGLESOUL EDUCATION SERVICE CO LTD

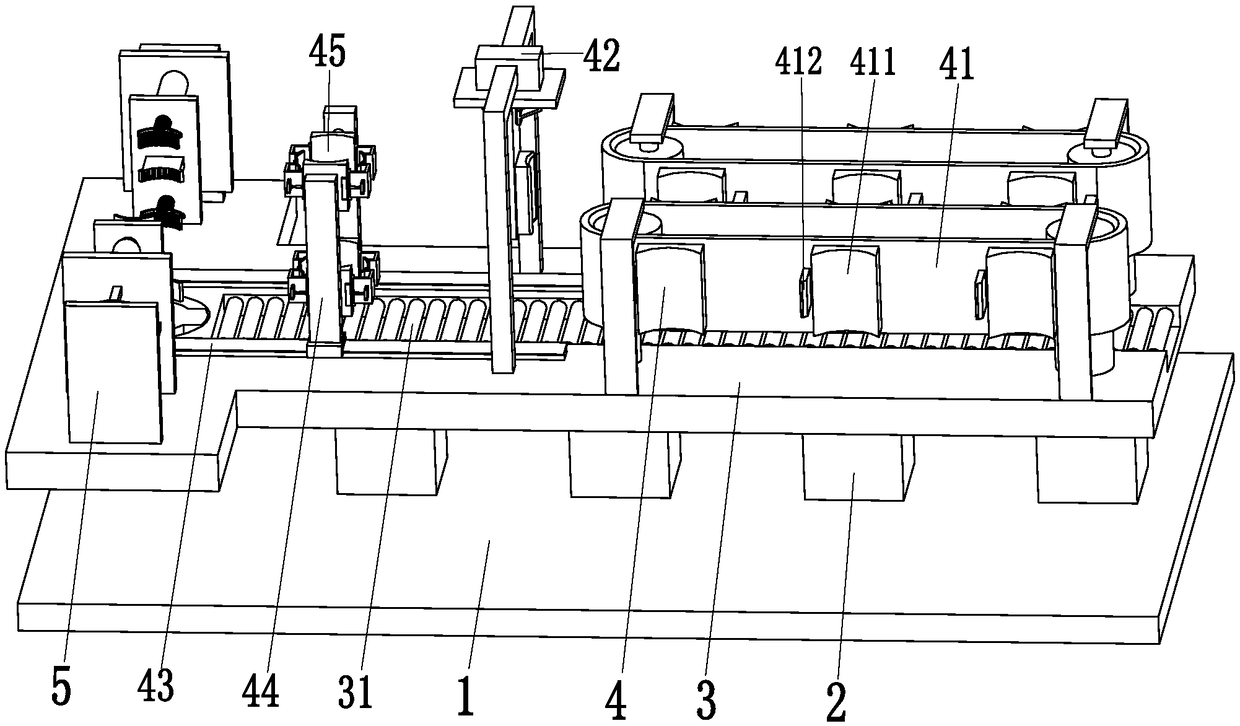

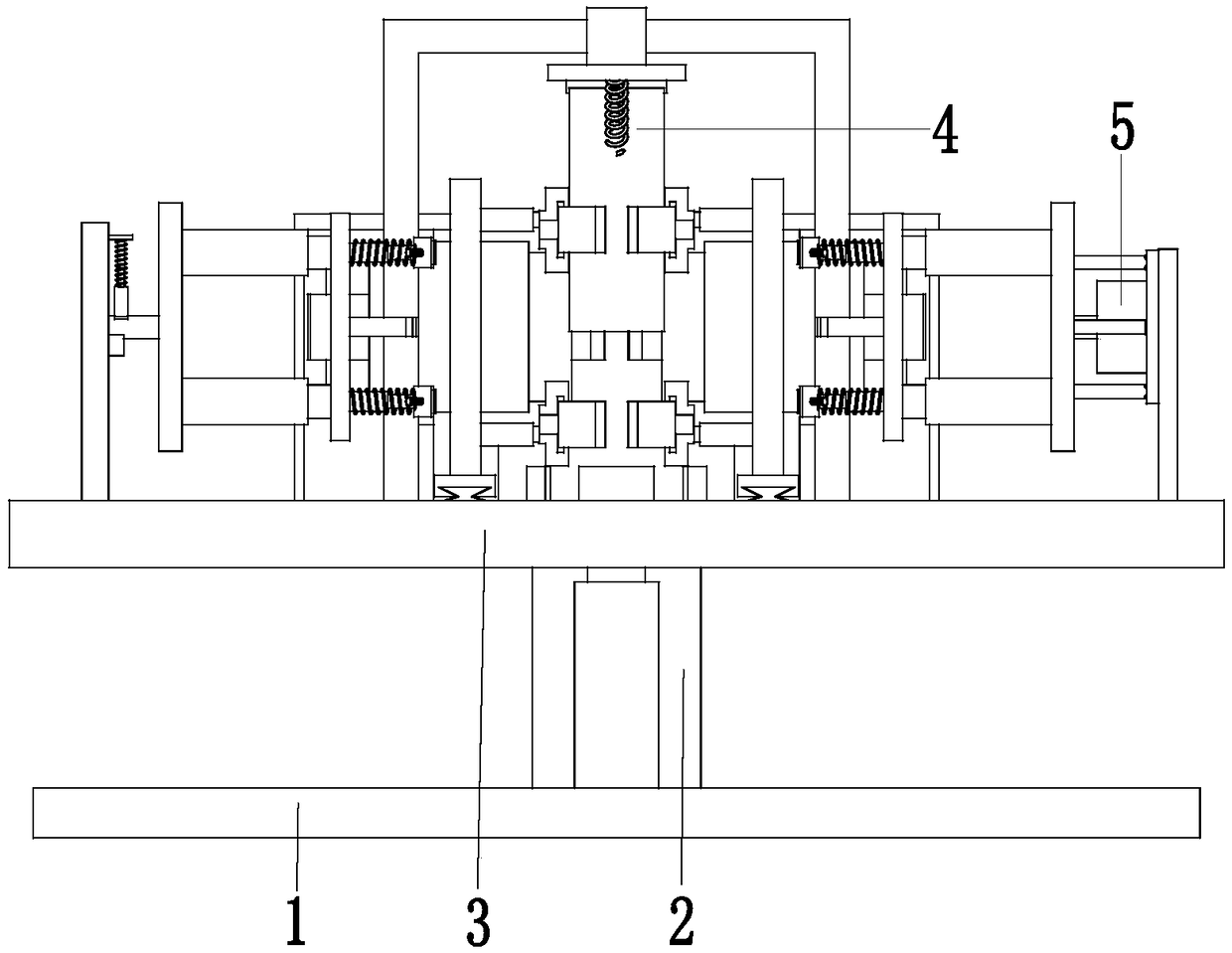

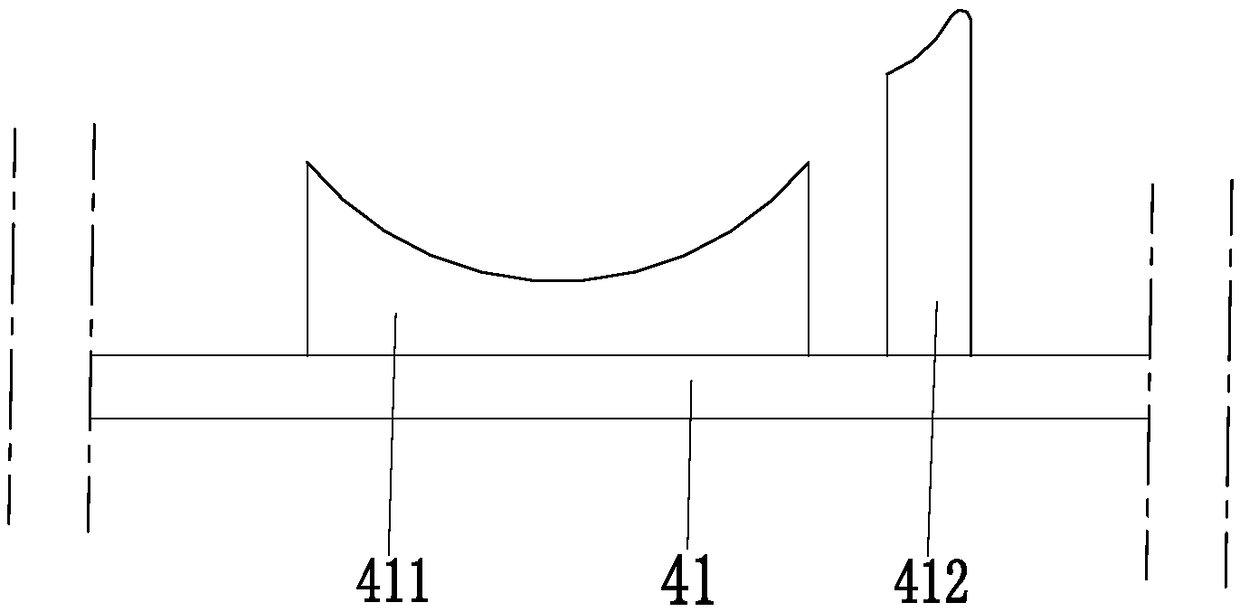

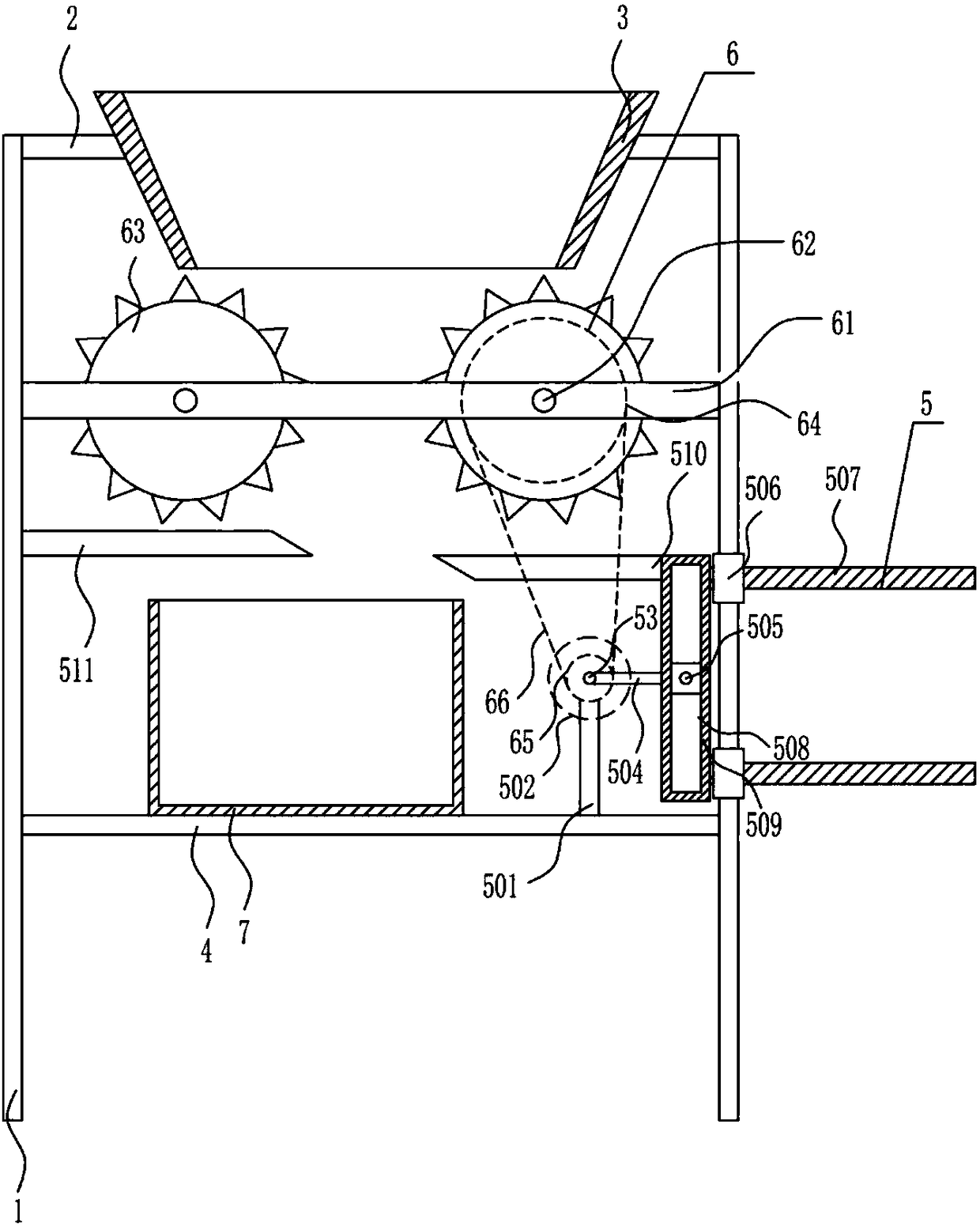

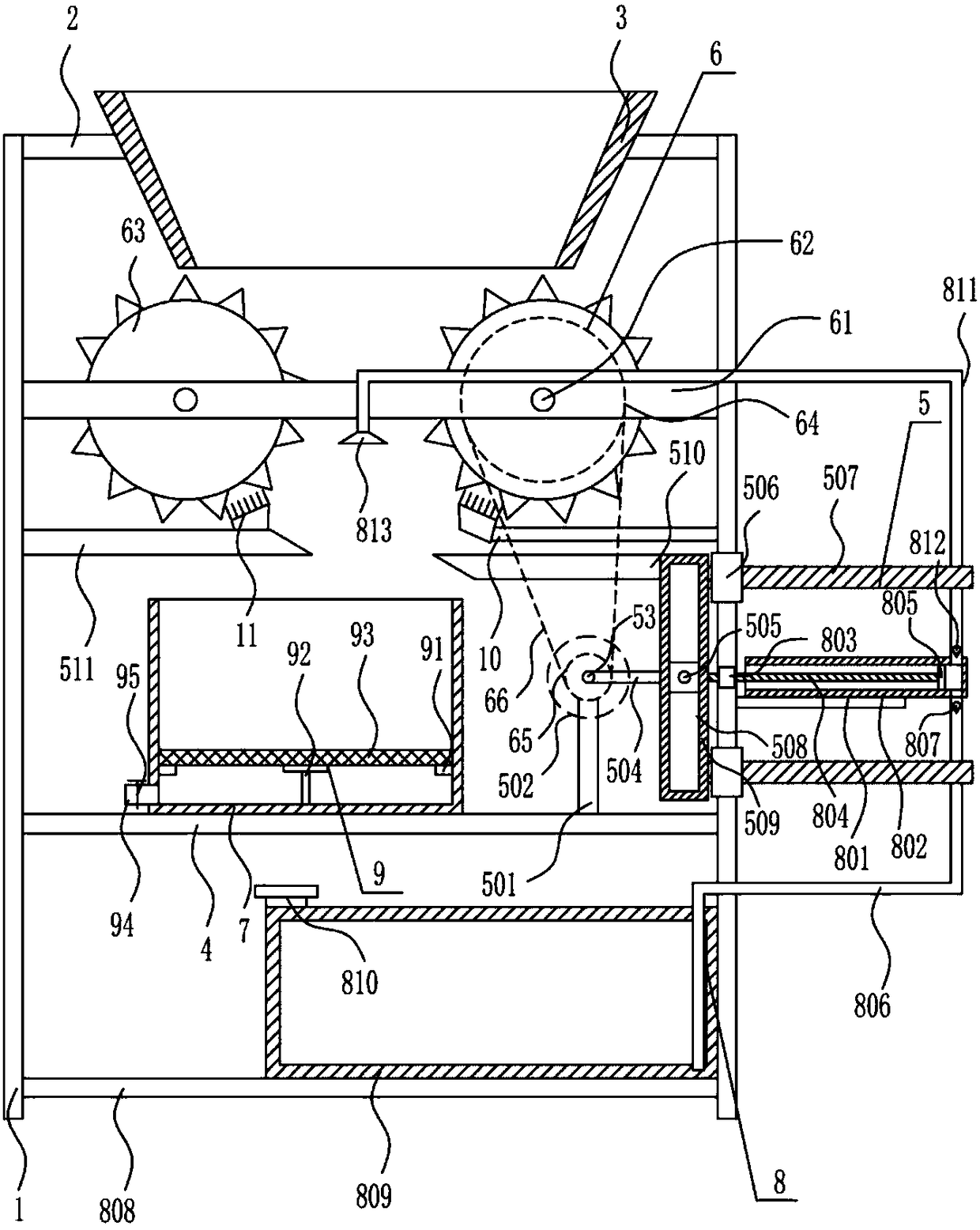

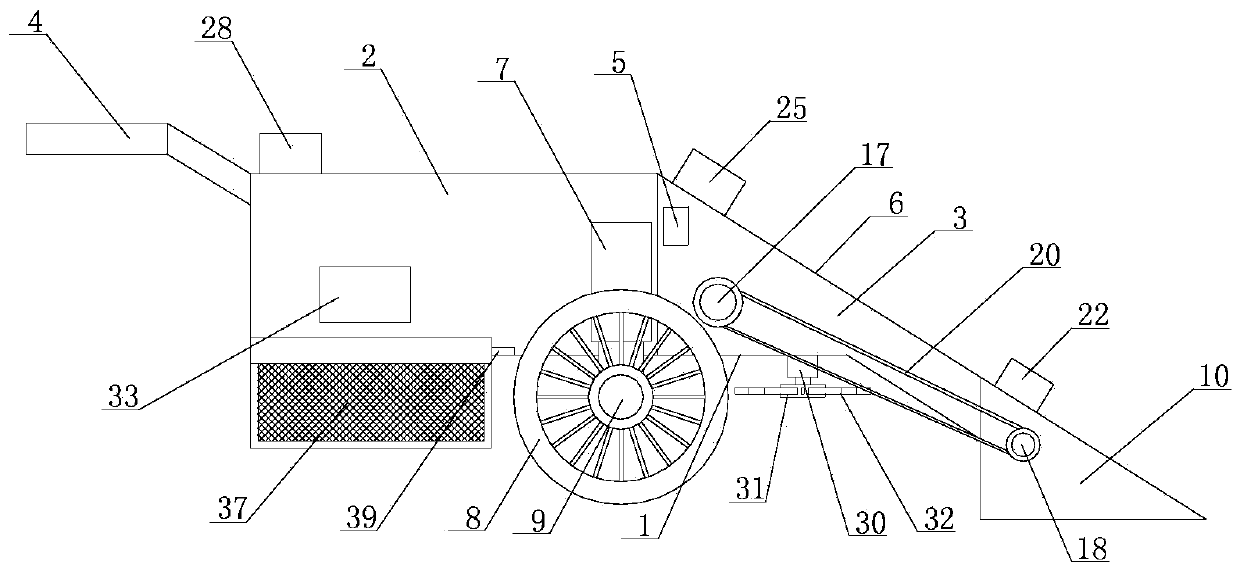

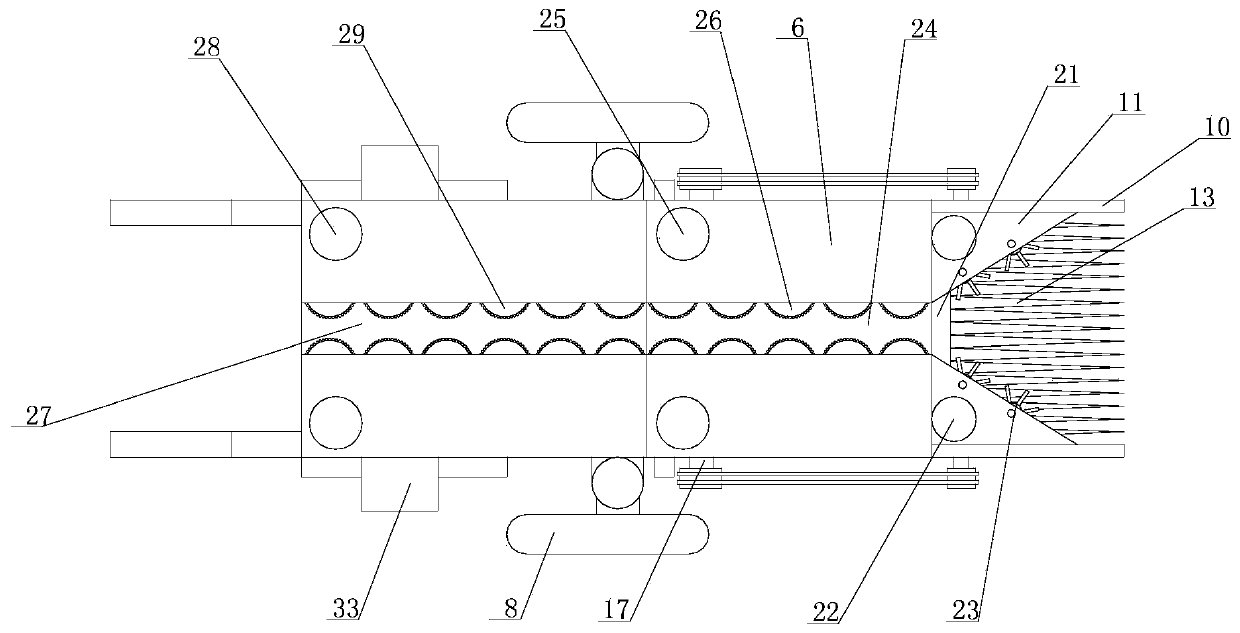

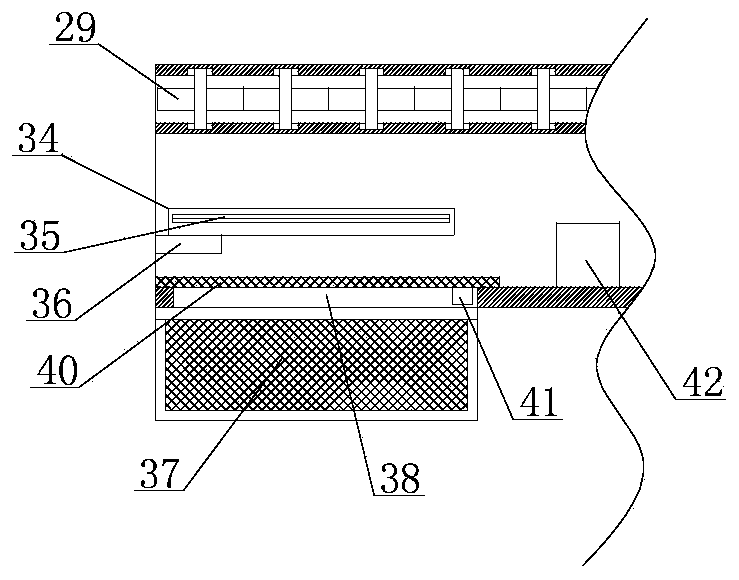

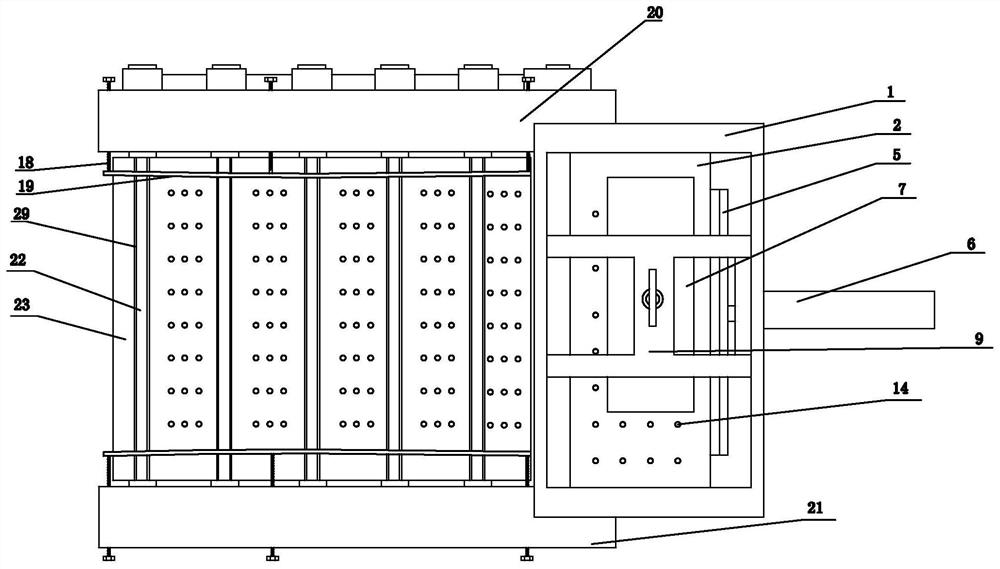

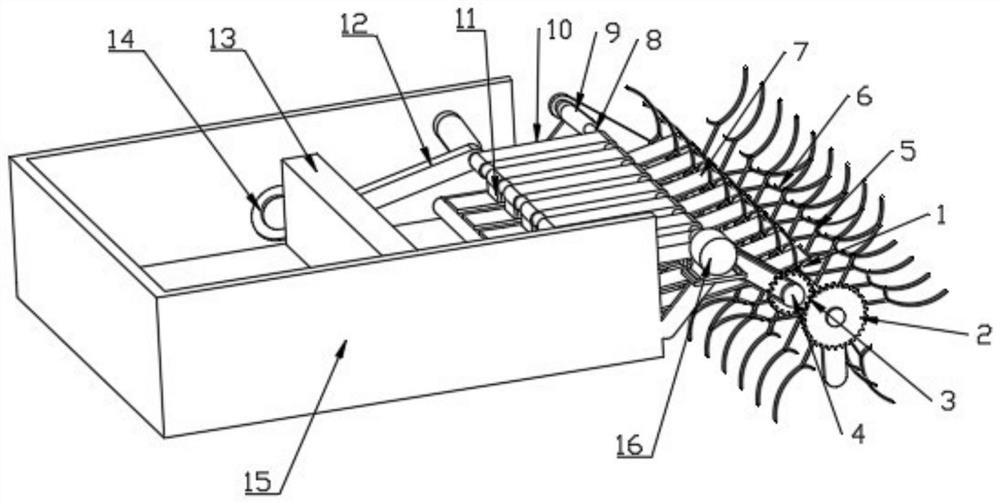

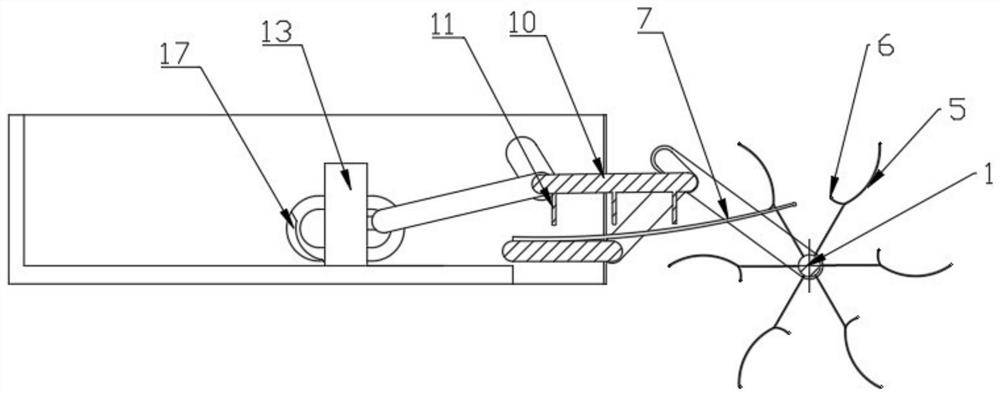

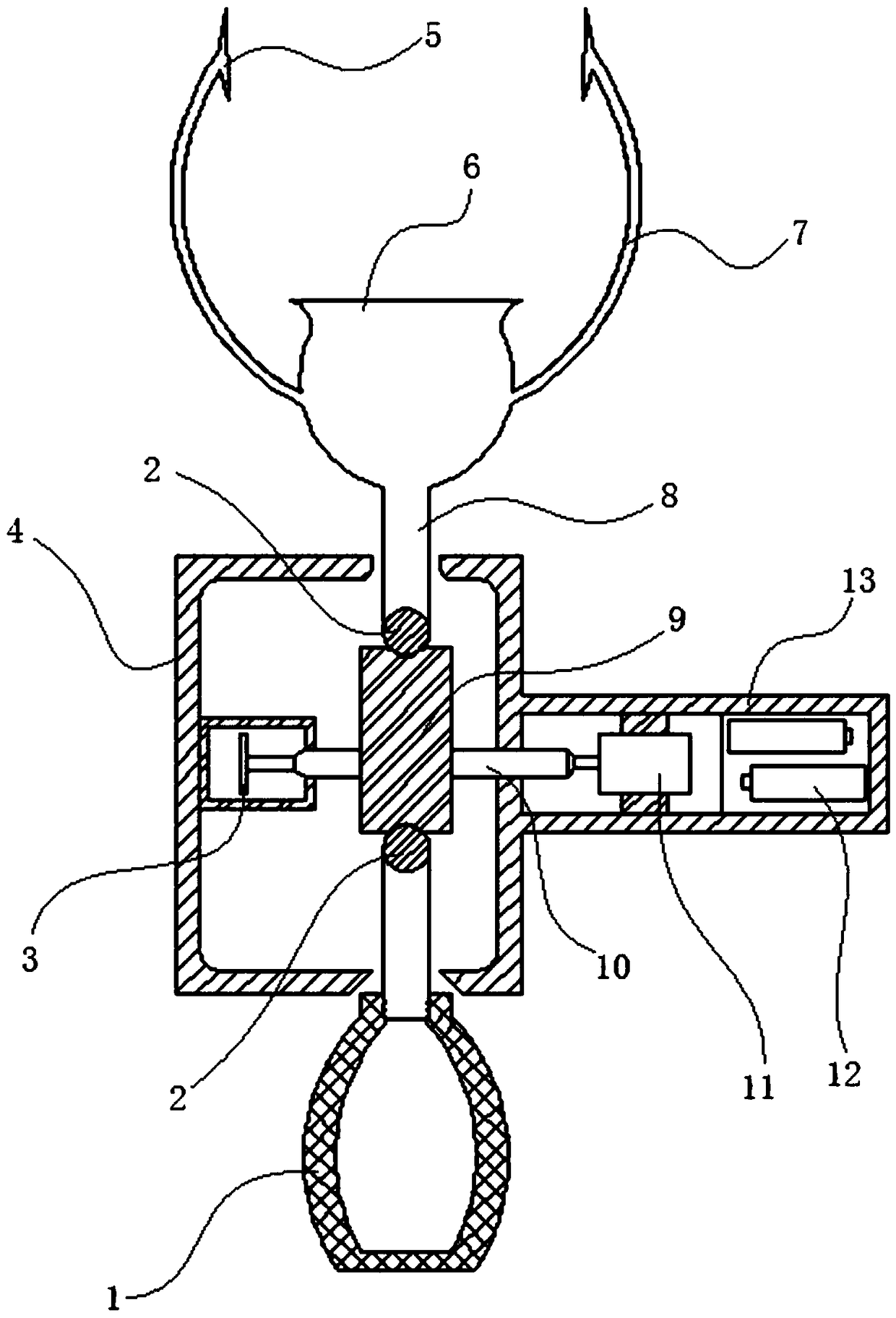

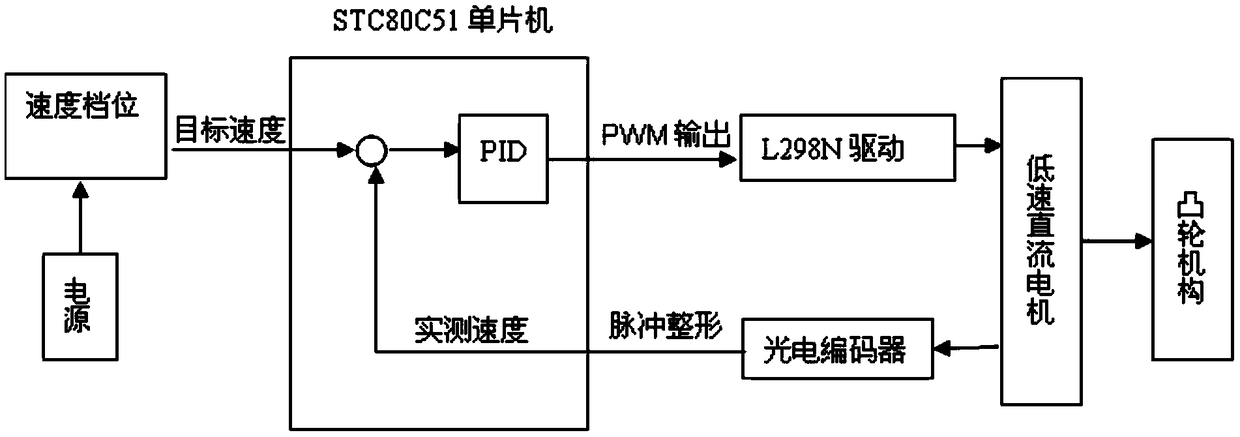

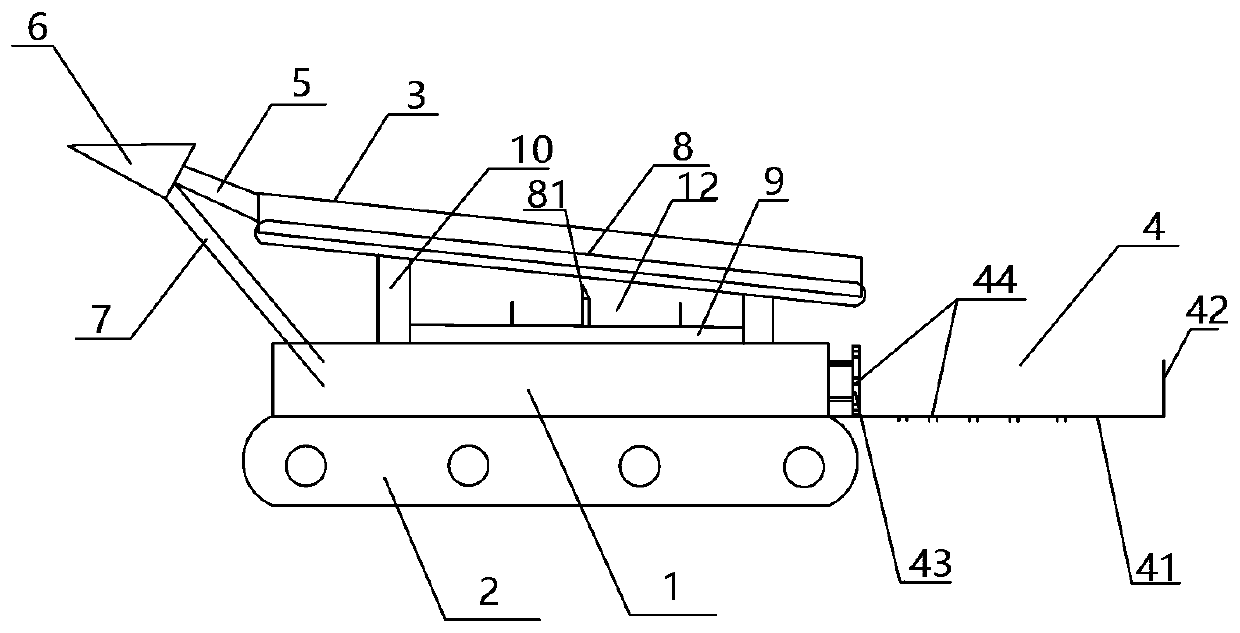

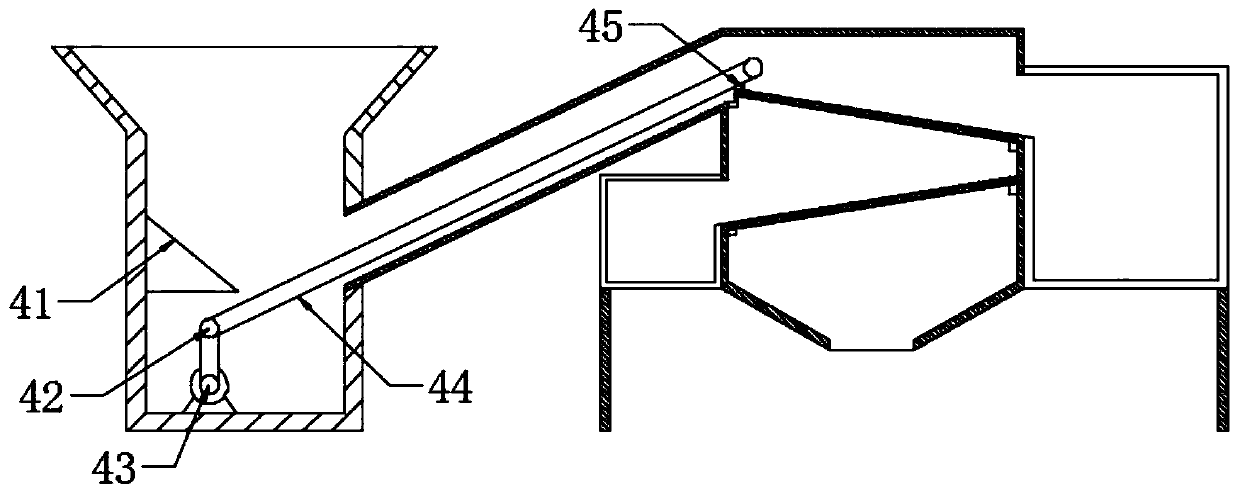

Lithium automatic transmitting and fixing equipment as well as transmitting and fixing process thereof

ActiveCN108750535AImprove teleportation effectShaking will not appearConveyorsGrinding feedersAutomatic controlEngineering

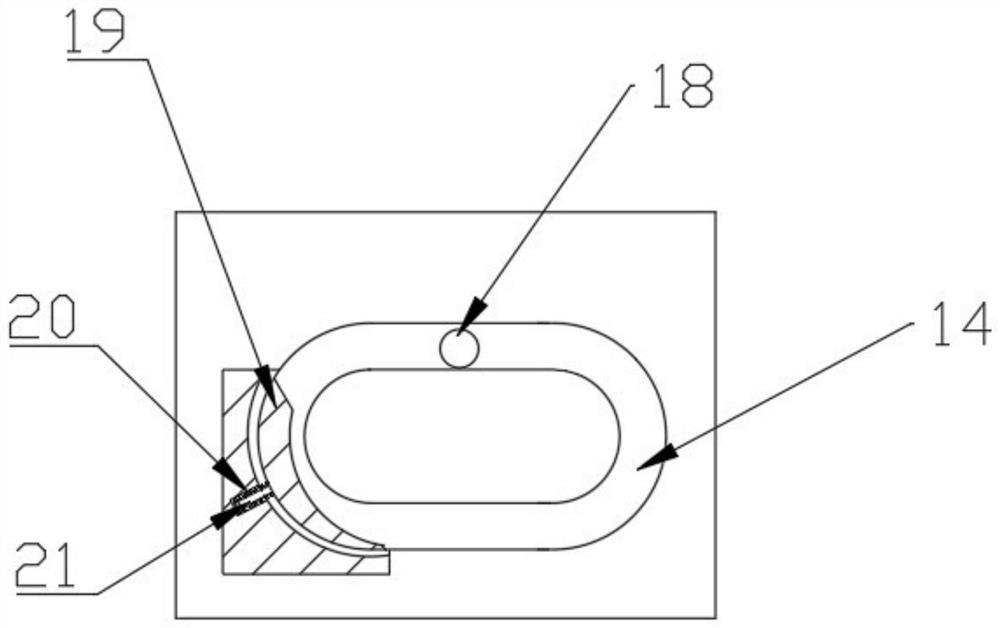

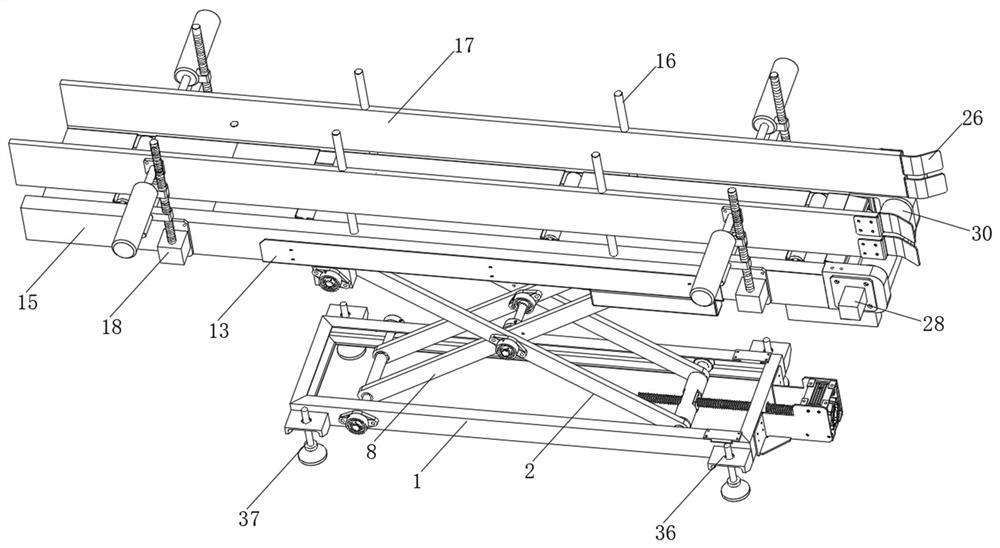

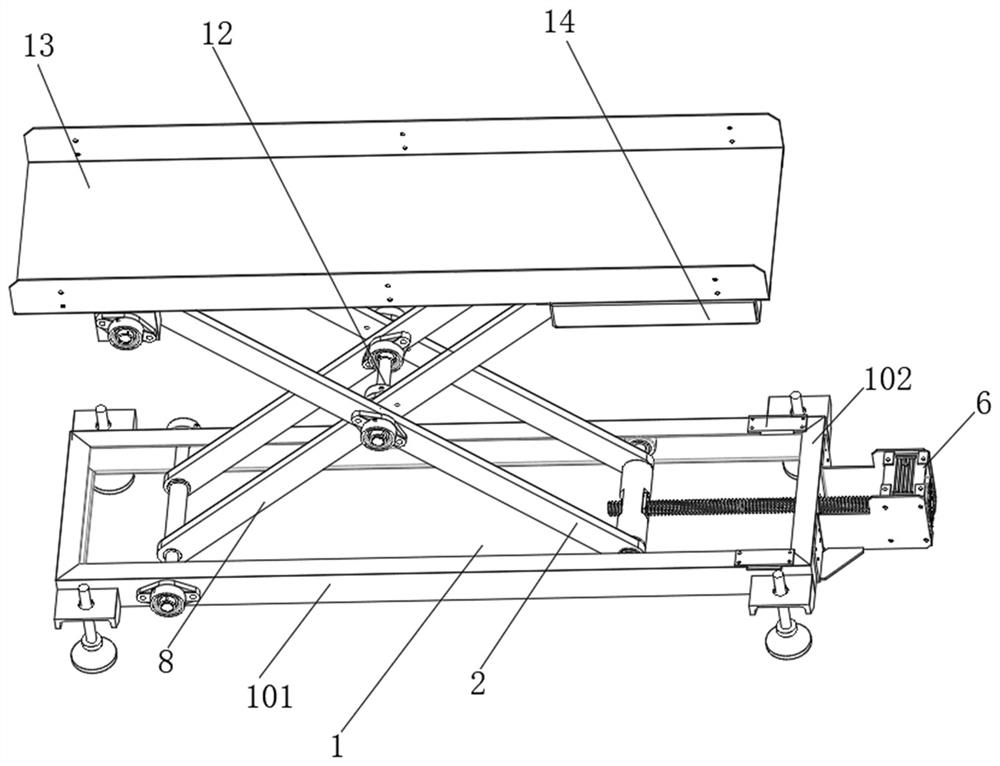

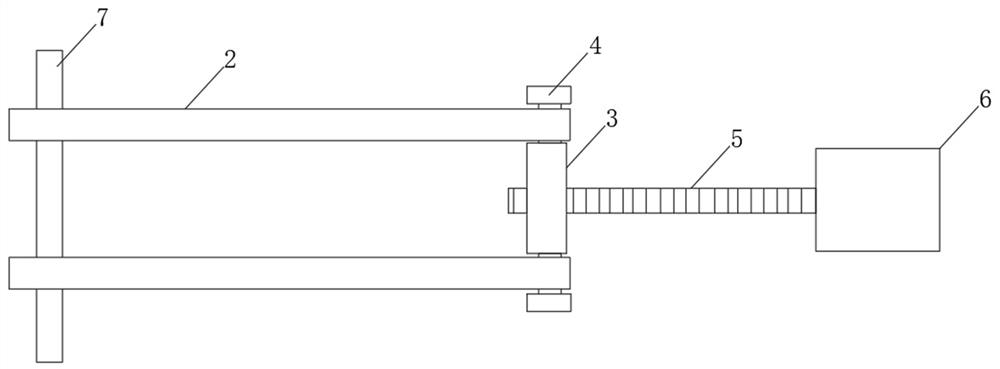

The invention relates to lithium automatic transmitting and fixing equipment as well as a transmitting and fixing process thereof. The lithium automatic transmitting and fixing equipment comprises a supporting bottom plate, supporting columns, a transmitting supporting plate, a transmitting device and a fixing device; a round hole is formed in the middle part of the left end of the transmitting supporting plate; the supporting columns are arranged at the top of the supporting bottom plate uniformly; the transmitting supporting plate is arranged at the top of each supporting column; the transmitting device is arranged at the top of the right end of the transmitting supporting plate; the fixing device is arranged at the top of the left end of the transmitting supporting plate; and the transmitting device comprises a transmitting belt, a limiting mechanism, a transmitting electric sliding block, a transmitting upright column and two transmitting and lamping branched chains. The problems that when the lithium battery needs to be fixed before being polished, the lithium battery cannot be transmitted automatically, omnibearing fixation cannot be conducted when the lithium battery is polished, the lithium battery is waggled when being polished, a negative electrode of the lithium battery needs to be clamped by a special clamp when being polished, the lithium battery cannot be automatically controlled to rotate as well as the placing position of the lithium battery causes deviation are solved.

Owner:领航国创新能源电池技术研究院(北京)有限公司

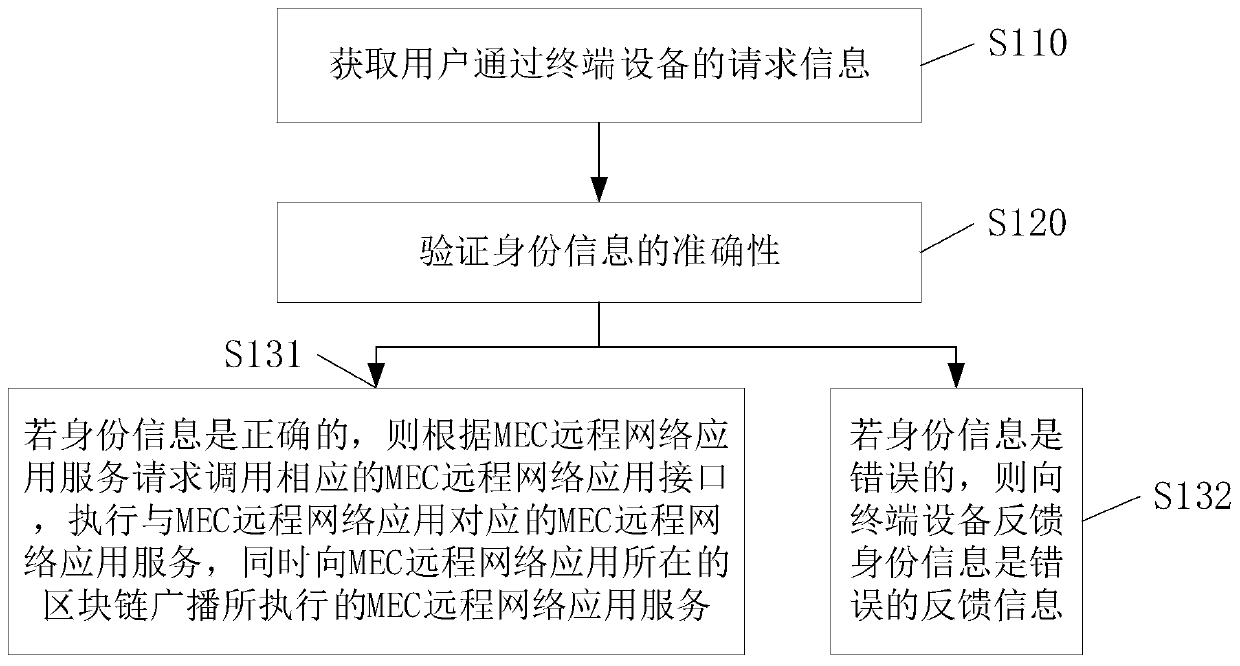

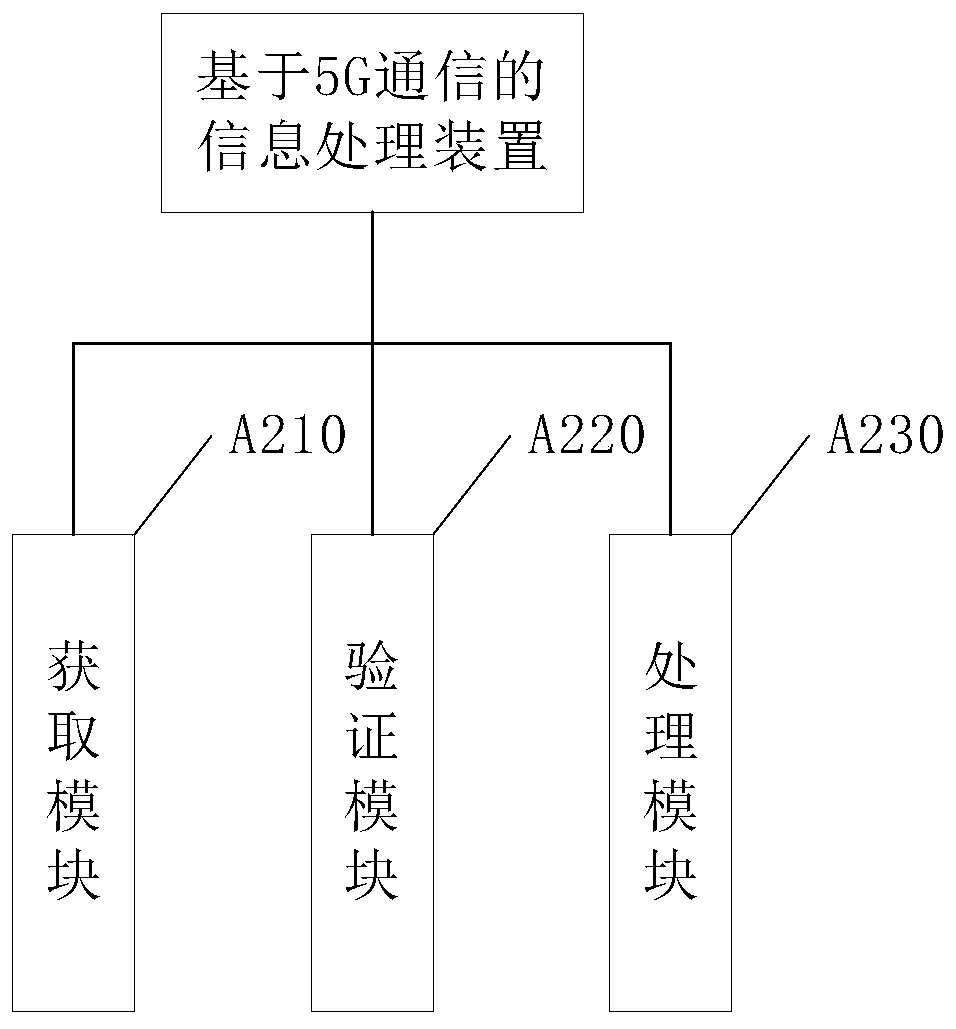

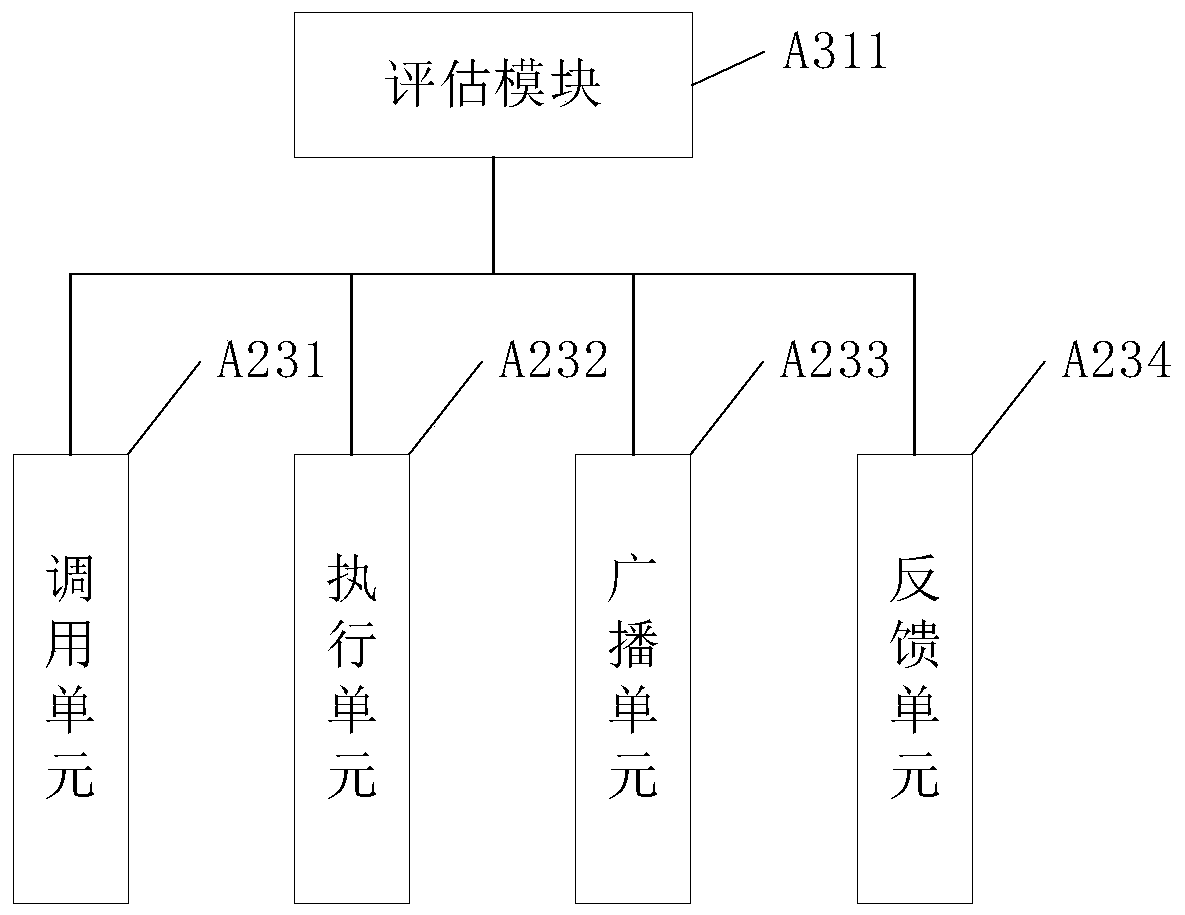

Information processing method and device based on 5G communication and related equipment

InactiveCN110177101ASolve the problem of address concealmentImprove real-time performanceTransmissionInformation processingTerminal equipment

The invention provides an information processing method and device based on 5G communication and related equipment, and the method comprises the following steps: obtaining the request information of auser through terminal equipment, the request information comprising an MEC remote network application service request and identity information; verifying the accuracy of the identity information; ifthe identity information is correct, calling a corresponding MEC remote network application interface according to the MEC remote network application service request, executing an MEC remote network application service corresponding to the MEC remote network application, and broadcasting the executed MEC remote network application service to a block chain where the MEC remote network application is located; and if the identity information is wrong, feeding back feedback information that the identity information is wrong to the terminal equipment. According to the invention, the address hidingproblem of the mobile equipment in the network can be solved, the real-time distribution and transmission capability of the server service can be improved, and the congestion in the core network can be effectively inhibited.

Owner:SICHUAN VOCATIONAL COLLEGE OF SICHUAN

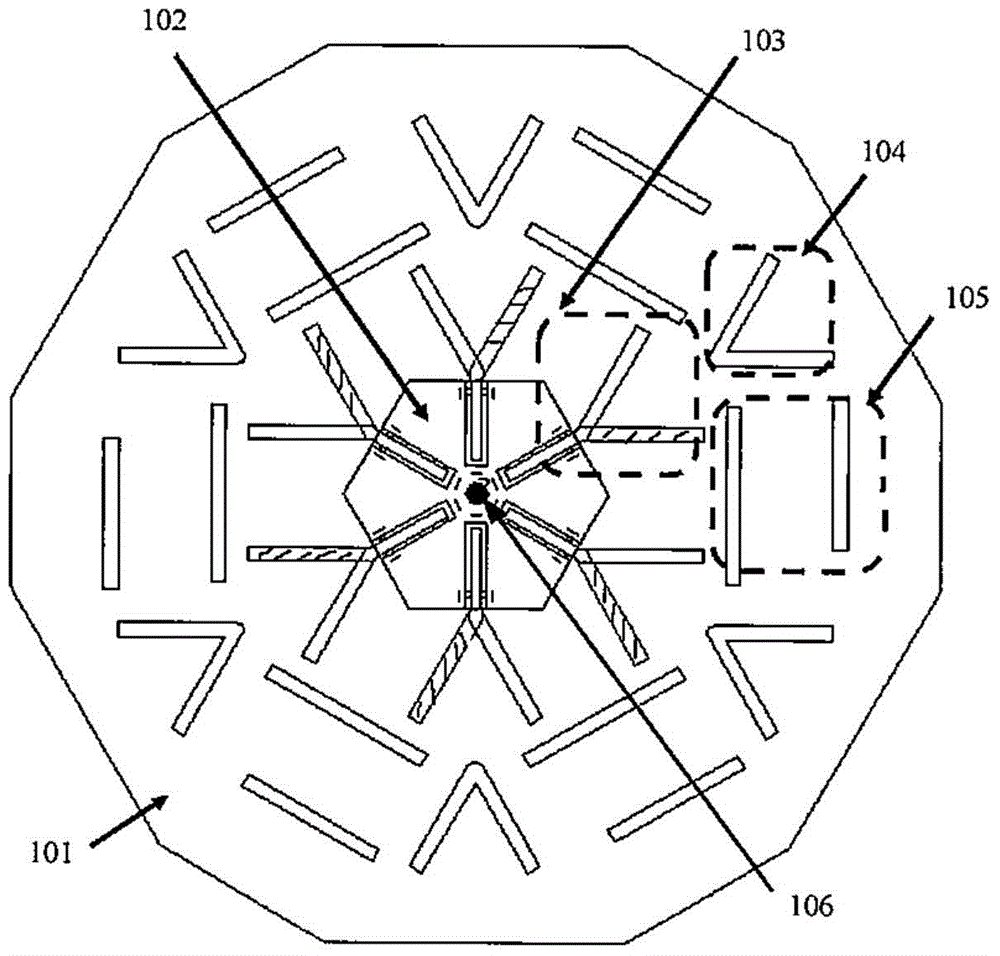

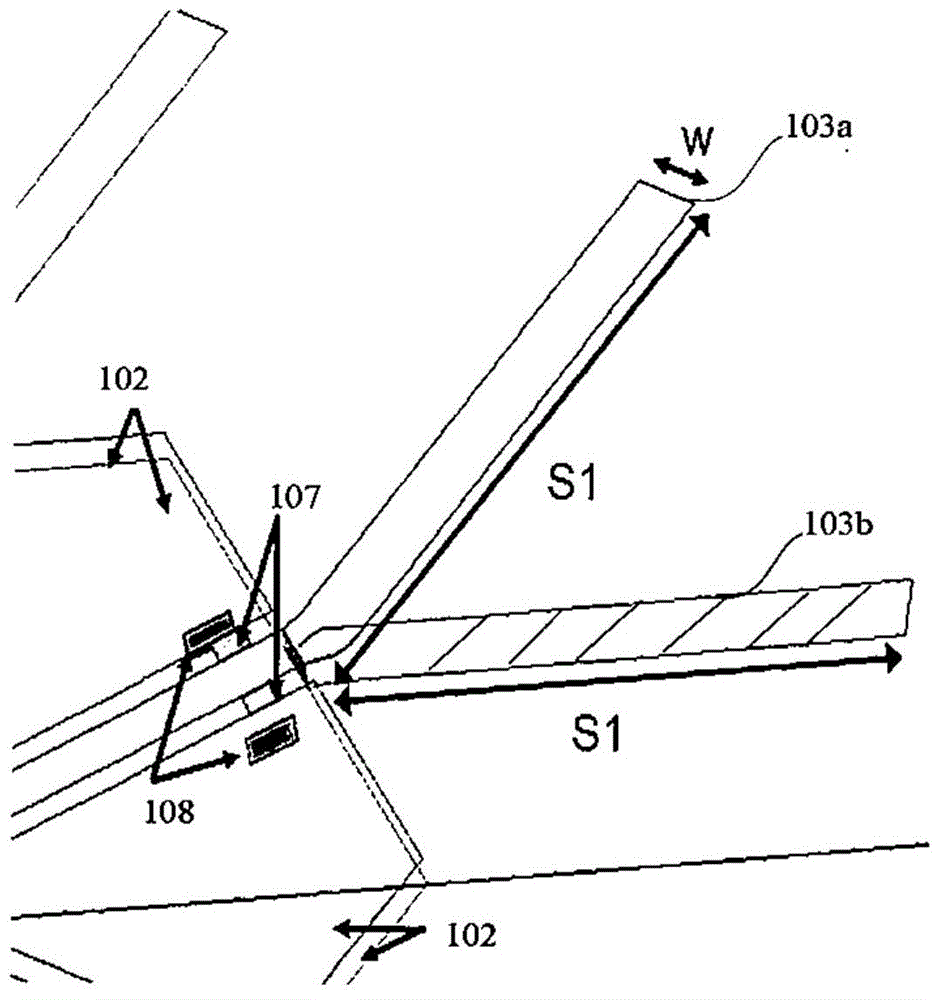

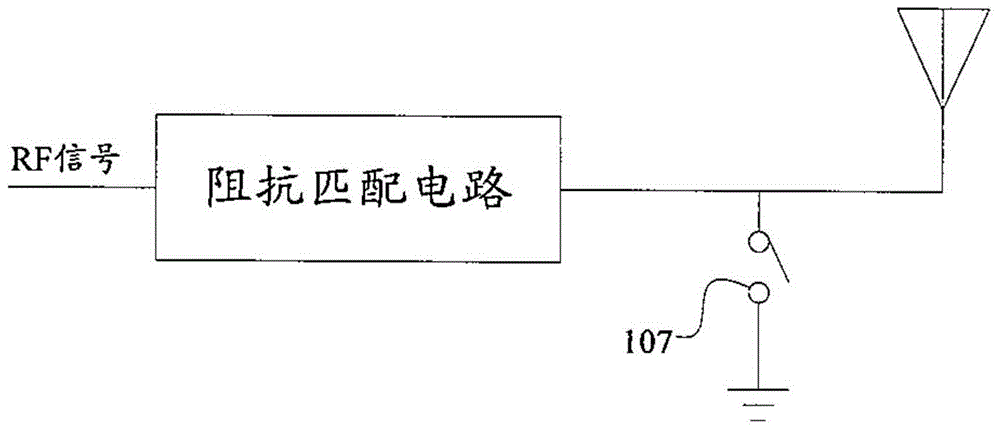

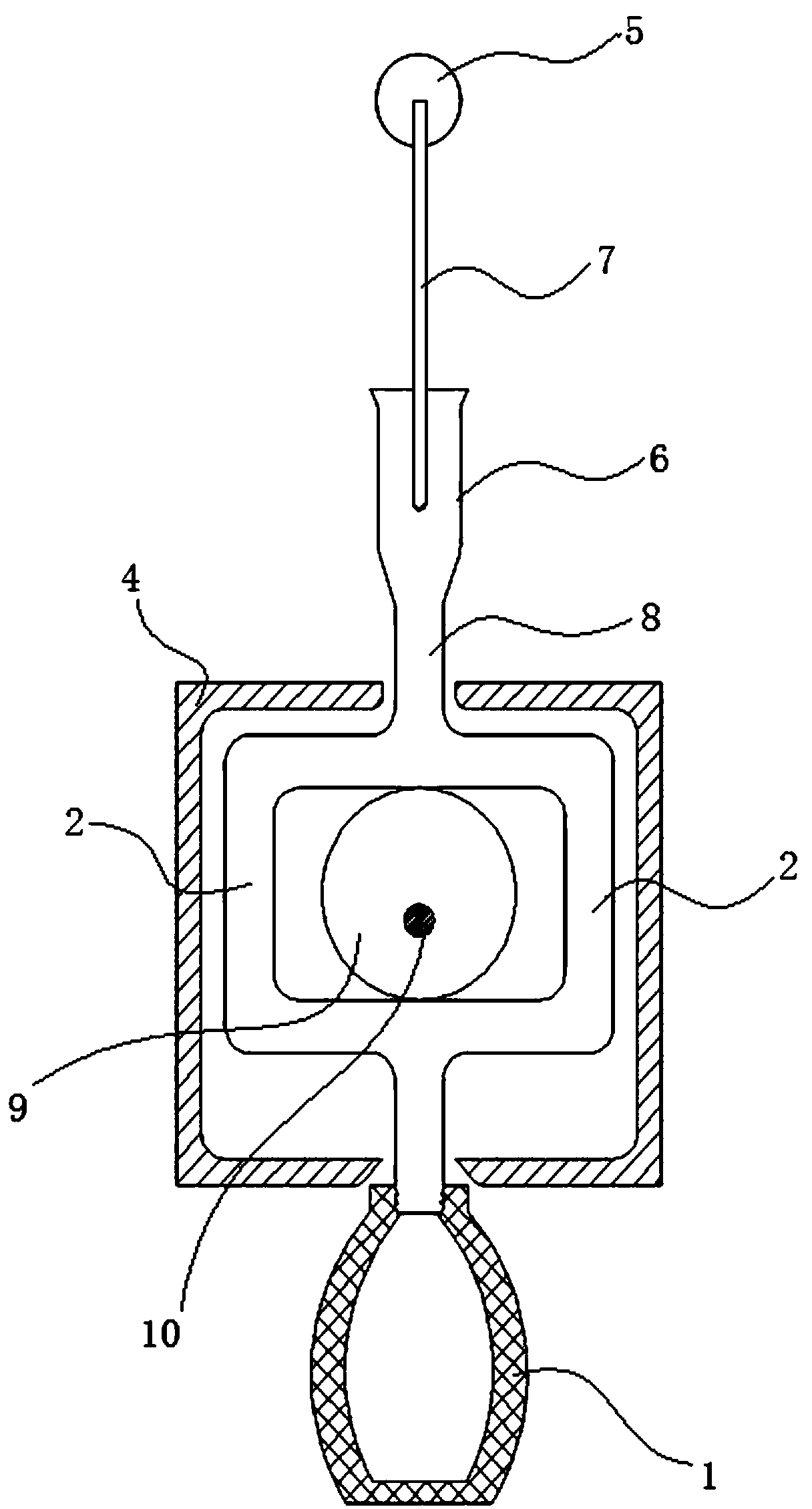

Planar antenna having reconfigurable radiation pattern

ActiveCN105576356AImprove teleportation effectReduce volumeRadiating elements structural formsAntenna earthingsElectricityImpedance matching

The invention provides a planar antenna having a reconfigurable radiation pattern. The planar antenna comprises a substrate, a grounding plate, a plurality of driving units, and a plurality of parasitic element groups. The grounding plate is disposed on the central area of the substrate, and can work in a main reflector mode. The plurality of driving units are arranged symmetrically on the periphery of the grounding plate in a radial direction. Each of the plurality of parasitic element groups comprises a director and an emitter, and the directors and the emitters are disposed on the outer side of the substrate according to the positions of the driving units. The antenna provided by the invention has advantages of small size, high production precision, low costs, simple feed network, good impedance matching performance, and high RF energy transmission capability.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

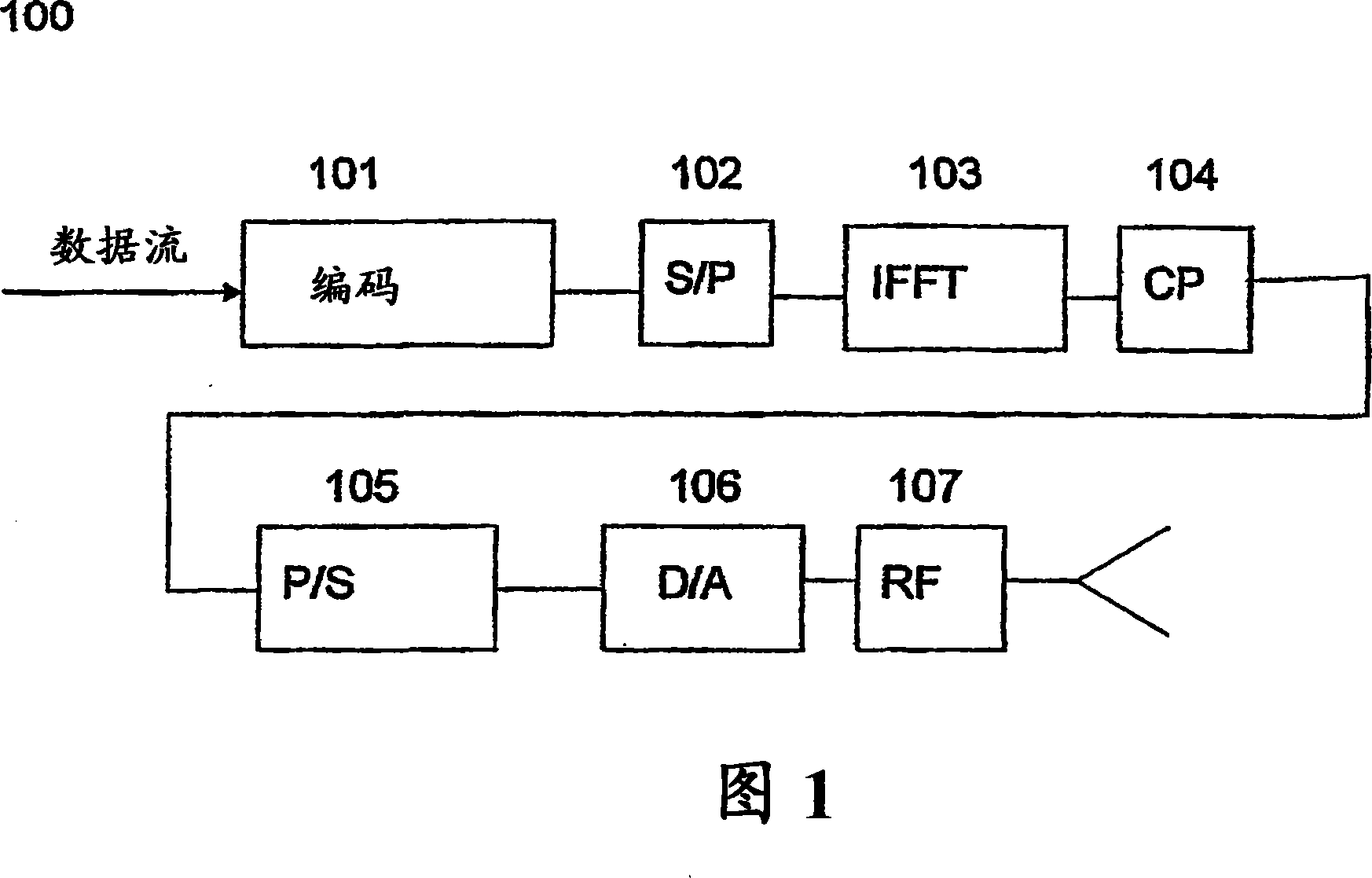

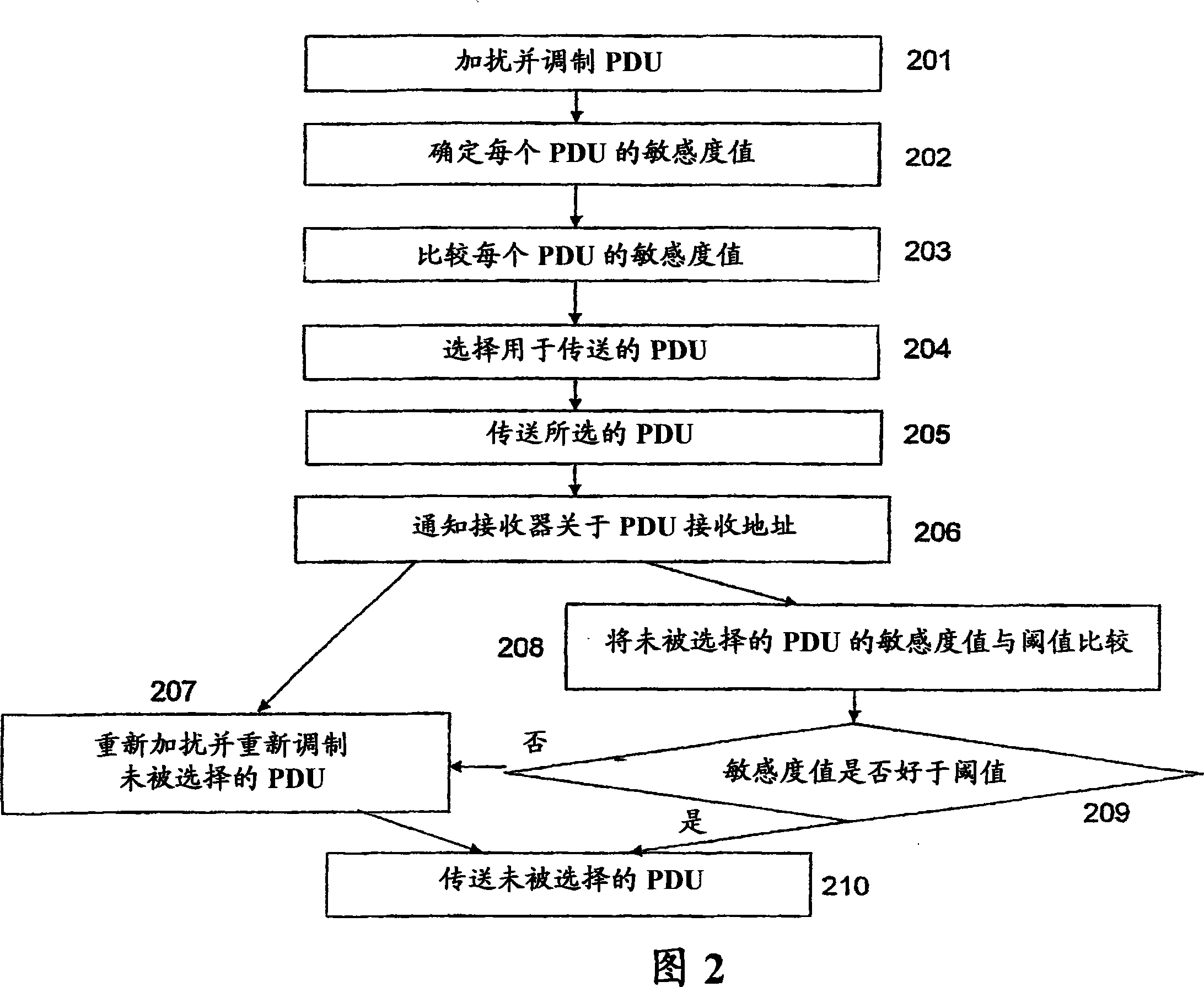

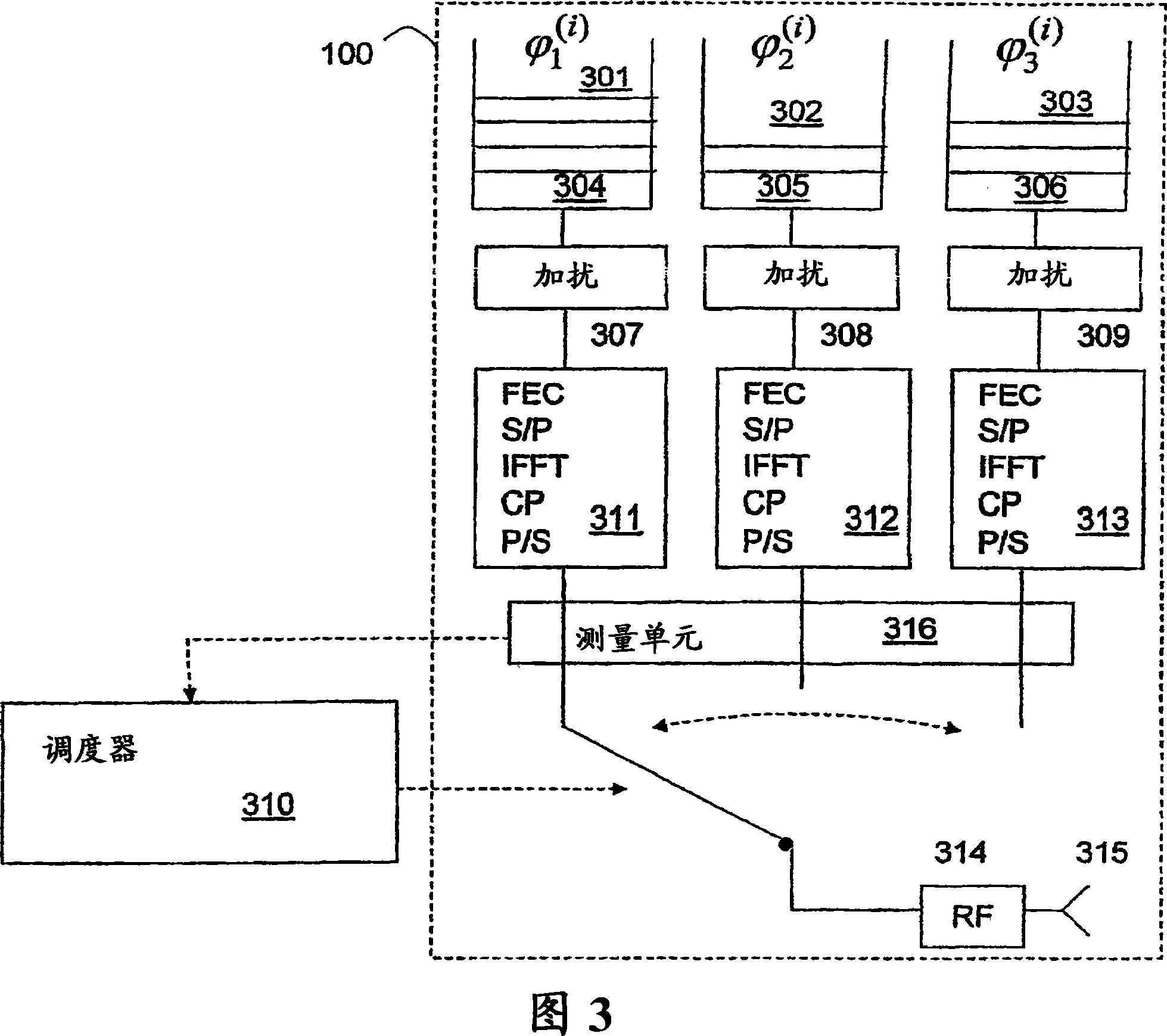

Transmitter device and method for transmitting packet data units in communication system

InactiveCN101120563AImprove teleportation effectReduce errorsMulti-frequency code systemsTransmitter/receiver shaping networksCommunications systemPeak value

Owner:TELEFON AB LM ERICSSON (PUBL)

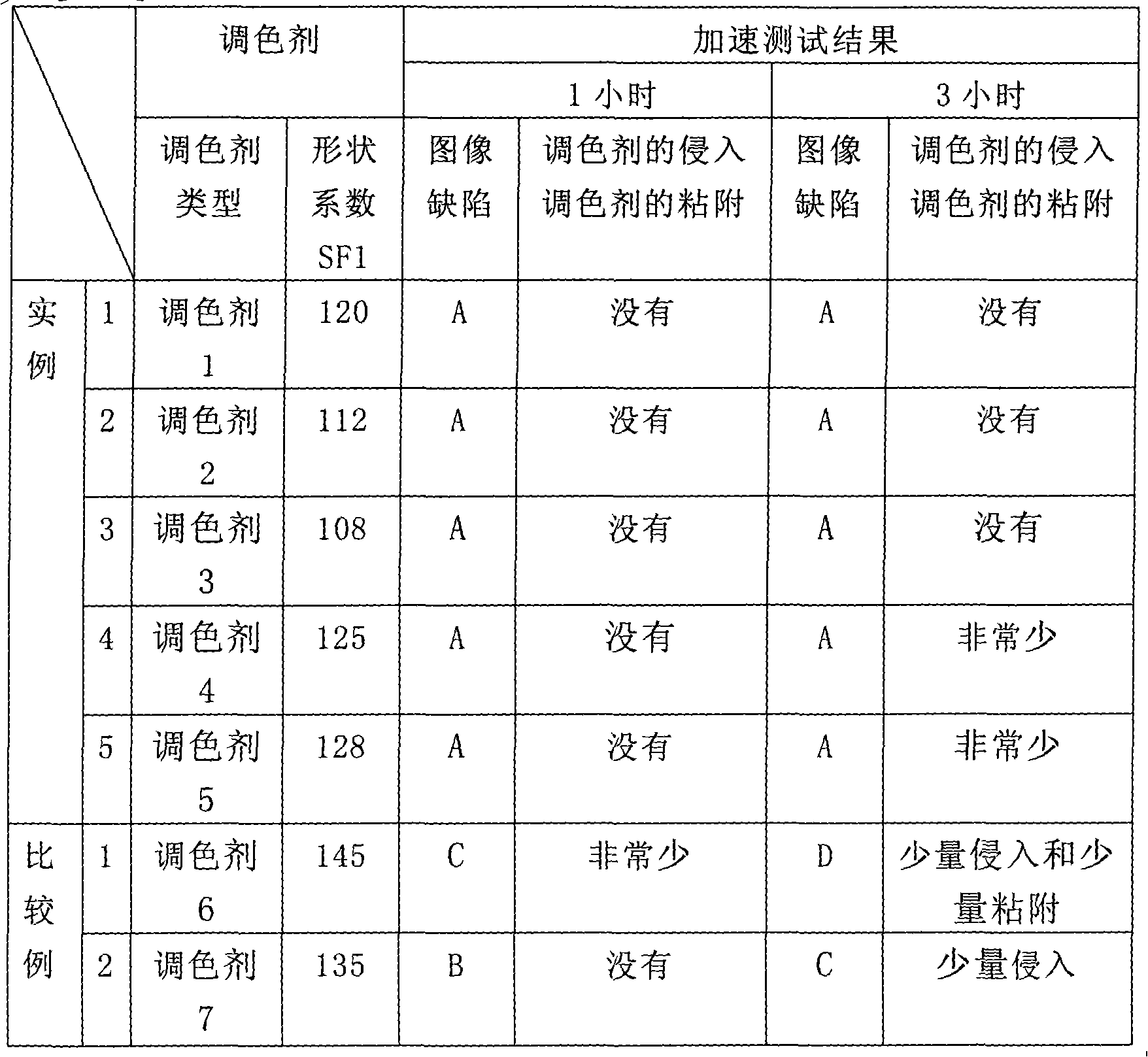

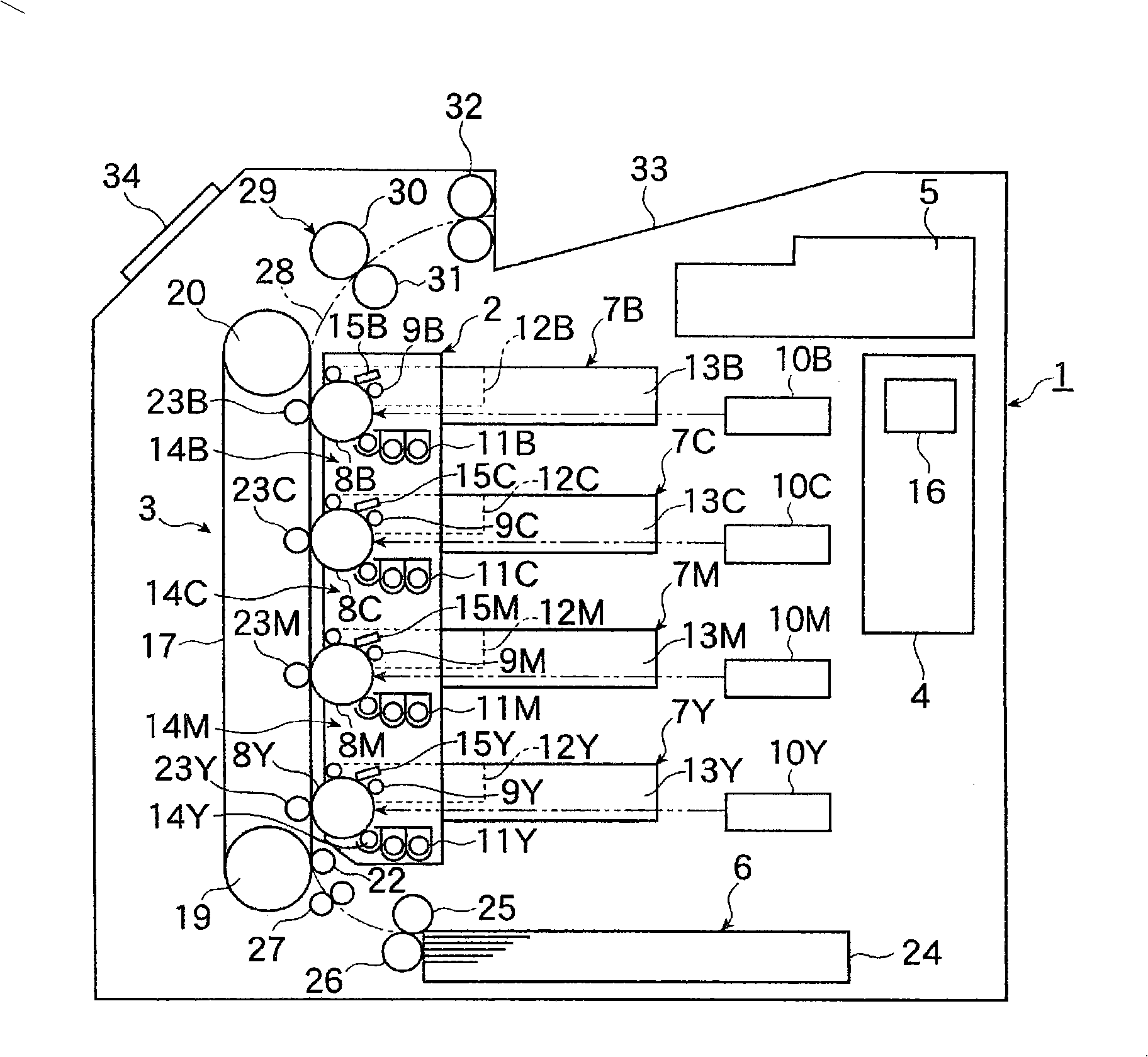

Toner cartridge

ActiveCN101290497APrevents toner aggregation and toner stickingReduce liquidityElectrographic process apparatusDevelopersEngineeringMechanical engineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

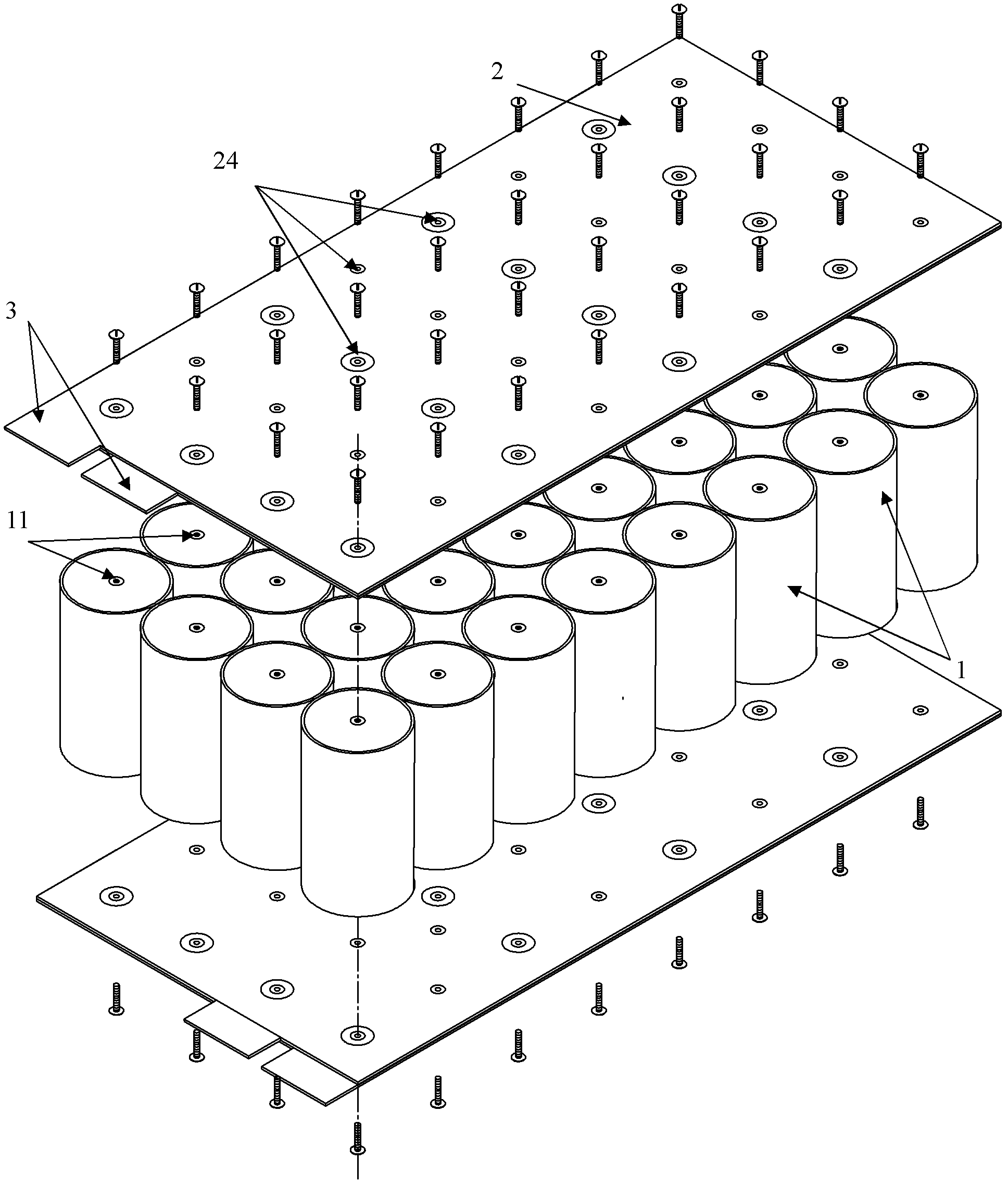

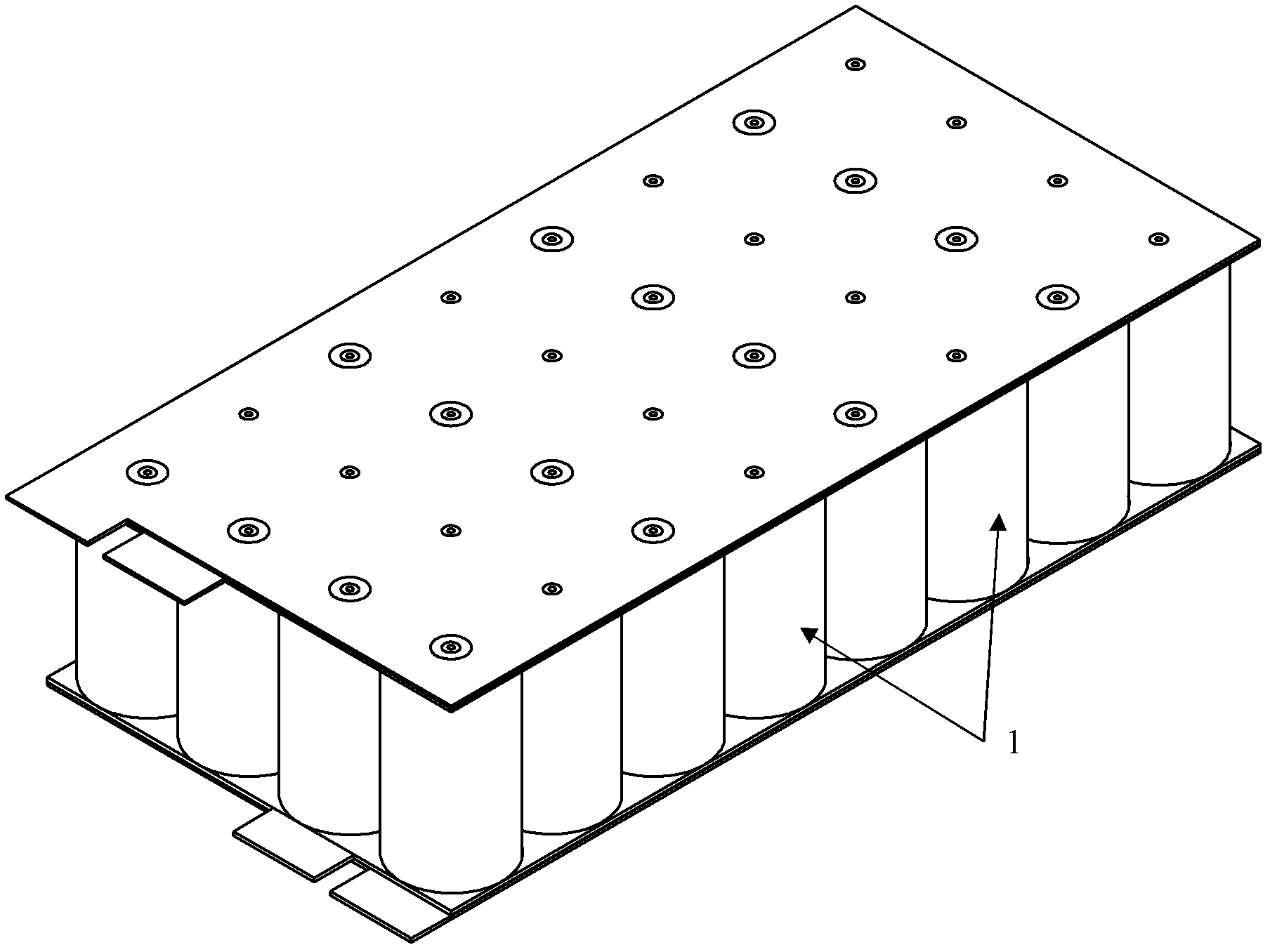

Capacitor unit

ActiveCN102683024AEasy to assembleEasy maintenanceMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceBusbar

The invention provides a capacitor unit which is invented for solving the problems of low integration, different maintenance, large inductance and the like in the prior art. A plurality of capacitor monomers are distributed into a capacitor array, an upper composite busbar and a lower composite busbar are covered on the upper side and the lower side of the capacitor array, electrode sheets are led out on the same sides of the upper composite busbar and the lower composite busbar, a terminal board is made of insulation materials and arranged on the side where the electrode sheets are led out on the composite busbars, and an inserting lead-out terminal is installed on the terminal board and electrically connected with the electrode sheets. The capacitor unit adopts an integrated structure and is convenient to assembly, maintain and use. Lead inductance is low, capacitors are evenly distributed, and the capacitor unit can be manufactured in batch easily.

Owner:中信科佳信(北京)电气技术研究院有限公司

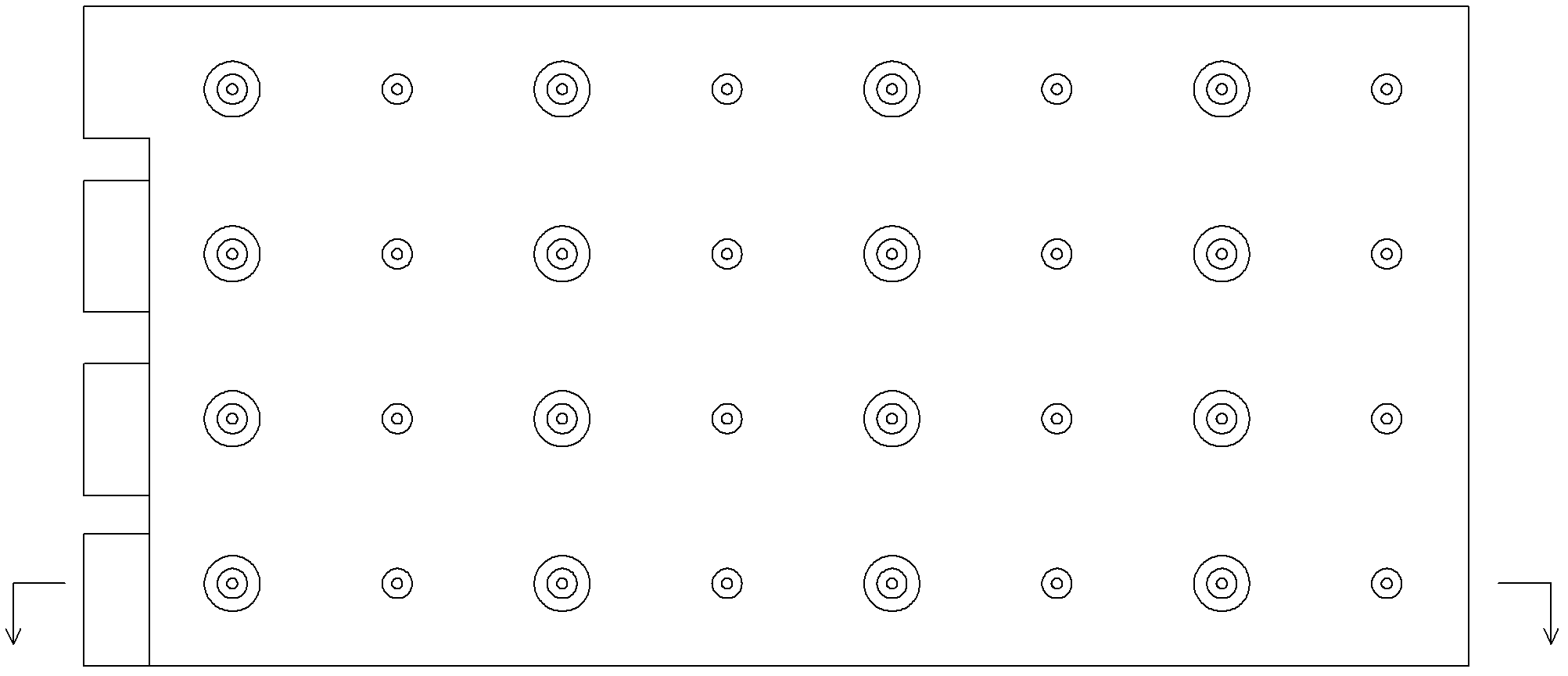

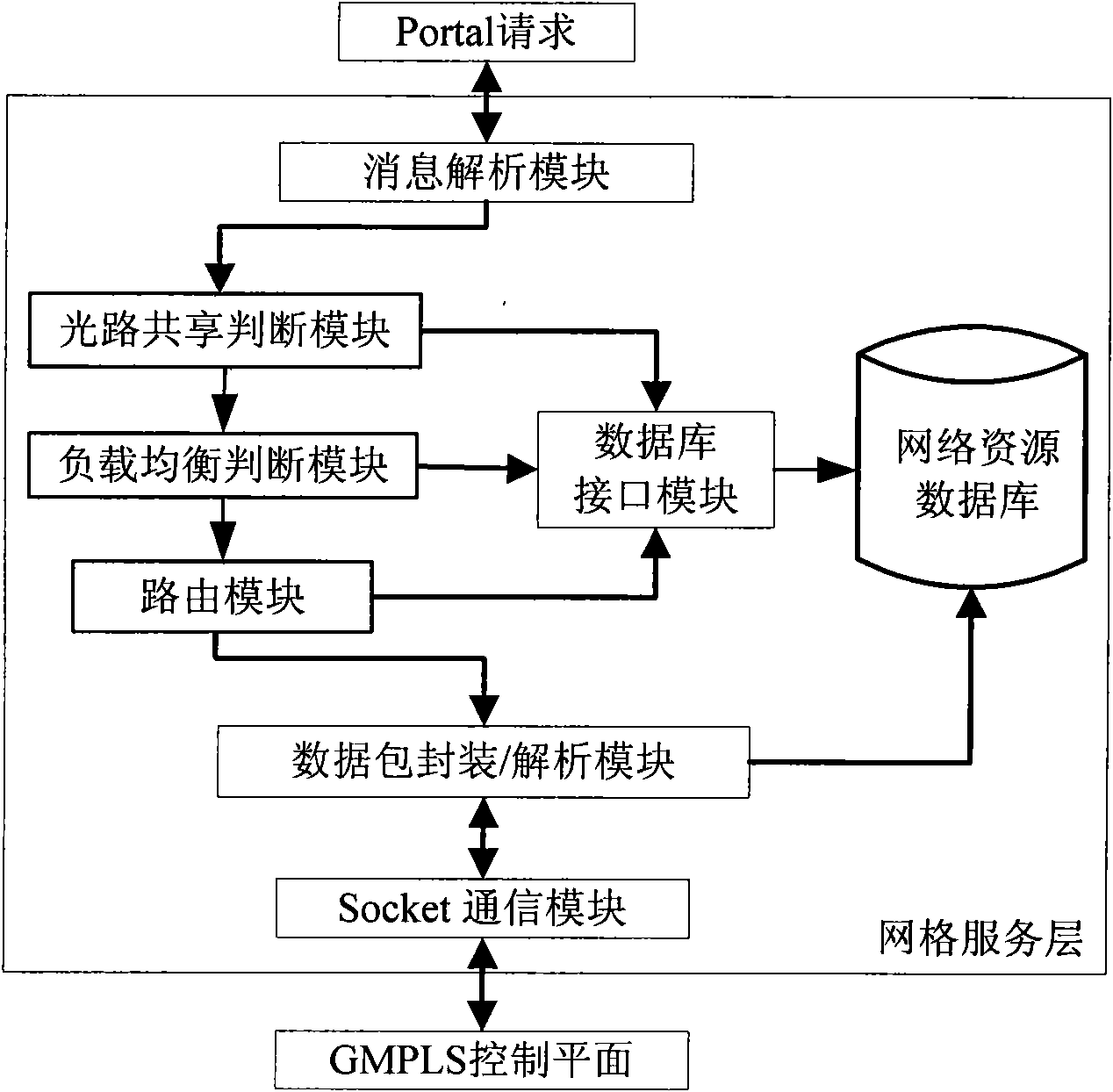

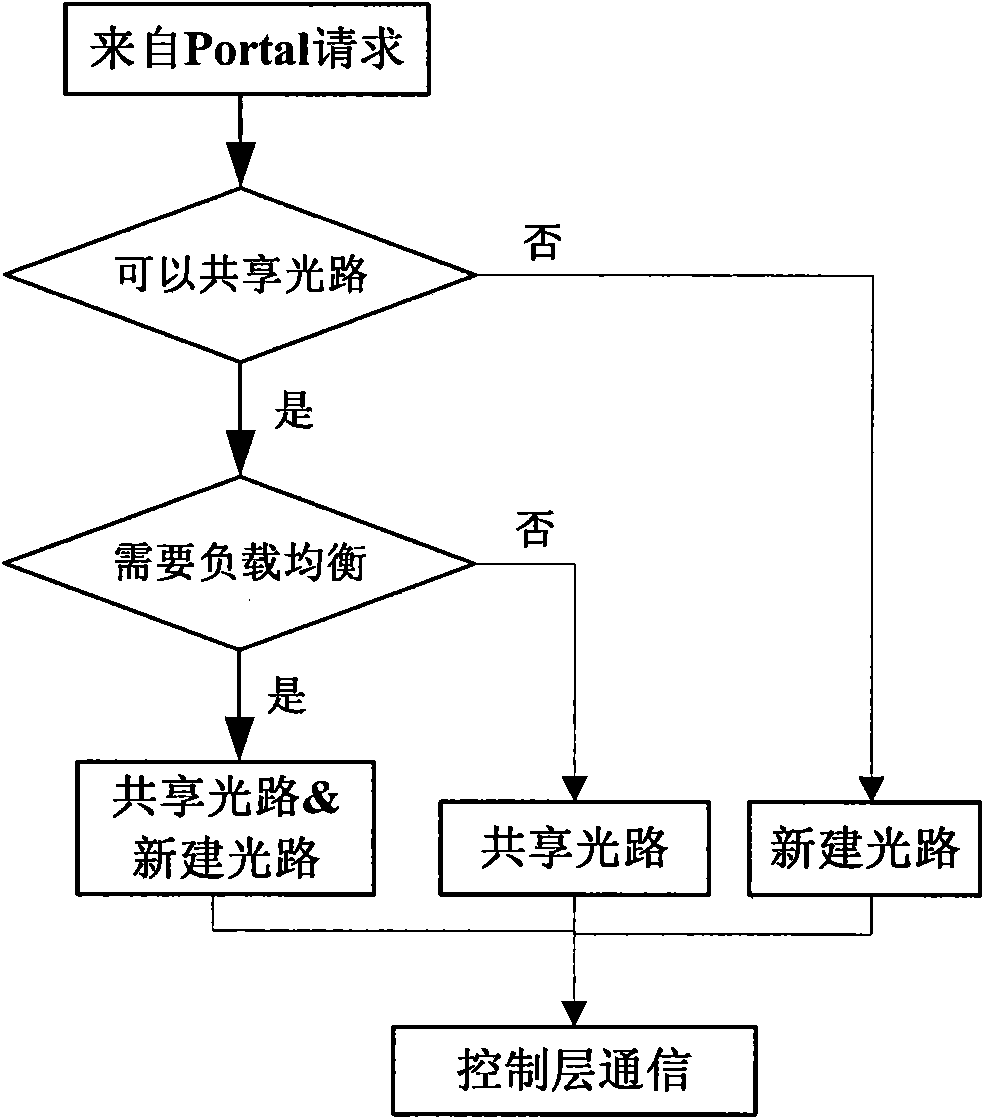

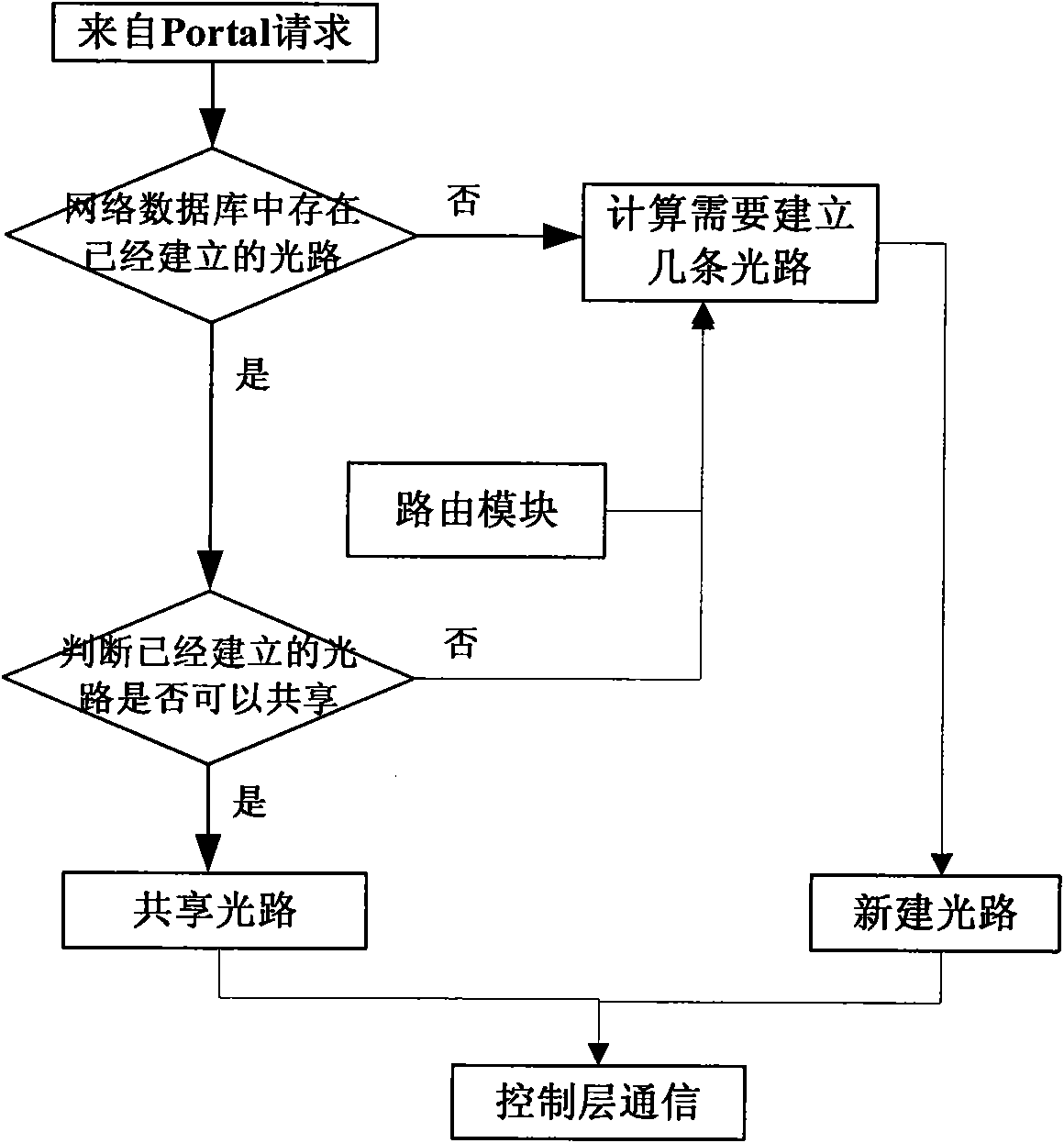

Method and device for dispatching load balancing network resource based on light path share

InactiveCN101621530AIncrease profitImprove teleportation effectMultiplex system selection arrangementsData switching networksControl layerTransmission performance

The invention discloses a method and a device for dispatching load balancing network resource based on light path share. The method comprises the following steps: receiving work request from an application layer, and extracting optical link resource information required by the work; acquiring light path share information from a network resource database to judge whether the optical link can be shared; further judging whether the flow rate exceeds a set threshold value for the optical link which can be shared, and judging that the optical link is a shared light path if the flow rate does not exceed the set threshold value; otherwise, judging that the optical link cannot be shared; if the number of the shared light path cannot meet the requirement of the work, establishing the optical link according to the requirement, and updating the corresponding information in the network resource database; and communicating with a control layer to deploy the optical network by the control layer. The method and the device can optimize the dispatch of the light resource in the optical network, and flexibly realize intelligent control for the light resource so as to improve the transmission performance of the whole optical network.

Owner:BEIJING UNIV OF POSTS & TELECOMM

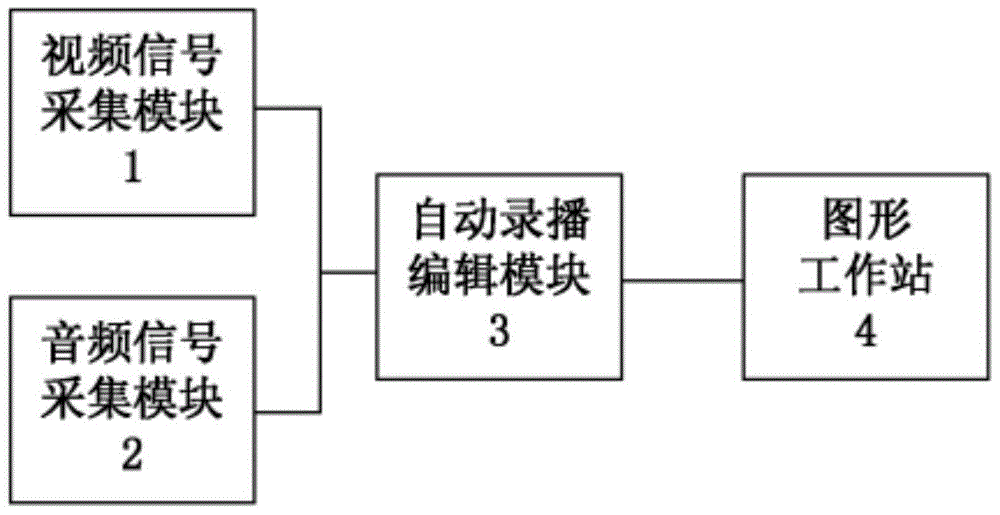

A network teaching method and system with speech recognition function

ActiveCN105681920BImprove review efficiencyRealize intelligent judgmentTelevision system detailsSpeech analysisSpoken languageSpeech identification

The invention provides a network teaching method and system. Double identity verification of face recognition and voice recognition is realized, the voice signal collection accuracy in a teaching process, an oral training process, a test process and an examination process are scored and assessed by a plurality of models, so that the assessment accuracy is improved, the network teaching is more autonomous and effective, and particularly in reading and listening and recitation teaching, the authenticity and effectiveness of learning can be improved by these functions of the system. By adopting the method provided by the invention, the face recognition is combined with the voice recognition, the user identity is checked before an oral test or system login of the user, and the user can be better encouraged to carry out a human voice test in a use process.

Owner:SHENZHEN EAGLESOUL EDUCATION SERVICE CO LTD

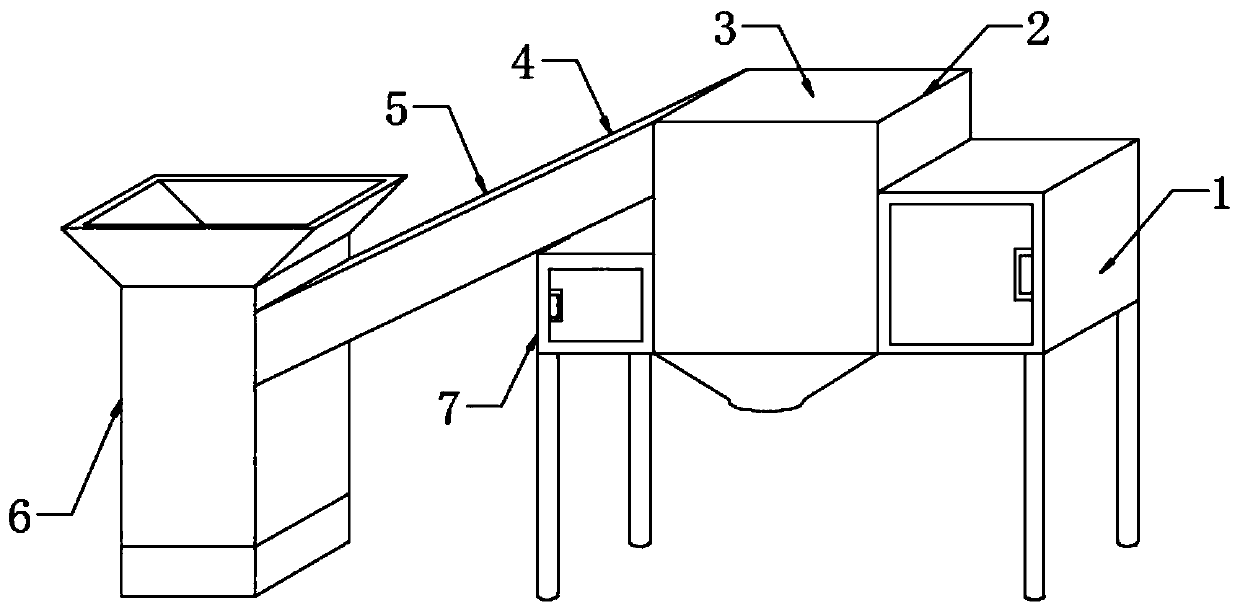

Plastic bag cutting device for recycling plastic bags

ActiveCN108515644APlay a guiding rolePrevent adhesionPlastic recyclingMedical waste disposalPlastic bagEngineering

The invention relates to a cutting device, and especially relates to a plastic bag cutting device for recycling plastic bags. A technical problem in the invention is to provide the plastic bag cuttingdevice which has simple and reliable structure, simple operation process, can completely cut the plastic bags, and is good in sanitary and cleanness. The device includes support legs, a first connection rod, a material hopper, a first placing board, a cutting mechanism, etc. The first connection rod is connected to the top part between the left and right support legs; the material hopper is disposed on the middle of the first connection rod; the first placing board is connected to the middle part between the left and right support legs. Through cooperation of the cutting mechanism and a conveying mechanism, the plastic bags in the material hopper are completely cut; by means of optimization of a spraying mechanism and a filtering mechanism, the device has simple and reliable structure, simple operation process, can completely cut the plastic bags, and is good in sanitary and cleanness.

Owner:泉州市菲式生物科技有限公司

Cement road anti-skid groove cleaning device for road construction

The invention relates to a cleaning device, in particular to a cement road anti-skid groove cleaning device for road construction. The cement road anti-skid groove cleaning device for the road construction is short in time consuming, thorough in cleaning and simple and easy to operate. According to the technical scheme, the cement road anti-skid groove cleaning device comprises an installation plate, a pushing handle, a cleaning mechanism, wheels and a collecting mechanism. The pushing handle is arranged on the right side of the top of the installation plate, the cleaning mechanism is arrangedat the bottom of the installation plate, the wheels are arranged at the bottom of the installation plate, and the collecting mechanism is arranged on the left side of the bottom of the installation plate. Through the mutual cooperation of the cleaning mechanism and the collecting mechanism, the cement road anti-skid groove cleaning device cleans an anti-skid groove on the cement road surface, anduses the optimization of an auxiliary mechanism and a spraying mechanism to achieve the effects of short time consumption, cleanliness and simple operation.

Owner:朱运图

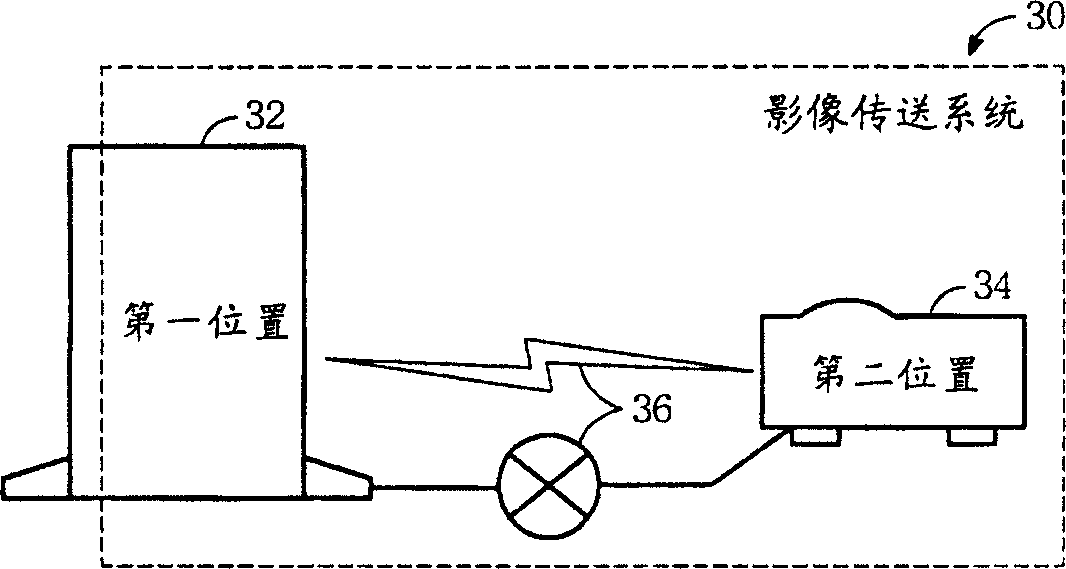

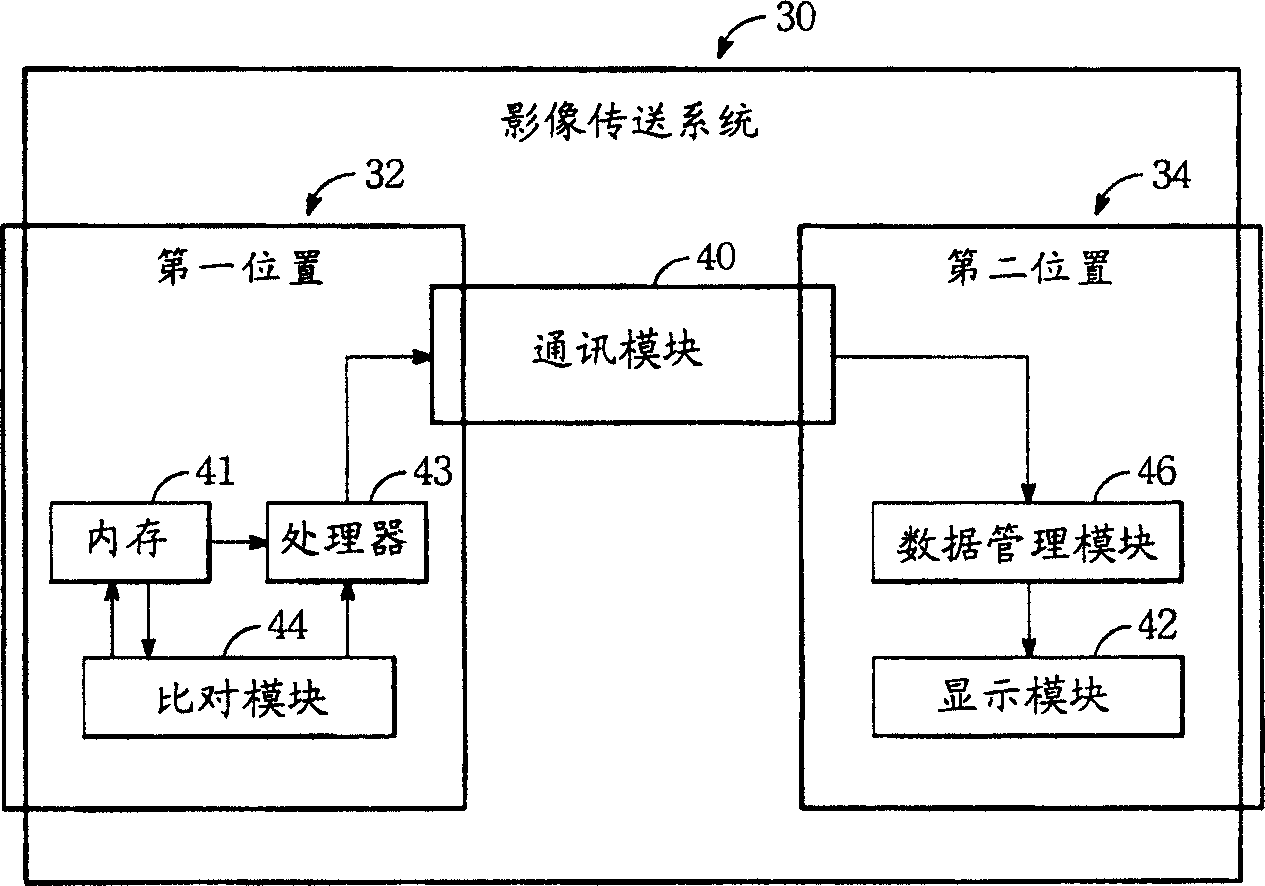

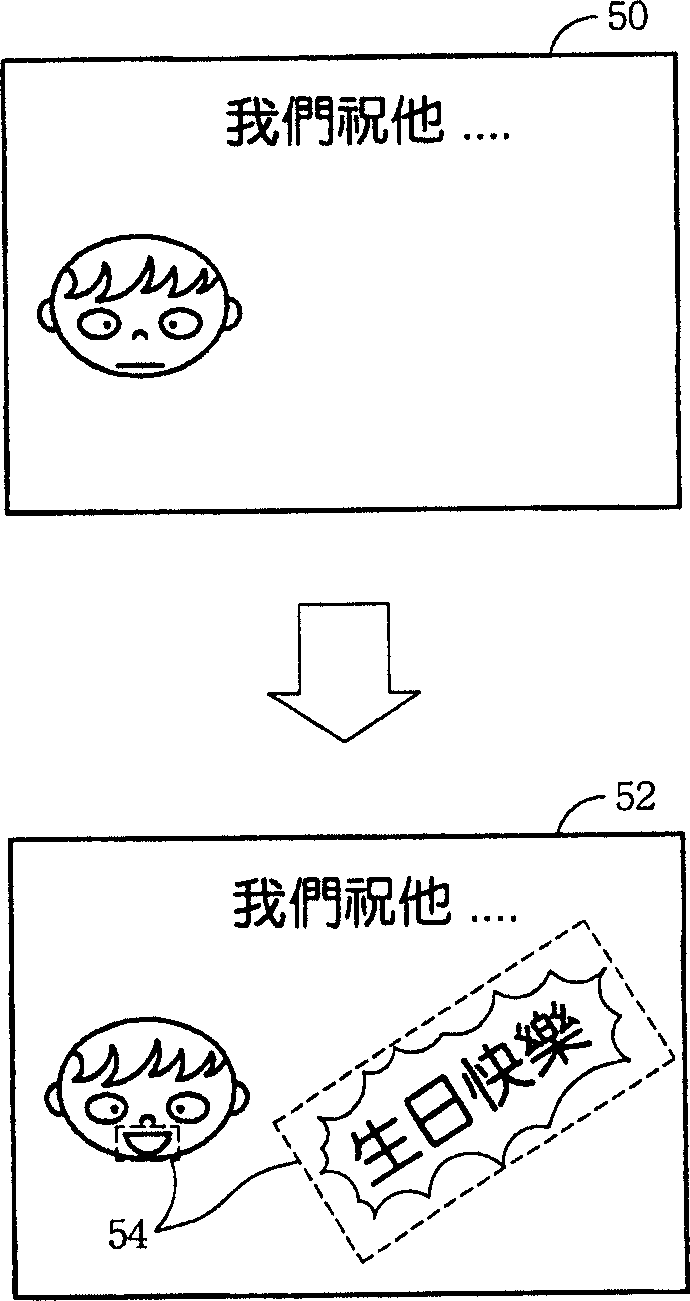

Image transmission system and image transmission method

InactiveCN1913570AImprove teleportation effectImprove the display effectData switching by path configurationPictoral communicationComputer visionImaging data

This invention relates to an image transmission system and a method for transmiting data of dynamic image, which first of all transmits data of a first image to a second position from a first position and displays related first image, utilizes a comparison module to compare the the part image in the second image different from that in the first one, then transmits the part image only to replace the image data in the corresponding position in the first to generate a paly image datum then to play said datum to display the corresponding second image at the second position.

Owner:VANTECH SOFTWARE

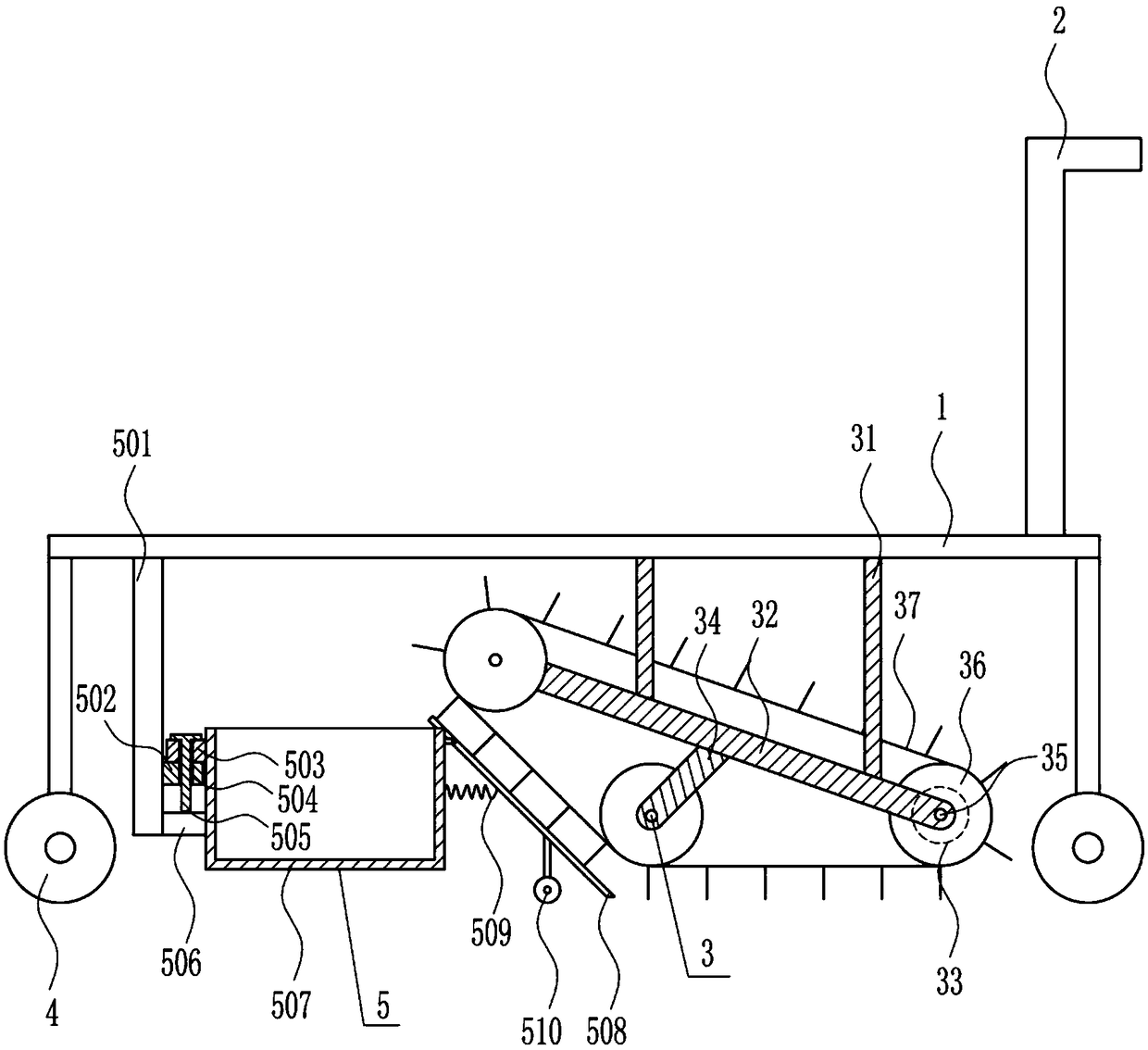

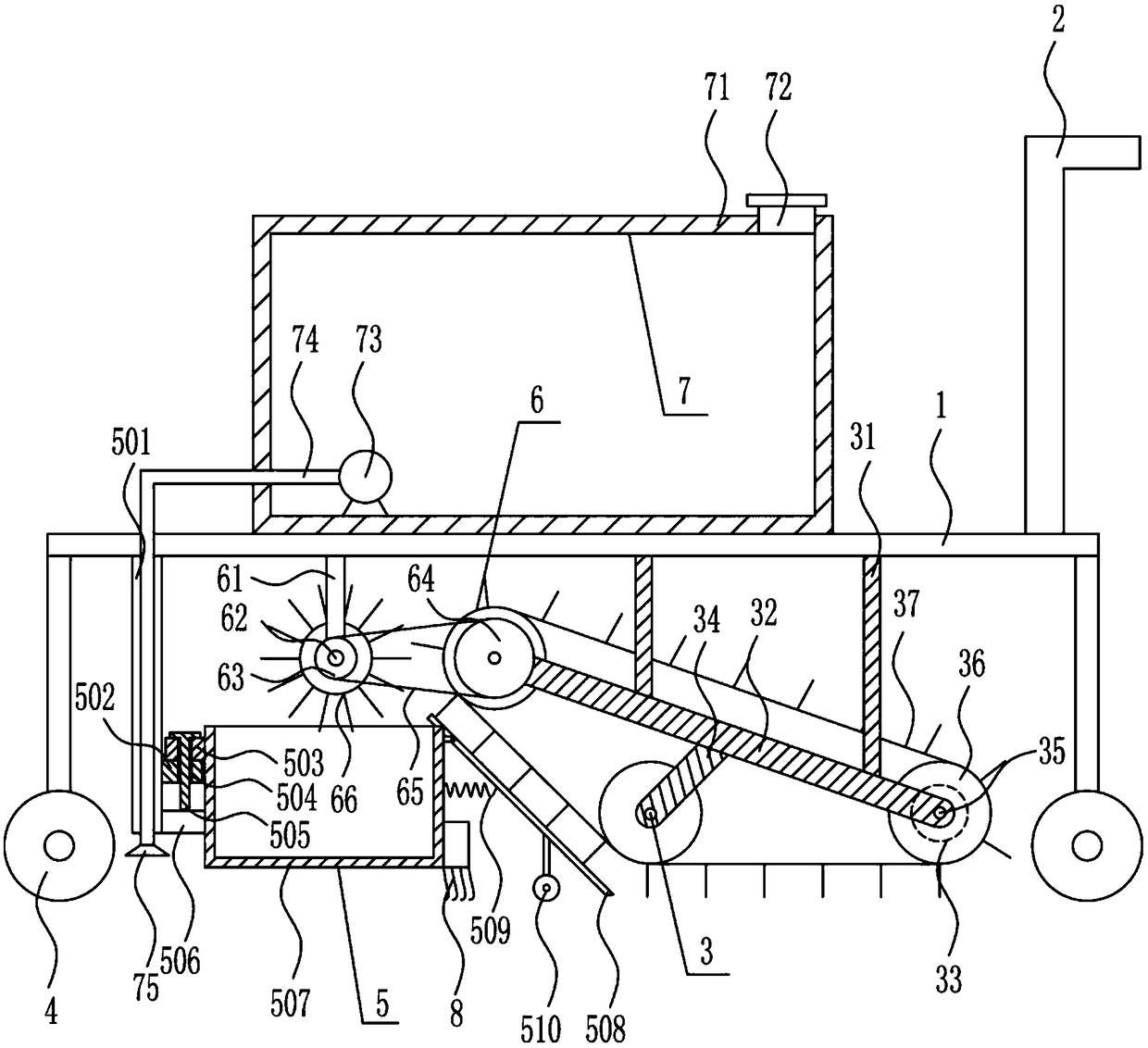

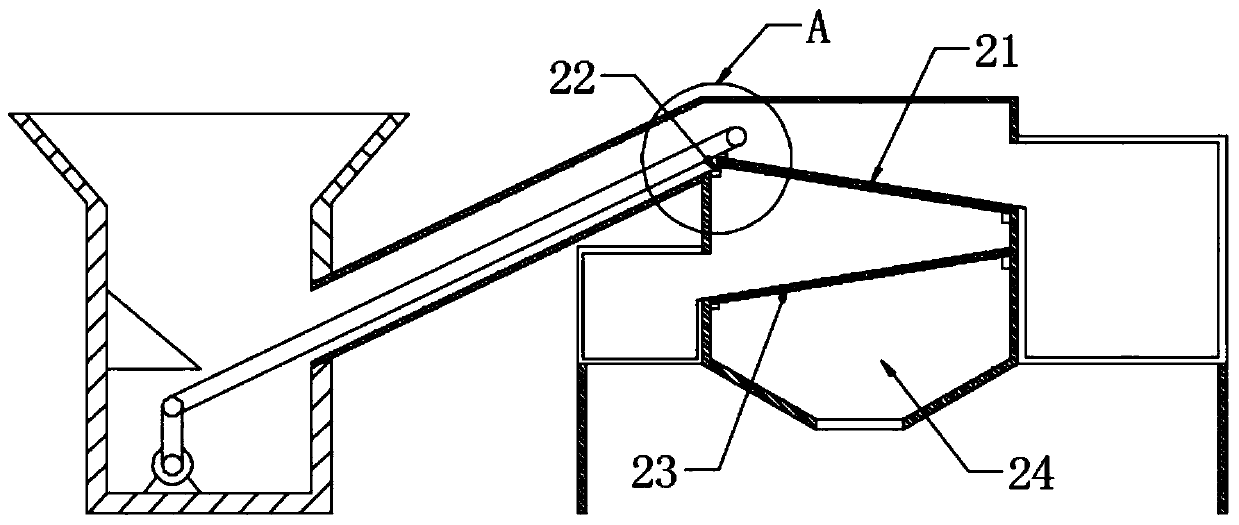

Radix ophiopogonis harvesting device

InactiveCN110301209ARealize automatic harvestingImprove work efficiencyThreshersDiggersShake upEngineering

The invention discloses a radix ophiopogonis harvesting device and belongs to the technical field of traditional Chinese medicine harvesting equipment. The device comprises a vehicle body, a digging mechanism, a conveying mechanism, a soil patting mechanism, a threshing mechanism, a collection net frame and a power supply device, the vehicle body serves as a carrier and is provided with a liftingwheel device, the digging mechanism is used for digging out radix ophiopogonis from soil and comprises a digging frame, a tooth rack and a driving device for driving the tooth rack to shake up and down, the conveying mechanism is used for conveying radix ophiopogonis which is dug out step by step, the soil patting mechanism is used for patting off clay at the head of radix ophiopogonis, the threshing mechanism is used for cutting down fruit grains of radix ophiopogonis, the collection net frame is used for collecting radix ophiopogonis which is cut off, and the power supply device is used forproviding power. By the device, the problem that conventional radix ophiopogonis harvesting modes are low in efficiency, troublesome in process, time-consuming and labor-consuming is solved.

Owner:LIUZHOU CITY HEALTHCARE HOSPITAL FOR WOMEN & CHILDREN

Printing advertisement production device

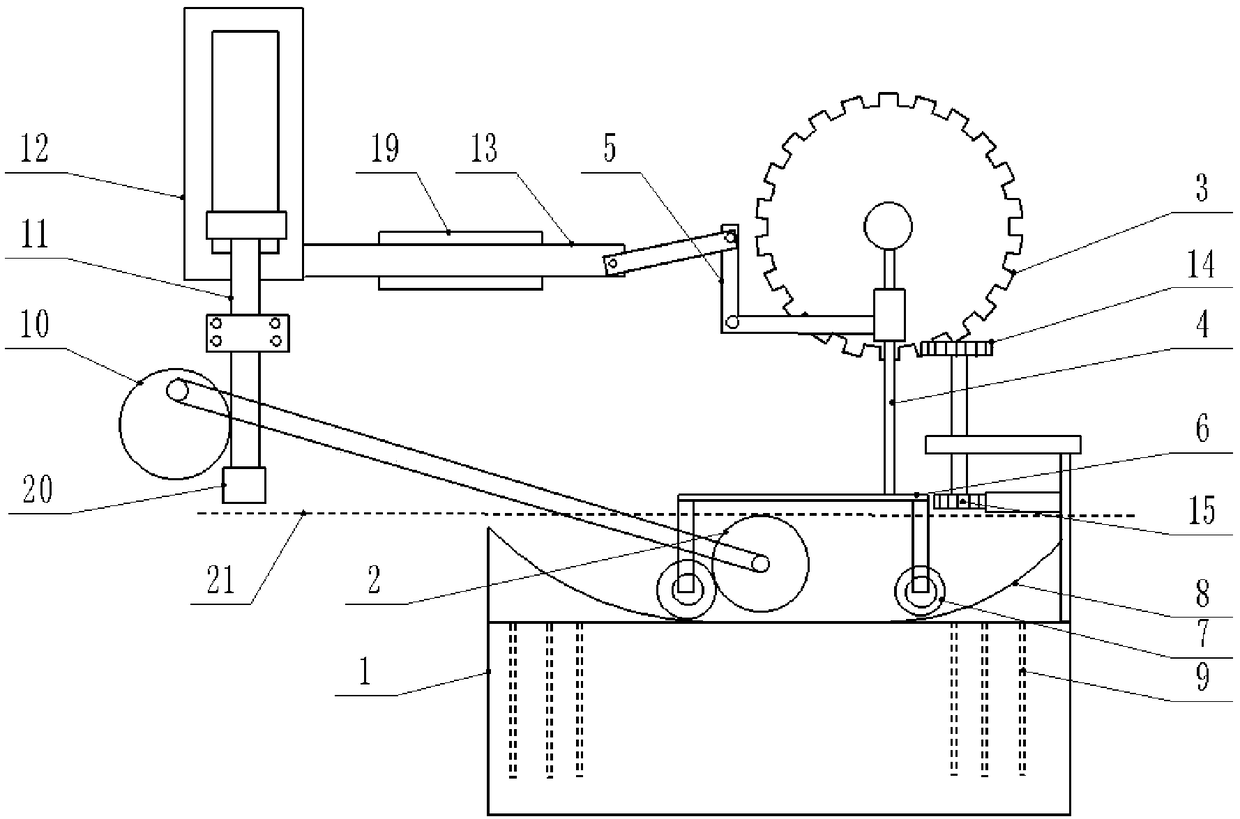

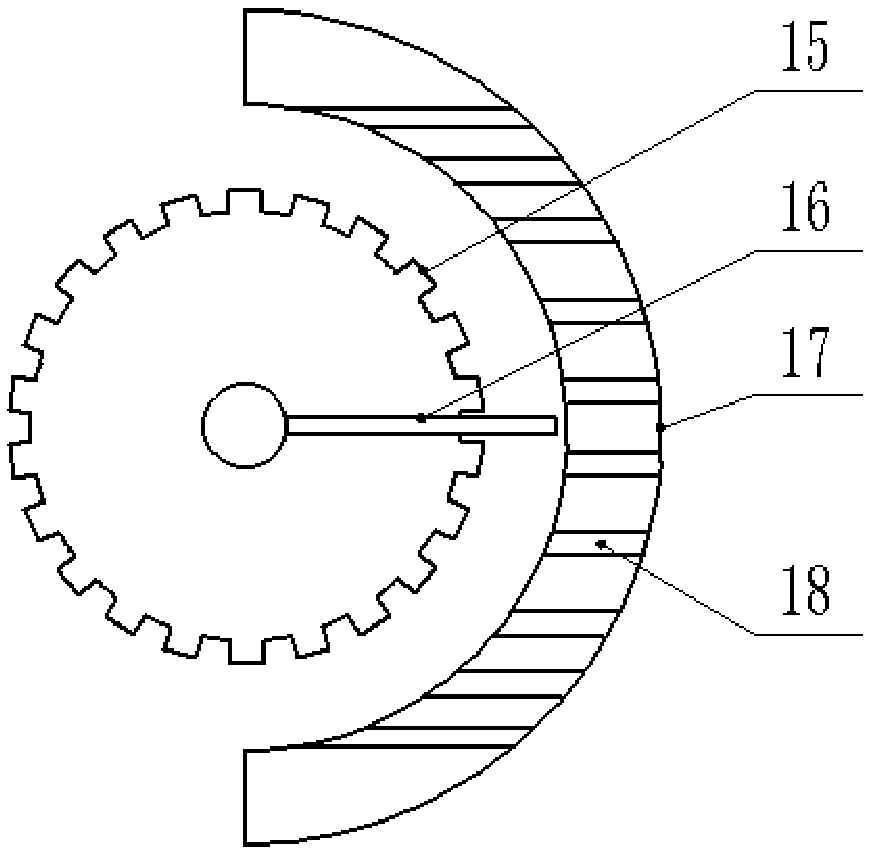

ActiveCN108357188APrevent throwingAvoid flyingCylinder pressesSpraying apparatusGear wheelEngineering

The invention relates to the technical field of printing production, and discloses a printing advertisement production device. The printing advertisement production device comprises an ink tank and aprinting roller located above the ink tank. An ink conveying mechanism is further included and comprises a rotationally-arranged main gear. A swinging rod is fixedly connected to the main gear and extends in the radial direction of the main gear. A rotationally-arranged L-shaped ejector rod is arranged on the outer side of the swinging rod, one end of the ejector rod is connected with a reciprocated swinging mechanism, and the other end of the ejector rod is hinged to the swinging rod. A swinging frame is hinged to the free end of the swinging rod and rotationally connected with an ink roller.The roller face of the ink roller abuts against the roller face of the printing roller. A sliding rail is arranged on the top of the ink tank, sponge is laid on the sliding rail, cotton threads penetrate the sponge, the end portions of the cotton threads are immersed in ink liquid in the ink tank, and the ink roller can slide to the sliding rail in the motion process. By means of the printing advertisement production device, the problem that in the prior art, when the printing roller conducts ink rolling, ink liquid in the ink tank is prone to being thrown out can be solved.

Owner:重庆新锐科技服务有限公司

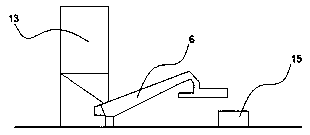

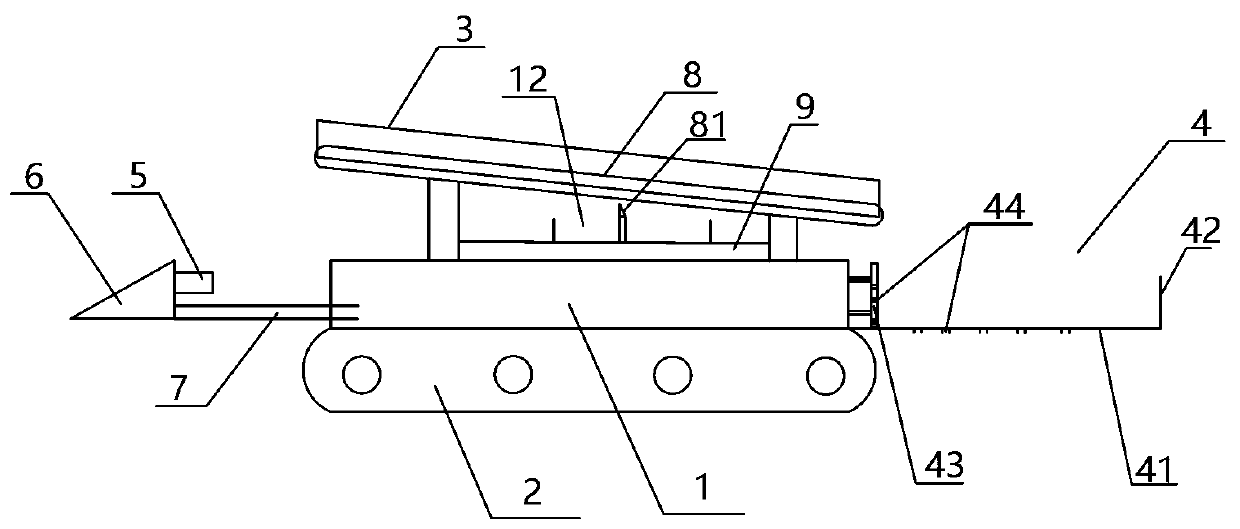

Efficient feeding device for color paperboard printing

InactiveCN111960147AAdjustable widthImprove applicabilityRotary pressesArticle feedersPaperboardStructural engineering

The invention discloses an efficient feeding device for color paperboard printing. The feeding device is simple in structure and high in applicability, the accuracy of the paperboard conveying position can be effectively guaranteed, later printing is facilitated, and the production efficiency is greatly improved. The feeding device comprises a conveying belt and a feeding frame, wherein the feeding frame comprises a rectangular frame, a bottom plate used for containing paperboards is arranged at the bottom of the frame, a baffle is vertically arranged at the front end of the frame, an outlet is formed in the baffle, a push plate is arranged in the frame, a driving air cylinder is connected to the rear end of the push plate and fixedly connected with the rear end of the frame, a pressing plate is further arranged in the frame, the two ends of the pressing plate are slidably connected with the left side and the right side of the frame correspondingly, tension springs are connected to thetwo ends of the pressing plate correspondingly, a top plate is arranged at the upper end of the frame, a guide hole is formed in the top plate, a guide rod is arranged in the guide hole, the lower end of the guide rod is fixedly connected with the upper surface of the pressing plate, and a width-adjustable deviation rectifying mechanism is arranged on a conveying belt.

Owner:SHANGHAI ZHIQIN PRINTING TECH CO LTD

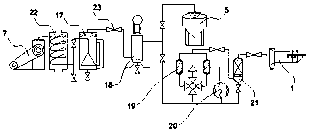

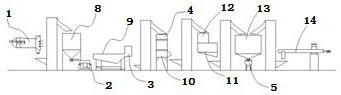

Resin sand treatment production line

ActiveCN110681821AIncrease the use value of regenerationAvoid damageMould handling/dressing devicesIndustrial gasMagnetic separator

The invention discloses a resin sand treatment production line. The resin sand treatment production line comprises an old sand recycling and regenerating device, a new sand conveying device and a pneumatic device, wherein the old sand recycling and regenerating device comprises a roller shakeout machine, a vibration regeneration machine, a suspension magnetic separator and a rotor regeneration machine. After shaking out from the roller shakeout machine and then being crushed by the vibration regeneration machine, old sand is demagnetized through the magnetic separator, then is regenerated through the rotor regeneration machine, and finally mixed with new sand so as to enter a double-arm sand mulling machine through a gas feeding device; one side of the roller shakeout machine is fed with heated compressed air for evaporating moisture; and the pneumatic device supplies the compressed air required by the roller shakeout machine and industrial gas required by the gas feeding device through an air compressor. According to the resin sand treatment production line, different compressed air is input to the roller shakeout machine and the gas feeding device based on the mounting requirements of the pneumatic device, resources are reasonably utilized, the damage of formed castings is reduced, and the regeneration use value of resin sand is improved.

Owner:含山盛荣机械配件厂

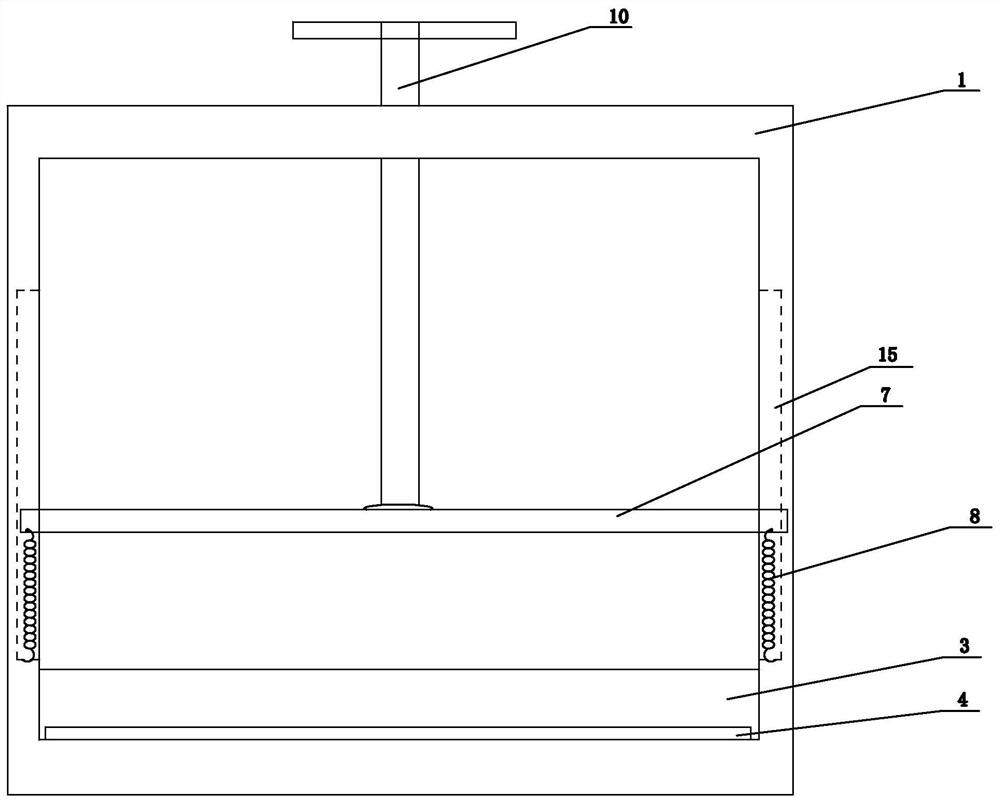

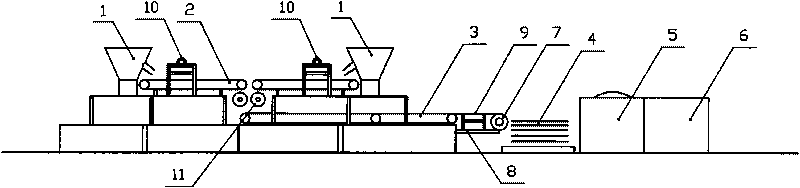

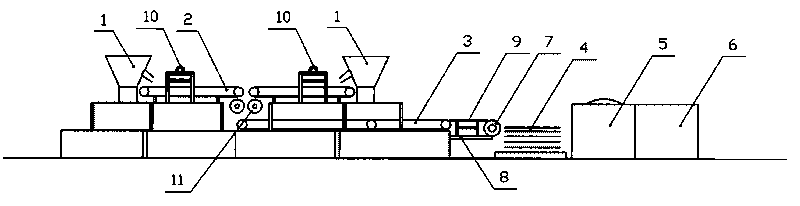

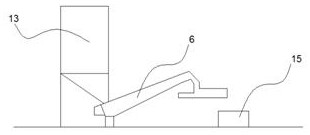

Tile production line

InactiveCN101733826AAvoid stacking and wrinklingImprove teleportation effectCeramic shaping apparatusProduction lineEngineering

The invention discloses a tile production line for producing waterproof heat-insulating tiles, which can improve the effect of conveying tile billets. The tile production line comprises a stirring system, a material-distributing system, a conveying-cutting system, a solidification mechanism, a cutting machine and a polishing machine, which are arranged in turn, wherein the conveying tail end of the conveying-cutting system is provided with a tile-billet conveying-guiding structure. Due to the tile-billet conveying-guiding structure, when soft-body tile billets reach the conveying tail end of the conveying-cutting system through the conveying-cutting system, the soft-body tile billets naturally transit to the upper surface of a tile die of the solidification mechanism from the tile-billet conveying-guiding structure, and under the guiding action of the tile-billet conveying-guiding structure, the whole cut soft-body tile billets are successfully placed onto the tile die. The production line can prevent the soft-body tile billets from being accumulated and wrinkled when entering the tile die, improves the effect of conveying the soft-body tile billets, greatly improves the yield of tile production, and is particularly suitable to be popularized and applied in the production of various waterproof heat-insulating tiles.

Owner:周兴和

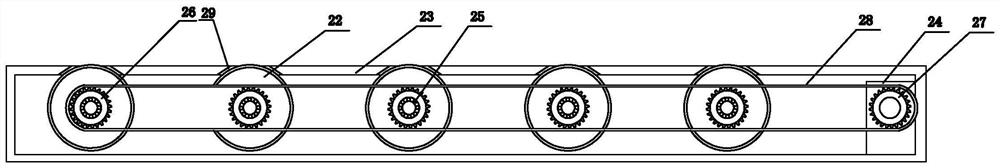

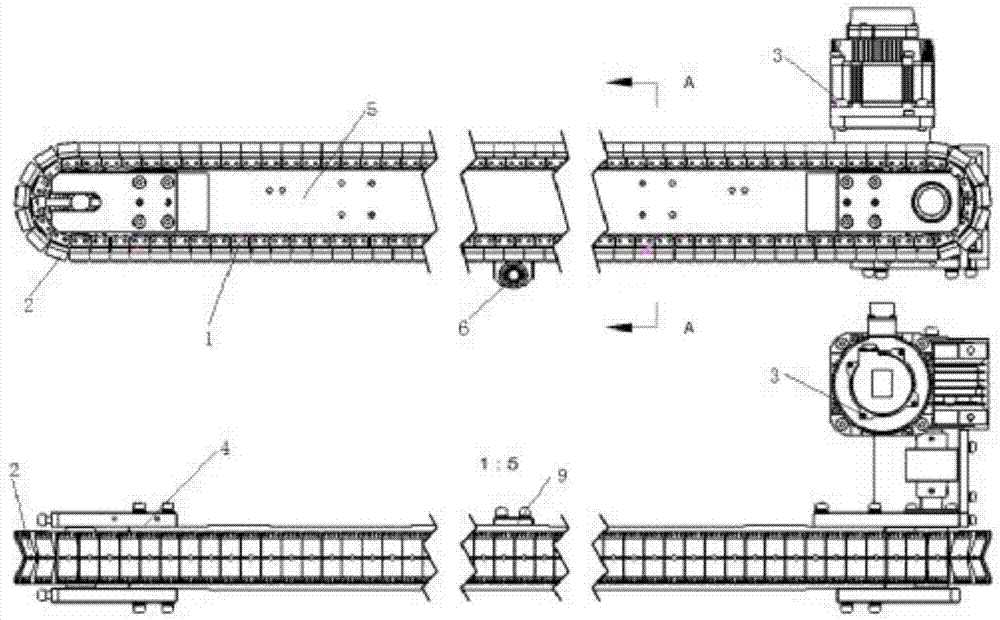

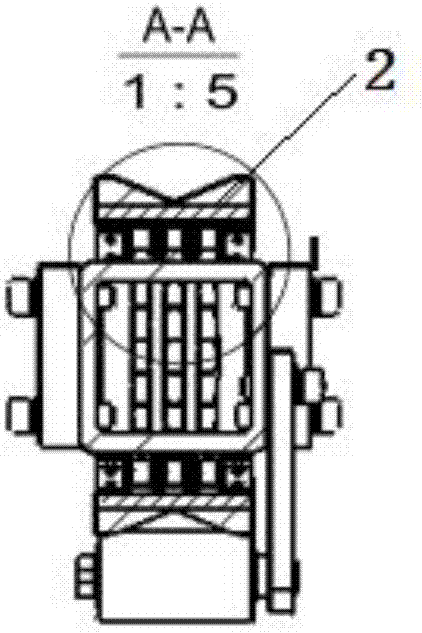

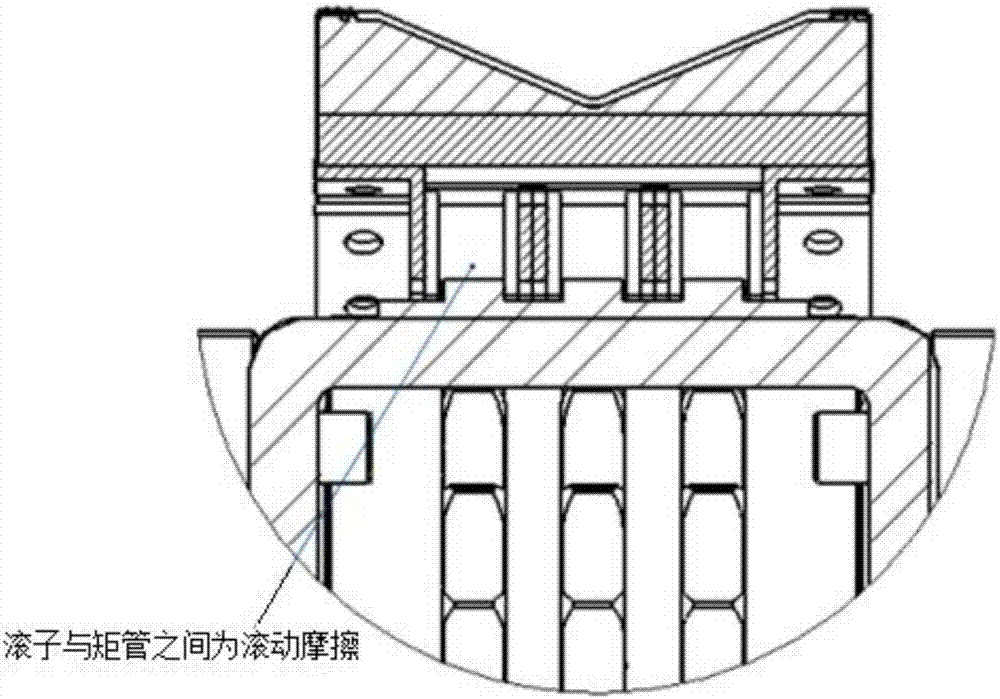

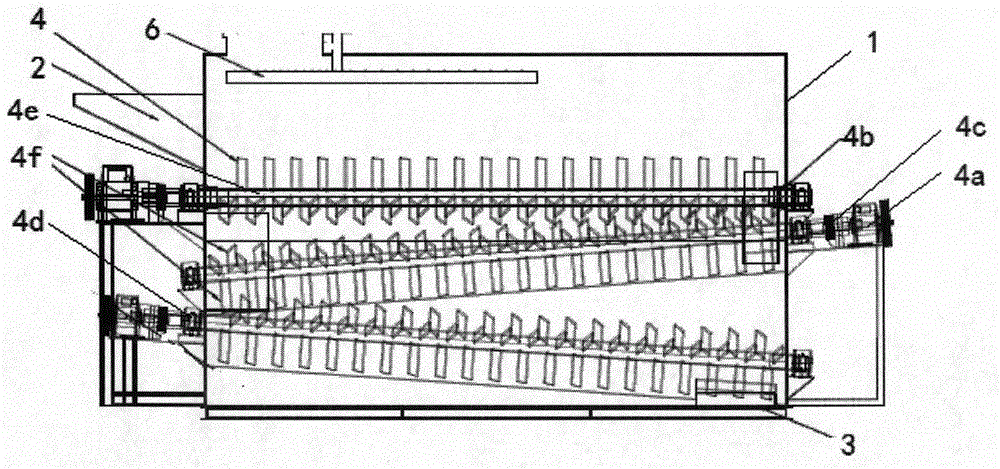

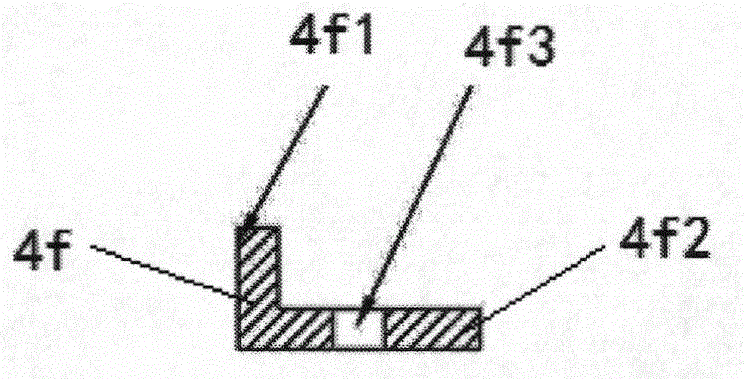

Transfer device for full-automatic hollow glass gumming machine

ActiveCN107310902AImprove stabilityThere will be no tooth skipping phenomenonLiquid surface applicatorsConveyorsSelf recoveryElectrical and Electronics engineering

The invention provides a transfer device for a full-automatic hollow glass gumming machine. The transfer device for the full-automatic hollow glass gumming machine comprises a transfer chain, a rectangular transfer tube, a drive assembly, a driven assembly and a gum removal assembly, wherein the transfer chain is arranged on the upper surface of the rectangular transfer tube; the drive assembly and one end of the transfer chain are in coaxial transmission, and the driven assembly and the other end of the transfer chain are also in coaxial transmission; the gum removal assembly is fixedly connected with the rectangular transfer tube; and the transfer chain comprises a plurality of V-shaped gum blocks, a chain body and L-shaped connecting pieces, the multiple V-shaped gum blocks are arranged on the chain body sequentially, and each V-shaped gum block is connected with the chain body through the corresponding L-shaped connecting piece. According to the transfer device for the full-automatic hollow glass gumming machine, chain transmission replaces belt transmission, so that transmission stability is improved; and as the V-shaped gum blocks are arranged on the chain and have the self-recovery function, abrasion to a transfer belt is reduced, and the production cost and the maintenance cost are reduced.

Owner:廊坊蓝天新海科技有限公司

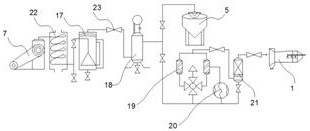

Stirring device of dedusting digester

PendingCN105879742AEasy to replaceExtended use timeRotary stirring mixersChemical/physical/physico-chemical stationary reactorsDust controlEngineering

The invention provides a stirring device of a dedusting digester. In the oblique digester, due to the action of gravity component force of digested lime, friction resistance is reduced, thrust required by movement of digested lime is reduced too, and abrasion of blades of the digester is reduced. Under the condition that driving force is unchanged, the transmission capacity of the digester is improved, most lime becomes powder and adheres to the digester in the third stage of digestion, powder can move fast automatically, and lime not digested completely continues to stay at the bottom of a cavity of the digester to be digested. The length of the digester can be increased appropriately so as to prolong lime digestion time; meanwhile, an outlet of the digester can be enlarged to avoid digester blocking caused by unsmooth discharging. A detachable alloy blade device is adopted, time and labor are saved, and using is convenient and quick. Due to the fact that a framework oil seal spindle is replaced with a labyrinth gland, sealing effect is good, maintenance is not needed at all, and operation and using are more convenient.

Owner:JIANDE QUANXIN CALCIUM IND CO LTD

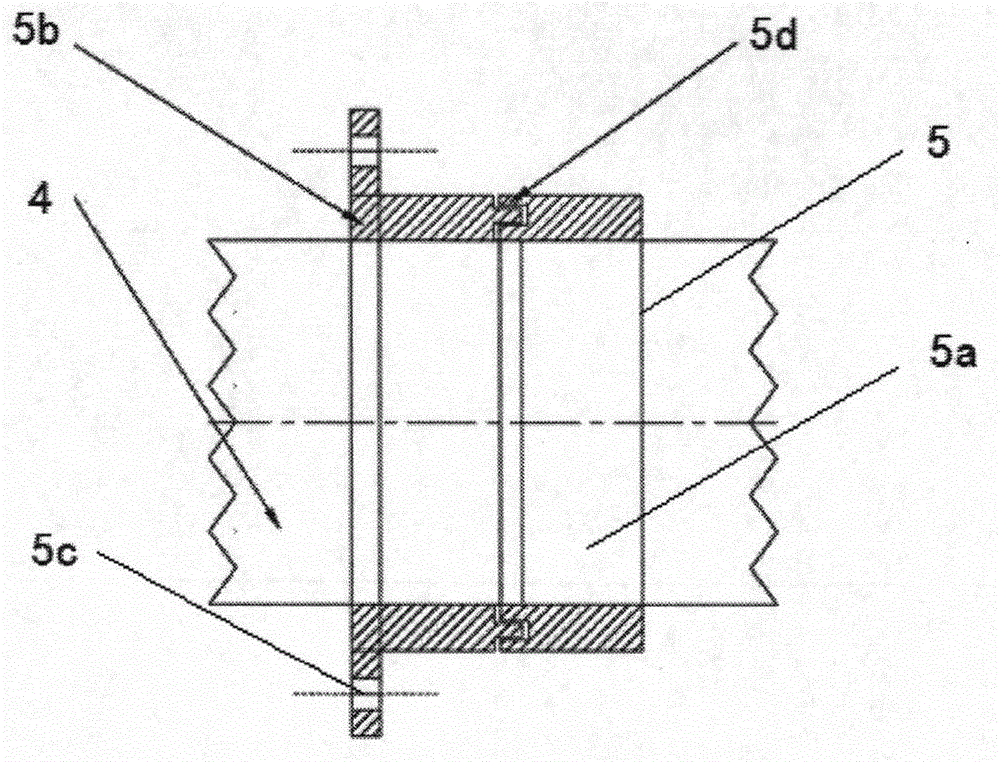

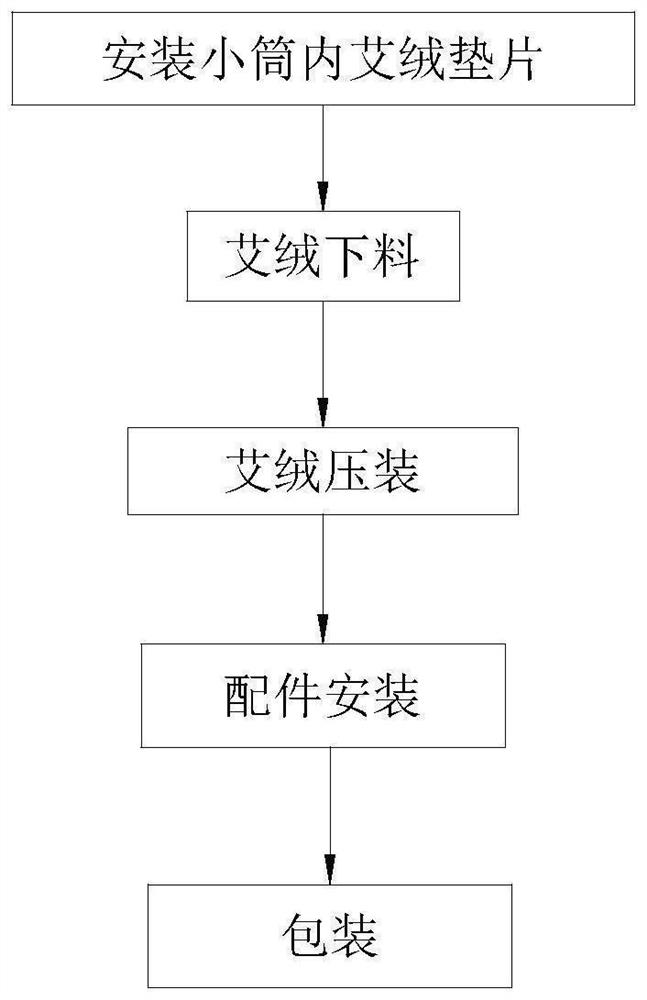

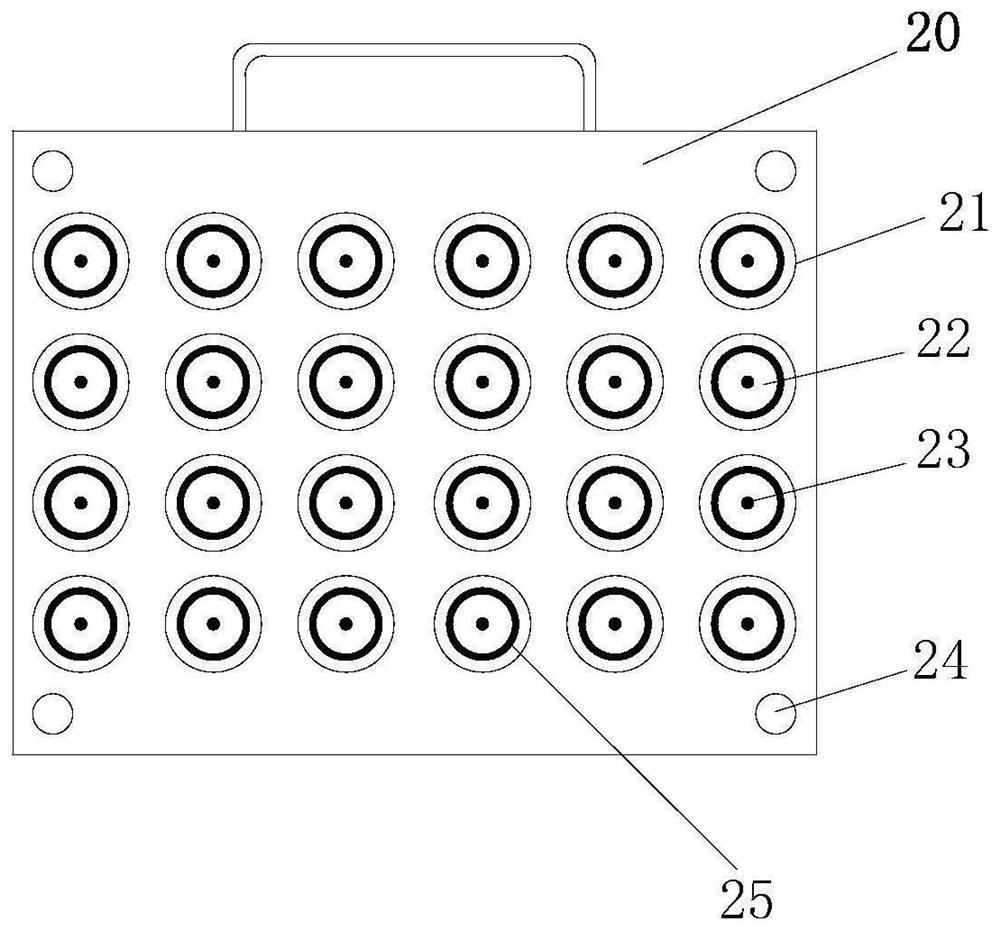

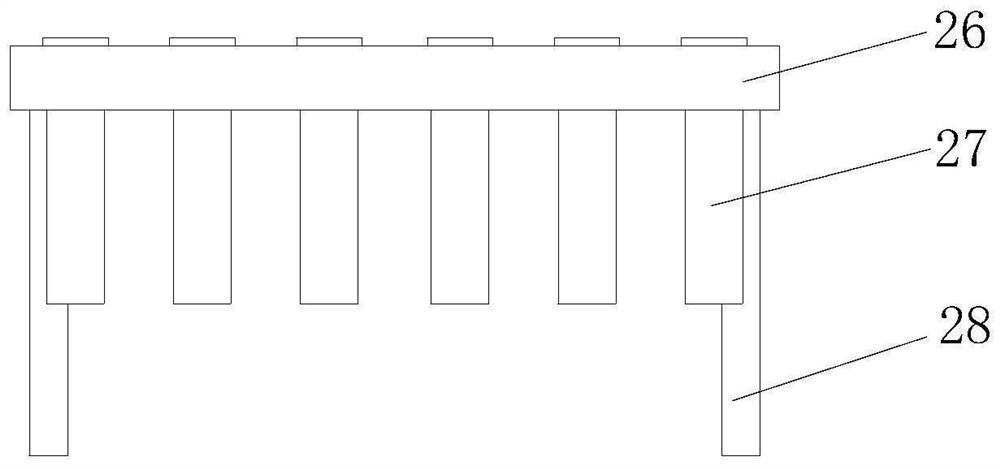

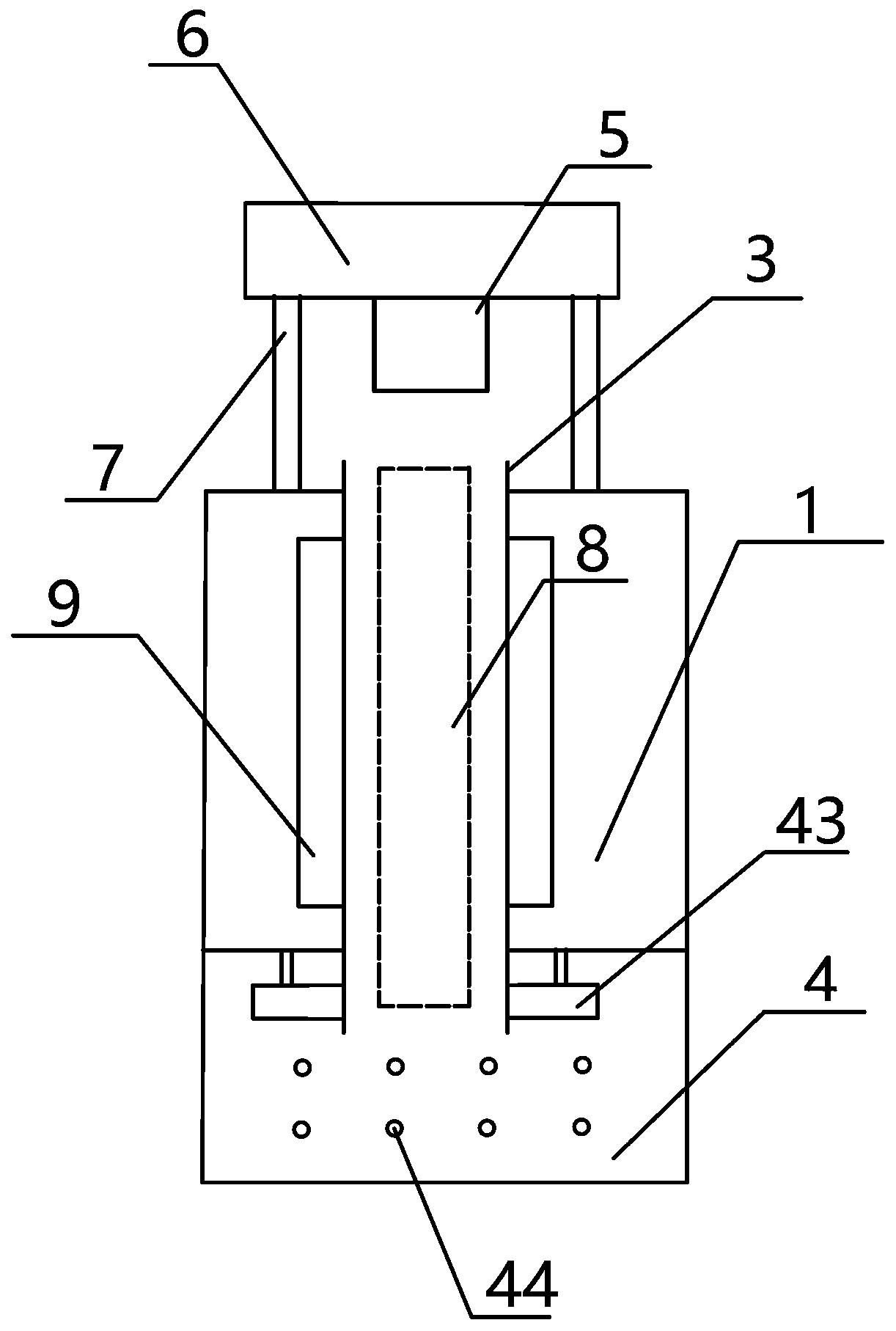

Production technology of cylindrical moxibustion tool

ActiveCN111904850AImprove teleportation effectAccurate stereotypesDevices for heating/cooling reflex pointsTemperature controlEngineering

The invention provides a production technology of a cylindrical moxibustion tool. The production technology comprises the following steps: S1, mounting moxa gaskets in a small cylinder: mounting the small cylinder of the cylindrical moxibustion tool on a lower mold of a special mold, and sleeving a circular moxa gasket with a central hole in the center on each positioning protrusion of the lower mold, downwards pressing the moxa gaskets until the moxa gaskets are in contact with the top surface of the lower mold to reach a required mounting position; S2, discharging moxa: weighing moxa according to the designed weight, and loading the weighed moxa into a feeding cylinder of the special mold; S3, performing moxa press fitting: pressing the moxa in the feeding cylinder into the small cylinder of the cylindrical moxibustion tool, wherein the temperature control range during pressing is 86-90 DEG C, the pressure control range is 15-20Mpa, and the press fitting time is 15-18S; S4, mountingfittings: mounting a base and a cover of the cylindrical moxibustion tool on the small cylinder; and S5, performing packaging: putting the cylindrical moxibustion tool into a packaging box and sealingthe packaging box. According to the production technology of the cylindrical moxibustion tool, the moxa of the cylindrical moxibustion tool is pressed tightly and is not prone to falling off, the dryness is good, ignition is easy, and the product quality is improved.

Owner:湖北蕲艾堂科技有限公司

A resin sand processing production line

ActiveCN110681821BIncrease the use value of regenerationAvoid damageMould handling/dressing devicesIndustrial gasMagnetic separator

The invention discloses a resin sand processing production line, which includes an old sand recovery and regeneration device, a new sand conveying device and a pneumatic device, and the old sand recovery and regeneration device includes a drum shakeout machine, a vibration regeneration machine, a suspension magnetic separator, and a rotor regeneration machine The old sand is crushed by the vibrating regenerator after being shaken out from the drum shakeout machine, then regenerated by the rotor regenerator after being demagnetized by the magnetic separator, and finally mixed with new sand and then entered into the double-arm sand mixer by means of an air supply device; the drum One side of the shakeout machine is fed with heated compressed air to evaporate water; the pneumatic device provides the compressed air required by the drum shakeout machine and the industrial air for the air delivery device through the air compressor. The resin sand processing production line of the present invention uses pneumatic devices to install different compressed air to the drum shakeout machine and air delivery device, rationally utilizes resources, reduces damage to molded castings, and improves the recycling value of resin sand.

Owner:含山盛荣机械配件厂

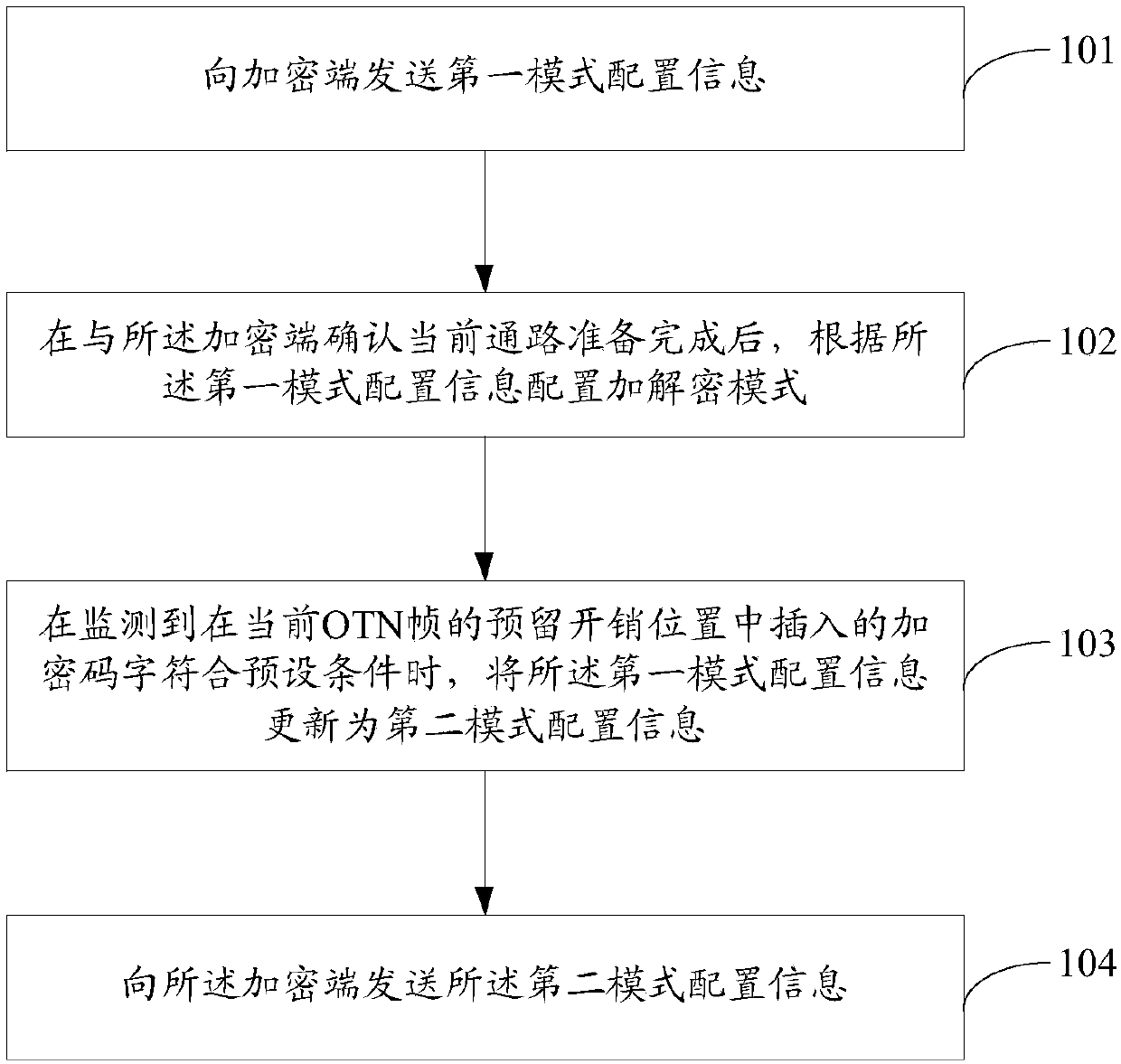

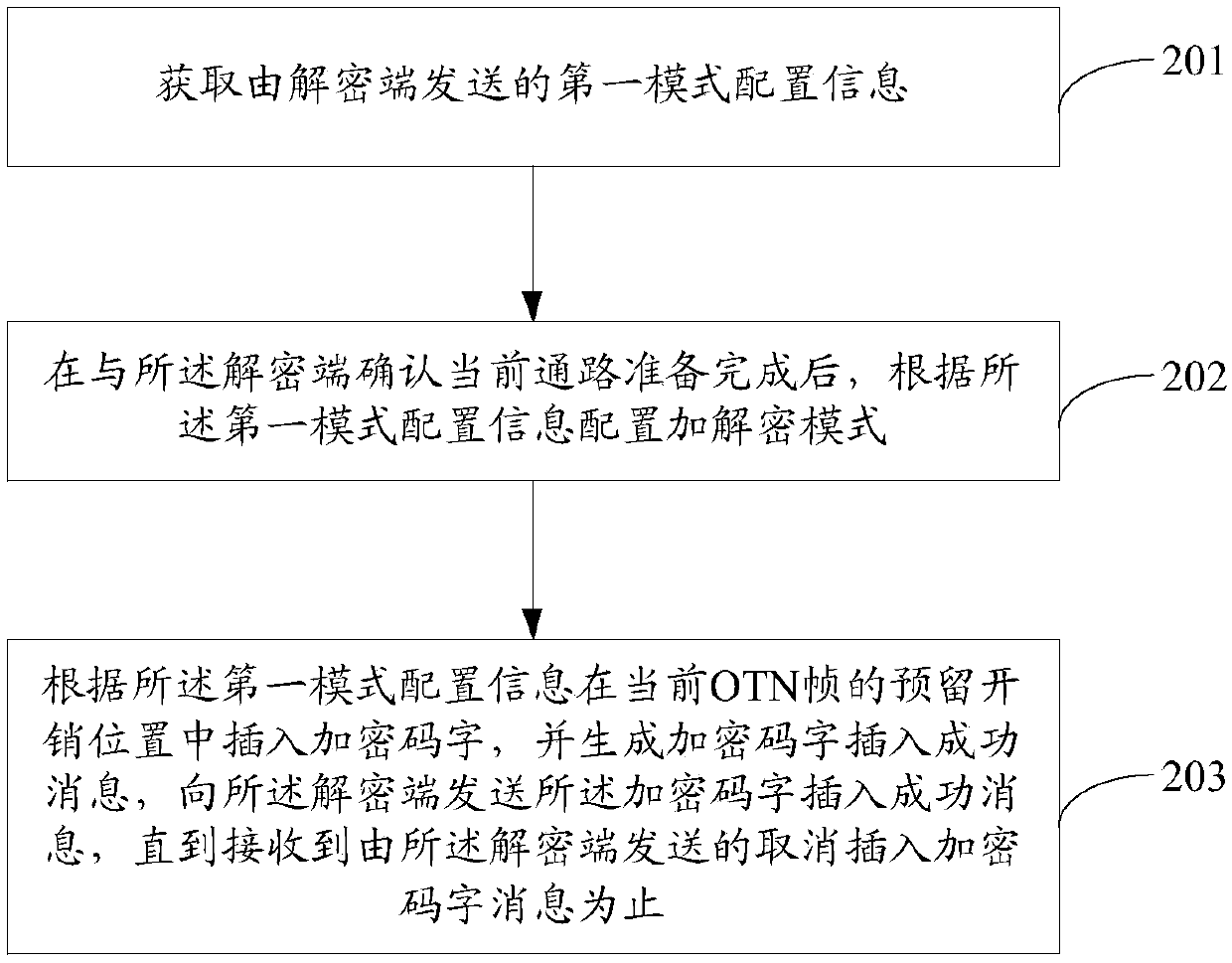

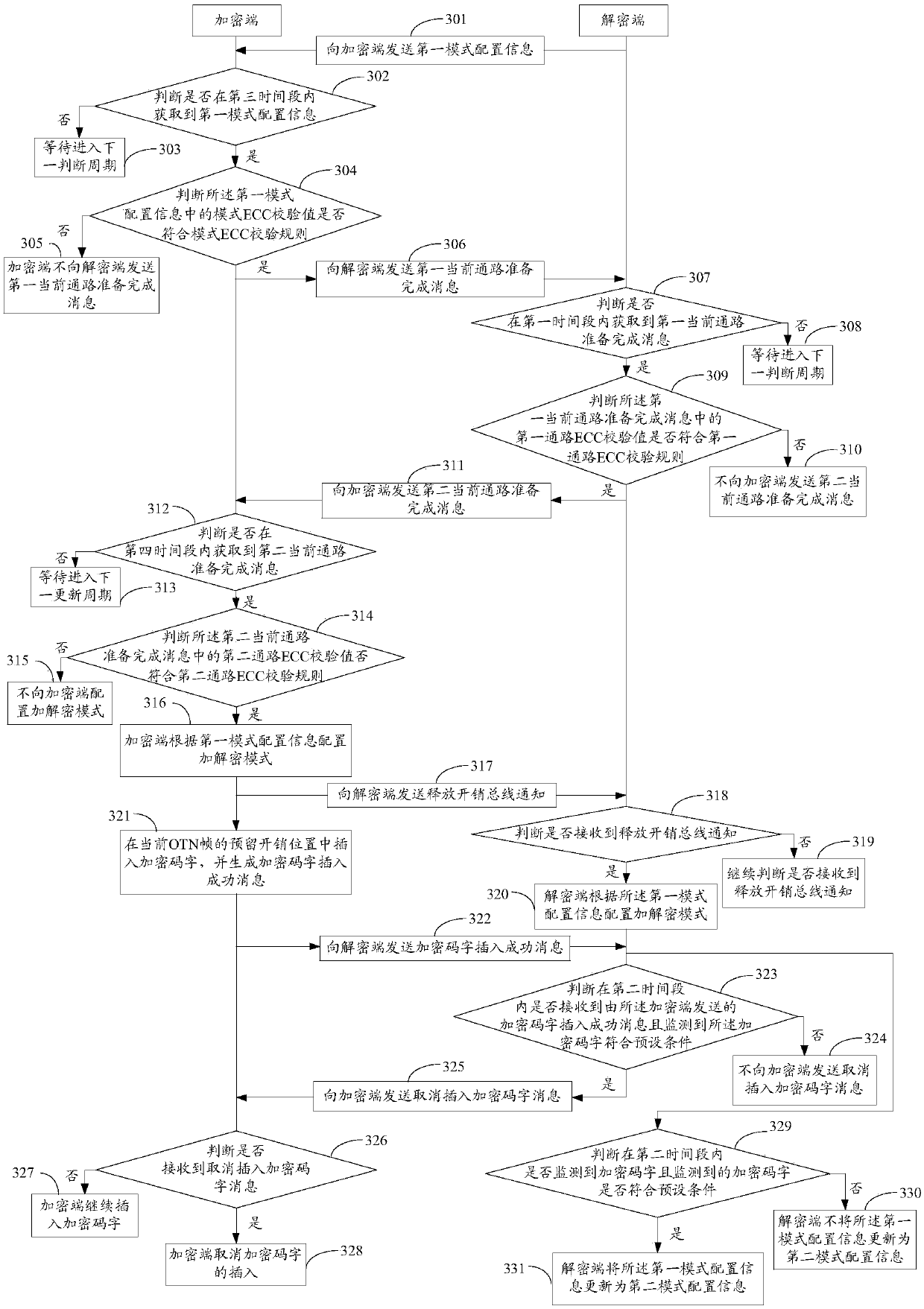

Method for switching between encryption mode and decryption mode

ActiveCN107800502AGuaranteed accuracyImprove teleportation effectKey distribution for secure communicationMultiple keys/algorithms usageComputer hardwareEncryption

An embodiment of the invention discloses a method for switching between an encryption mode and a decryption mode. The method comprises the steps of transmitting first mode configuration information toan encryption end; wherein the first mode configuration information comprises the encryption mode, the decryption mode, a mode ECC verification value and a reserved expenditure position; after preparation finishing of a current path is configured from the encryption end, configuring an encryption / decryption mode according to the first mode configuration information; when a fact that an encryptioncode character which is inserted into the reserved expenditure position of a current OTN frame satisfies a preset condition is monitored, updating the first mode configuration information to second mode configuration information; and transmitting the second mode configuration information to the encryption end. The embodiment of the invention further discloses a device for switching between the encryption mode and the decryption mode.

Owner:SANECHIPS TECH CO LTD

Water surface garbage cleaning device

InactiveCN112854167AIncrease capacityAvoid manual removalWater cleaningStructural engineeringMechanical engineering

The invention is suitable for the technical field of environmental protection, and provides a water surface garbage cleaning device. The water surface garbage cleaning device comprises a material collecting box, rotating shafts, material cleaning rakes, material penetrating plates, eccentric rods, connecting shafts, material conveying plates and driving parts; the rotating shafts are rotationally connected to the moving front end of the material collecting box; the material cleaning rakes are fixedly connected to the radial position of the material conveying plate in an array mode and used for grabbing garbage; the material penetrating plates are obliquely and fixedly arranged at the front end of the material collecting box, are spaced from the material cleaning rakes and are used for conveying garbage through gravity and rotation of the material cleaning rakes; the eccentric rods are arranged on the inner walls of the two sides of the material collecting box in the advancing direction, and two eccentric rods are arranged on each side; the connecting shafts are connected to the eccentric rods at the corresponding positions, and the two connecting shafts are connected through at least one connecting plate; the material conveying plates are fixedly connected to the bottom of the connecting plates in an array mode and used for conveying the garbage; and the driving parts are connected to the eccentric rods, used for driving the eccentric rods to rotate, connected to the rotating shafts through transmission parts and used for driving the rotating shafts to rotate. The device has the advantages of being simple in structure, convenient to operate, energy-saving and high in cleaning capacity.

Owner:王雨曦

Anti-vibration structure of belt conveyor

InactiveCN112124894AForce balanceReduce vibrationConveyorsSupporting framesHydraulic cylinderTransmission belt

The invention relates to the technical field of belt conveyors, in particular to an anti-vibration structure of a belt conveyor. The anti-vibration structure comprises a bottom frame, driving supportrods, support bottom plates and a second hydraulic cylinder, wherein the second hydraulic cylinder drives a second hydraulic rod to move, and the second hydraulic rod drives a second push plate to move at the bottom end of the support bottom frame; the second push plate drives a mounting plate to move left and right; the mounting plate drives a second roller to move; the second roller is put in aconveyor belt of the belt conveyor through movement of the second roller; a third motor drives a rotating shaft to rotate; the rotating shaft drives the second roller to rotate; through the use of a third roller,a belt on the belt conveyor can be tightened, so that the conveying stability of the conveyor is further improved, meanwhile, the third motor drives the third roller, and during the rotating process of the third roller, the power conveyed by the conveyor is enhanced.

Owner:安徽德基汇金机械科技有限公司

Intelligent tongue muscle trainer

The invention discloses an intelligent tongue muscle trainer which comprises a tongue cover for tongue tip suction and a manual air pump for generating negative pressure. The tongue cover is communicated with the air pump. One end of a ventilating guide pipe is connected with the tongue cover, and the other end of the ventilating guide pipe is connected with the air pump. The middle of the ventilating guide pipe is connected with a driving mechanism for driving the tongue cover to do linear reciprocating movements. The intelligent tongue muscle trainer has the advantages of being convenient tocarry, durable in use, safe and the like; rehabilitation work does not need to be manually conducted, a patient can operate and use the trainer by himself / herself, labor cost is saved, the use convenience and flexibility are improved, and meanwhile risks caused by operation of other people are avoided; by means of the trainer, the rehabilitation effect is greatly improved.

Owner:HUNAN UNIV OF CHINESE MEDICINE

Garbage cleaning equipment

ActiveCN111535436AEasy to cleanImplement preliminary classification cleanupMechanical machines/dredgersSewer cleaningWater filterSewage

The invention discloses garbage cleaning equipment. The garbage cleaning equipment comprises a chassis, a garbage transfer pipe is arranged on the chassis, a pushing device and a collecting box are correspondingly arranged at the two ends of the chassis in the length extension direction of the garbage transfer pipe, and the end, close to the collecting box, of the garbage transfer pipe communicates with the collecting box or extends to the upper side of the collecting box; the pushing device comprises a bucket and a transfer pipe, the transfer pipe communicates with the bucket, the bucket is connected with the chassis through the pushing rod, and the pushing rod is used for lifting the bucket to communicate the transfer pipe with the garbage transfer pipe; and the collecting box comprisesa bottom wall and a side wall arranged around the bottom wall, an extrusion plate is arranged at the end, connected with the bottom wall, of the chassis, and water filtering holes are formed in the extrusion plate and the bottom wall. According to the garbage cleaning equipment, a river channel, a sewer and a sewage pipeline can be effectively cleaned, and the equipment can be not prone to being blocked.

Owner:于海林

Sand and stone sorting device for mechanical engineering

InactiveCN110665788AImprove the ability to sort sand and gravelSolve the problem of poor sorting effect of sand and gravelSievingConveyorsDrive wheelElectric machinery

The invention provides a sand and stone sorting device for mechanical engineering. The sand and stone sorting device comprises a coarse screening net, a positioning block, a fine screening net, sand storing chamber, a sliding plate, a driven wheel, an alternating-current motor, a conveying belt and a scraping block; the sand storing chamber is formed in the lower side in a screening box, the finescreening net is placed on the upper side of the sand storing chamber, and the coarse screening net is placed on the upper side of the fine screening net; and the positioning block is assembled on theleft side of the lower end face of the coarse screening net. Through the design, the problem that an original screening box is poor in sand and stone sorting effect is solved, the alternating-currentmotor is mounted on the lower side in a feeding box, the driven wheel is assembled on the upper side of the alternating-current motor, the conveying belt is mounted on the annular side face of the driven wheel, the sliding plate is assembled on the upper side of the driven wheel, and the scraping block is mounted on the lower side of the conveying belt; and through the design, the problem that asfor original sand and stone sorting, manual conveying is needed for sorting is solved, and the sand and stone sorting device is reasonable in structure, good in sorting effect and high in working efficiency.

Owner:西安科技成果转化工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com