Resin sand treatment production line

A production line and resin sand technology, applied in the field of pig iron casting, can solve the problems of environmental pollution, waste of resources, resin sand cannot be simply reused, etc., and achieve the effects of enhancing safety, improving the utilization rate of compressed air, and increasing the value of regeneration and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

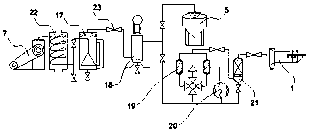

[0016] see Figures 1 to 3 As shown, a resin sand processing production line includes an old sand recycling device, a new sand conveying device 14, and a pneumatic device. The old sand recycling device includes a drum shakeout machine 1, a vibrating regeneration machine 2, a suspension magnetic separator 3, and a rotor Recycling machine 4; the old sand is shaken from the drum shakeout machine 1 and then crushed by the vibrating regenerator 2, then demagnetized by the suspension magnetic separator 3, regenerated by the rotor regenerator 4, and finally mixed with new sand and then entered by the air delivery device 5 Double-arm sand mixer 6; one side of the drum shakeout machine 1 is fed with heated compressed air to evaporate water; the pneumatic device provides the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com