Capacitor unit

A technology of capacitor units and capacitors, which is applied to multiple fixed capacitors, fixed capacitor leads, fixed capacitor shells/packages, etc. It can solve the problems of intricate connection between capacitors and devices, large lead inductance, and uneven capacitance distribution, etc., to achieve easy industrialization Mass production, easy installation and maintenance, uniform capacitance distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

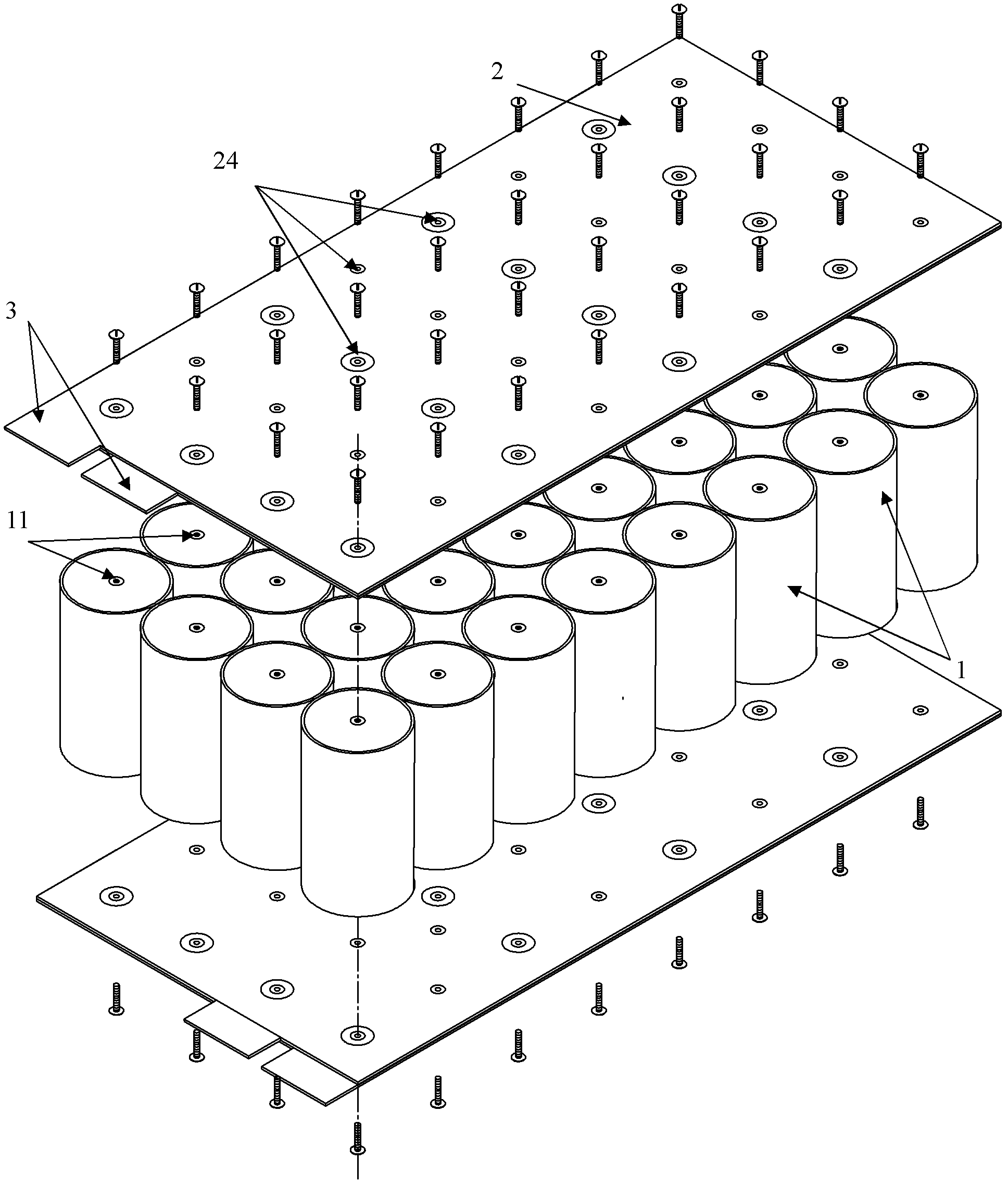

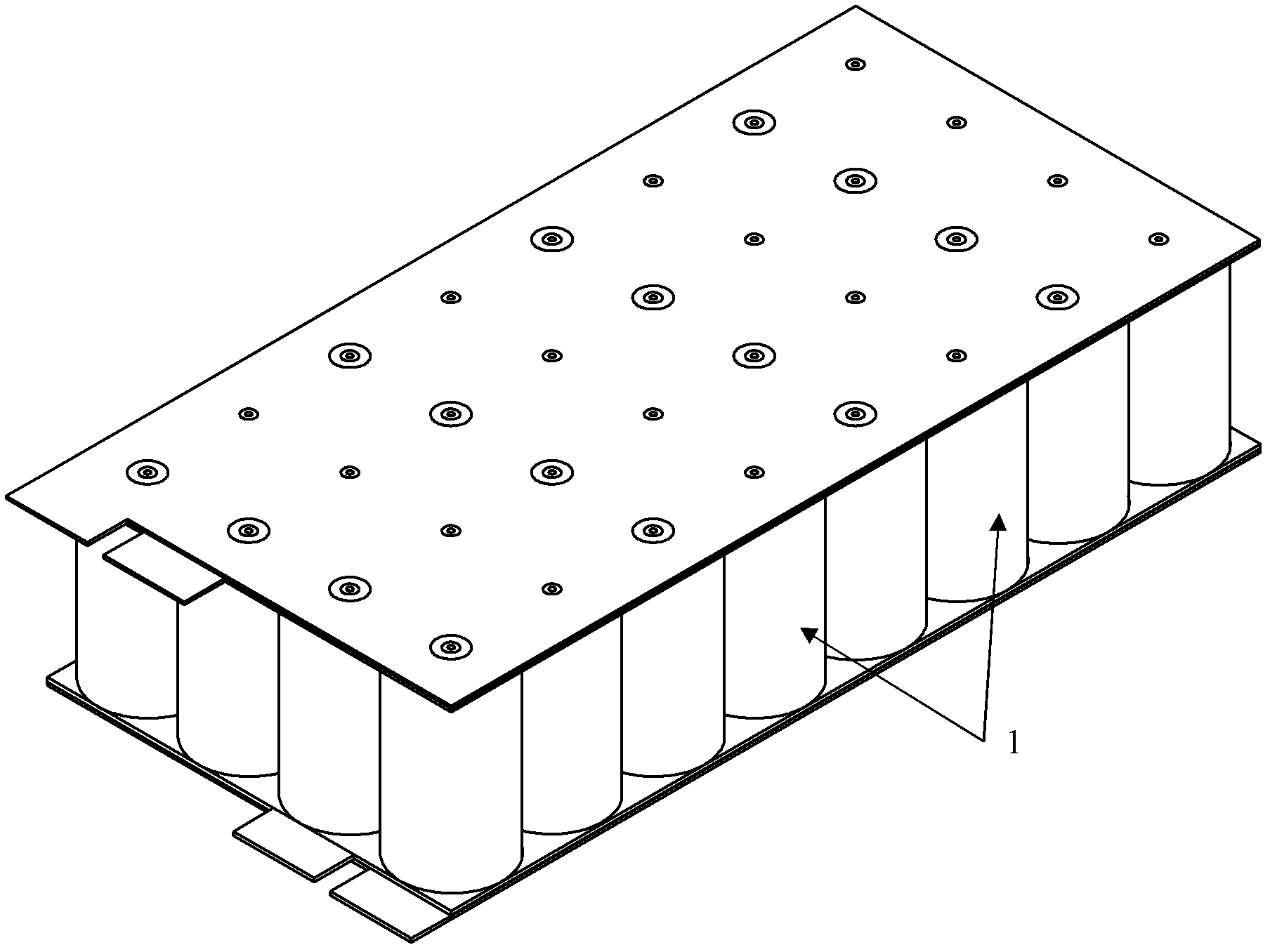

[0067] Such as Figure 1 to Figure 5 Shown, the capacitor unit of the present invention comprises:

[0068] A plurality of capacitor cells 1, all the capacitor cells are arranged in a matrix to form a capacitor array, and the electrodes 11 of each capacitor cell are bidirectionally drawn out from top to bottom;

[0069] The upper and lower composite busbars 2 cover the upper and lower sides of the capacitor array and are connected to the electrodes of each capacitor cell 1; each composite busbar is composed of upper and lower layers of metal electrodes with the same size and correspondingly arranged Plates 21, 22 are compounded, and the two layers of electrode plates are insulated from each other by an insulating layer 23; among the two layers of electrode plates 21, 22, one of the electrode plates 21 is a positive electrode plate connected to the forward current, and in addition One layer of electrode plates 22 is a negative electrode plate connected to the negative current;...

Embodiment 2

[0076] This embodiment is based on Embodiment 1, and the technical features are added on the basis of Embodiment 1. In order to save space, this embodiment only points out that the following technical features are added on the basis of Embodiment 1:

[0077] Such as Figure 7 As shown, the electrode sheet of the composite busbar and the composite busbar form an inverted L shape, and figure 1 On the basis, a terminal board 5 for connecting terminals and electrode sheets is added. The terminal board 5 is made of insulating material, arranged on the leading side of the electrode sheet 3 of the composite busbar, and installed between the electrode sheet 3 and the capacitor array;

[0078] The lead-out terminal 6 is plugged and installed on the terminal board 5 to be electrically connected with the electrode sheet 4 .

[0079] This embodiment provides a new structural form. In this structure, unified plug-in terminals are used to facilitate integrated installation and use on the c...

Embodiment 3

[0081] This embodiment is based on Embodiment 1, and some technical features have been improved on the basis of Embodiment 1. In order to save space, this embodiment only points out the differences from Embodiment 1:

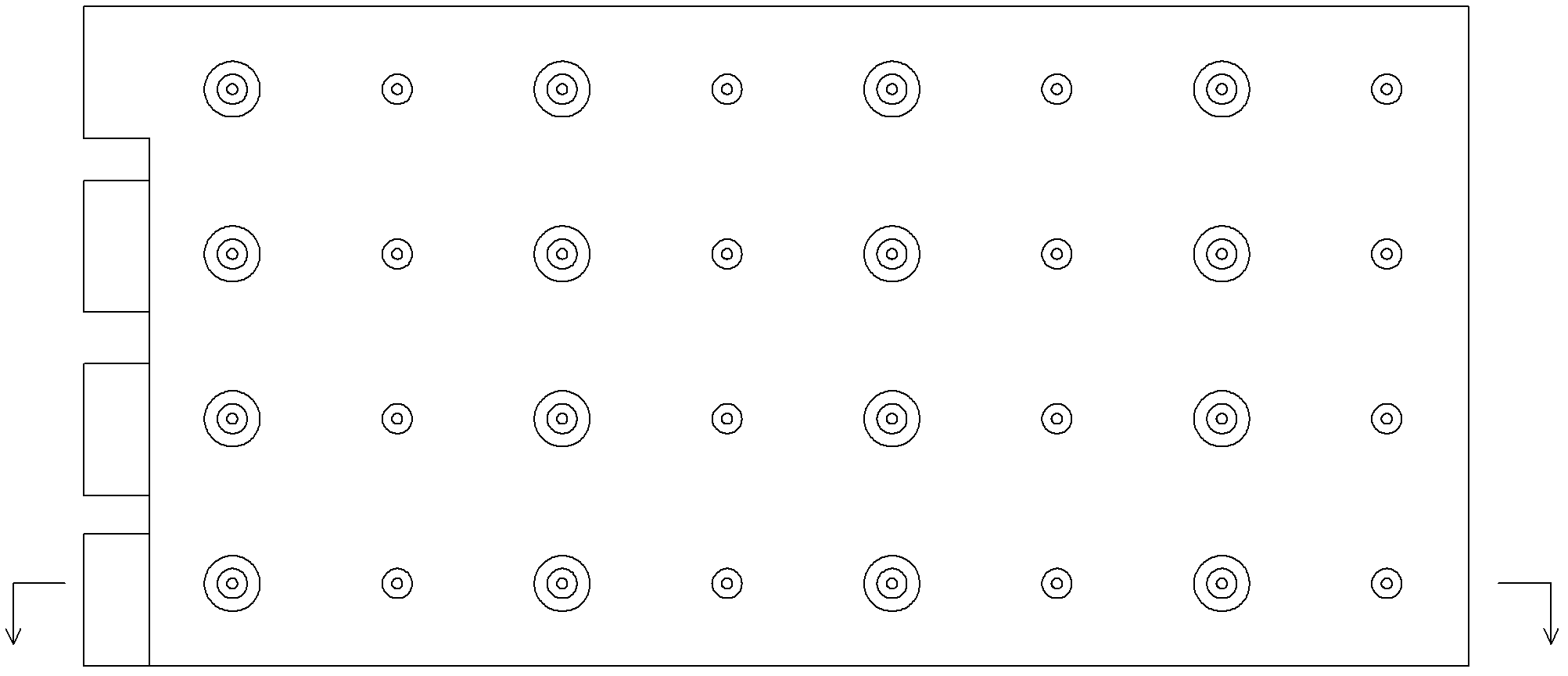

[0082] The arrangement of the capacitor cells in the first part and the capacitor cells in the second part in the capacitor array is not staggered in rows and columns but staggered with each other;

[0083] Figure 8 Shown is the arrangement of capacitor monomers connected to the upper composite busbar, where the "+" sign indicates that the corresponding capacitor is connected to the positive electrode plate end of the composite busbar, and the "-" sign indicates that the corresponding capacitor is connected to the positive electrode plate end of the composite busbar. It is the negative electrode plate end of the composite busbar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com