A method of using a perforating U-turn device

A technology of equipment and heading machine, which is applied in the field of punching and turning equipment, and achieves the effects of strong practicability, low production cost and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

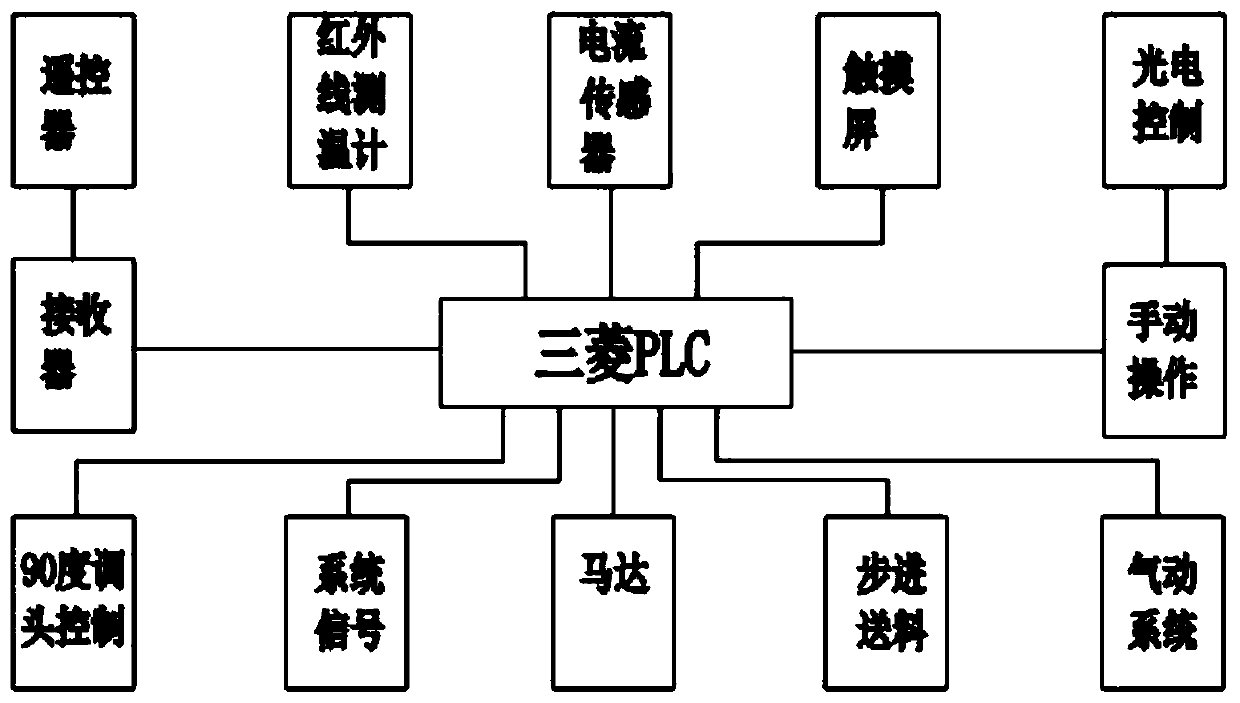

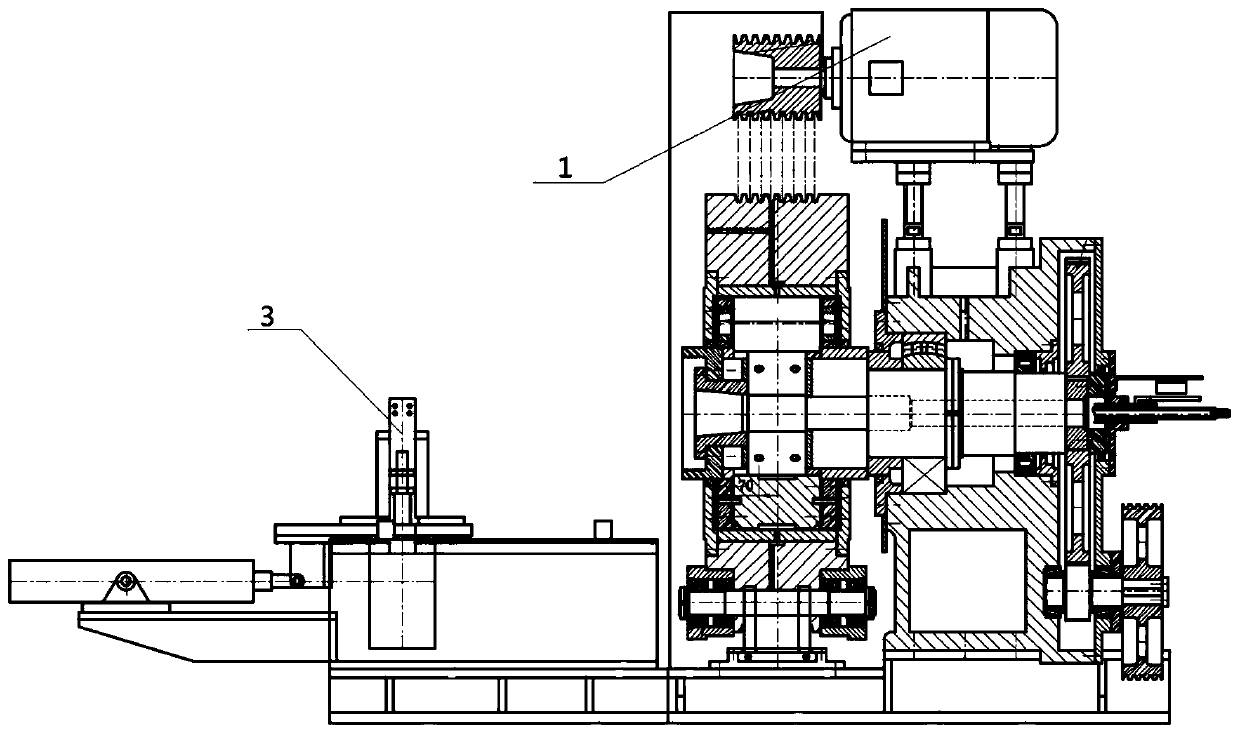

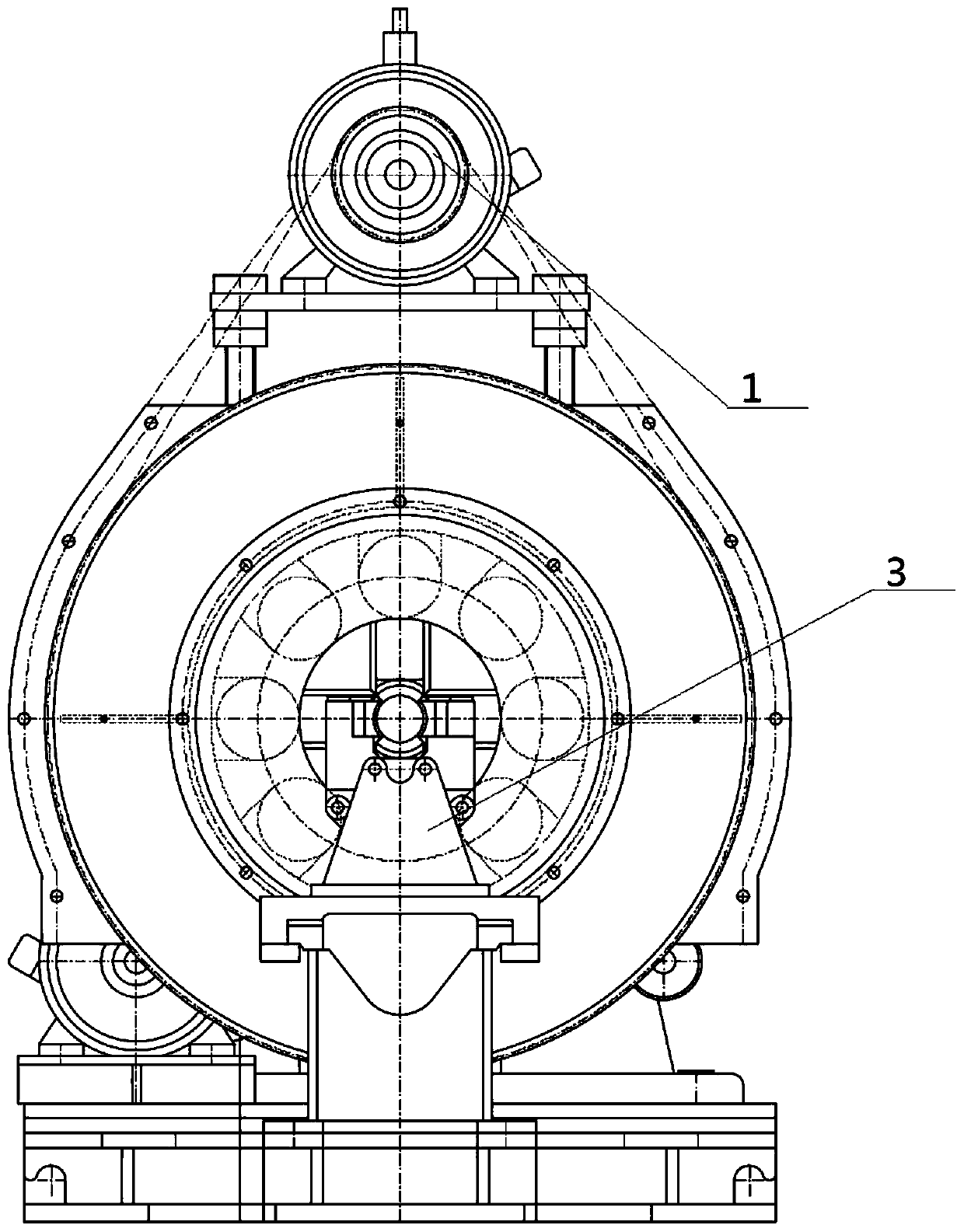

[0029] Such as Figure 1 to Figure 5 As shown, a method of using a piercing and turning equipment, the equipment mainly includes a PLC module, a signal monitoring module, a photoelectric switch, a cooling mechanism, a heading machine, a roll box, a gantry and a rod piercing trolley. The device is also equipped with a remote controller, a receiver and a touch screen, so as to achieve remote control of the machine and the touch screen for control, specifically including the following steps:

[0030] 101) Material heating treatment step: controlled by the PLC module of the equipment, the steel pipe material is sent into the walking furnace, and the walking furnace is continuously heated to a high temperature, and the high temperature is 1000°C to 1300°C. The walking furnace is a device with fixed height, width and length. The PLC module adopts M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com