Stirring device of dedusting digester

A stirring device and digester technology, which is applied in mixers with rotary stirring devices, chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, etc., can solve problems such as inability to continue digestion and achieve wear-resistant use time, reducing the chance of replacing the bushing, the effect of increasing the transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

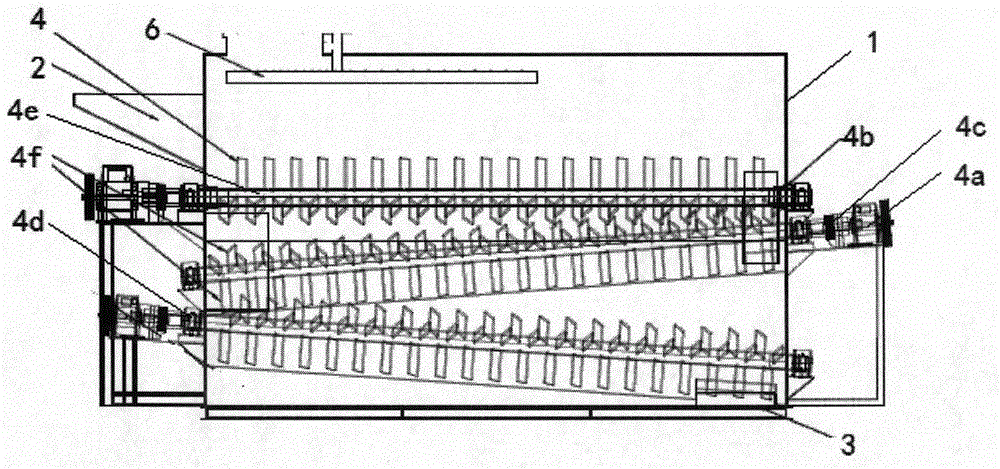

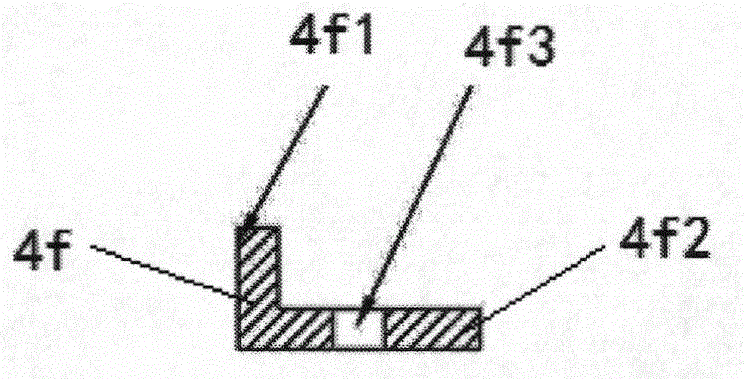

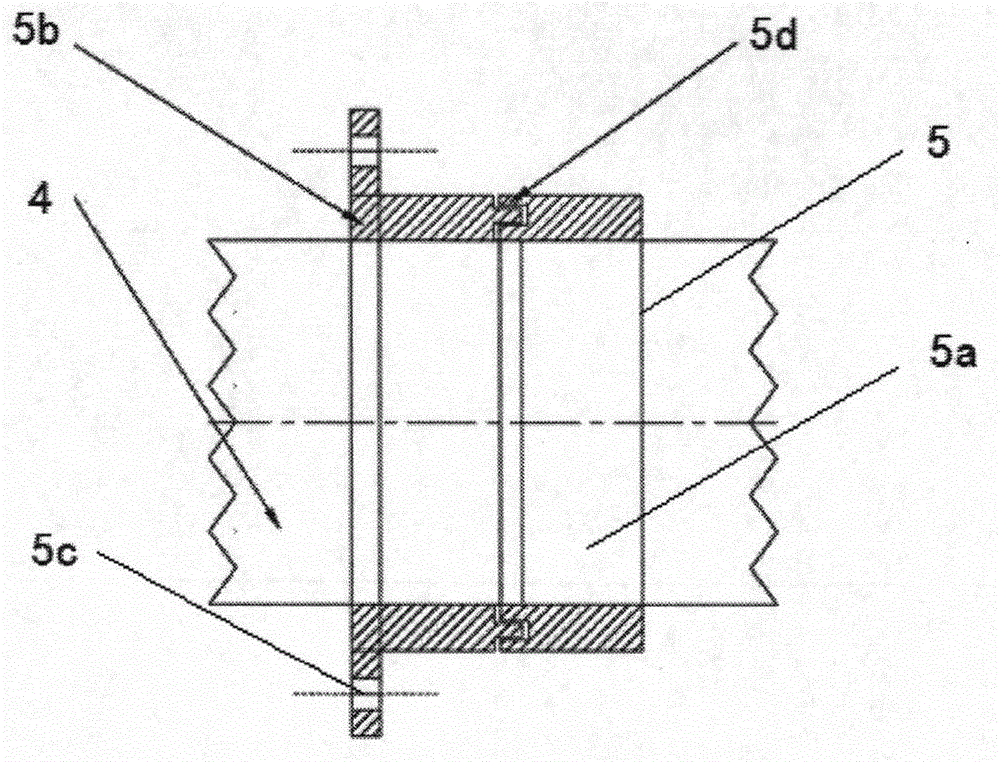

[0022] Such as figure 1 As shown, the stirring device of the dedusting digester includes a shell 1, a raw material inlet 2, a finished product outlet 3 and a digestion system 4. The upper part of the shell 1 is provided with a raw material inlet 2, the bottom of the shell 1 is provided with a finished product outlet 3, and the inside of the shell 1 is provided with a digestive system. 4. Digestive system 4 is a three-level digestive system. The three-level digestive system has the same structure and is arranged inside shell 1 from top to bottom at a certain angle. The inclination angle is a, Sina=H / L, when the length L of the digestive system 4 is constant, the greater the elevation H is, the greater the value of Sina is, and the compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com