A pressure compensation douche quick development method

A pressure compensation and sprinkler technology, which is applied in the direction of botany equipment and methods, instruments, watering devices, etc., can solve the problems of long research and development cycle and high cost, and achieve the effect of shortening the cycle, reducing the cost and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

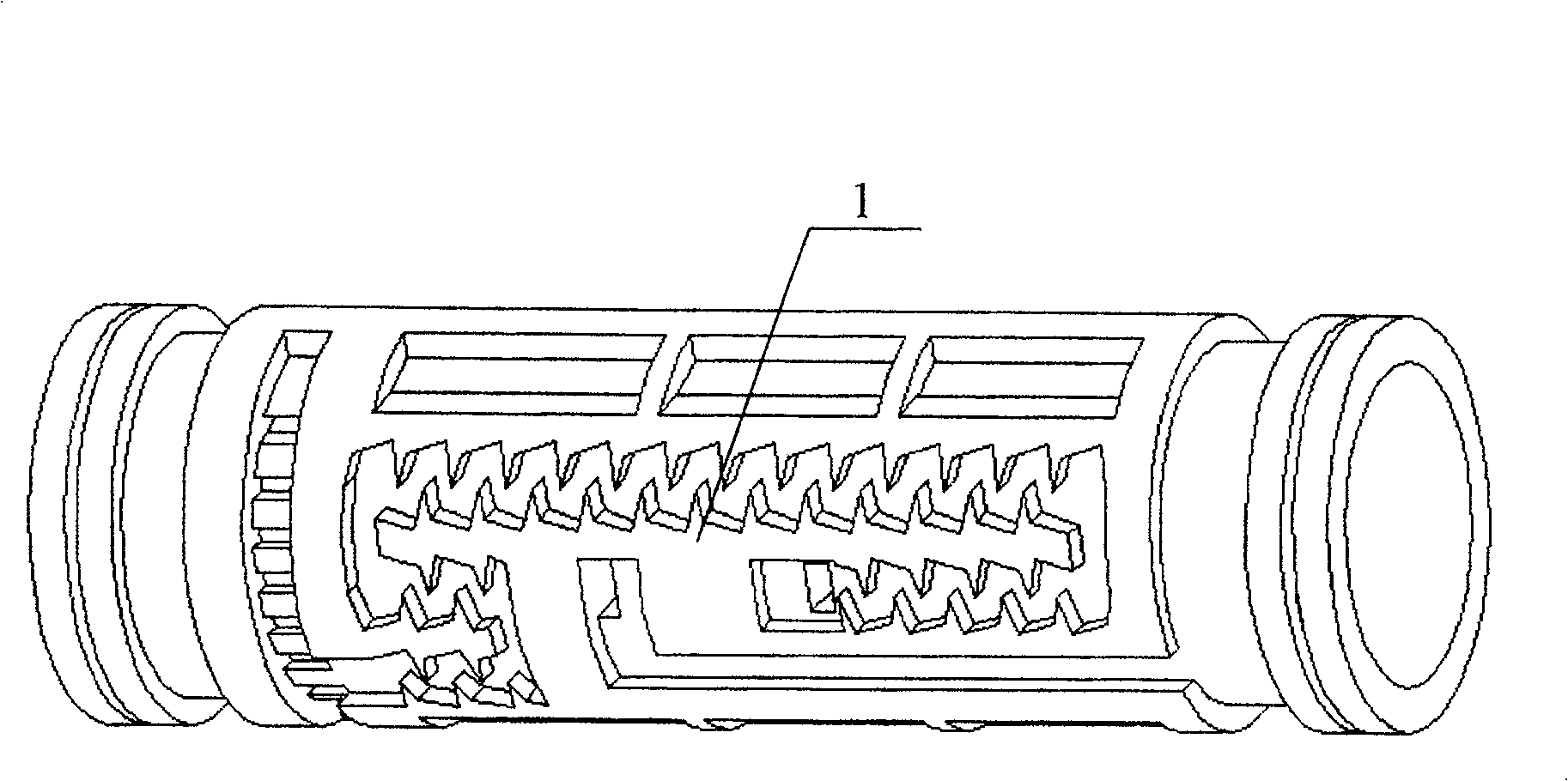

[0010] see figure 1 , 2, 1) firstly adopt the design software pro / e to establish the parametric CAD pressure compensation dripper model 1 of the dripper according to the flow requirement of the emitter;

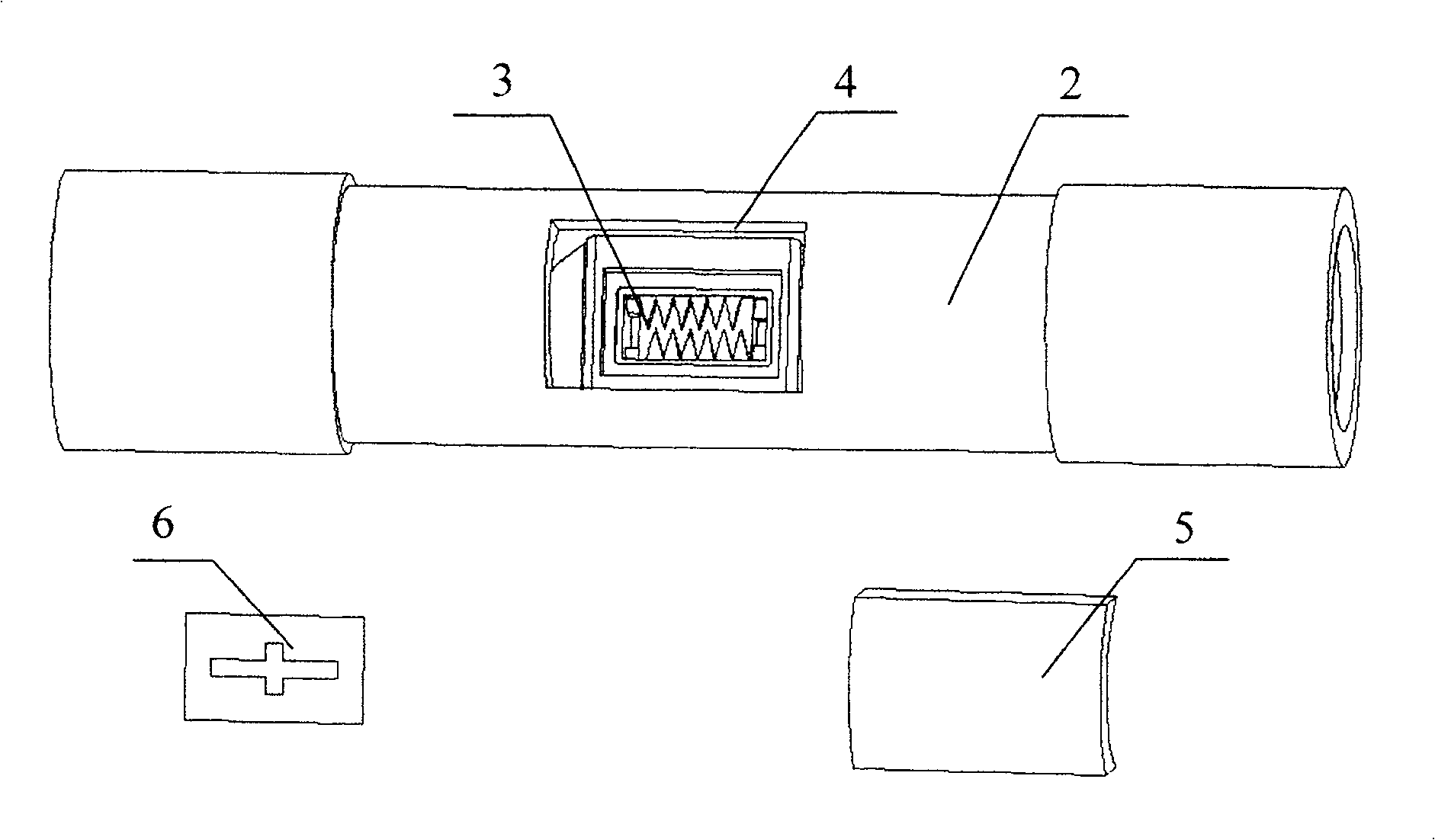

[0011] 2) Then, on the basis of the pressure compensation dripper model 1, an outer tube with a window is designed, and the outer tube and the pressure compensation dripper model 1 are integrated to form a model of a pressure compensation emitter integrated dripper 2 with a window, And cut a rectangular gap on the outer tube at the place opposite to the pressure compensation area 3 of the pressure compensation dripper as the pressure regulating diaphragm loading window 4, in order to close the diaphragm loading window 4 on the outer tube, install the diaphragm The model of the outer pipe sealing block 5 is also set on the window 4;

[0012] 3) Data convers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com