Patents

Literature

30results about How to "Accurate stereotypes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing three-plain-stitch woolen sweaters

InactiveCN101880935AClear textureAccurate stereotypesWeft knittingHeating/cooling textile fabricsYarnEngineering

The invention discloses a method for manufacturing three-plain-stitch woolen sweaters. The manufacturing method comprises the following steps of: preparing of grey yarns serving as a raw material; dyeing; fluffing; piece weaving; steam setting; piece examining; linking; set examining; hand sewing; seam examining; washing; preliminary examining; finish ironing; flat machine setting; drying; fixing; final examining; and packaging. In the method, the step of steam setting is performed before the step of piece examining on weaved pieces to ensure flatness and distinct wale of the three-plain-stitch weaved pieces and further ensure the flatness and the distinct wale of the three-plain-stitch woolen sweaters; besides, the manufacturing sequence of the three-plain-stitch woolen sweaters is changed, namely the step of flat machine setting is performed after the step of washing, so the flat machine setting of the three-plain-stitch woolen sweaters is more accurate, and the defective rate of the three-plain-stitch woolen sweaters is reduced; and furthermore, the steps of piece examining, set examining and seam examining are added in the method, so the management and control over quality of each stage is strengthened, the yield of products is improved, and simultaneously the manufacturing efficiency is also improved.

Owner:太仓市隆丝达针织时装有限责任公司

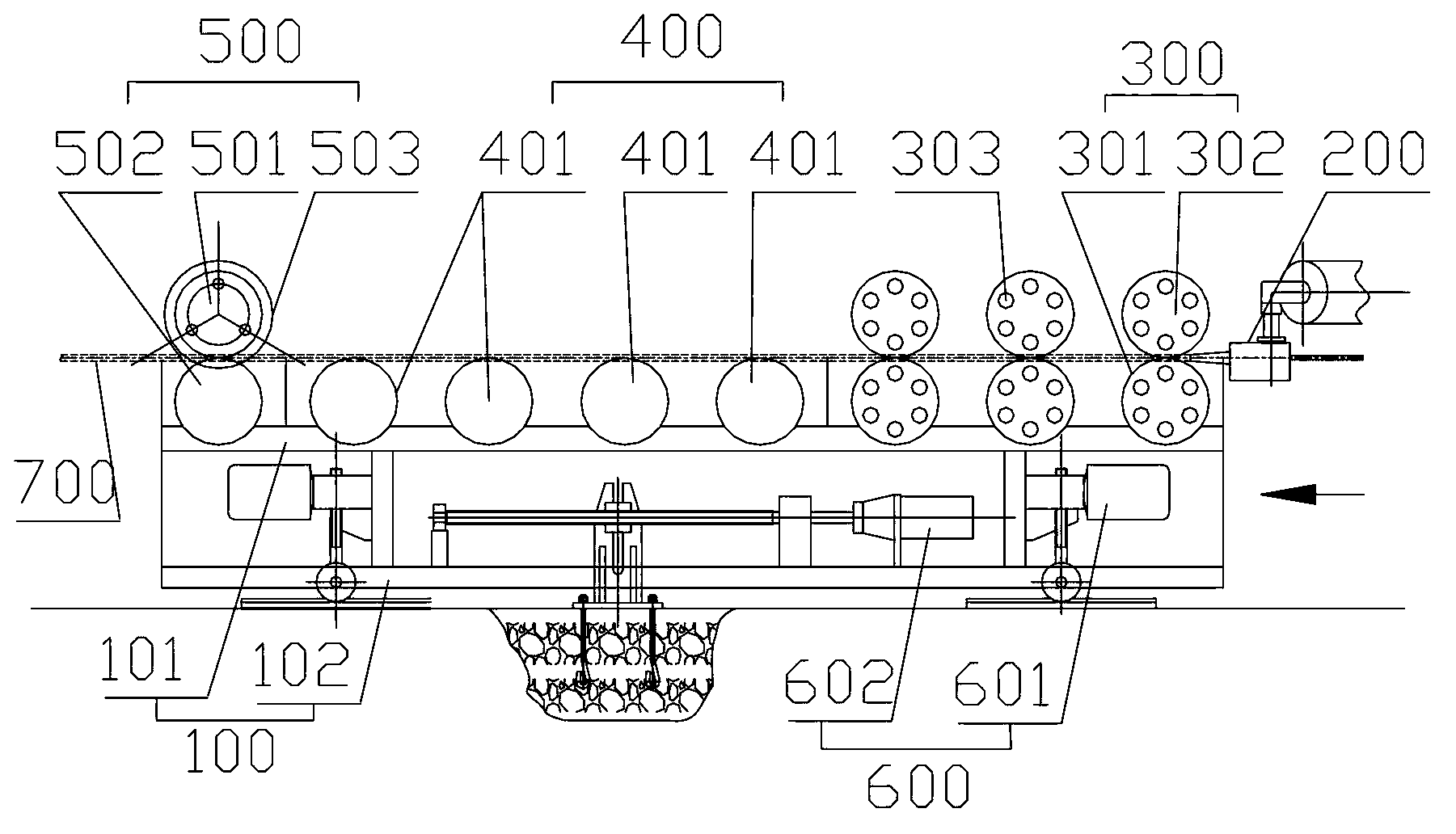

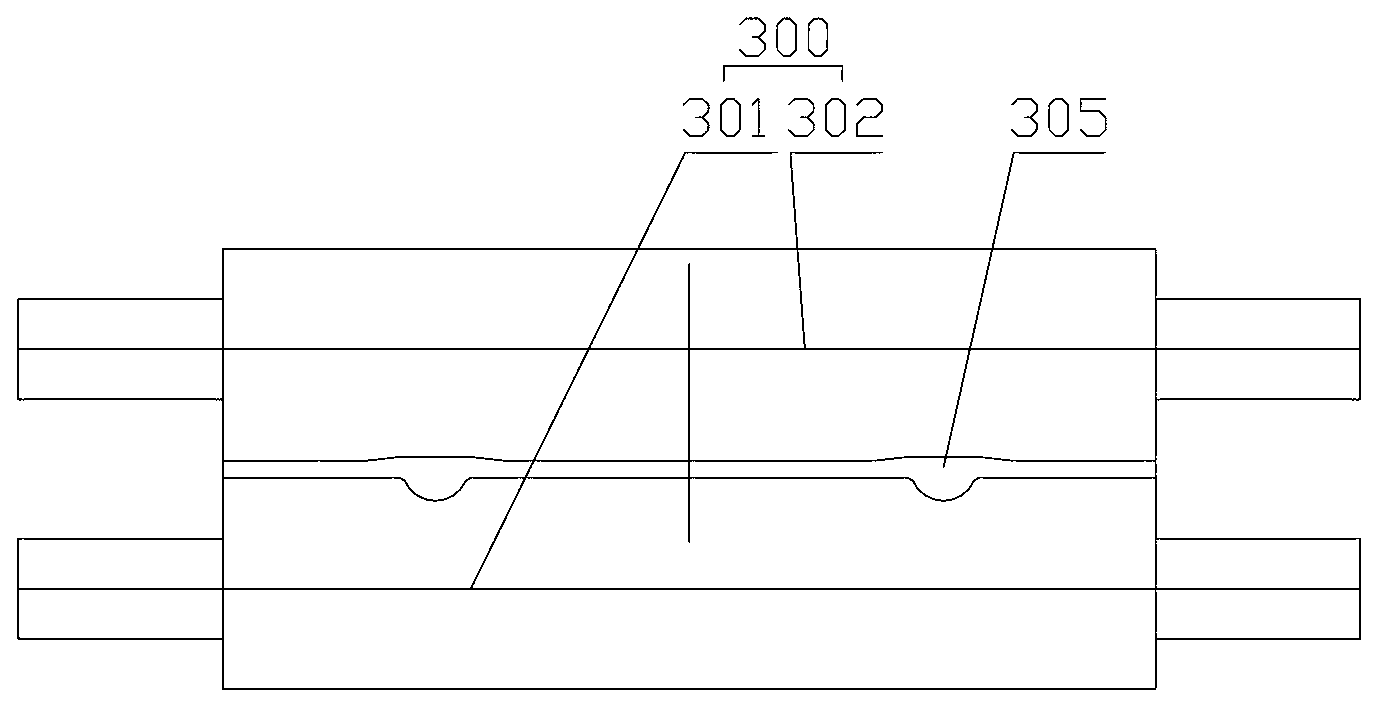

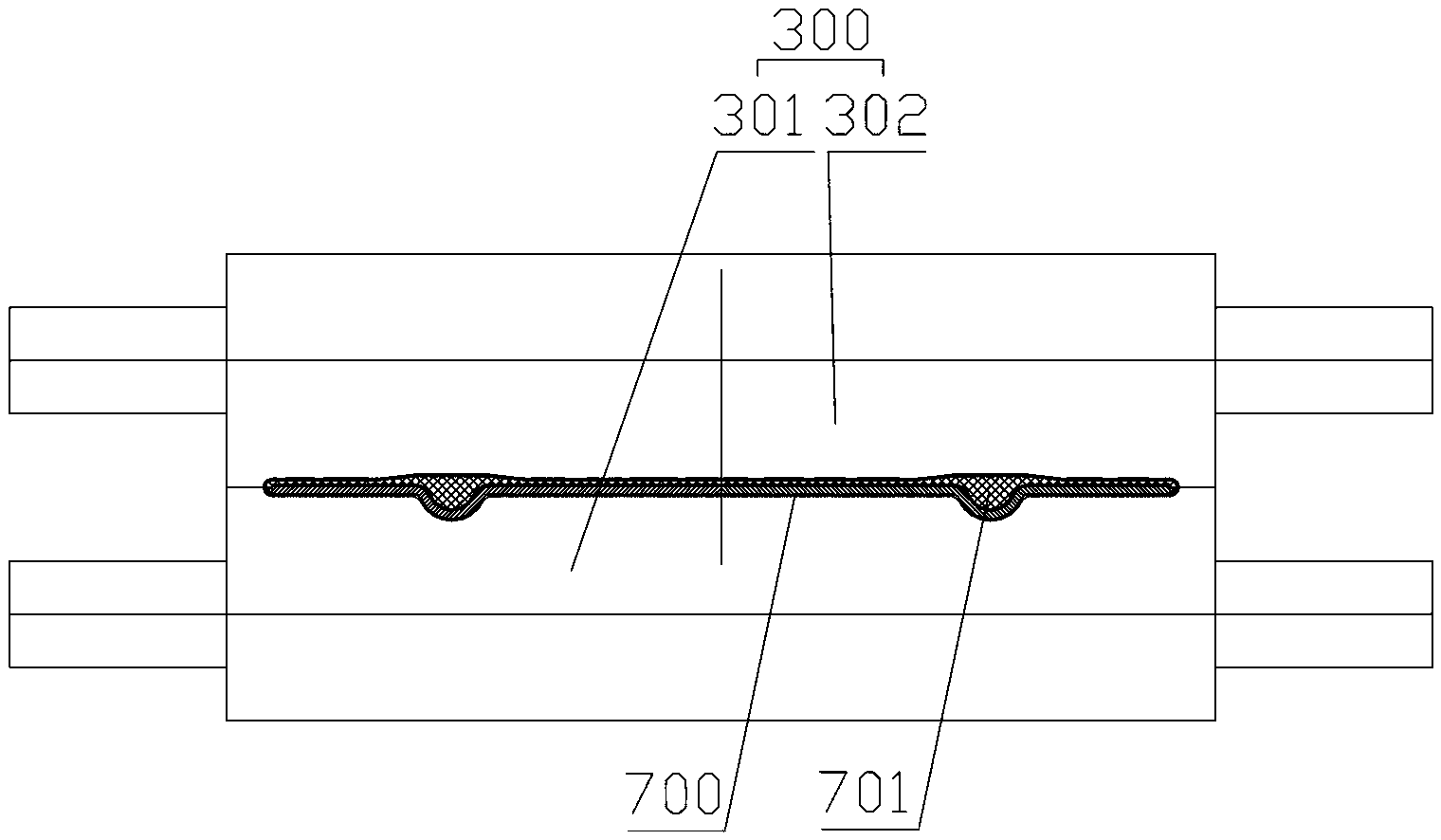

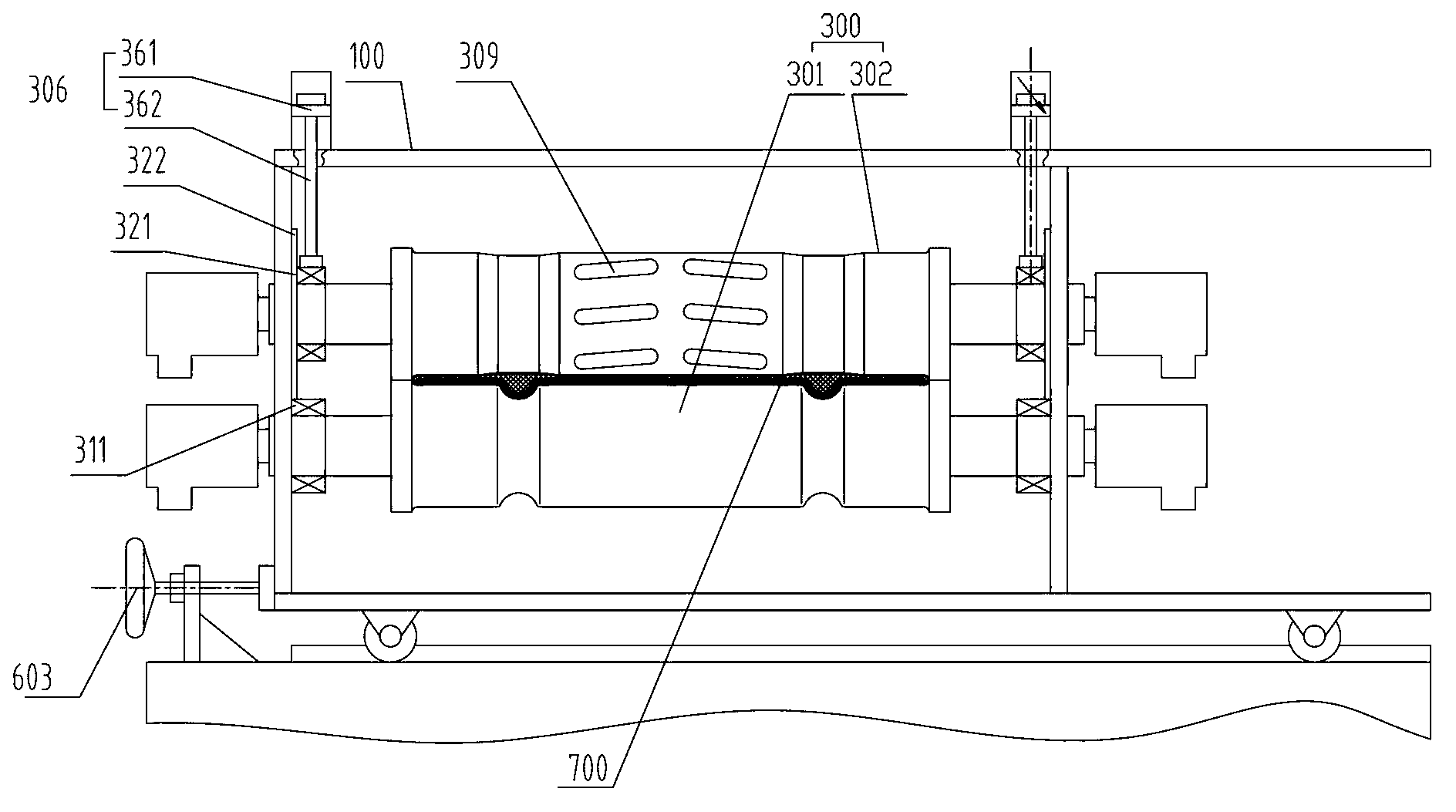

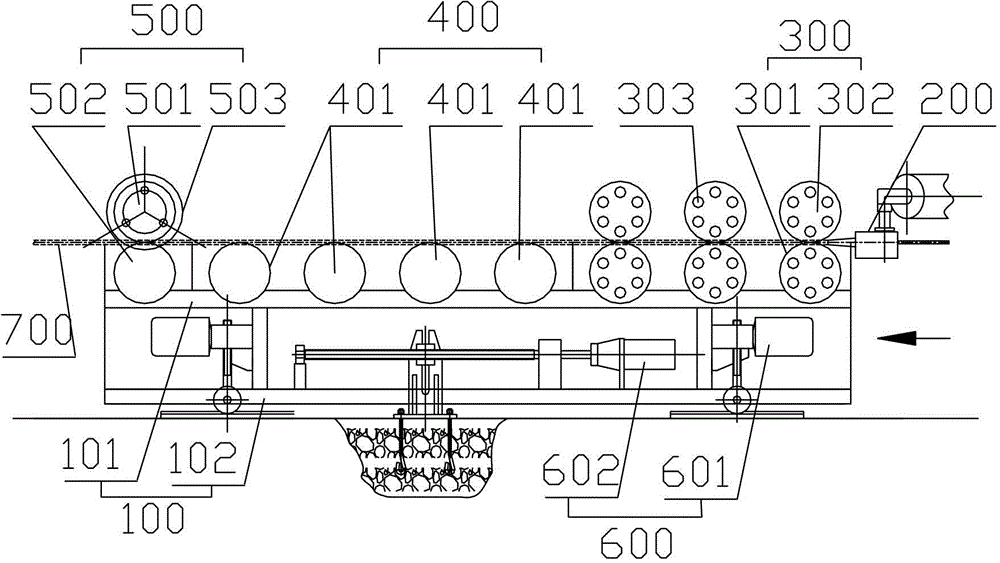

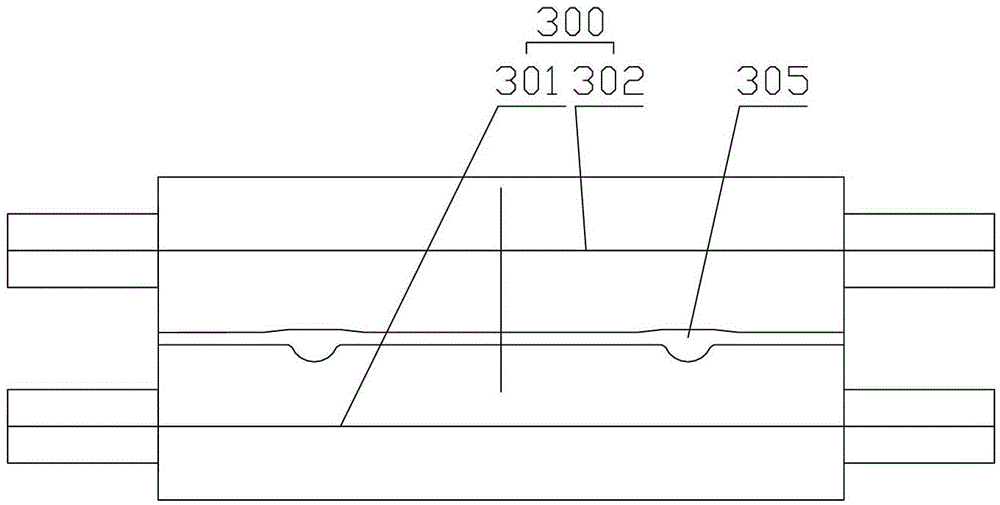

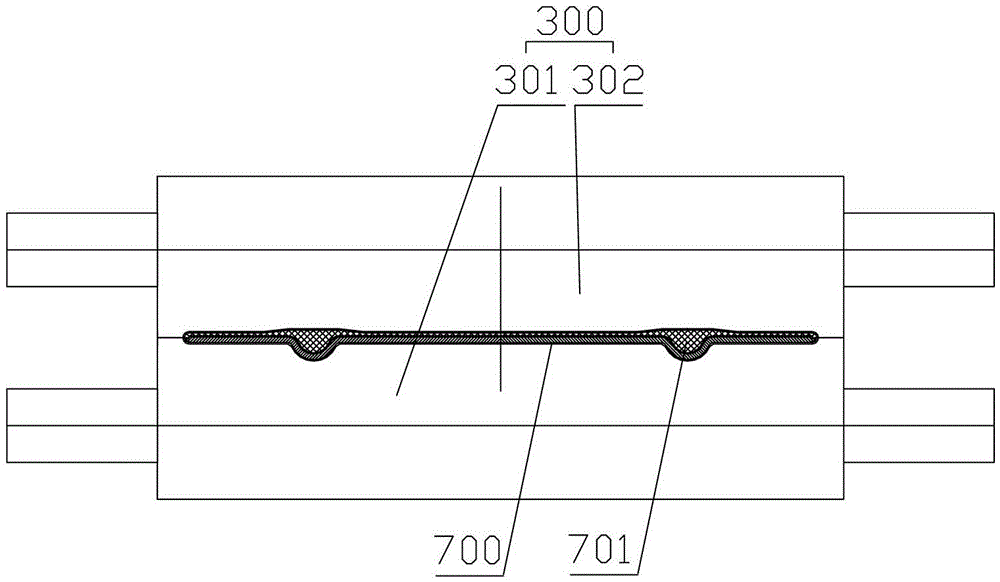

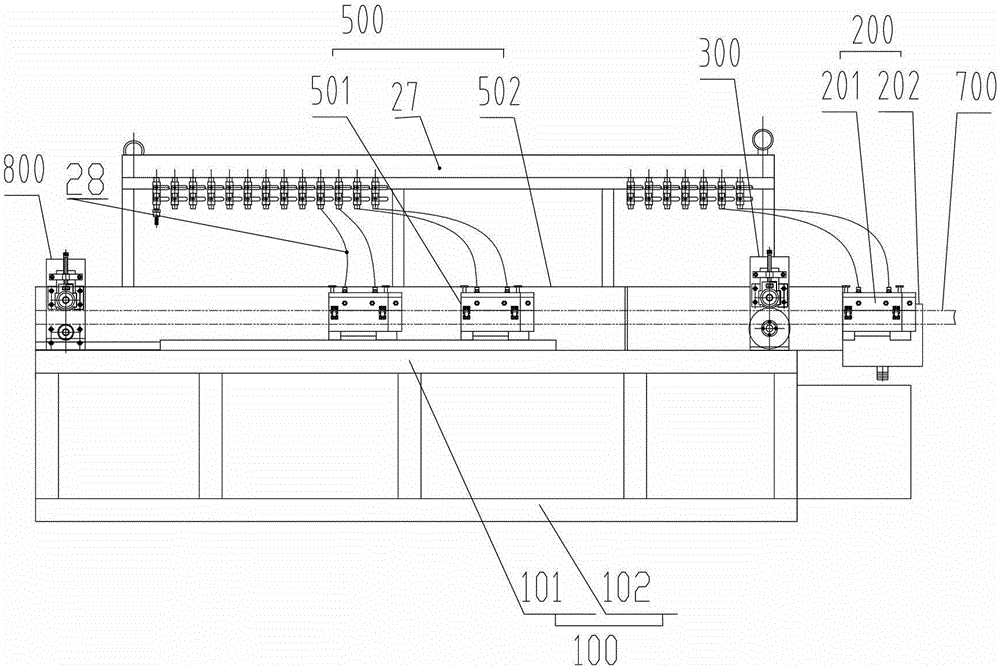

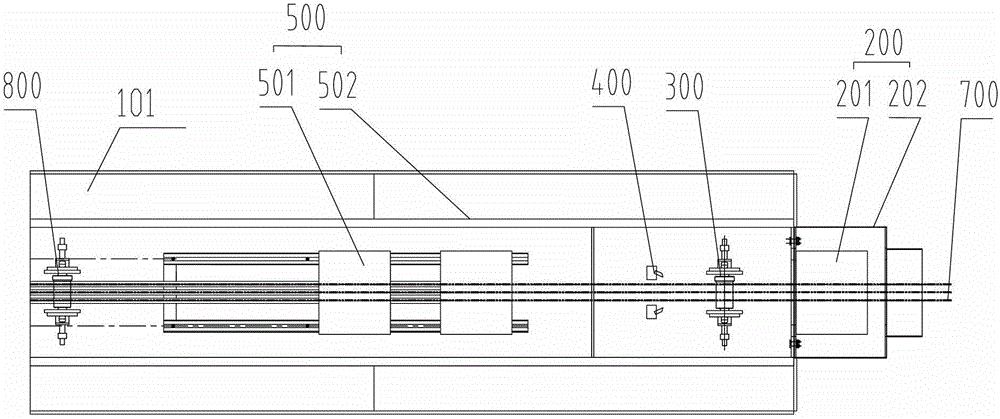

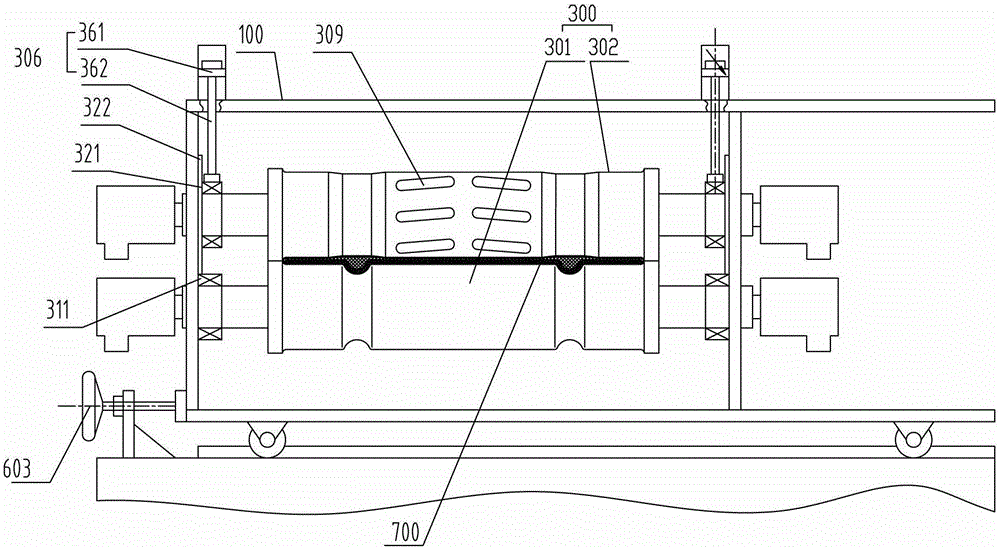

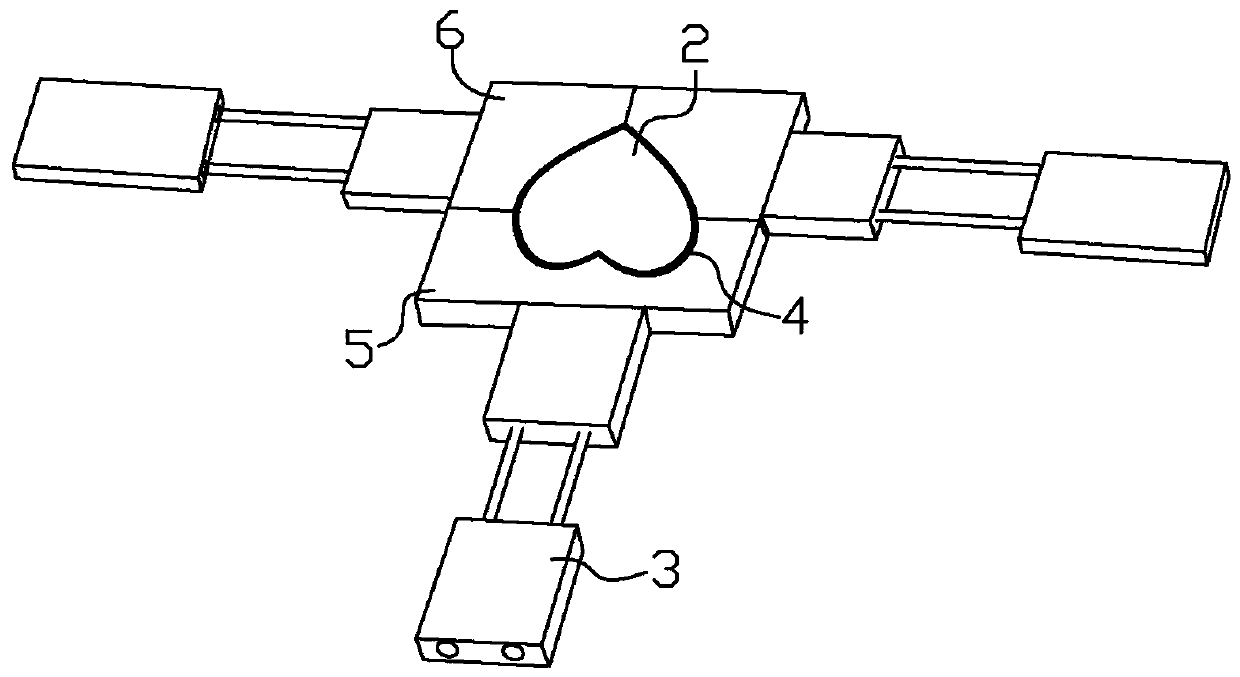

Rolling sizing device

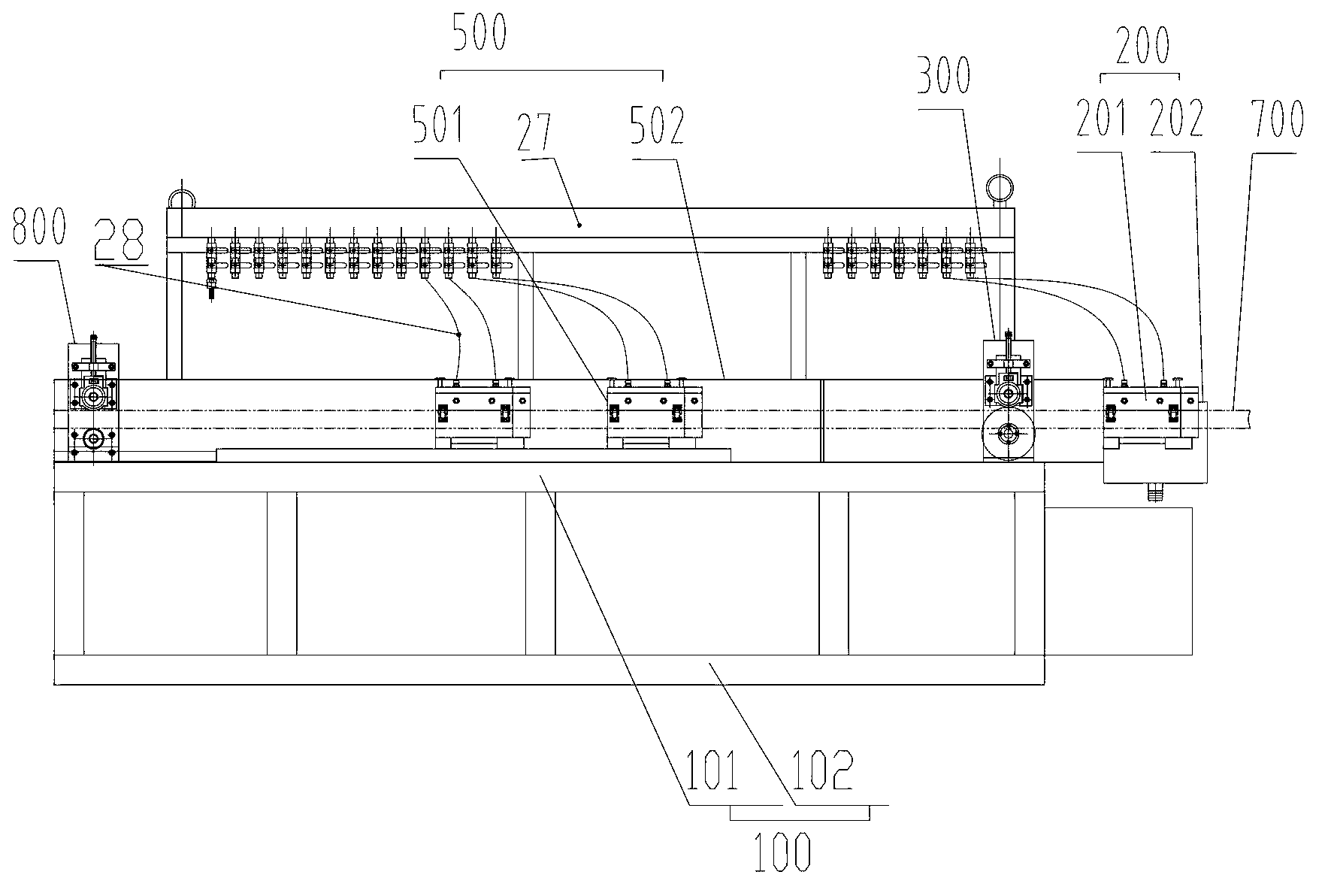

The invention discloses a rolling sizing device comprising a frame. The following components are sequentially arranged on the frame: a rolling roller set used for carrying out drawing and progressive extrusion and sizing upon a strip-shaped thermoplastic composite material, a slow-cooling guide roller set used in further sizing, and an edge-cutting roller set used for trimming the edge of the strip-shaped thermoplastic composite material. The rolling roller set, the slow-cooling guide roller set, and the edge-cutting roller set are linearly arranged. The rolling sizing device also comprise a position adjustment mechanism used for adjusting the relative positions of the rolling roller set, the slow-cooling guide roller set, the edge-cutting roller set, and an extrusion mold. With the strip-shaped thermoplastic composite material rolling sizing device provided by the invention, strip-shaped thermoplastic composite material continuous sizing can be carried out, and the sizing is precise.

Owner:四川江瀚工业股份有限公司

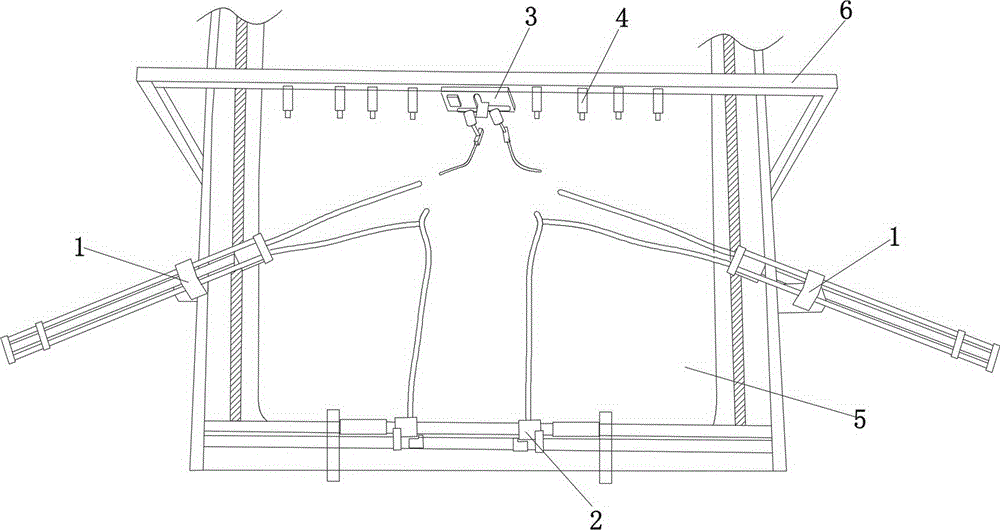

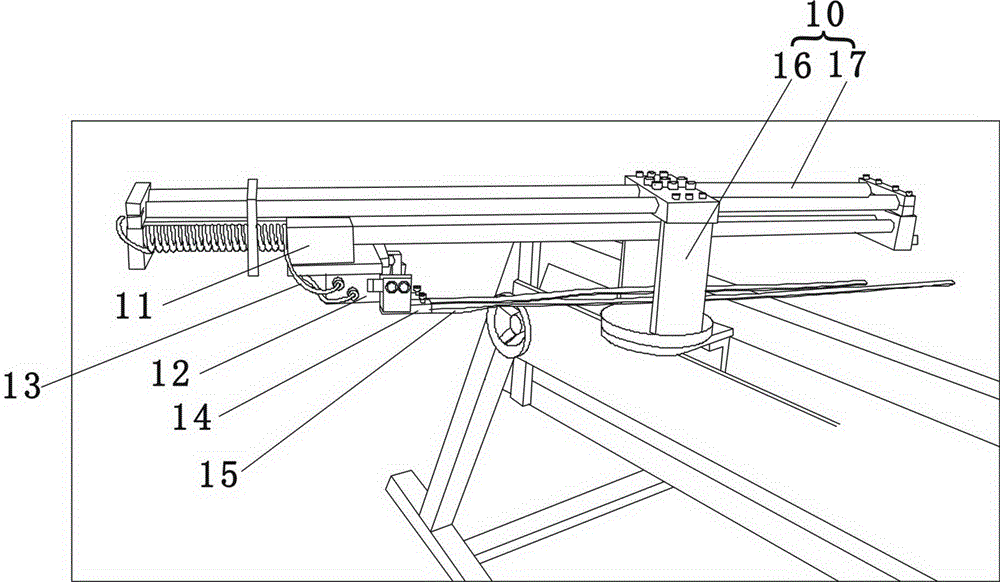

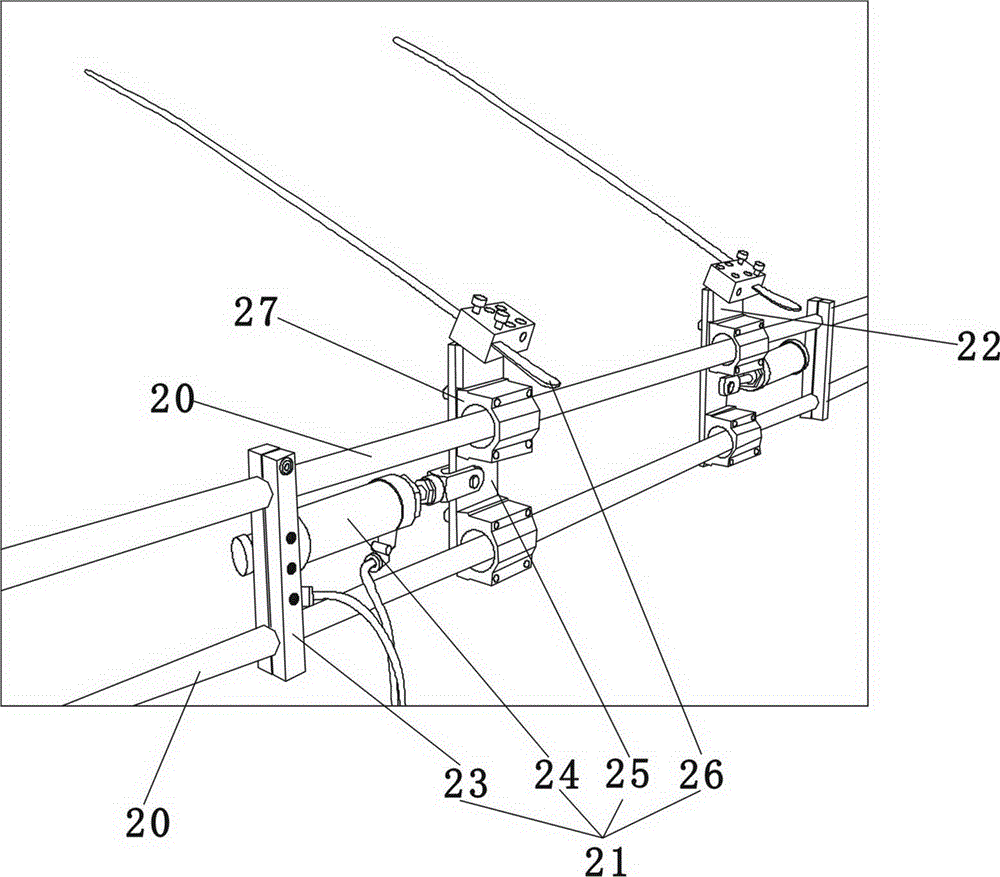

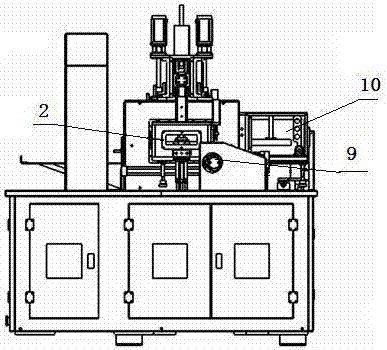

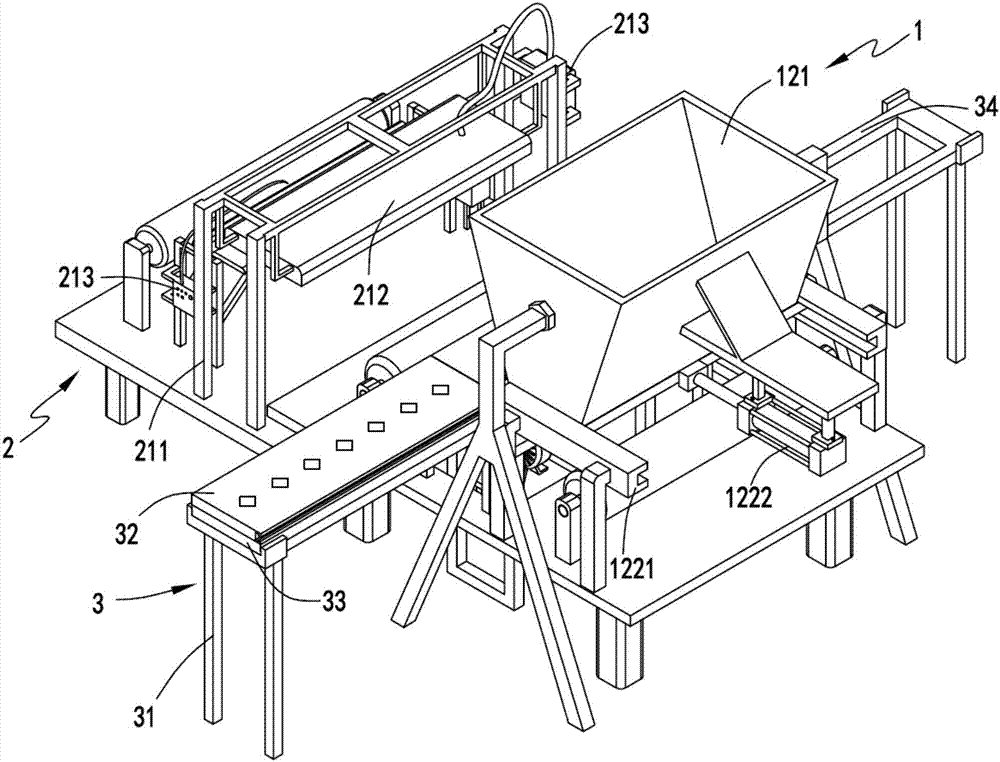

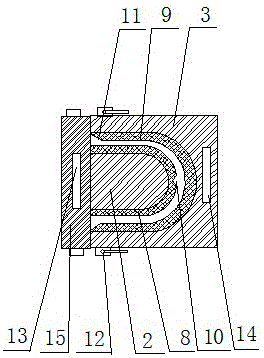

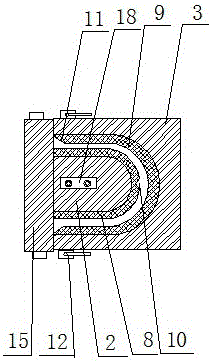

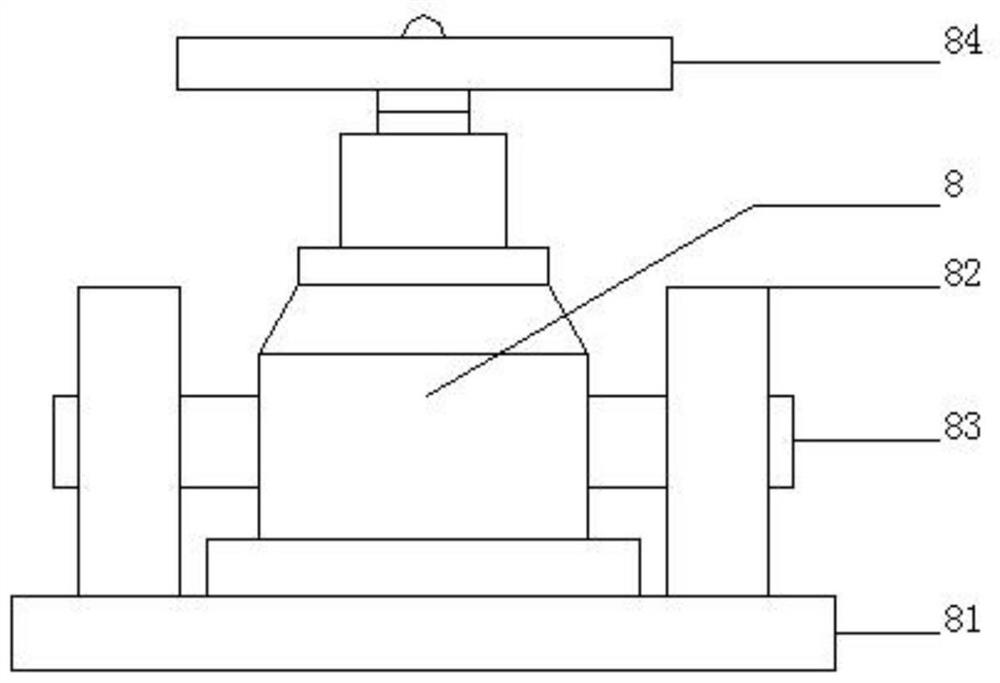

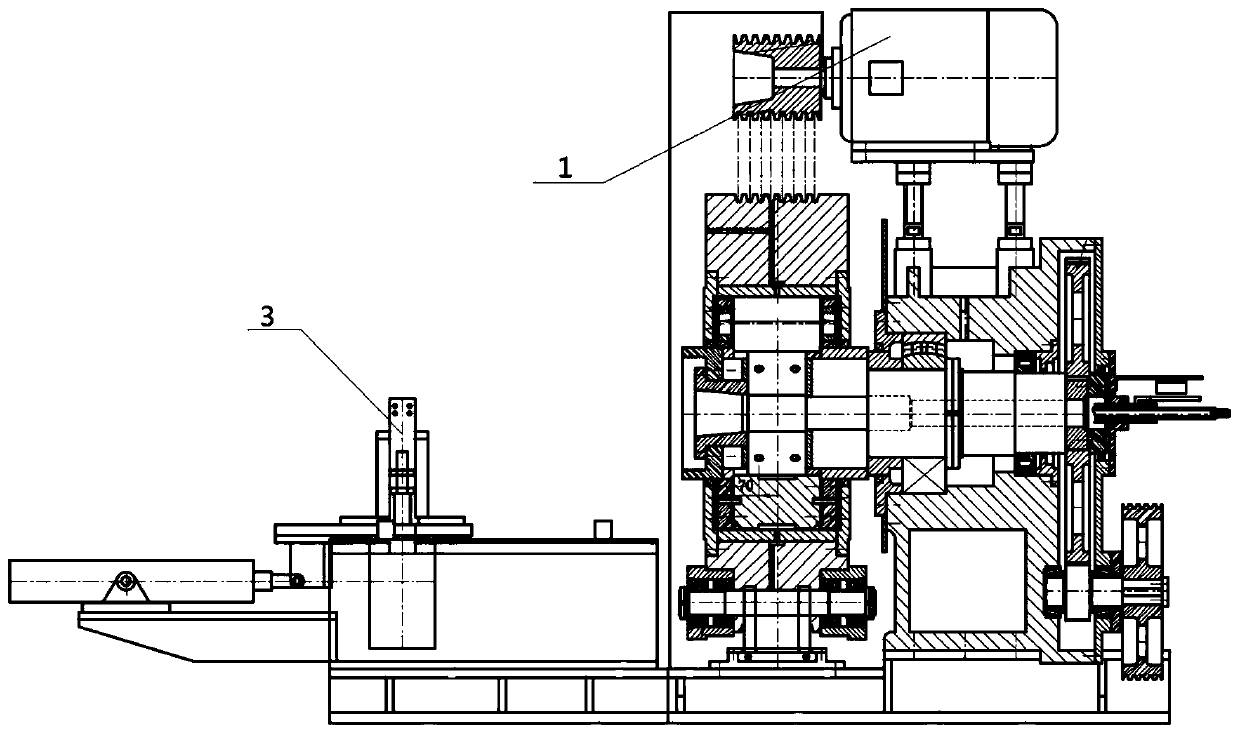

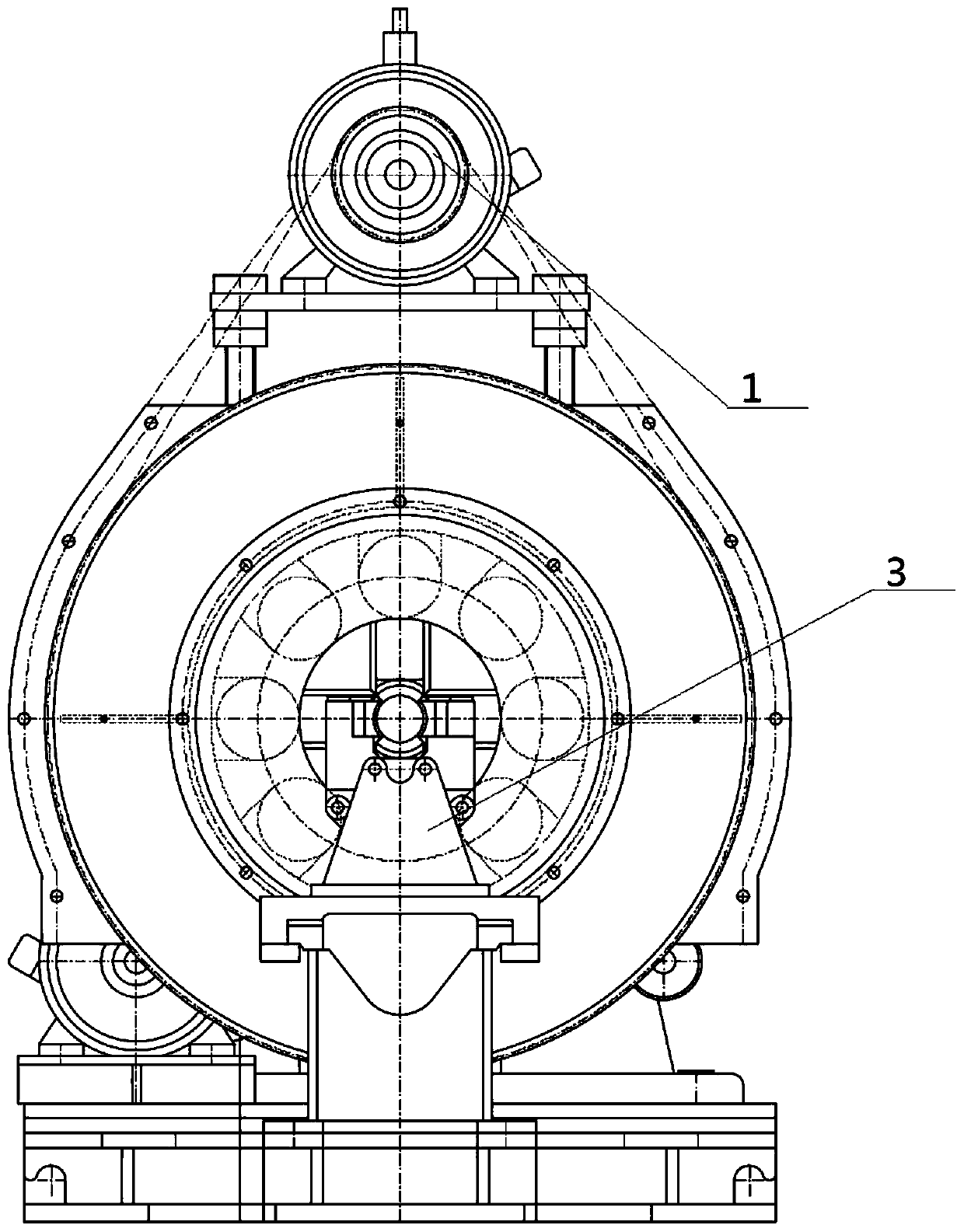

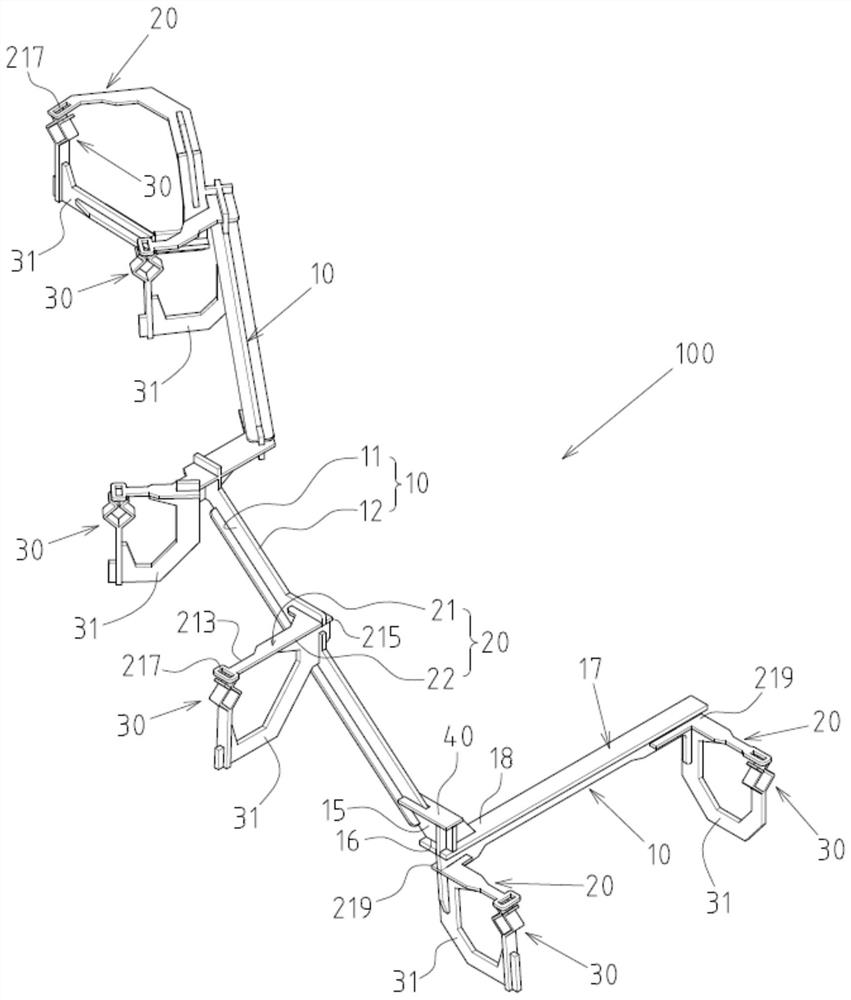

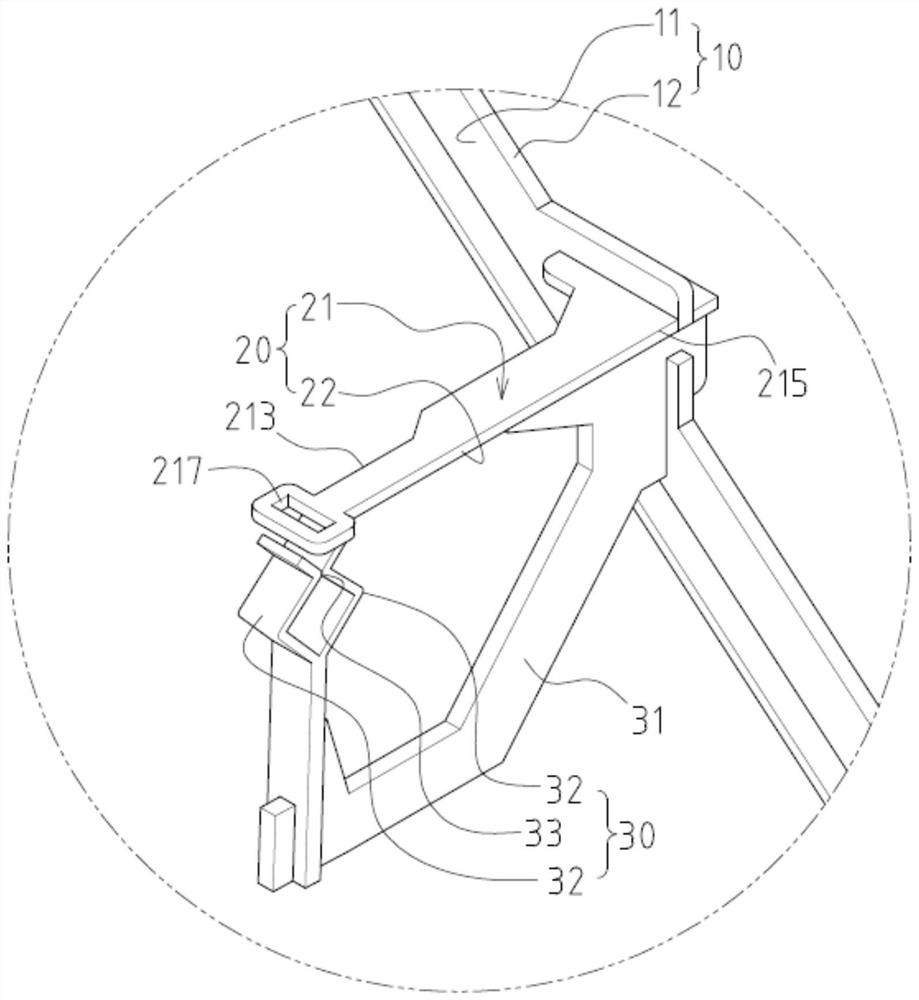

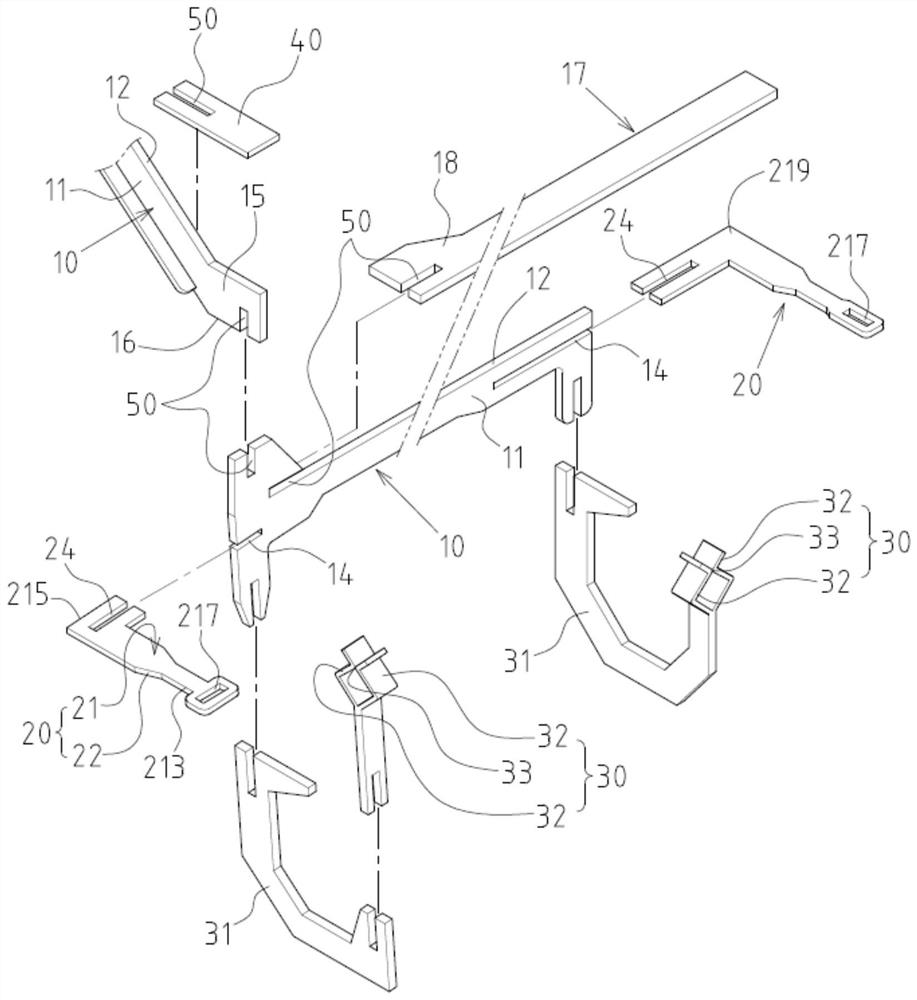

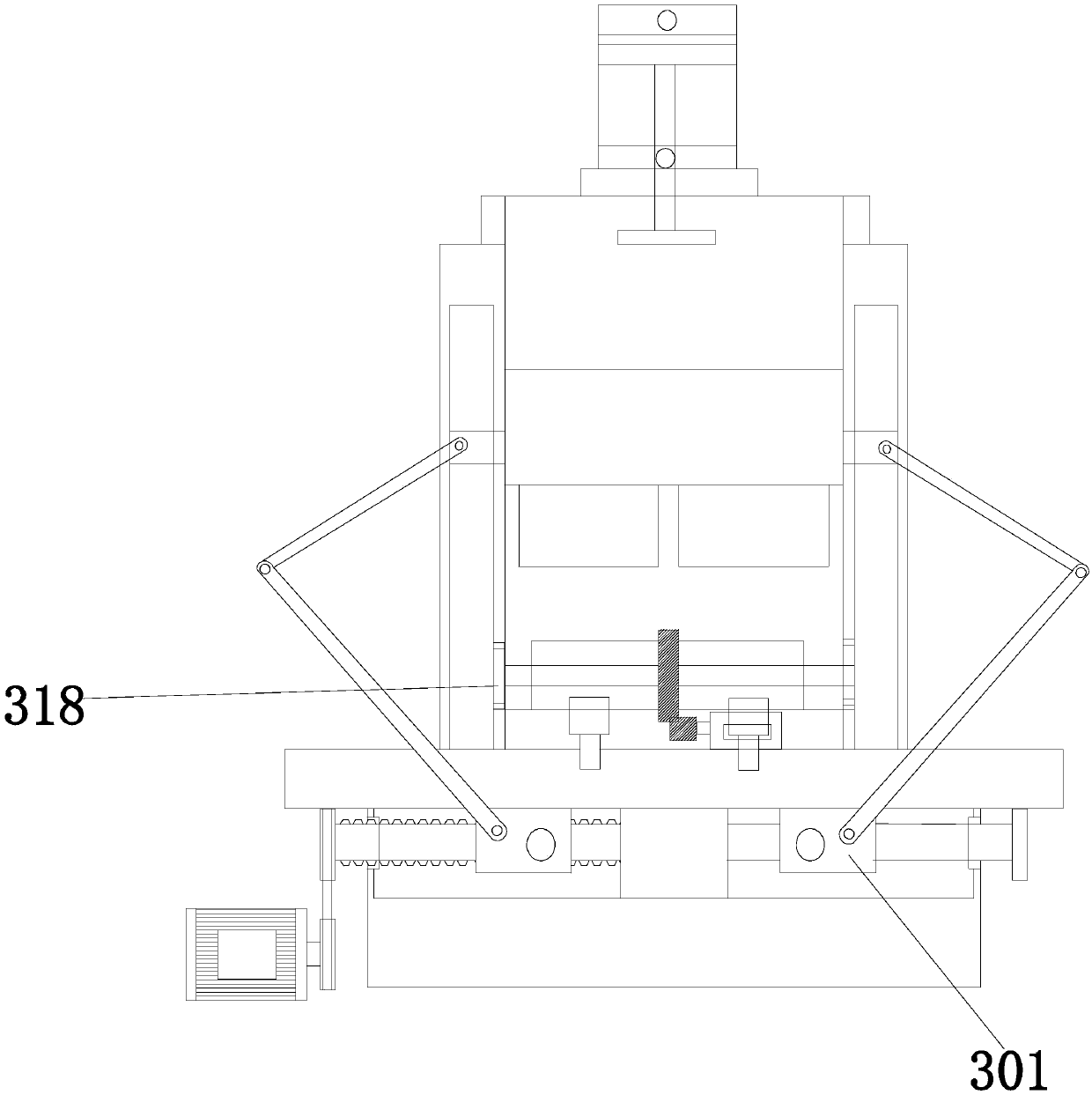

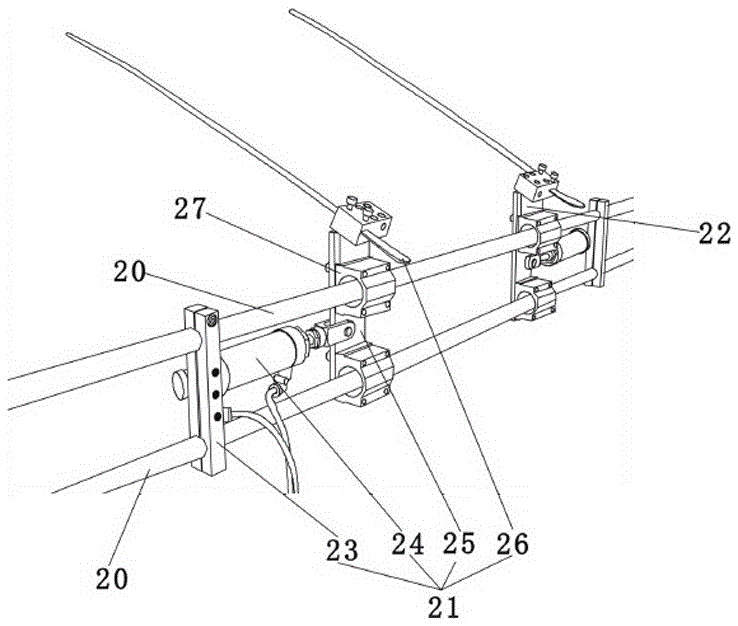

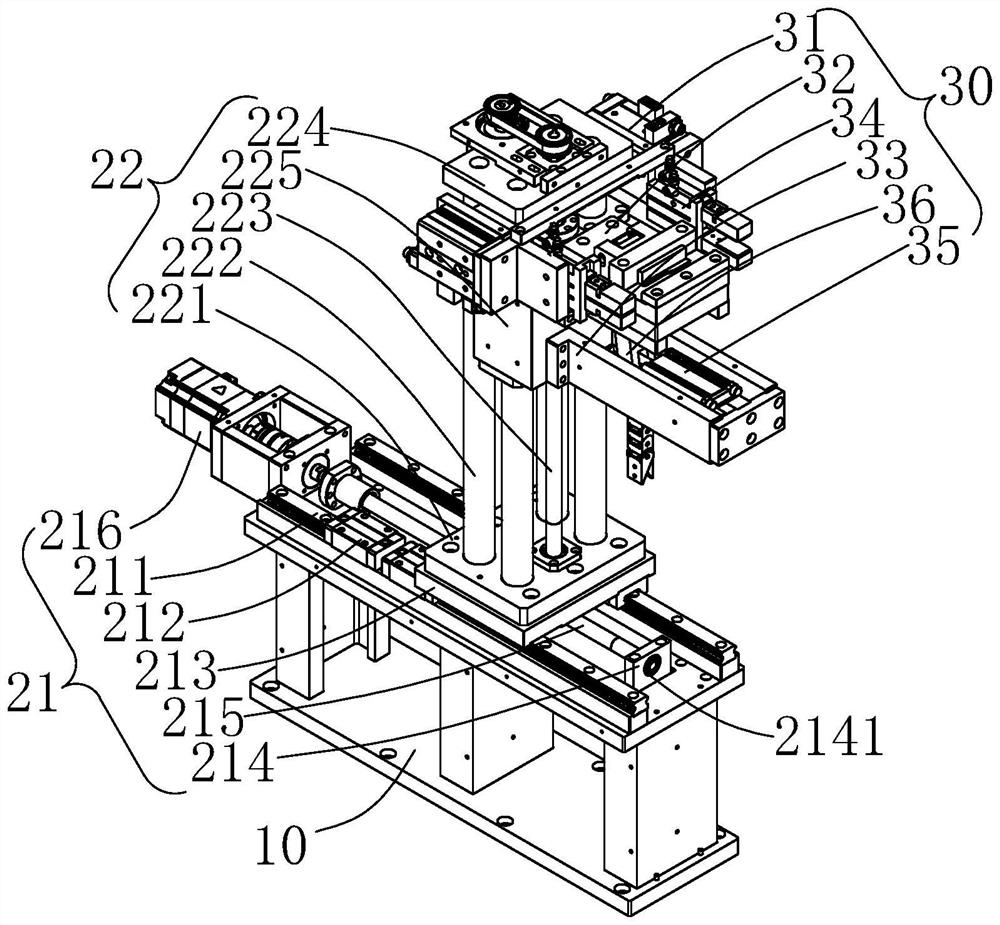

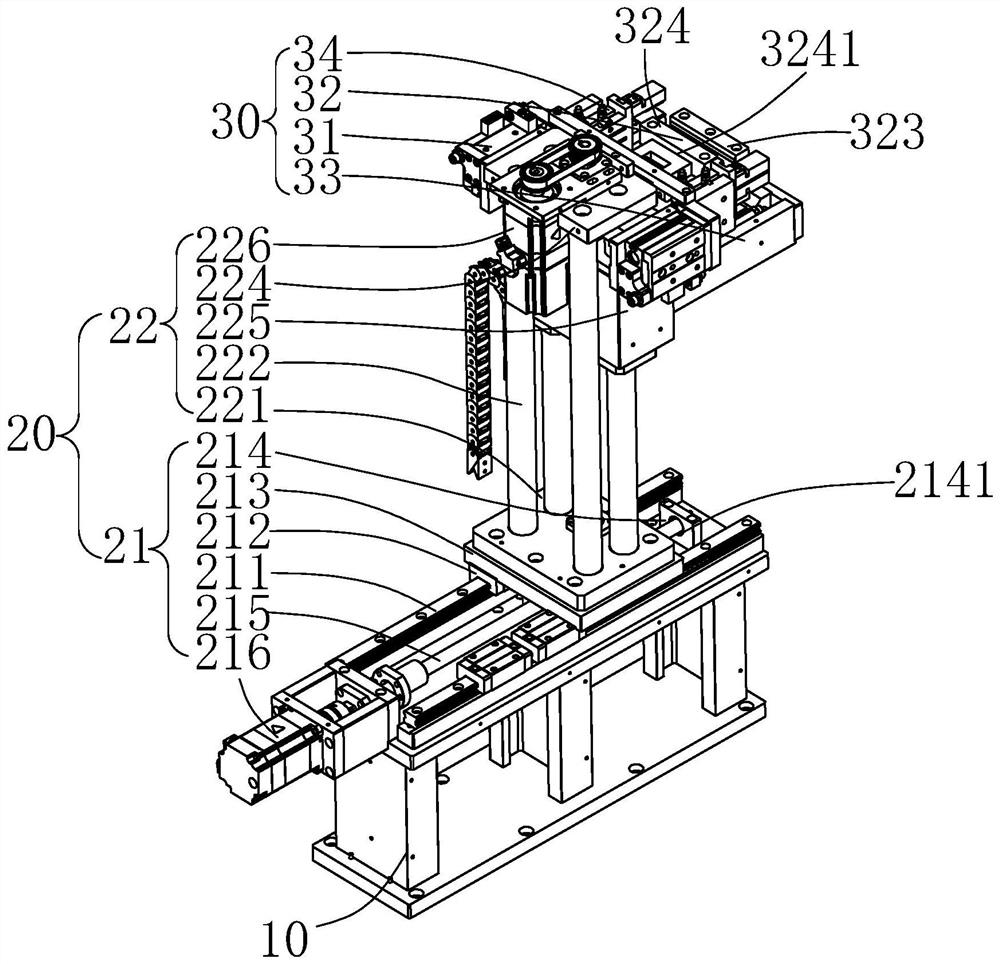

Supporting-unfolding device of costume ironing machine

ActiveCN104480678APrecise positioningImprove labor efficiencyIroning apparatusTextiles and paperLaser transmitterEngineering

The invention provides a supporting-unfolding device of a costume ironing machine. The supporting-unfolding device comprises at least one telescopic type unfolding mechanism consisting of a cylinder control device, a steam guide pipe, a mounting frame, a rod-free cylinder, a finger cylinder, a chuck and a sizing rod, and further comprises an expansion type unfolding mechanism consisting of a sliding rod, a left rod mechanism and a right rod mechanism, wherein both the left rod mechanism and the right rod mechanism comprise cylinder seats, piston type cylinders, mounting seats and sizing rods which are mounted in parallel at certain interval; the supporting-unfolding device further comprises a splay unfolding mechanism including a mounting plate sheet, a piston type cylinder, a gas guide pipe, a transmission assembly, a chuck and a supporting rod; the transmission assembly comprises a transmission rack, a left rotating shaft, a right rotating shaft, a left shaft seat, a right shaft seat and a chuck mounting supporting rod; the supporting-unfolding device is also provided with a supporting-unfolding auxiliary positioning device which is a projection device or a laser emitter group and is mounted above the supporting-unfolding device. The supporting-unfolding device has the characteristics of high automation degree, accurate sizing and high generality and can be used by replacing an ironing template; the production cost is lowered, and the production efficiency is improved.

Owner:NINGBO YUREN INTELLIGENT CONTROL TECH CO LTD

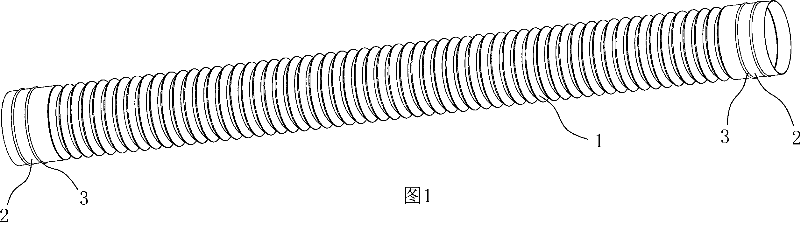

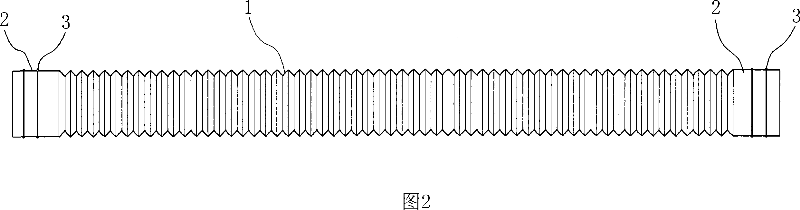

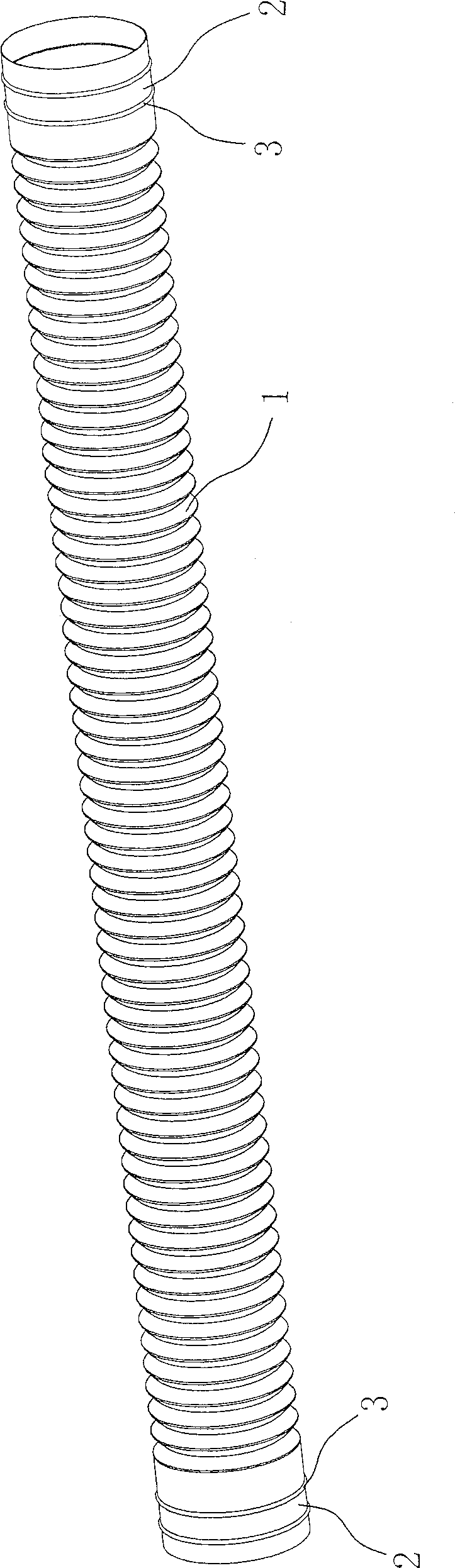

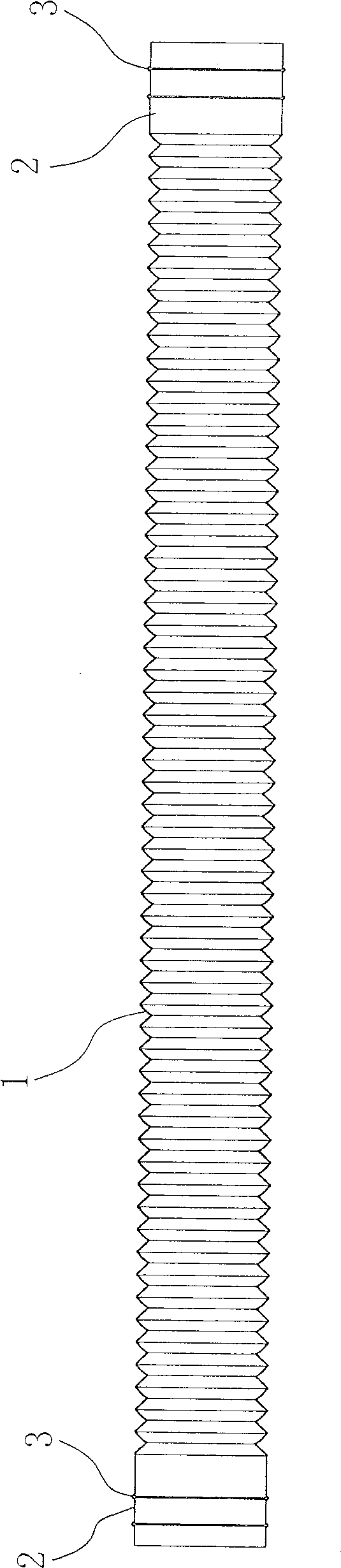

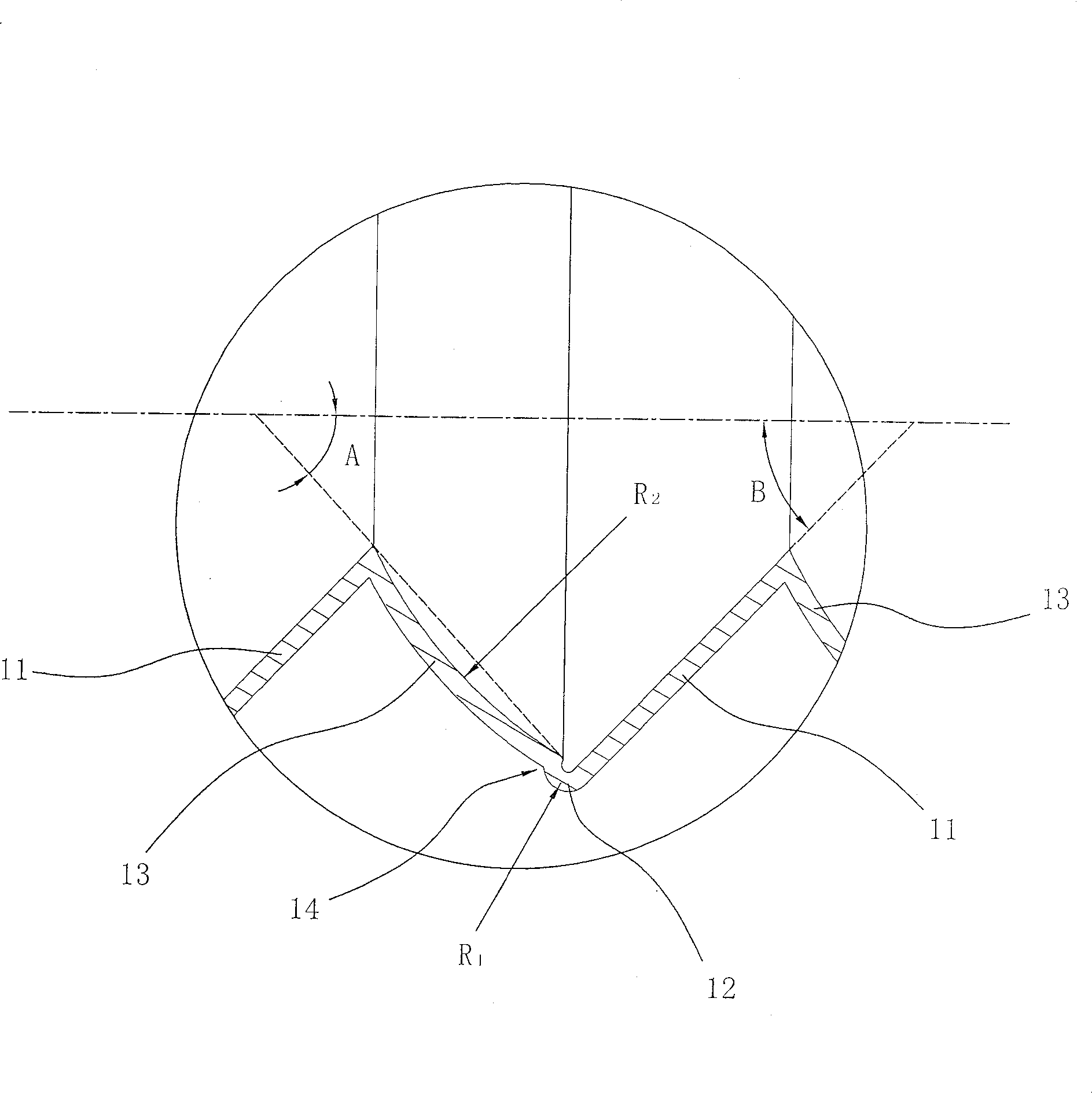

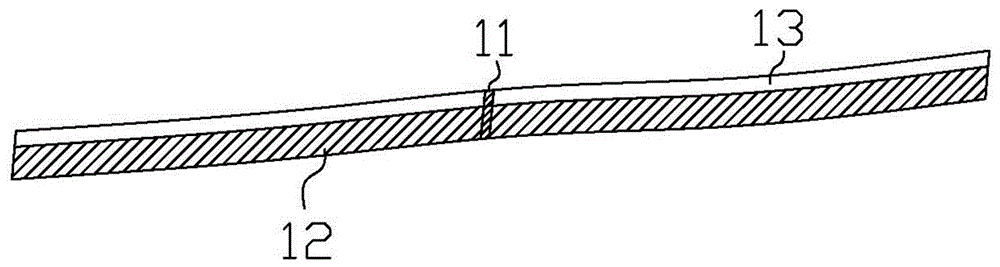

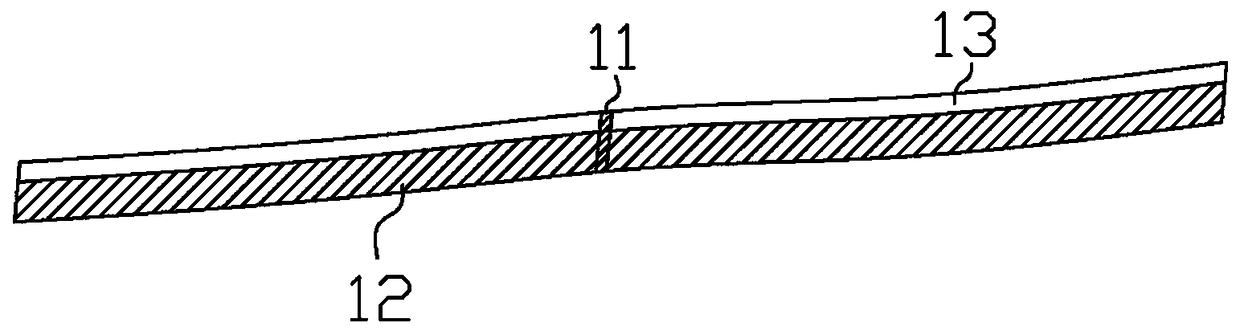

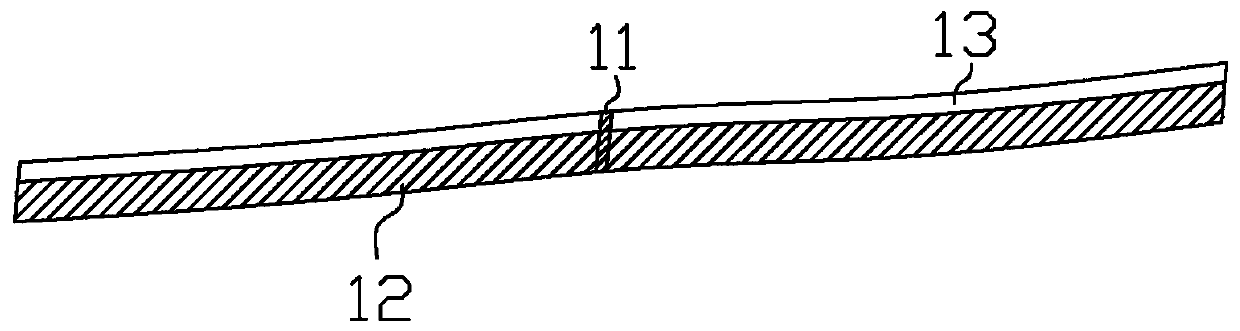

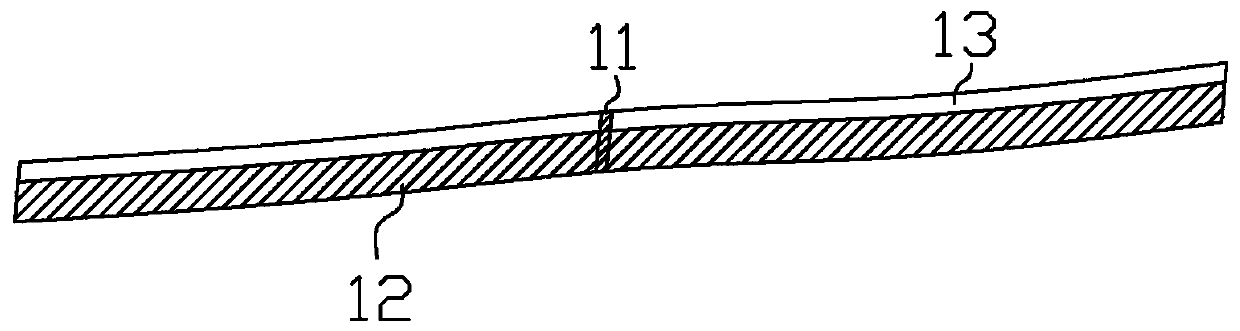

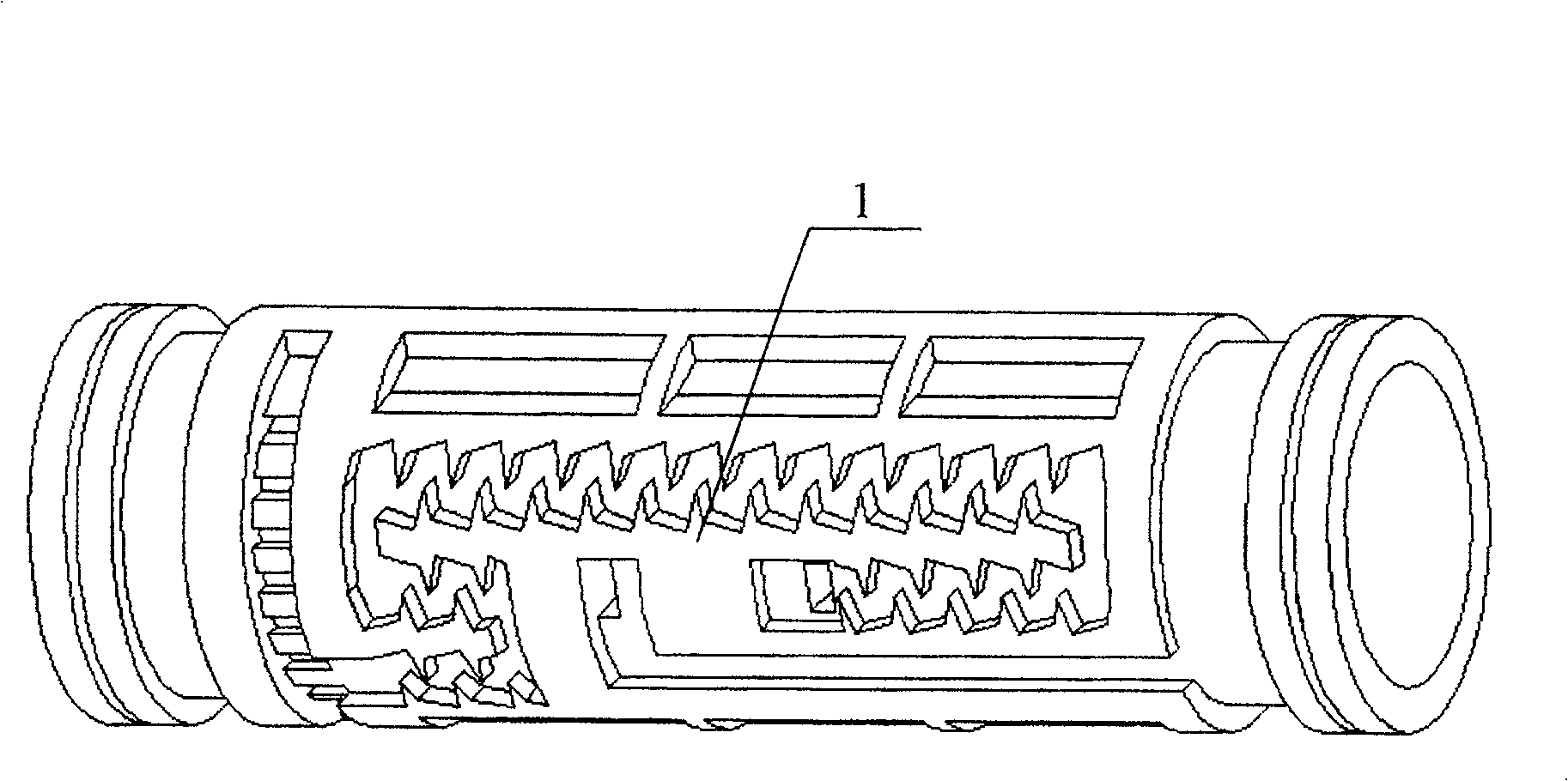

Plastic telescopic pipe and method for manufacturing same

ActiveCN101038054AEasy to fold and foldImprove customization capabilitiesFlexible pipesHigh rateWave shape

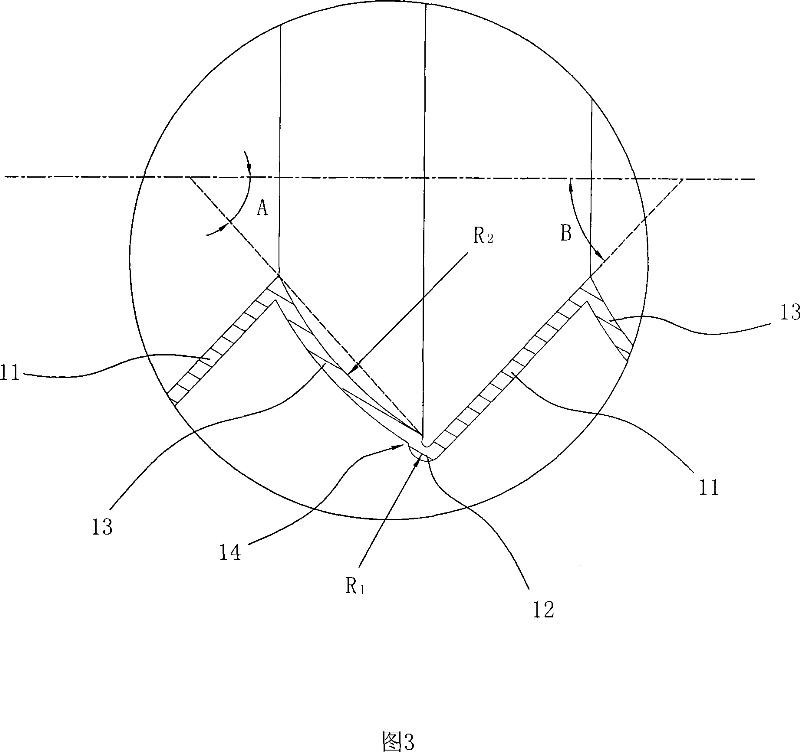

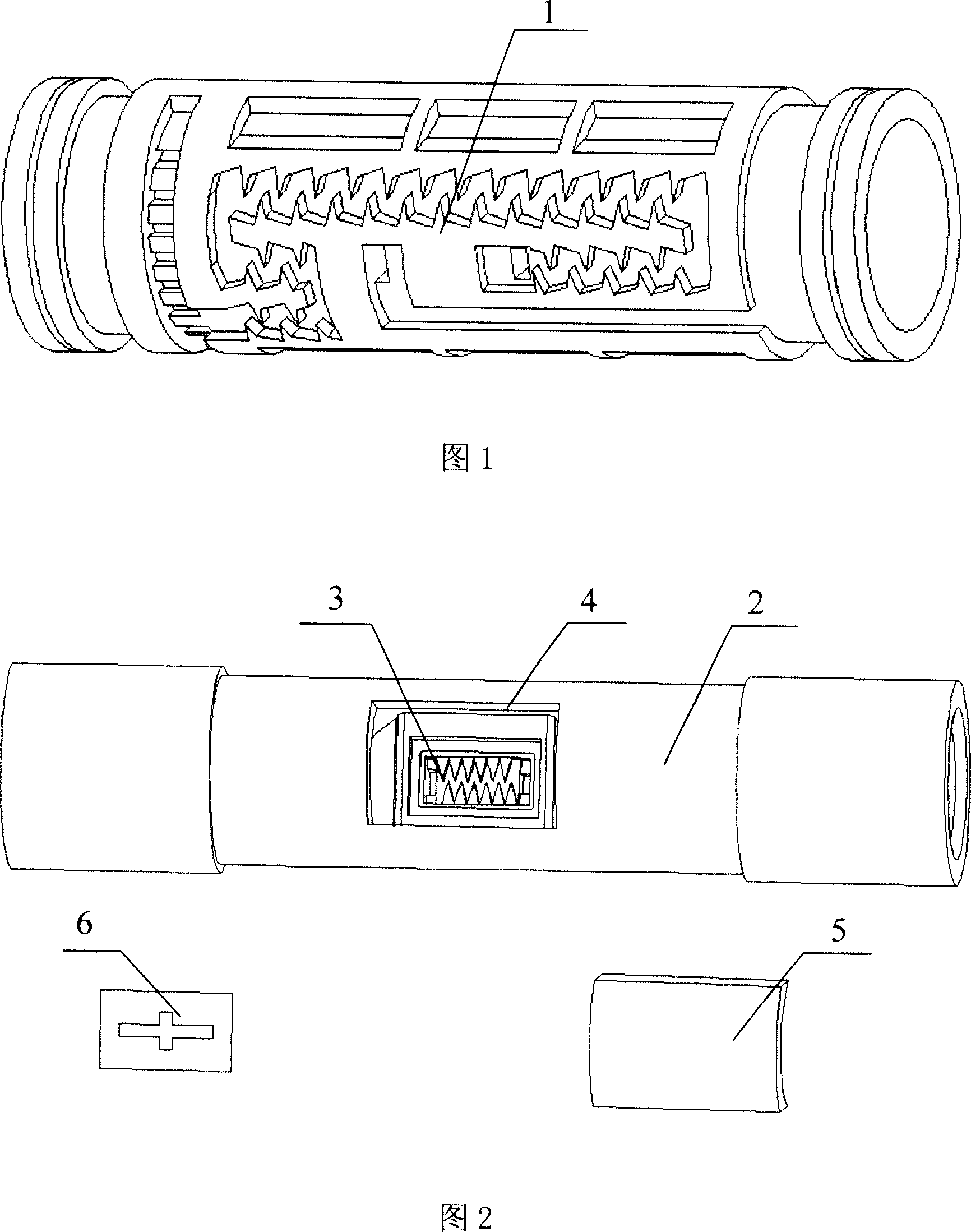

The invention discloses a plastic extension pipe and manufacturing method thereof. The plastic extension pipe is provided with a corrugated pipe body, both ends of which are integrally jointed with adapters, characterized in that viewed from the extended longitudinal section, the pipe wall presents a wave shape by ordinal alternant connections of a right side-wall, circular wave peak wall and a left side wall, curvature radius of the wave peak wall arc is 0.5 to 2 millimeters, a smooth transition is provided between the right side wall and the wave peak wall arc, a break point protruding to the inner pipe is formed by intersection of the left side wall and the wave peak wall arc. Manufacturing method includes steps of pipe blank extrusion moulding, pipe blank inflation forming in shaping mould and compression shaping. Advantages of the product are: good appearance, folding held facilitation and hard unpacking, strong self-shaping capability. Advantages of the method are: easy and simple, exact shaping and high rate of finished products. The product can be widely used as ventilation, exhaustion and drainage elements, for example super baths, ventilators, water channels, washing machines and smoke exhaust ventilators.

Owner:林和平

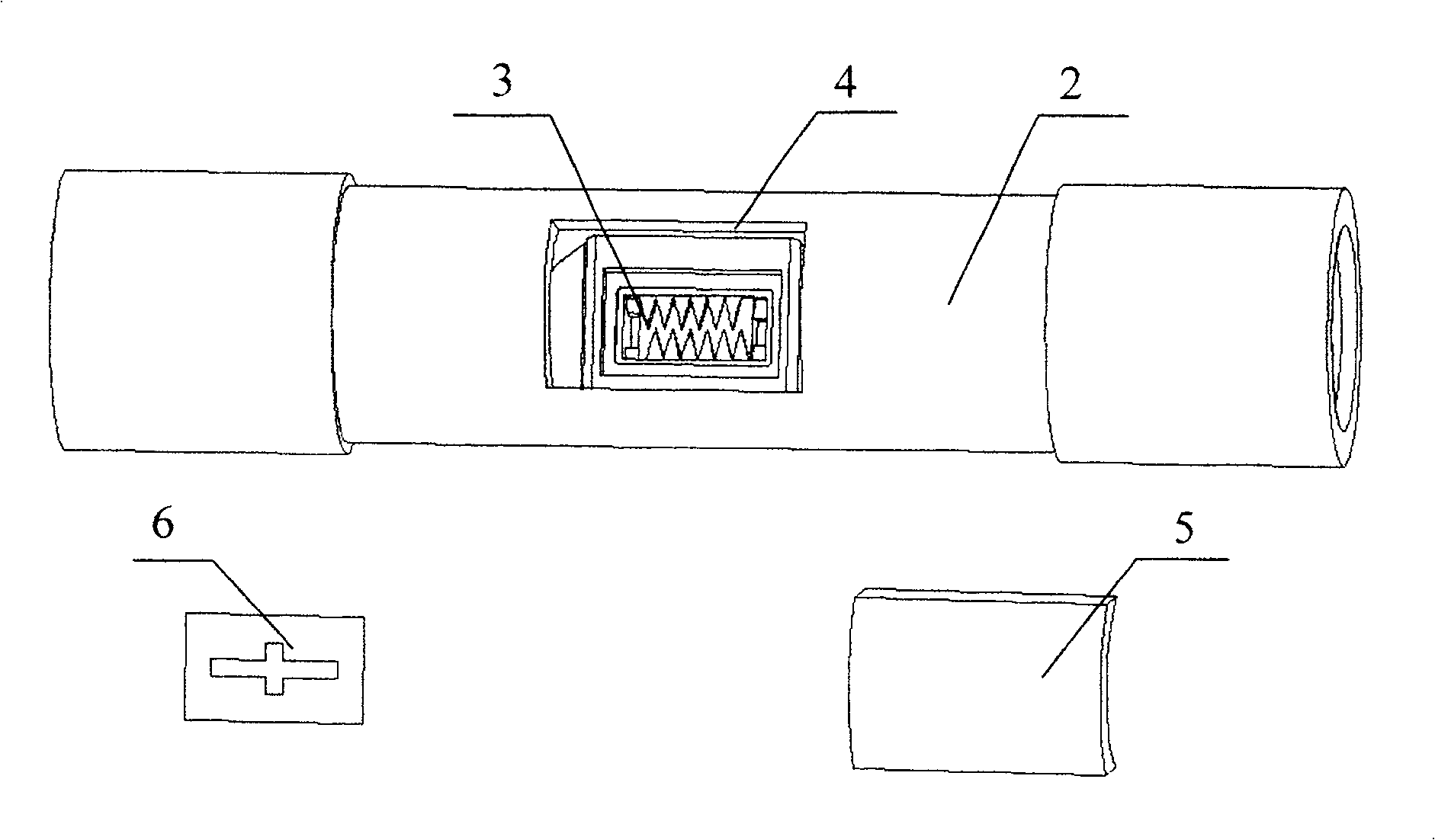

A pressure compensation douche quick development method

InactiveCN1994055AShorten the development cycleAccurate stereotypesWatering devicesCultivating equipmentsProduction lineEngineering

The invention relates to a method for developing pressure compensation drenching apparatus, wherein based on laser quick shaping technique, designs the mode, uses laser quick shaper to process test element of drenching apparatus, fills membrane, to form the test one, feeds into test table, quickly completing the test mode of drenching apparatus. The invention uses parameter mode, to reach demand, shorten develop period. Compared with traditional method, it can avoid mould and product line.

Owner:XI AN JIAOTONG UNIV

Dry sizing device

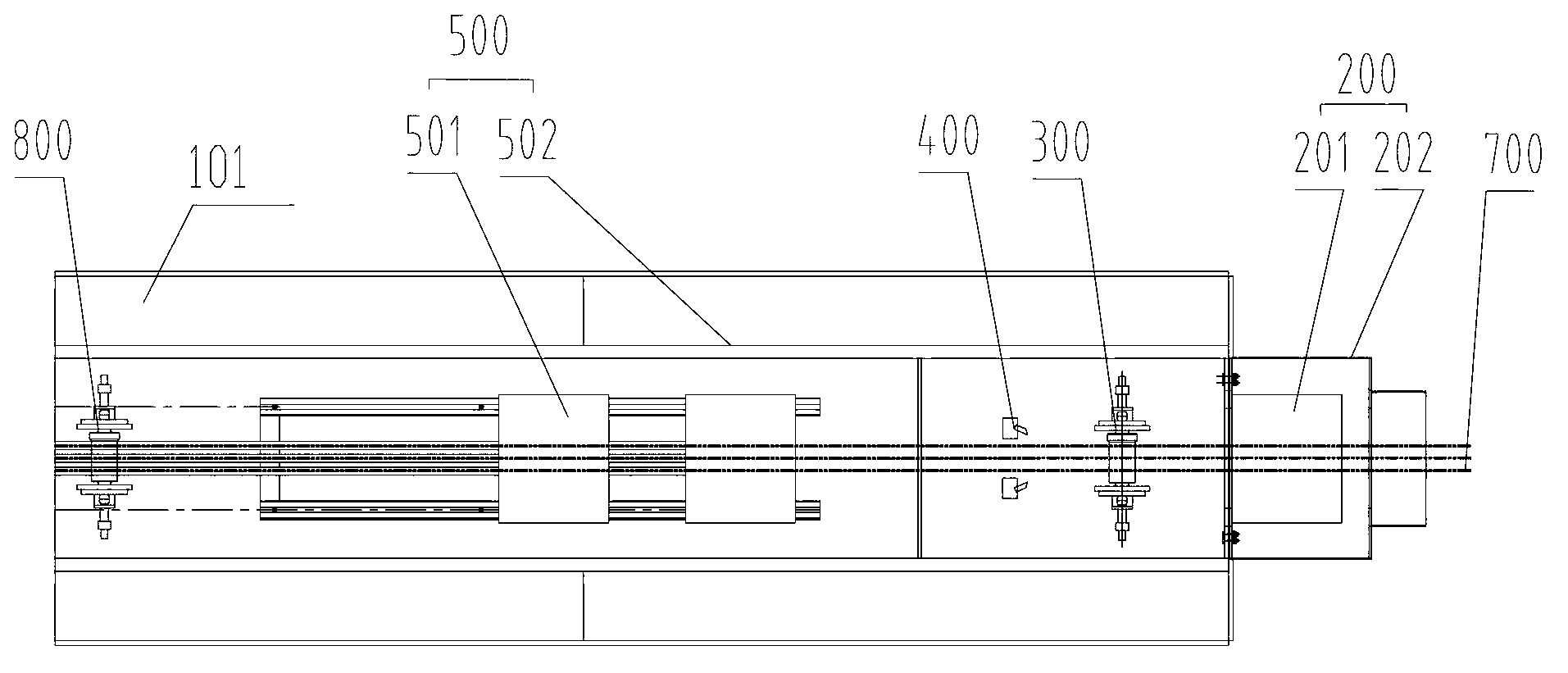

The invention discloses a dry sizing device comprising a frame. The following components are sequentially arranged on the frame: a pre-cooling mechanism used for carrying out pre-cooling upon thermoplastic composite belt material delivered from an extrusion device, a sizing roller set used for extruding and sizing the thermoplastic composite belt material, an edge-cutting mechanism used for trimming the edge of the thermoplastic composite belt material, and a vacuum sizing mechanism used in further sizing. The pre-cooling mechanism, the sizing roller set, the edge-cutting mechanism, and the vacuum sizing mechanism are linearly arranged. With the dry sizing device, thermoplastic composite belt material sizing is precise, belt material size precision is high, and belt material surface quality is high.

Owner:四川江瀚工业股份有限公司

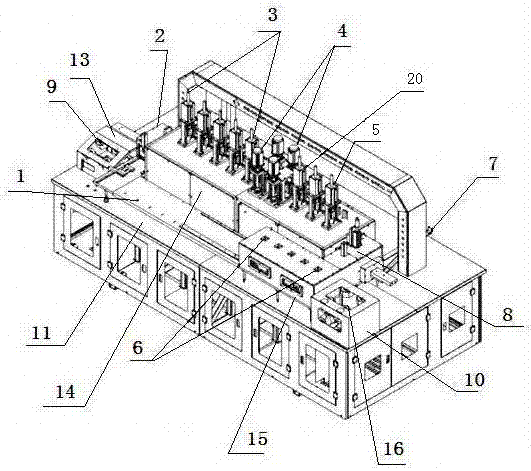

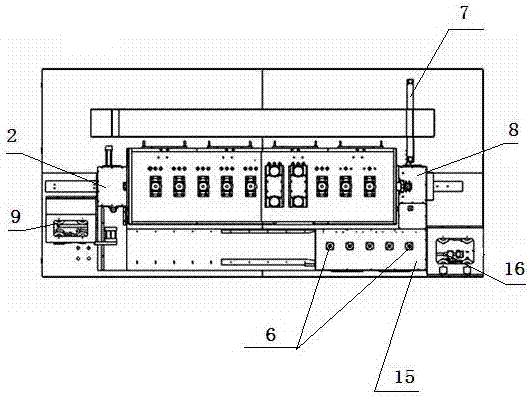

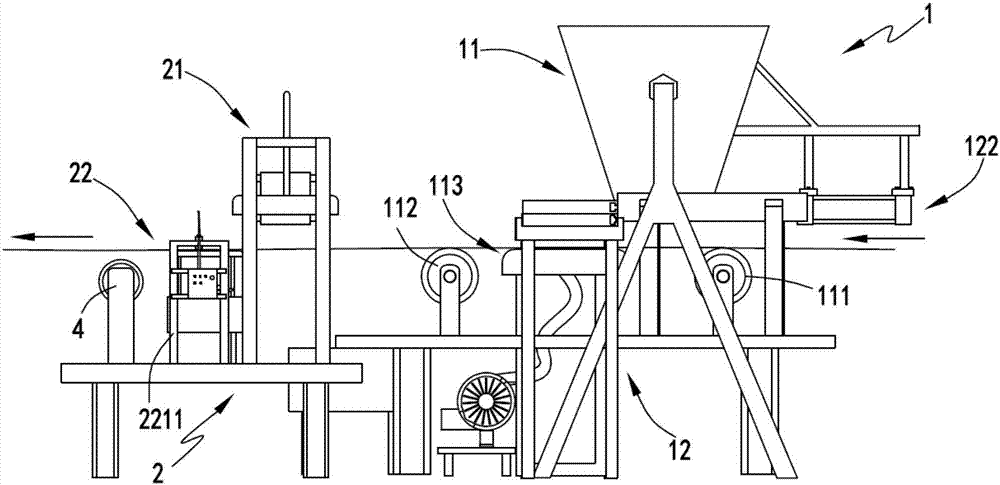

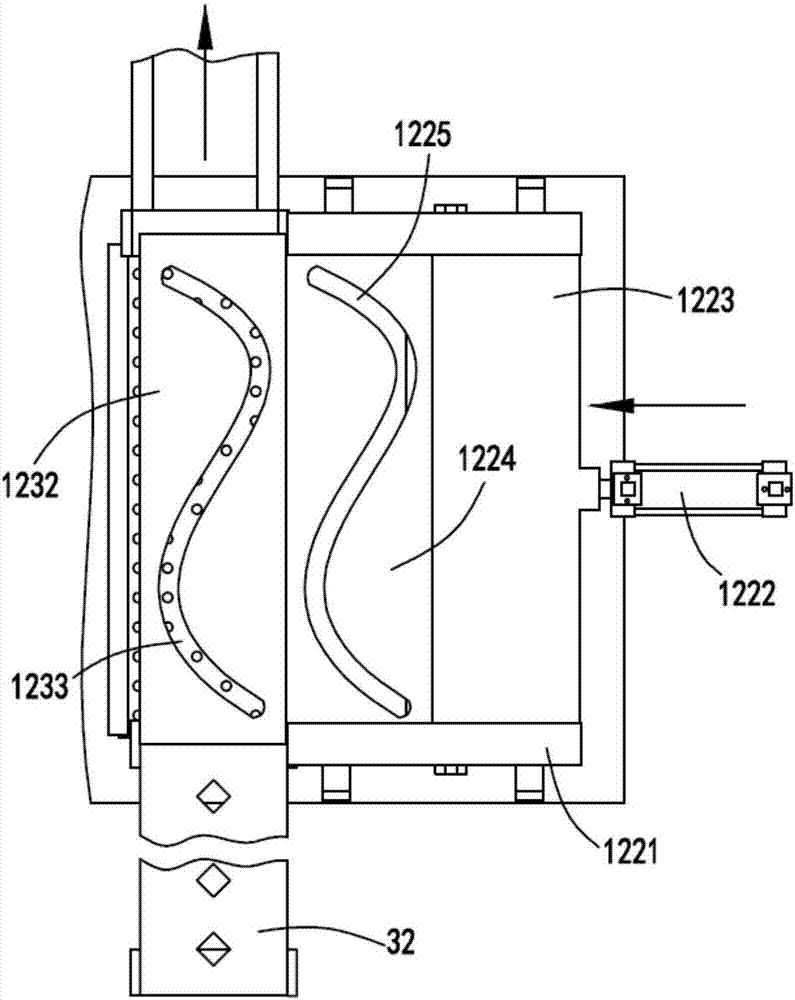

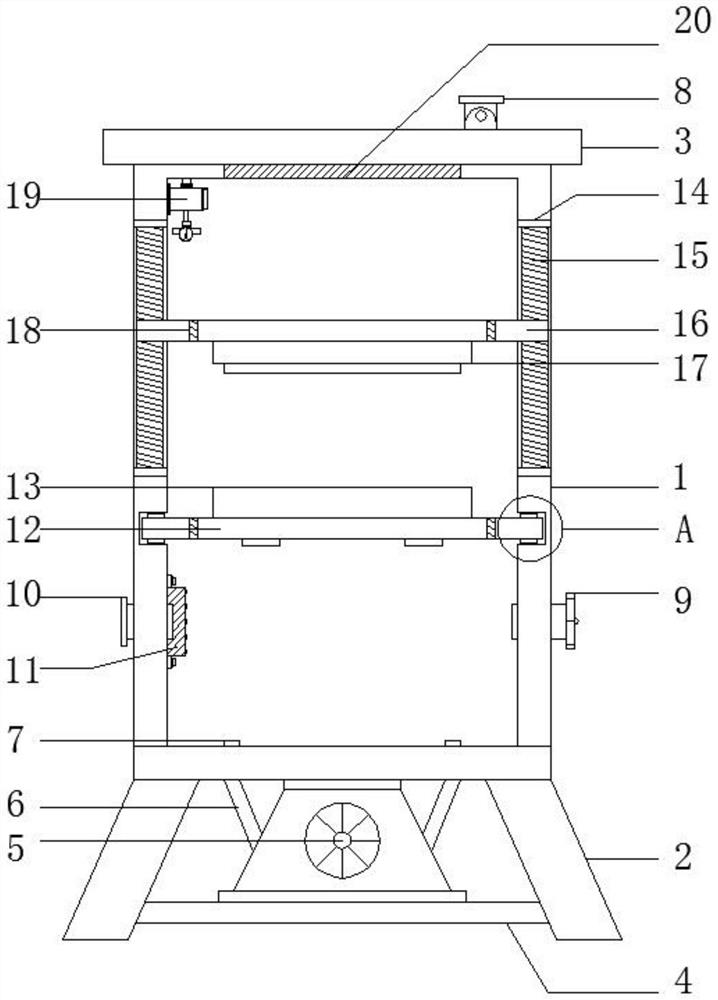

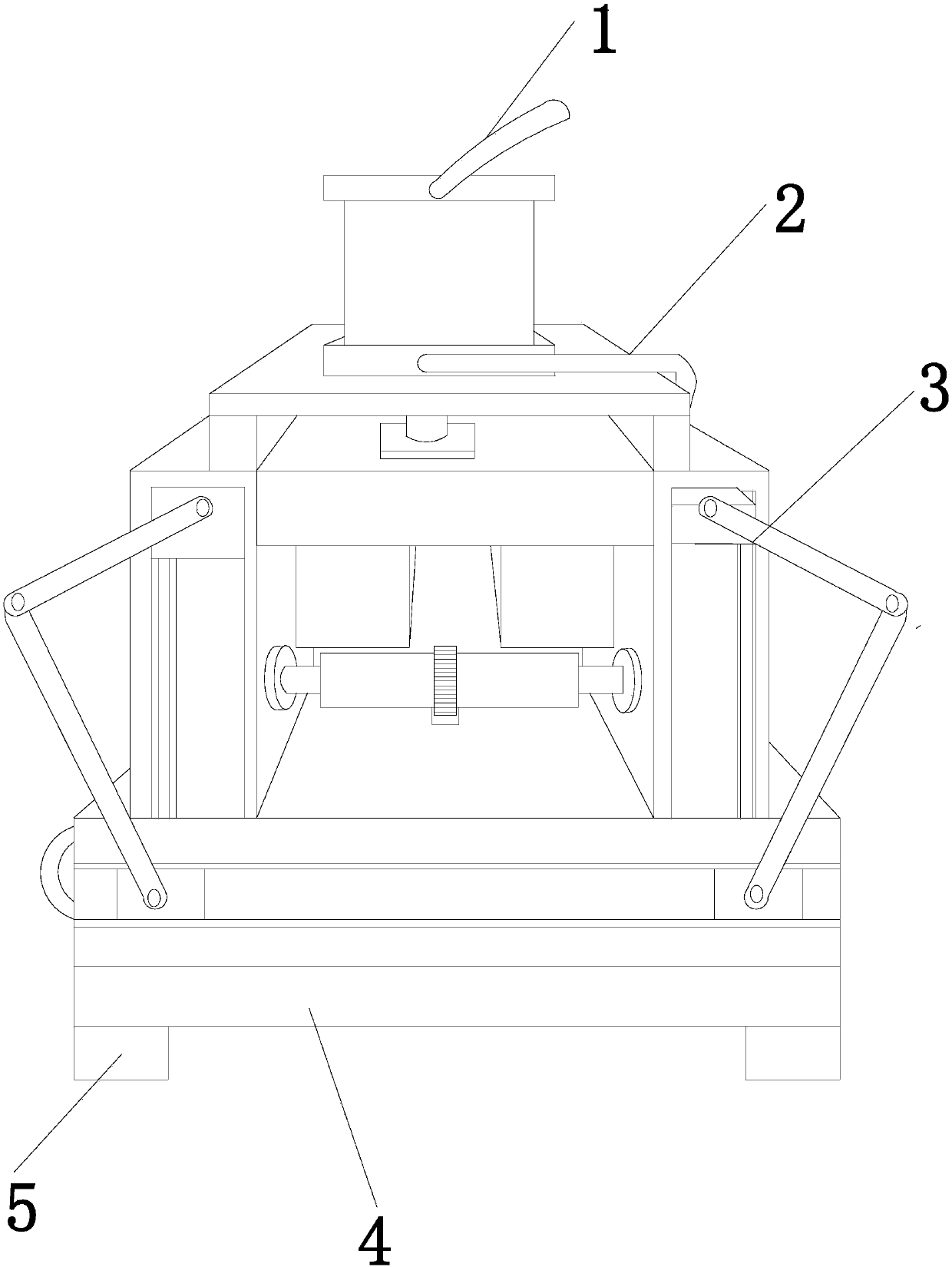

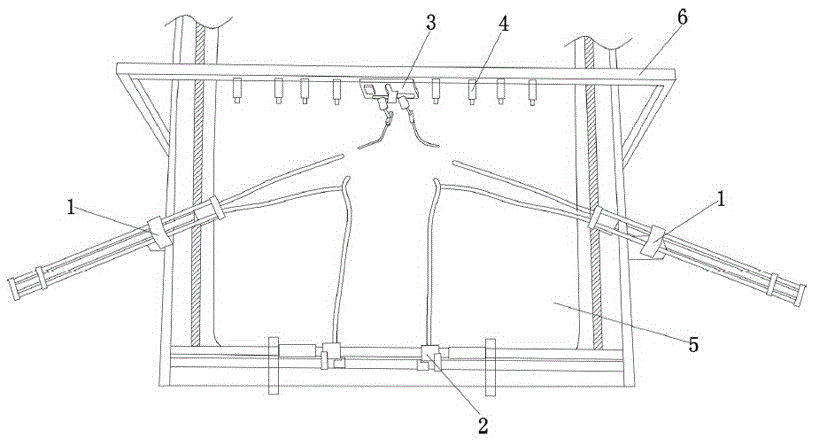

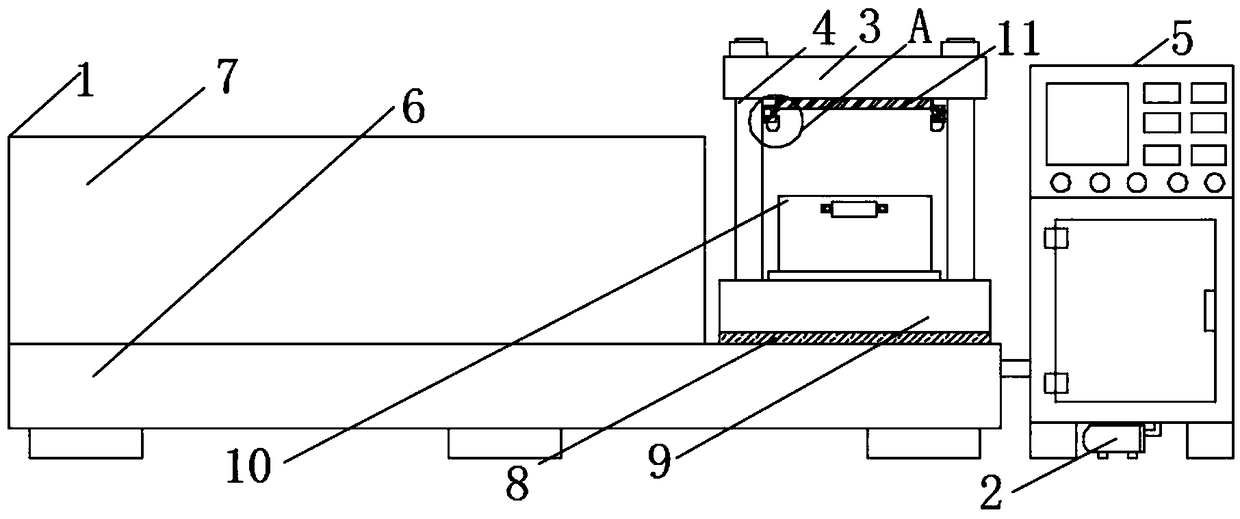

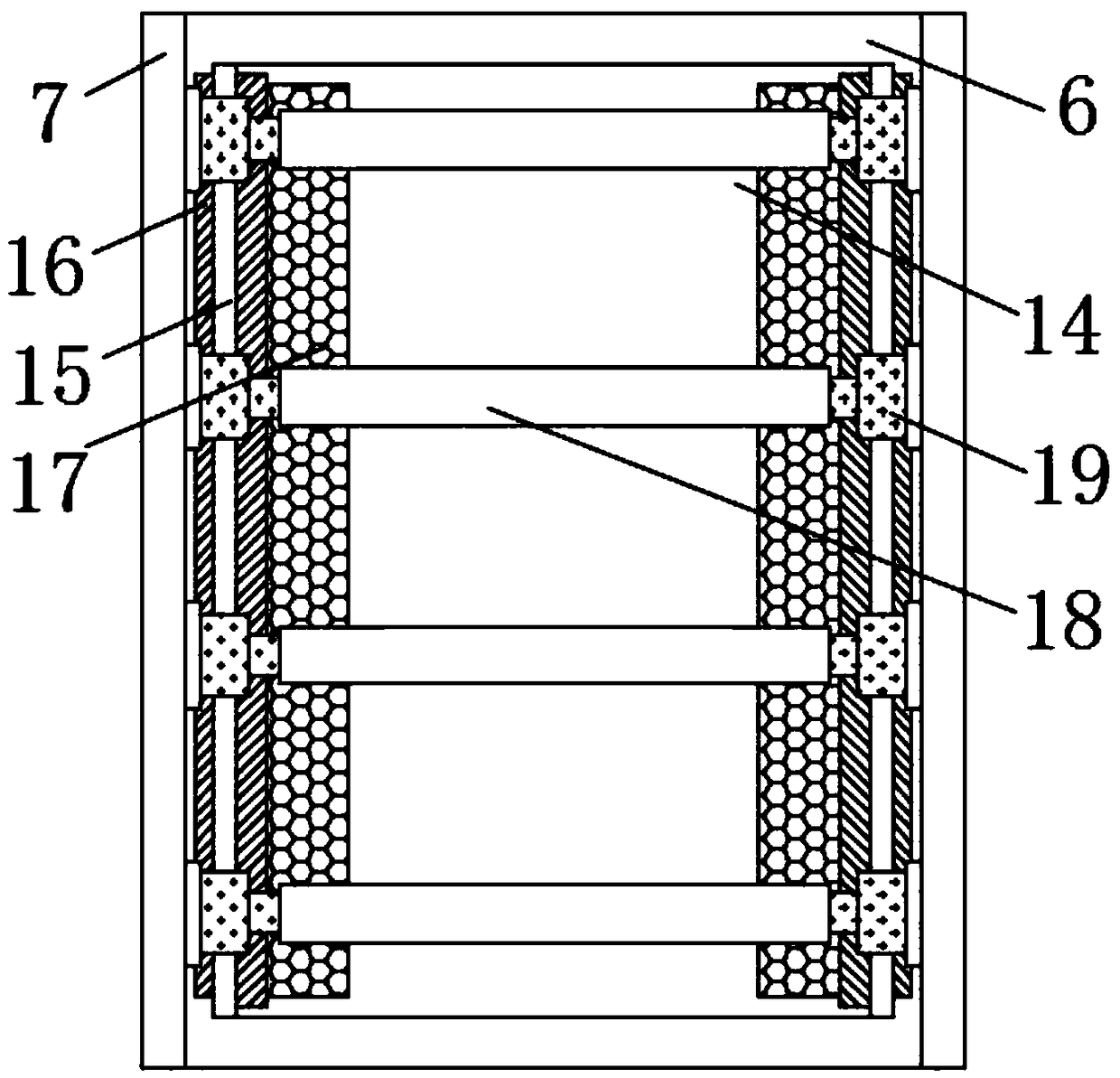

Machine and method for forming free curved surfaces of silicate glass

InactiveCN107129133AImprove insulation effectReduce power consumptionGlass reforming apparatusGlass productionSilicate glassMolding machine

The invention discloses a machine and a method for forming free curved surfaces of silicate glass, and is applicable to machines and methods for forming free curved surfaces of silicate glass. The machine comprises a tank (11). An upper plane of the tank is fixed to a worktable (1), a furnace chamber (14) and a cooling chamber (15) are mounted above the worktable, the cooling chamber is mounted at the front end of the furnace chamber, a feed chamber (2) and a discharge chamber (8) are arranged on two sides of the furnace chamber, a push mechanism B (10) is mounted on the right side of the cooling chamber, the left side of the worktable is connected with a push mechanism A (13) by bolts, preheating devices (3), forming devices (4), a setting device (20) and a slow cooling device (5) are arranged in the furnace chamber, and cooling devices (6) are arranged in the cooling chamber. The machine and the method have the advantage that the problems of explosion and deformation phenomena of glass, decrease of the yield of products and deterioration of the quality of the products due to the fact that existing hot bending machines for the glass with curved surfaces directly enter annealing stations after the glass is formed, molds are excessively high in cooling speeds and the glass is excessively high in temperature difference can be solved.

Owner:HARBIN XINLI PHOTOELECTRIC TECH

Textile fabric singeing and printing production line

InactiveCN107217519AGood shaping effectEasy to shapePattern makingTextile decorationEngineeringManufacturing line

The invention relates to a singeing printing production line for textile fabrics, which includes a shaping part, which is used to put metal particles into the hair gap on the surface of the cloth according to the shape of the cloth to be embossed, and the shaping part includes a Support the adsorption mechanism and the upper metal particle mechanism arranged above the cloth; the adsorption hot stamping mechanism, the adsorption hot stamping mechanism is arranged at the rear end of the shaping part, and the adsorption hot stamping mechanism includes a magnetic force mechanism for absorbing the metal particles on the cloth And the singeing mechanism that is arranged on the rear side of the magnetic mechanism and is used to burn off the hair that stands up under the action of the magnetic mechanism; the present invention overcomes the difficulty in setting the shape when the surface of the fabric needs to be burnt according to a predetermined pattern during the singeing process, Inaccurate shaping leads to irregular patterns and low production efficiency.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

Plastic telescopic pipe and method for manufacturing same

ActiveCN100523580CEasy to fold and foldImprove customization capabilitiesFlexible pipesLaundry washing machineWave shape

The invention discloses a plastic extension pipe and manufacturing method thereof. The plastic extension pipe is provided with a corrugated pipe body, both ends of which are integrally jointed with adapters, characterized in that viewed from the extended longitudinal section, the pipe wall presents a wave shape by ordinal alternant connections of a right side-wall, circular wave peak wall and a left side wall, curvature radius of the wave peak wall arc is 0.5 to 2 millimeters, a smooth transition is provided between the right side wall and the wave peak wall arc, a break point protruding to the inner pipe is formed by intersection of the left side wall and the wave peak wall arc. Manufacturing method includes steps of pipe blank extrusion moulding, pipe blank inflation forming in shaping mould and compression shaping. Advantages of the product are: good appearance, folding held facilitation and hard unpacking, strong self-shaping capability. Advantages of the method are: easy and simple, exact shaping and high rate of finished products. The product can be widely used as ventilation, exhaustion and drainage elements, for example super baths, ventilators, water channels, washing machines and smoke exhaust ventilators.

Owner:林和平

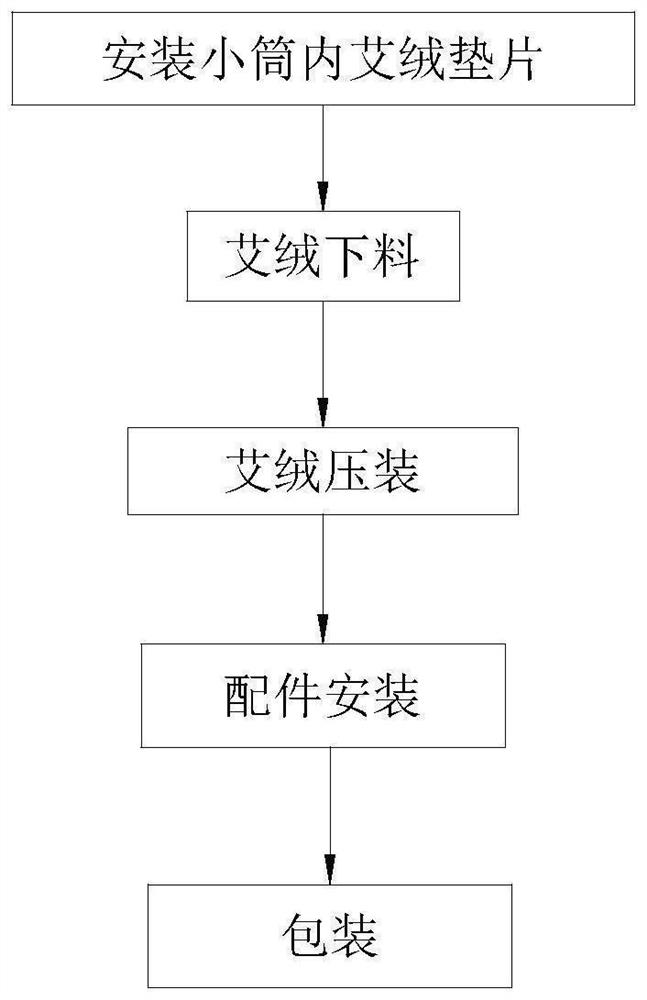

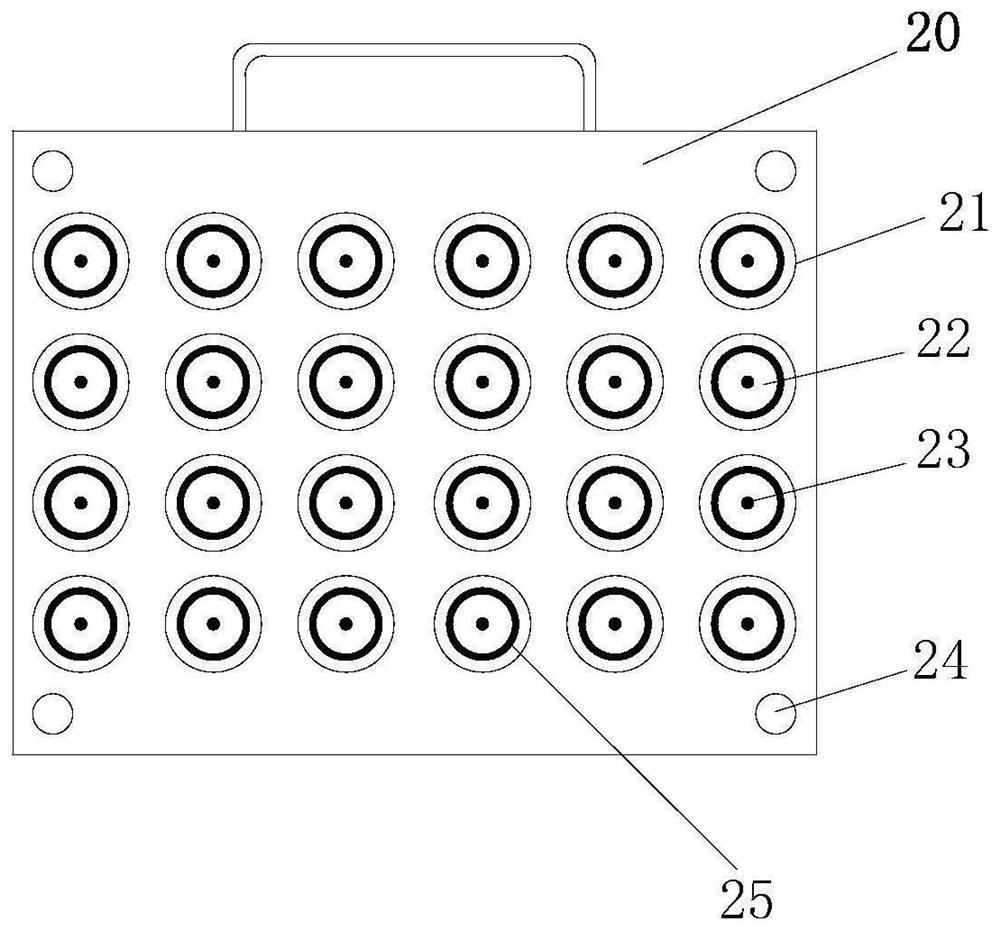

Production technology of cylindrical moxibustion tool

ActiveCN111904850AImprove teleportation effectAccurate stereotypesDevices for heating/cooling reflex pointsTemperature controlEngineering

The invention provides a production technology of a cylindrical moxibustion tool. The production technology comprises the following steps: S1, mounting moxa gaskets in a small cylinder: mounting the small cylinder of the cylindrical moxibustion tool on a lower mold of a special mold, and sleeving a circular moxa gasket with a central hole in the center on each positioning protrusion of the lower mold, downwards pressing the moxa gaskets until the moxa gaskets are in contact with the top surface of the lower mold to reach a required mounting position; S2, discharging moxa: weighing moxa according to the designed weight, and loading the weighed moxa into a feeding cylinder of the special mold; S3, performing moxa press fitting: pressing the moxa in the feeding cylinder into the small cylinder of the cylindrical moxibustion tool, wherein the temperature control range during pressing is 86-90 DEG C, the pressure control range is 15-20Mpa, and the press fitting time is 15-18S; S4, mountingfittings: mounting a base and a cover of the cylindrical moxibustion tool on the small cylinder; and S5, performing packaging: putting the cylindrical moxibustion tool into a packaging box and sealingthe packaging box. According to the production technology of the cylindrical moxibustion tool, the moxa of the cylindrical moxibustion tool is pressed tightly and is not prone to falling off, the dryness is good, ignition is easy, and the product quality is improved.

Owner:湖北蕲艾堂科技有限公司

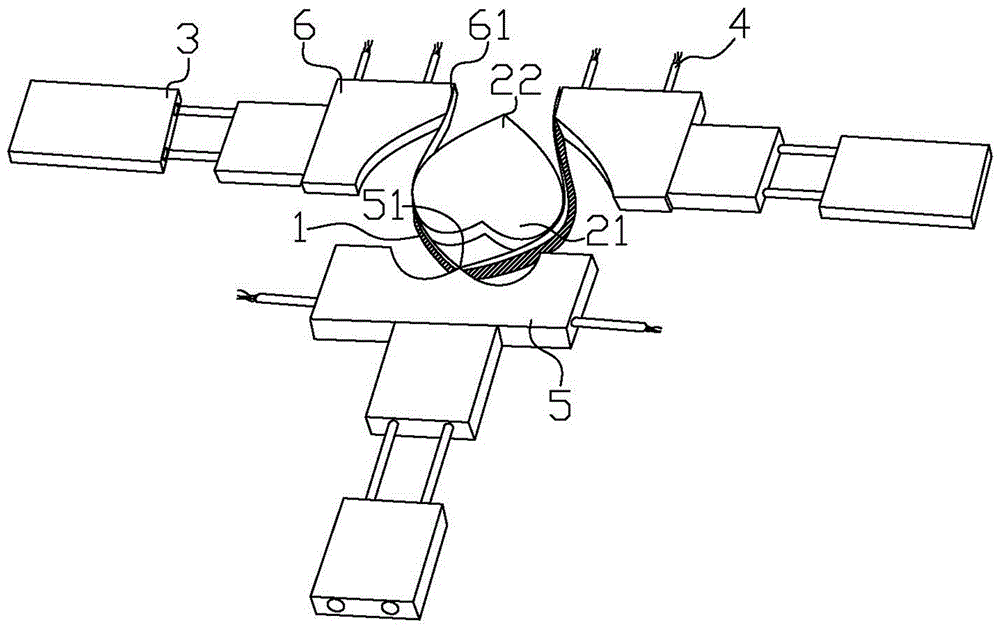

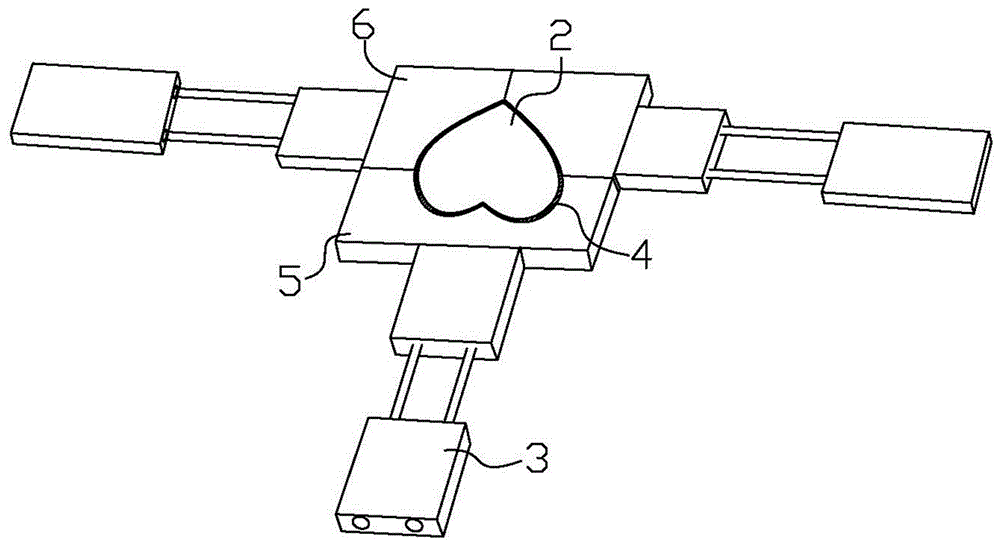

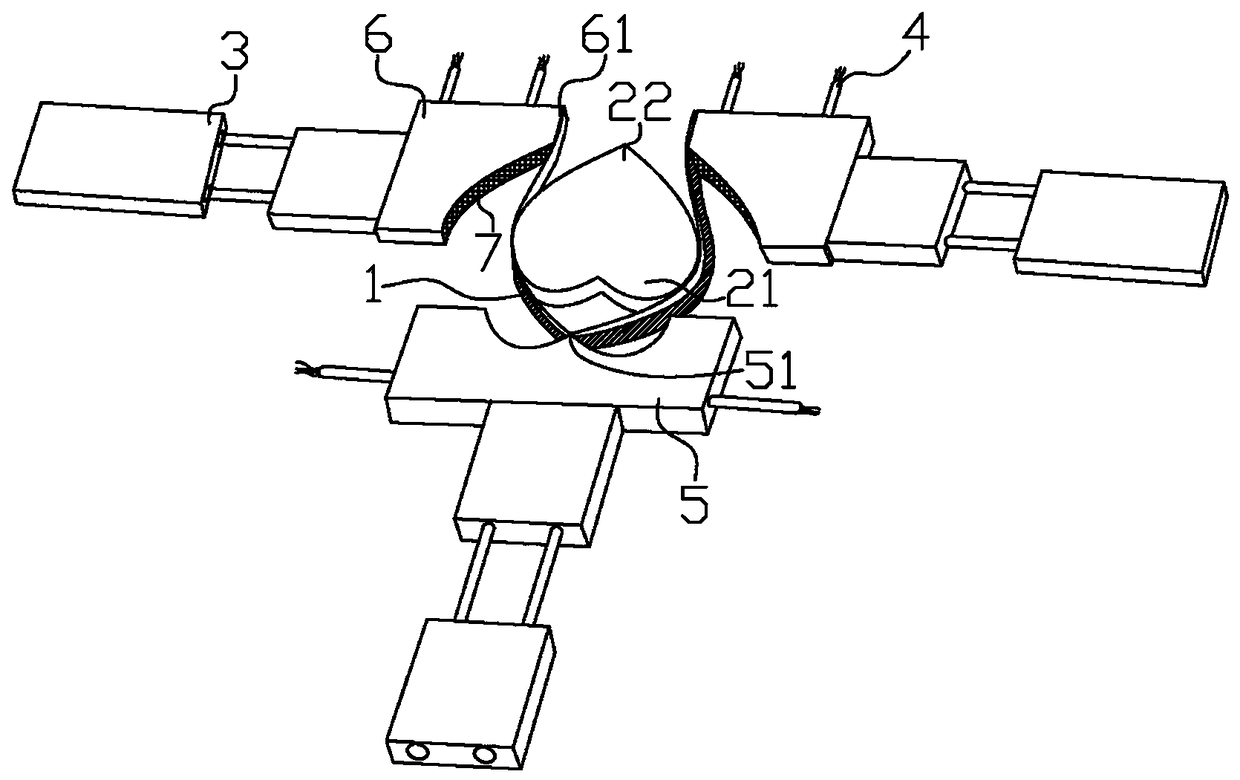

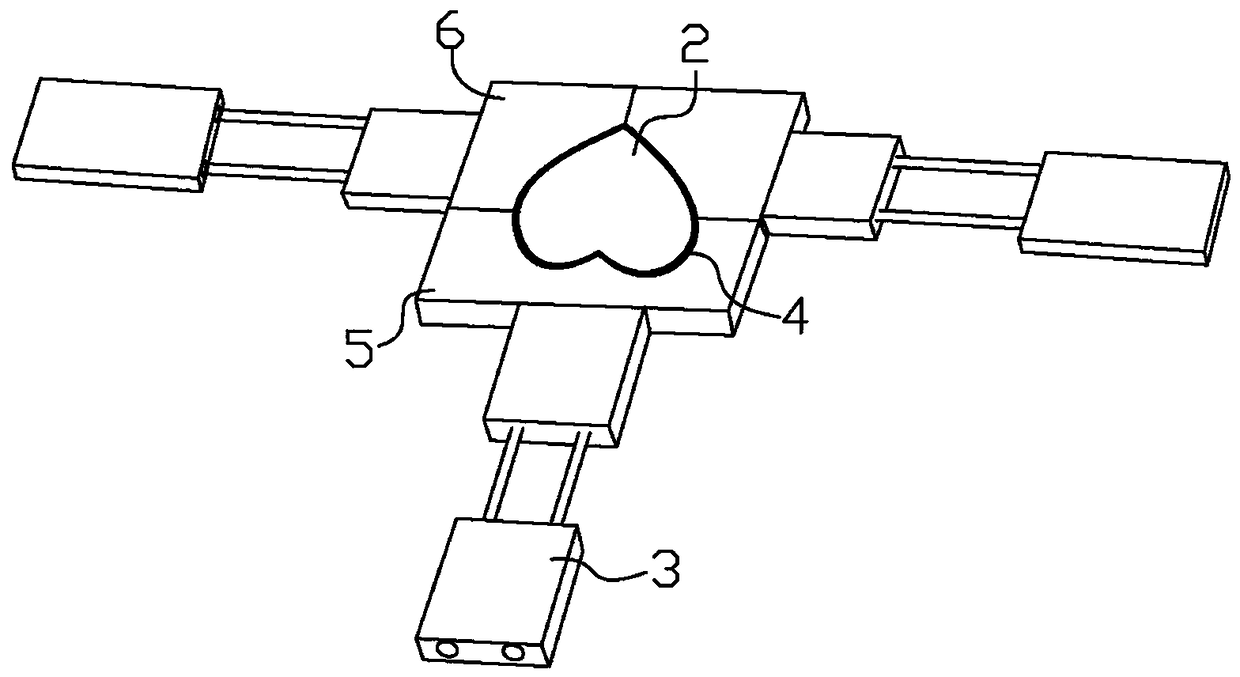

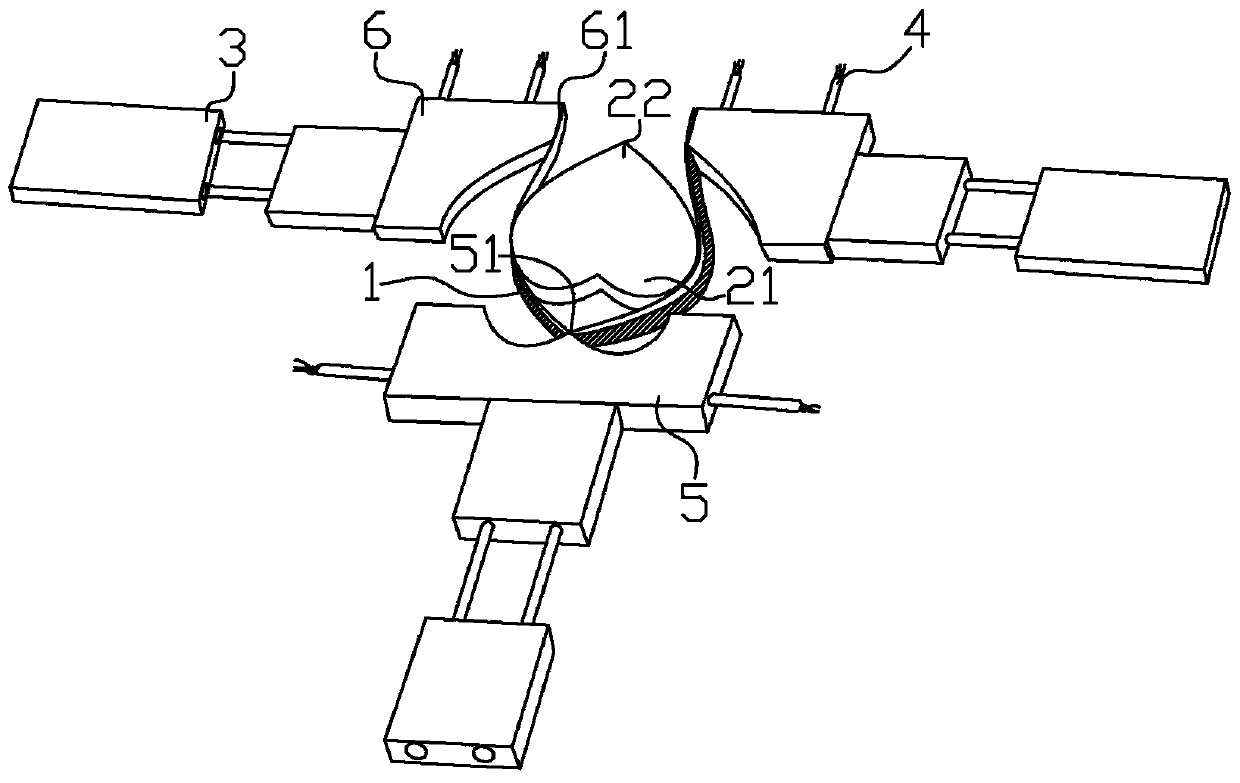

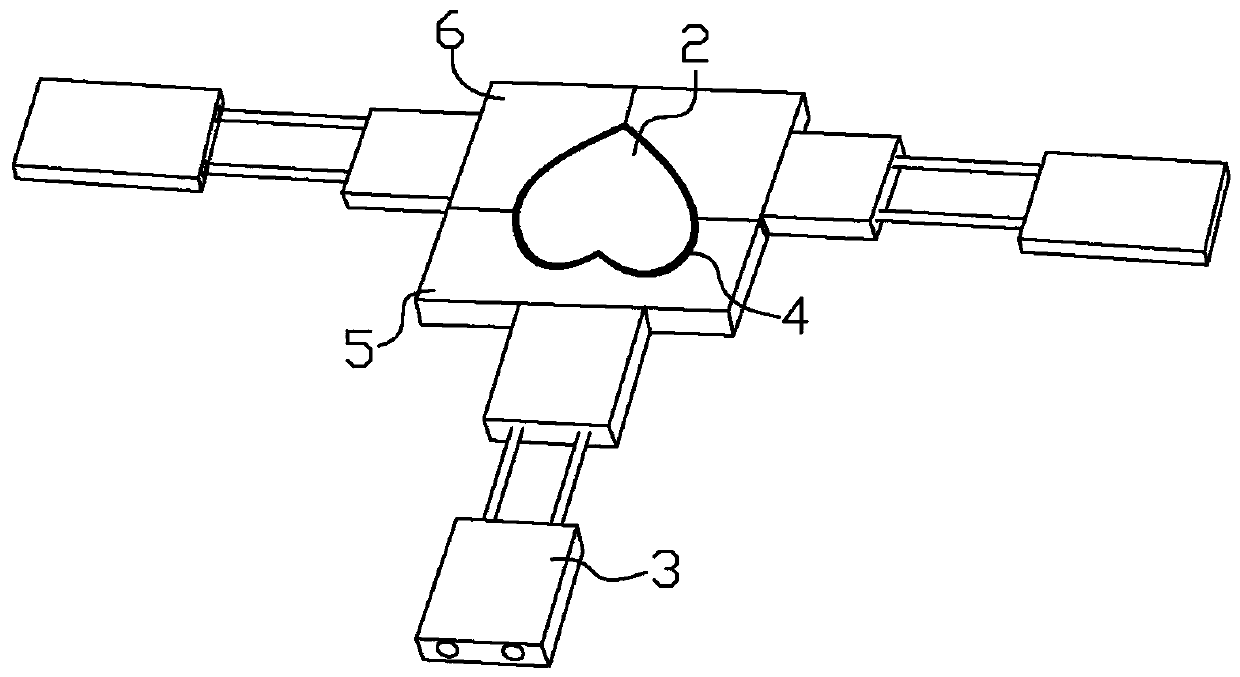

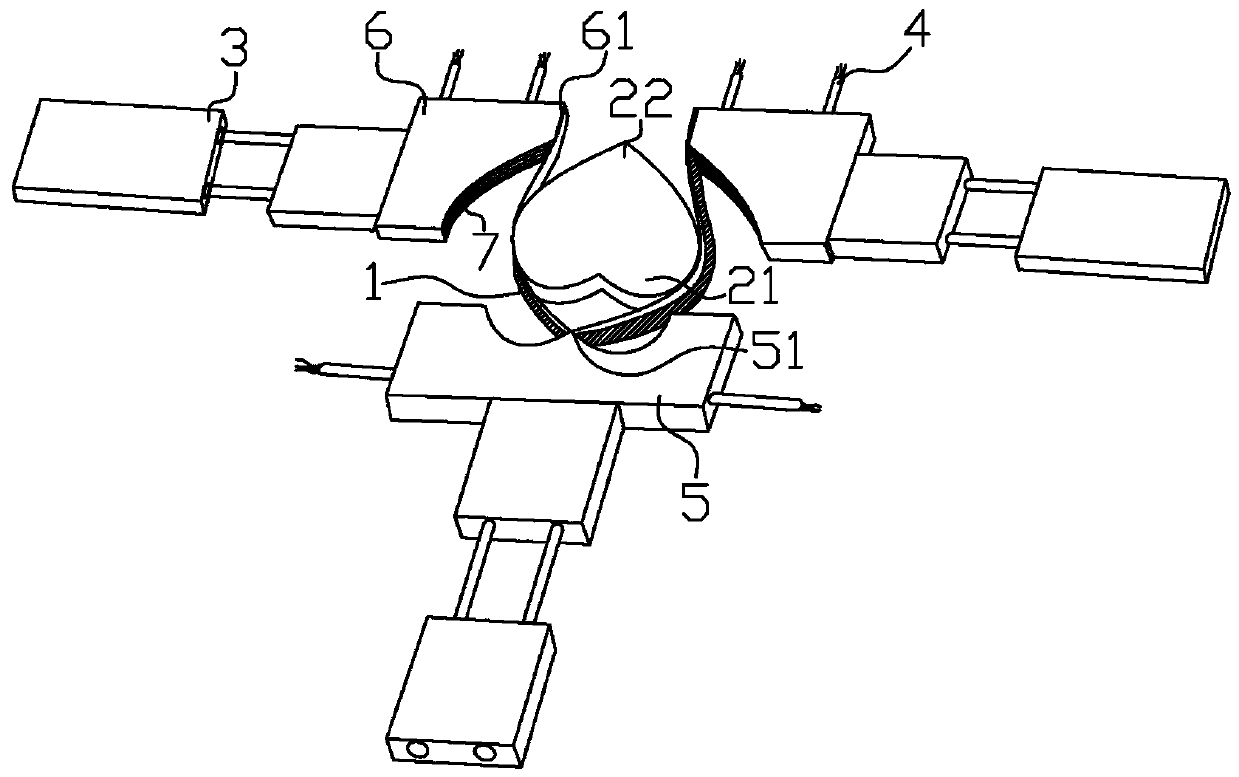

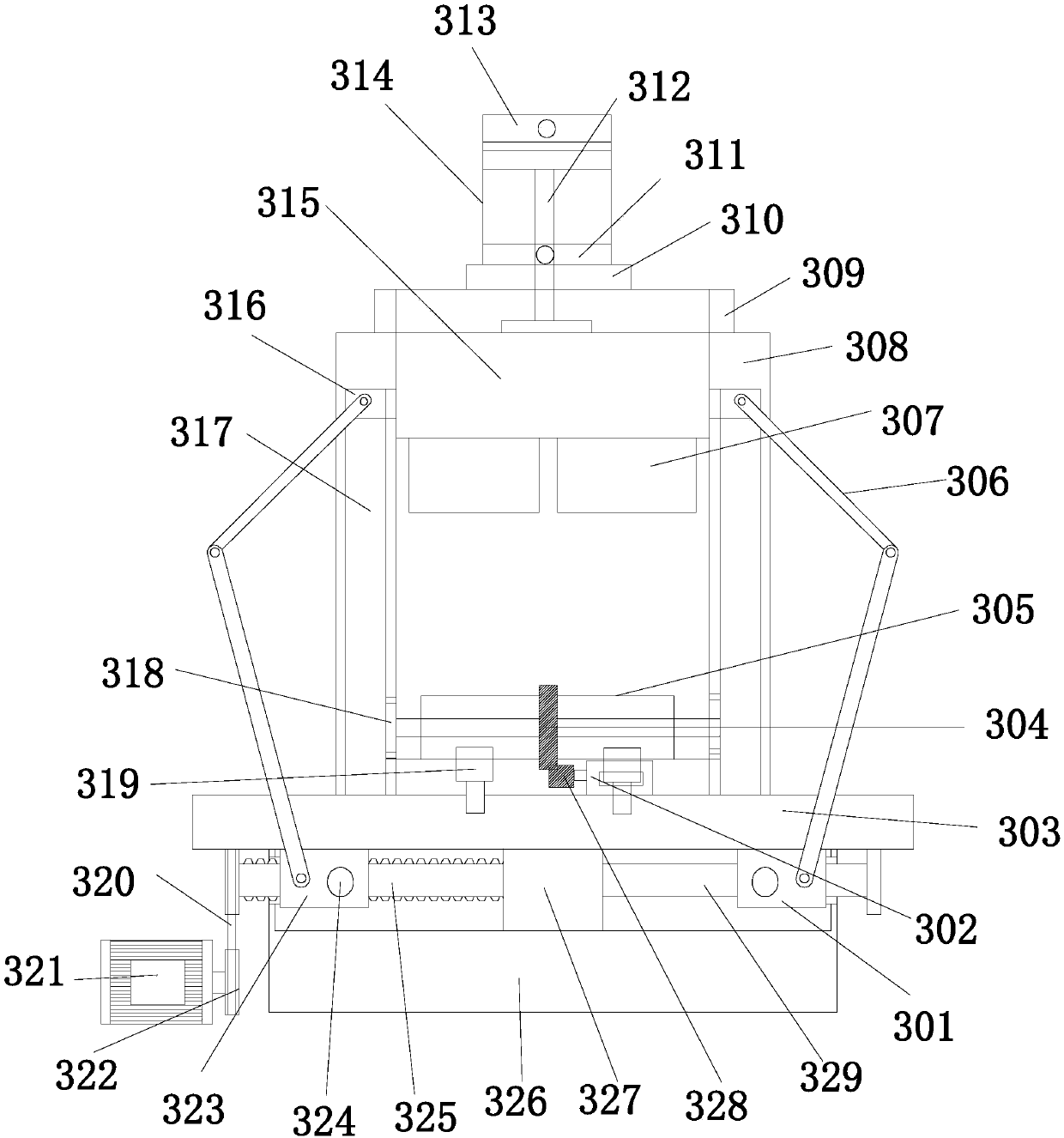

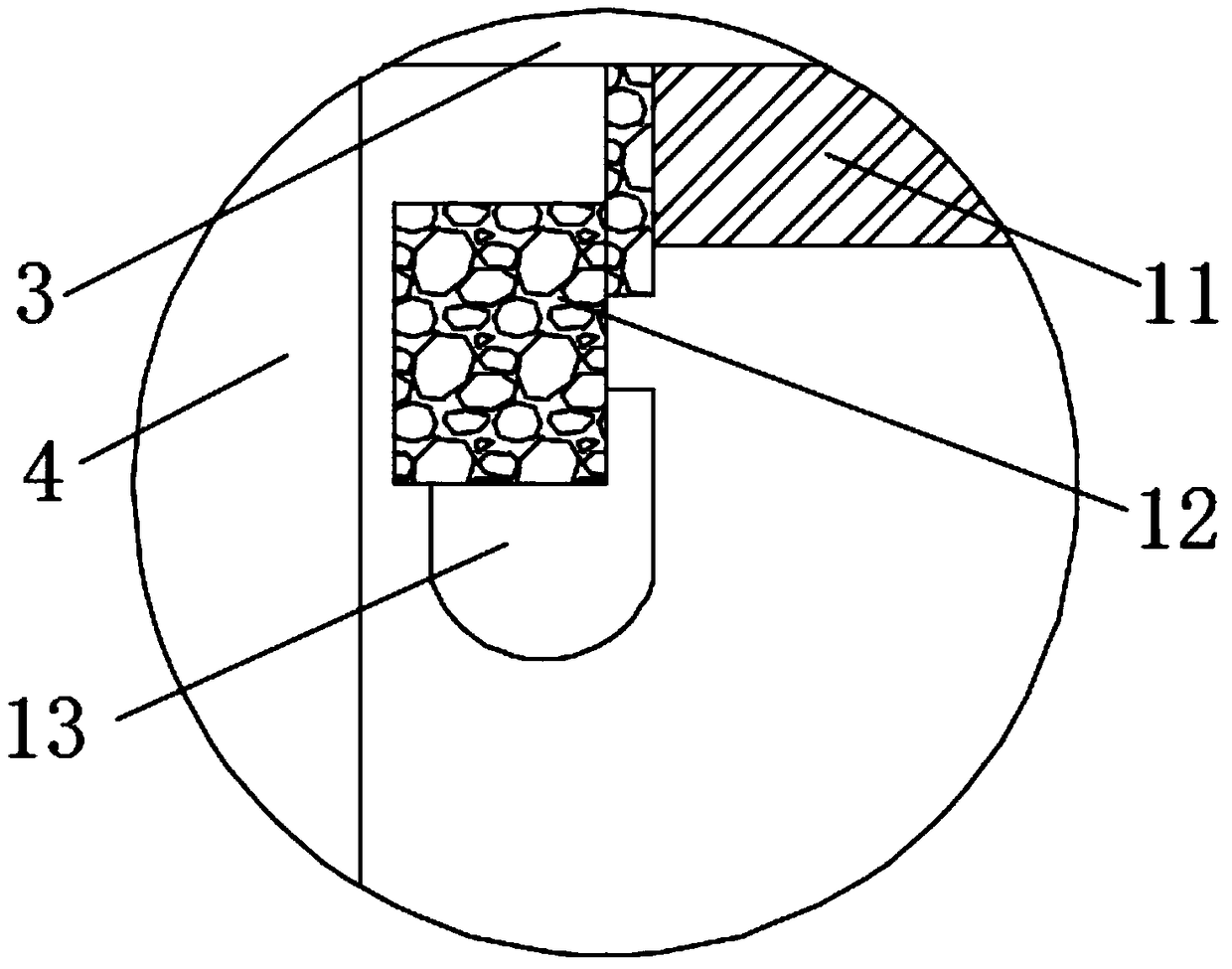

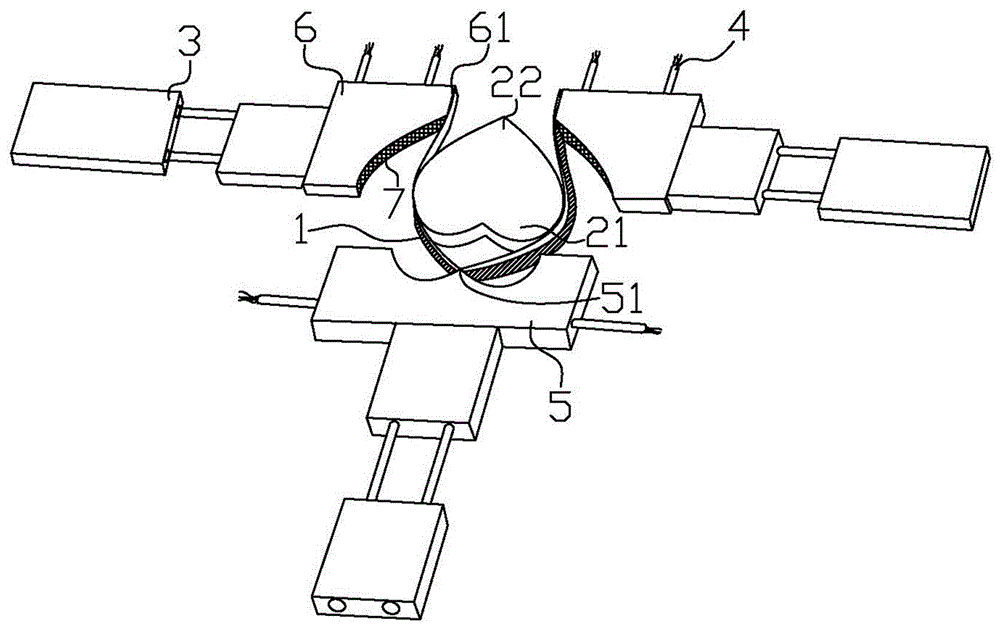

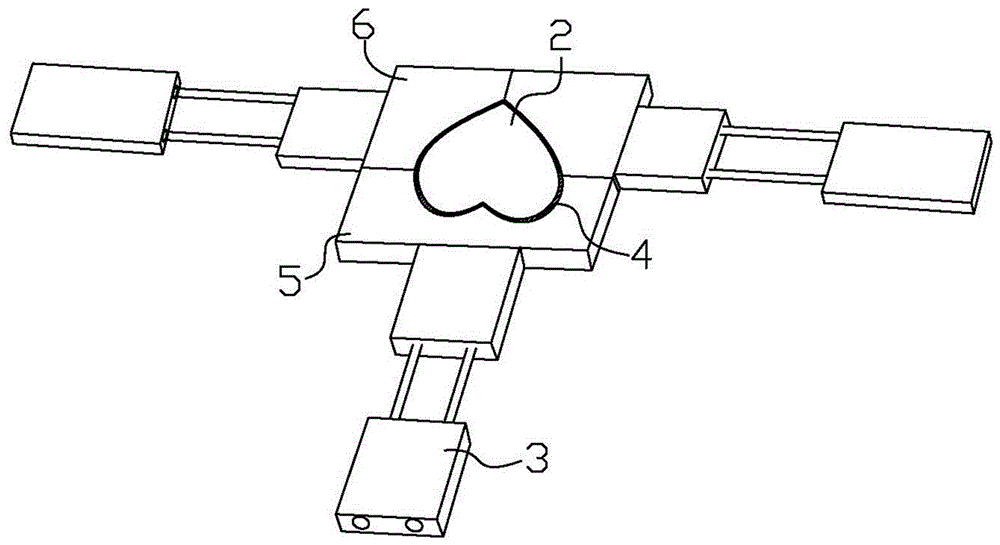

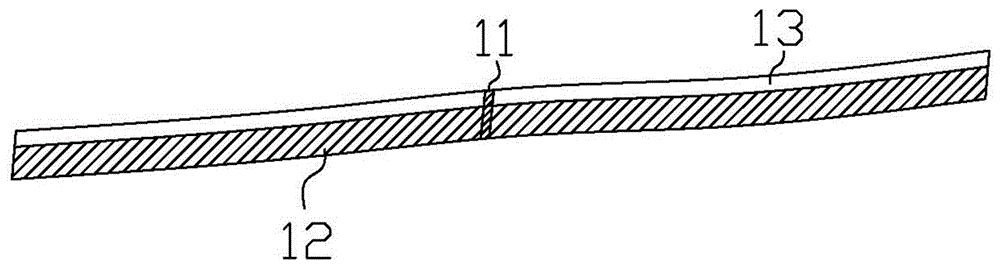

Edge enclosing forming structure and method for heart-shaped packing box

ActiveCN106113588AStable positioningAccurate stereotypesPaper/cardboard articlesPneumatic cylinderPiston

The invention relates to an edge enclosing forming structure and method for a heart-shaped packing box and belongs to the technical field of manufacturing of packing boxes. The edge enclosing forming structure for the heart-shaped packing box comprises heart-shaped edge enclosing forming equipment and an enclosing edge arranged in the heart-shaped edge enclosing forming equipment. The heart-shaped edge enclosing forming equipment comprises a heart-shaped forming block and pushing blocks driven by piston type pneumatic cylinders. Heating devices are arranged in the forming block or the pushing blocks. The pushing blocks comprise the main pushing block matched with the outline of a concave part, and the two auxiliary pushing blocks located on the two sides of the main pushing block. The main pushing block and the two auxiliary pushing blocks are driven by the piston type pneumatic cylinders to do reciprocating motion. The edge enclosing forming structure for the heart-shaped packing box is firm in positioning, accurate in forming, high in yield and low in failure rate, and the forming method is easy to implement and apply.

Owner:浙江中赢包装有限公司

Removable shaping mould

InactiveCN106239653AAccurate stereotypesPrecise bending and shapingCane mechanical workingWood stock bendingNinetieth percentileEngineering

Owner:广德县灵峰竹木工艺品有限公司

Rolling sizing device

The invention discloses a rolling sizing device comprising a frame. The following components are sequentially arranged on the frame: a rolling roller set used for carrying out drawing and progressive extrusion and sizing upon a strip-shaped thermoplastic composite material, a slow-cooling guide roller set used in further sizing, and an edge-cutting roller set used for trimming the edge of the strip-shaped thermoplastic composite material. The rolling roller set, the slow-cooling guide roller set, and the edge-cutting roller set are linearly arranged. The rolling sizing device also comprise a position adjustment mechanism used for adjusting the relative positions of the rolling roller set, the slow-cooling guide roller set, the edge-cutting roller set, and an extrusion mold. With the strip-shaped thermoplastic composite material rolling sizing device provided by the invention, strip-shaped thermoplastic composite material continuous sizing can be carried out, and the sizing is precise.

Owner:四川江瀚工业股份有限公司

An anti-collision packaging box perimeter shaping structure

ActiveCN106113578BPrecise positioningAccurate stereotypesBox making operationsPaper-makingFailure rateHeat conducting

The invention relates to an anti-collision edge enclosing forming structure for a packing box and belongs to the technical field of manufacturing of packing boxes. The anti-collision edge enclosing forming structure for the packing box comprises heart-shaped edge enclosing forming equipment and an enclosing edge arranged in the heart-shaped edge enclosing forming equipment. The heart-shaped edge enclosing forming equipment comprises a heart-shaped forming block and pushing blocks driven by piston type pneumatic cylinders. Heating devices are arranged in the forming block or the pushing blocks. The pushing blocks comprise the main pushing block matched with the outline of a concave part, and the two auxiliary pushing blocks located on the two sides of the main pushing block. The main pushing block and the two auxiliary pushing blocks are driven by the piston type pneumatic cylinders to do reciprocating motion. The side wall, making contact with the forming block, of the main pushing block, and the side walls, making contact with the forming block, of the auxiliary pushing blocks are provided with heat-conducting glue layers. The edge enclosing forming structure for the heart-shaped packing box is firm in positioning, accurate in forming, high in yield and low in failure rate.

Owner:浙江中赢包装有限公司

A kind of peripheral shaping structure and shaping method of heart-shaped packaging box

ActiveCN106113588BPrecise positioningAccurate stereotypesPaper/cardboard articlesFailure rateReciprocating motion

Owner:浙江中赢包装有限公司

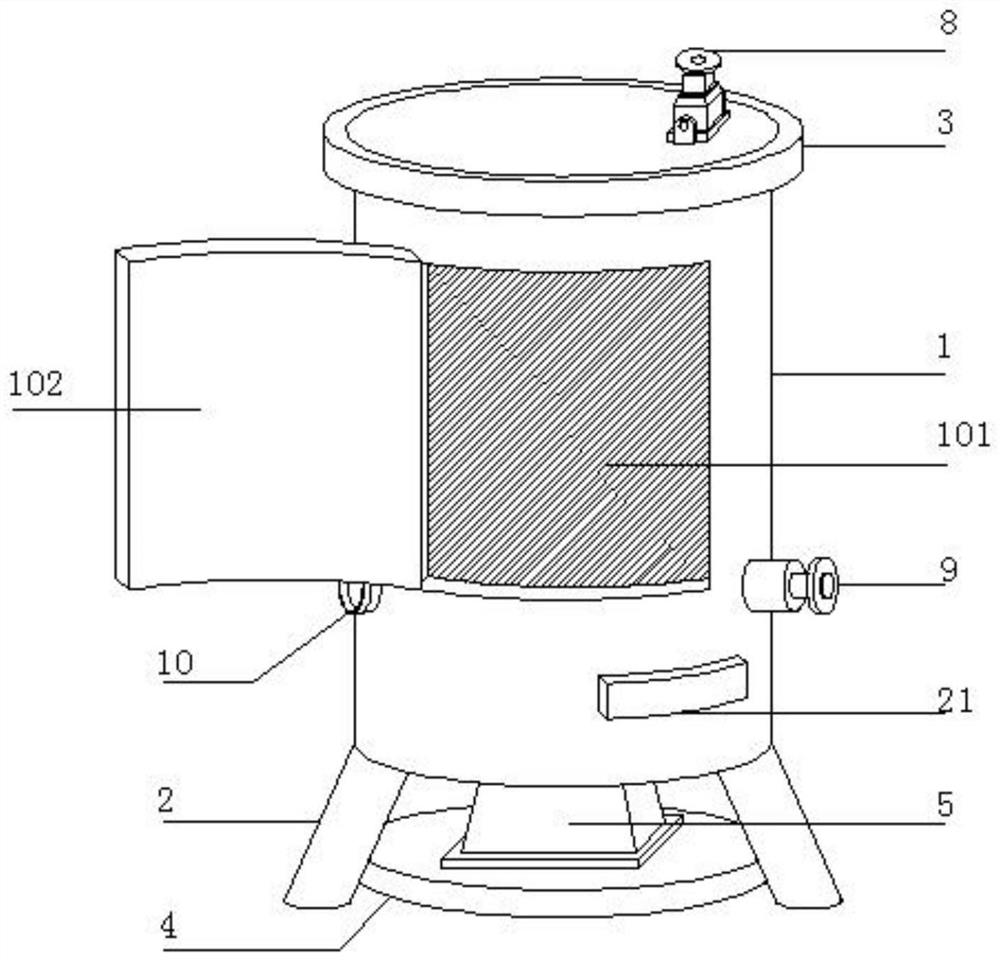

Shaping device and method for aluminum alloy heat treatment

InactiveCN112481563AEasy to import materialsGuaranteed air tightnessHeat recirculationEnergy consumption

The invention discloses a shaping device and method for aluminum alloy heat treatment. The shaping device comprises a device main body. Supporting columns are arranged at the bottom of the device mainbody. A top cover is arranged at the upper end of the device main body. A connecting plate is arranged between the two sets of supporting columns. A draught fan is arranged on the upper end face of the connecting plate. The output end and the input end of the draught fan are each provided with an air guide pipe. An air guide opening is formed in the bottom end in the device main body. A pressurerelease valve is arranged at the upper end of the top cover. An inert gas atomization device is arranged at the position, located in the device main body, of one end of a connecting pipe. An installing frame is arranged at the position, located at the upper end of the gas atomization device, in the device main body. According to the shaping device and method for aluminum alloy heat treatment, thedraught fan is arranged, heat circulation is formed in the device, and energy consumption is reduced while the shaping efficiency is improved; the inert gas atomization device is arranged, materials are prevented from being subjected to reactions such as oxidization, and the device preparing precision is improved; and a lower shaping assembly and inner components of the lower shaping assembly arearranged, and after device shaping is finished, the materials are more convenient to take out.

Owner:重庆重铝新材料科技有限公司

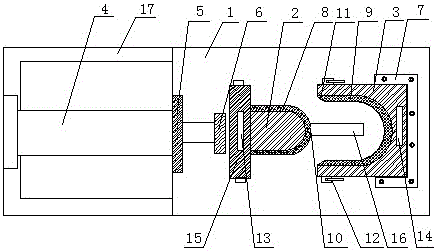

A method of using a perforating U-turn device

The invention discloses a use method of a punching turning-around device. The method specifically comprises following steps of material heating treatment, conveying separating, roller shaping, steep pipe conveying, heading treatment and cooling transmission. The use method of the punching turning-around device saves cost and facilitates manufacturing.

Owner:NINGBO YONGXIN STEEL TUBE

Dry setting device

The invention discloses a dry sizing device comprising a frame. The following components are sequentially arranged on the frame: a pre-cooling mechanism used for carrying out pre-cooling upon thermoplastic composite belt material delivered from an extrusion device, a sizing roller set used for extruding and sizing the thermoplastic composite belt material, an edge-cutting mechanism used for trimming the edge of the thermoplastic composite belt material, and a vacuum sizing mechanism used in further sizing. The pre-cooling mechanism, the sizing roller set, the edge-cutting mechanism, and the vacuum sizing mechanism are linearly arranged. With the dry sizing device, thermoplastic composite belt material sizing is precise, belt material size precision is high, and belt material surface quality is high.

Owner:四川江瀚工业股份有限公司

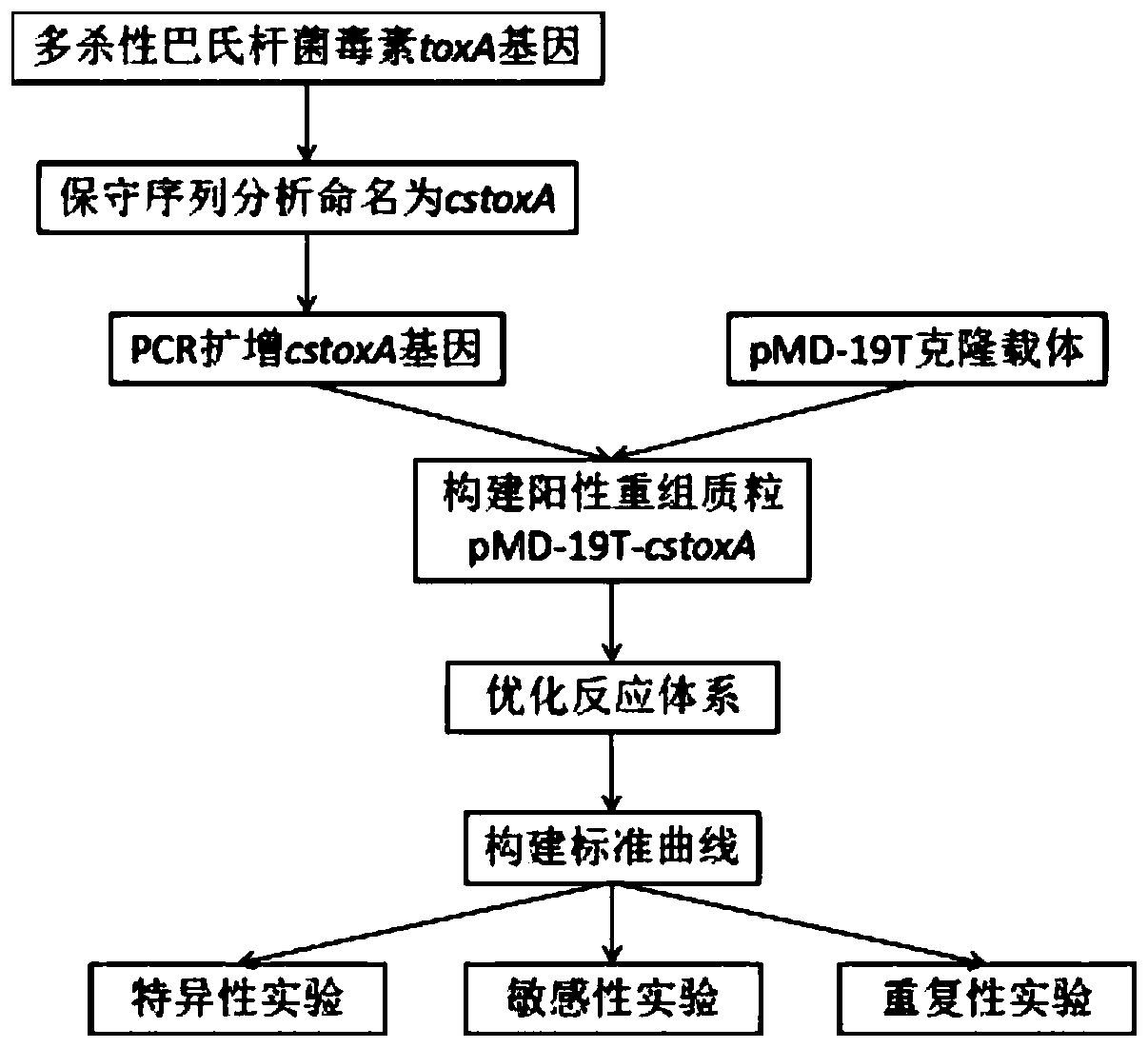

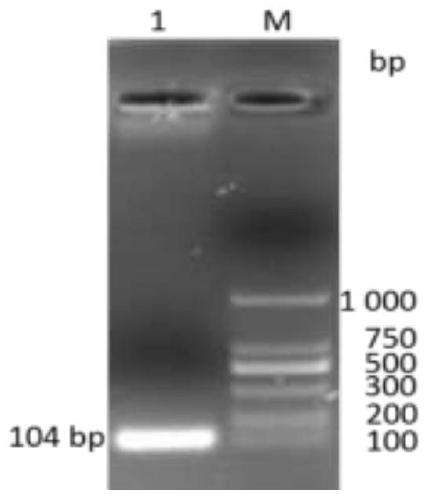

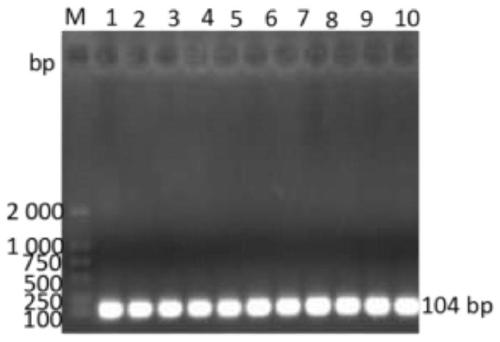

Creation of sheep-derived pasteurella multocida fluorescent quantitative PCR (polymerase chain reaction) standard curves

PendingCN109797206AGood repeatabilityIncreased sensitivityMicrobiological testing/measurementVector-based foreign material introductionInformation analysisBacterial strain typing

The invention discloses creation of sheep-derived pasteurella multocida fluorescent quantitative PCR (polymerase chain reaction) standard curves. The creation has the advantages that toxA toxin genesin Pasteurella multocida genomes published in GenBank are taken as reference, conservative sequences cstoxA are acquired by the aid of information analysis software, recombinant plasmids pMD-19T-cstoxA of positive standard substances are constructed by means of PCR, fluorescent quantitative PCR systems are optimized, accordingly, the sheep-derived pasteurella multocida fluorescent quantitative PCRstandard curves can be created, pasteurella multocida fluorescent quantitative PCR standard curves with high specificity and sensitivity and good repeatability can be obtained, convenient, speedy andaccurate bacterial strain typing effects and the like can be realized, the specificity can be improved as compared with the traditional laboratory PCR operation, and the expenditure for laboratory consumables and the like further can be reduced as compared with the traditional laboratory PCR operation.

Owner:HAINAN UNIVERSITY

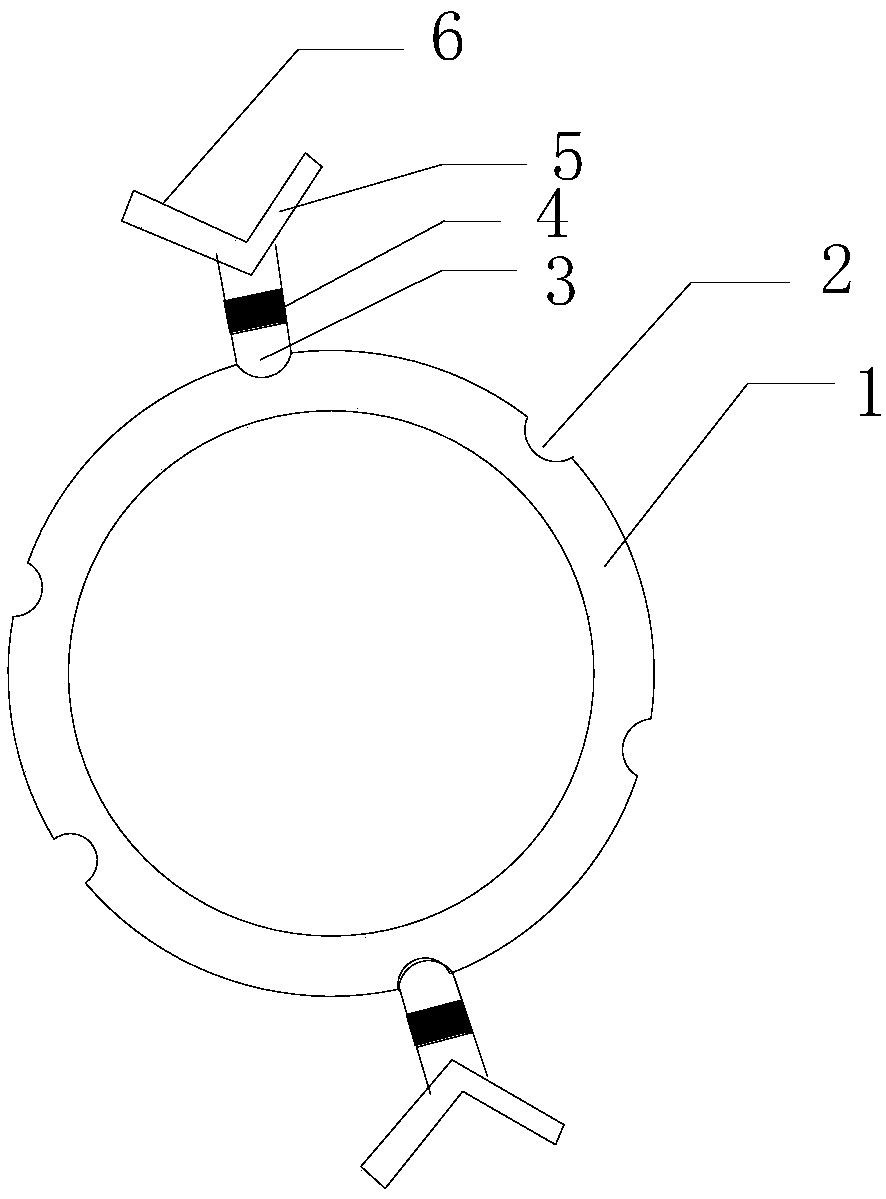

Seedling shaping device

InactiveCN110731192AAccurate stereotypesSo as not to damageHorticulture methodsAgricultural engineeringSeedling

The invention discloses a seedling shaping device, which comprises a shaping ring and Y-shaped supporting frames. The outer periphery of the shaping ring is uniformly provided with a plurality of holes. Each supporting frame comprises a supporting rod and a fixing part, wherein one end of the supporting rod is inserted into the corresponding hole while the other end is connected with the middle ofthe fixing part, and an opening of the fixing part is outward. The seedling shaping device is simple in structure, convenient to use and capable of accurately shaping seedlings, and certain bufferingin use of the shaping device can be realized by adoption of elastic parts, so that the seedlings can be protected from damage.

Owner:成都东山兰韵农业有限公司

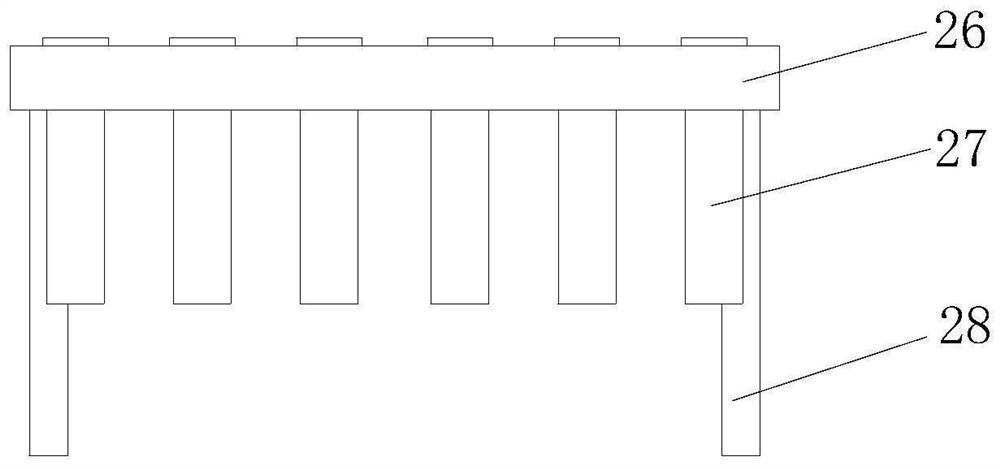

Penetrating and inserting combined type electroplating workpiece clamp

ActiveCN113737262AAvoid deformationReduce the error valueElectrolysis componentsEngineeringStructural engineering

The invention discloses a penetrating and inserting combined type electroplating workpiece clamp. The penetrating and inserting combined type electroplating workpiece clamp mainly comprises a main frame body and a plurality of support plate pieces, wherein the main frame body and the support plate pieces are combined in an embedded and inserting mode, and the main frame body comprises two frame faces and a side edge formed on the peripheries of the two frame faces. Each support plate piece comprises an insertion plate surface and a side edge formed on the periphery of the insertion plate surface, the insertion plate surface faces the insertion group direction of insertion pins of an electroplated workpiece, the insertion plate surface comprises an insertion section and a combination section, the combination section is combined with the main frame body, the insertion section forms an alignment insertion hole for insertion of the insertion pins of the electroplated workpiece, a clamping and positioning part is arranged at the interval alignment position of each alignment insertion hole, and the clamping and positioning parts are combined and positioned on the main frame body or the support plate pieces in an embedded and inserted mode through an embedded and inserted type connecting arm.

Owner:翁健名 +1

Forming structure and forming method of a packaging box

ActiveCN106113579BPrecise positioningAccurate stereotypesBox making operationsPaper-makingFailure rateReciprocating motion

The invention relates to a shaping structure and a shaping method for a surrounding edge of a packaging box, and belongs to the technical field of packaging box production. A surrounding sizing structure for a packaging box, comprising a heart-shaped sizing device and a sizing device arranged in the heart-shaped sizing device; the heart-shaped sizing device includes a heart-shaped sizing block and a piston A push block driven by a type pneumatic cylinder; a heating device is arranged in the shaped block or the push block; the push block includes a main push block that matches the contour of the concave part and two As for the auxiliary push block, the main push block and the two auxiliary push blocks reciprocate under the drive of the piston-type pneumatic cylinder, and heat-conducting wires are arranged on the shaped block or the push block. The packaging box has firm positioning of the shaped structure around the edge, accurate shaping, high yield rate and low failure rate, and the shaping method is easy to operate and learn.

Owner:浙江中赢包装有限公司

A suitcase high-efficiency shaping device for suitcase making

ActiveCN107772706BDisplacement stabilityReduce distanceLuggageEngineeringElectrical and Electronics engineering

Owner:嘉兴市驰宇五金股份有限公司

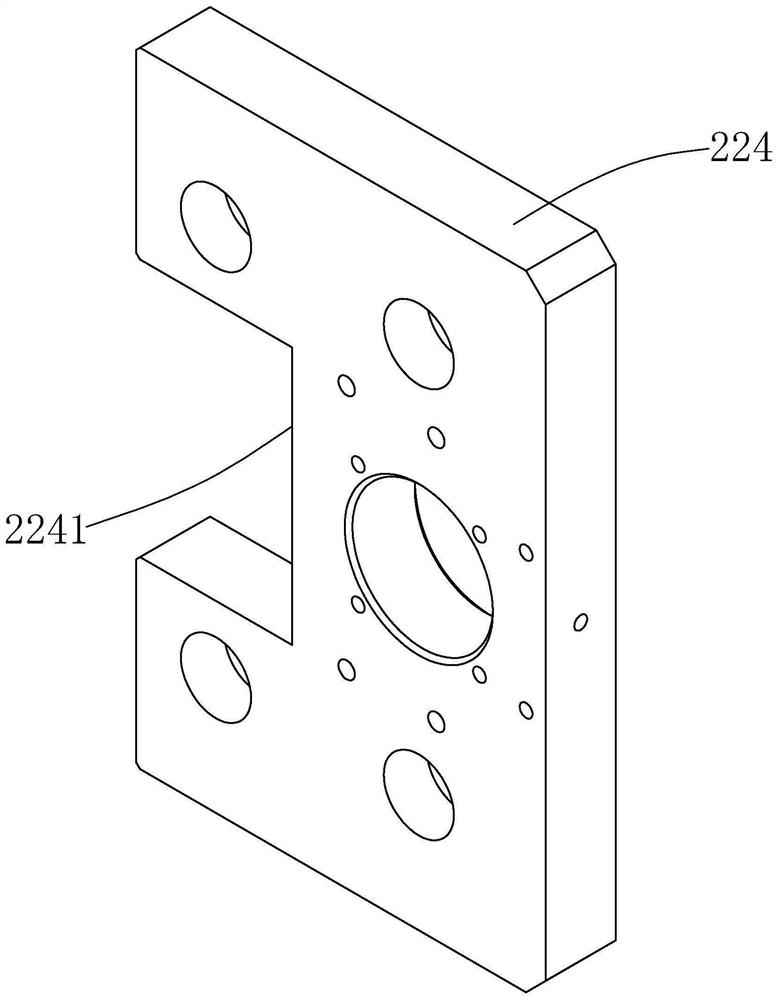

Stretching device for garment ironing machine

ActiveCN104480678BPrecise positioningImprove labor efficiencyIroning apparatusTextiles and paperLaser transmitterEngineering

The invention provides a supporting-unfolding device of a costume ironing machine. The supporting-unfolding device comprises at least one telescopic type unfolding mechanism consisting of a cylinder control device, a steam guide pipe, a mounting frame, a rod-free cylinder, a finger cylinder, a chuck and a sizing rod, and further comprises an expansion type unfolding mechanism consisting of a sliding rod, a left rod mechanism and a right rod mechanism, wherein both the left rod mechanism and the right rod mechanism comprise cylinder seats, piston type cylinders, mounting seats and sizing rods which are mounted in parallel at certain interval; the supporting-unfolding device further comprises a splay unfolding mechanism including a mounting plate sheet, a piston type cylinder, a gas guide pipe, a transmission assembly, a chuck and a supporting rod; the transmission assembly comprises a transmission rack, a left rotating shaft, a right rotating shaft, a left shaft seat, a right shaft seat and a chuck mounting supporting rod; the supporting-unfolding device is also provided with a supporting-unfolding auxiliary positioning device which is a projection device or a laser emitter group and is mounted above the supporting-unfolding device. The supporting-unfolding device has the characteristics of high automation degree, accurate sizing and high generality and can be used by replacing an ironing template; the production cost is lowered, and the production efficiency is improved.

Owner:NINGBO YUREN INTELLIGENT CONTROL TECH CO LTD

A pressure compensation douche quick development method

InactiveCN100527943CShorten the development cycleAccurate stereotypesWatering devicesCultivating equipmentsSoftware engineeringDrip irrigation

The invention discloses a rapid development method of a pressure compensation emitter. The method is based on laser rapid prototyping technology. After designing an integrated model of a pressure compensation emitter with a window according to design requirements, the emitter is processed by a laser rapid prototyping machine. After the test piece is loaded with the diaphragm, it forms an integrated experimental original, which is connected to the comprehensive performance test bench of the emitter, and the experimental finalization of the pressure compensation emitter is quickly completed. The emitter model of the present invention adopts parametric modeling, only needs to modify the corresponding parameters to meet the design requirements, further shortens the development cycle of the emitter, and completes the rapid and accurate finalization of the emitter. Compared with the traditional method, the product finalization of the emitter can be completed without the need for molds and drip irrigation pipe production lines, the cycle is significantly shortened, and the cost is significantly reduced.

Owner:XI AN JIAOTONG UNIV

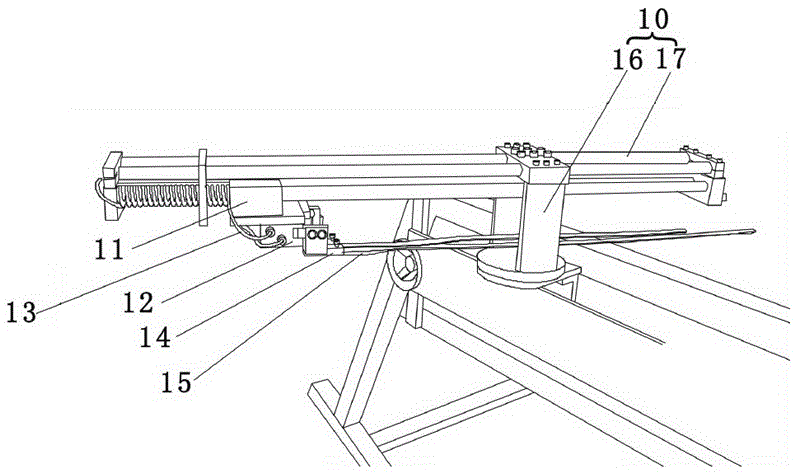

Rapid wire bending mechanism

PendingCN114309347AAccurate stereotypesGood shaping and bending effectEngineeringStructural engineering

A rapid wire bending mechanism comprises a rack, a direction adjusting mechanism and a bending assembly. The direction adjusting mechanism comprises an X-axis machine table and a Z-axis machine table. The bending assembly comprises a first air cylinder, a line folding base and a U-shaped mounting base. The first air cylinder is provided with an L-shaped installation base, and the two second air cylinders are arranged on the L-shaped installation base. A clamping jaw is arranged at the output end of the second air cylinder, and the shaping assembly is arranged on the line folding base. A third air cylinder is arranged in the U-shaped mounting base, and the two ends of a connecting arm are connected with the third air cylinder and the shaping assembly respectively; the third air cylinder pushes one end of the connecting arm, so that the connecting arm swings, and the shaping assembly connected with the other end of the connecting arm is closed. According to the rapid wire bending mechanism, the direction adjusting mechanism is designed to adapt to wires at different positions, the to-be-machined wires are clamped and shaped through the pre-designed shaping assembly, positioning is accurate, and the shaping and bending effect is good.

Owner:TANAC AUTOMATION

Magnesium alloy and aluminum alloy machining shaping equipment

InactiveCN108687529AAvoid the hassle of cuttingImprove work efficiencyOther manufacturing equipments/toolsMachine partsMetal machining

The invention belongs to the technical field of aluminum alloy processing, in particular to magnesium alloy and aluminum alloy machining shaping equipment. The magnesium alloy and aluminum alloy machining shaping equipment comprises a machining shaping equipment body and a supporting table, wherein a motor is fixedly mounted at the lower end of the machining shaping equipment body, a sliding headis movably mounted at the upper end of the machining shaping equipment body, a supporting column is movably mounted on the inner surface of the sliding head, a control box is installed on the one side, near the upper portion of the motor, of the machining shaping equipment. A fixed baffle is fixedly mounted at the upper end, near one side of the supporting column, of the supporting table. A fixedbase is fixedly mounted at the upper end, near one side of the control box, of the supporting table. A supporting base is fixedly mounted at the upper end of the fixed base. According to the magnesiumalloy and aluminum alloy machining shaping equipment, a cutting knife, a width sizing plate and a height sizing plate are arranged, so that the metal machining parts shape better, labor is saved, andbetter application prospect is brought.

Owner:NANJING JIAMING DIE CASTING FACTORY

Anti-collision edge enclosing forming structure for packing box

ActiveCN106113578APrecise positioningAccurate stereotypesContainer making machineryFailure rateReciprocating motion

The invention relates to an anti-collision edge enclosing forming structure for a packing box and belongs to the technical field of manufacturing of packing boxes. The anti-collision edge enclosing forming structure for the packing box comprises heart-shaped edge enclosing forming equipment and an enclosing edge arranged in the heart-shaped edge enclosing forming equipment. The heart-shaped edge enclosing forming equipment comprises a heart-shaped forming block and pushing blocks driven by piston type pneumatic cylinders. Heating devices are arranged in the forming block or the pushing blocks. The pushing blocks comprise the main pushing block matched with the outline of a concave part, and the two auxiliary pushing blocks located on the two sides of the main pushing block. The main pushing block and the two auxiliary pushing blocks are driven by the piston type pneumatic cylinders to do reciprocating motion. The side wall, making contact with the forming block, of the main pushing block, and the side walls, making contact with the forming block, of the auxiliary pushing blocks are provided with heat-conducting glue layers. The edge enclosing forming structure for the heart-shaped packing box is firm in positioning, accurate in forming, high in yield and low in failure rate.

Owner:浙江中赢包装有限公司

Method for preventing aerotyre of small dimension generating naked wire at aerotyre sidewall

The invention discloses a method which prevents an exposed stitching of the side wall of an aerotire with small size and comprises the following techniques: (1) the exhaust aperture on a tyre mold is reduced; (2) sidewall rubber is thickened; (3) before optimum cure, the time of collecting inner-pressure heat water and the outer temperature warming are shortened; (4) the sizing pressure is reduced and the time of sizing is prolonged. The invention has the advantages that by adopting technique, the problem of the exposed stitching of the side wall of the aerotire is solved, and the production qualification rate is increased.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

A kind of nail art aluminum foil and its manufacturing method

ActiveCN107087883BStrong resistance to dissolutionKeep Paste IntegrityPolyureas/polyurethane adhesivesManicure/pedicureNonwoven fabricAluminum foil

The invention discloses a manufacturing method of nail-beautifying aluminum foil. The method comprises the following steps that firstly, the surface of the aluminum foil is cleaned; secondly, the bonding surface of the aluminum foil is coated with base layer paint, and heating and curing are carried out; thirdly, a cured base layer is coated with an adhesive layer; fourthly, non-woven cloth is attached to the base layer, and heating and curing are carried out; fifthly, the aluminum foil attached with the non-woven cloth is cut into sections and packaged, so that the finished nail-beautifying aluminum foil product is manufactured. By means of the method, the defects in the prior art can be overcome, so that the bonding effect between the non-woven cloth and the aluminum foil in the environment with a nail polish remover is improved.

Owner:ZHUOZHOU HAOYUAN FOIL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com