Forming structure and forming method of a packaging box

A packaging box and border technology, which is applied in the field of shaping structure and shaping of the packaging box, can solve the problems of cumbersome operation, inability to guarantee the quality of the packaging box, and difficulty in processing heart-shaped borders, etc., to achieve easy-to-use, The surrounding shaping structure is simple and the shaping effect is accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

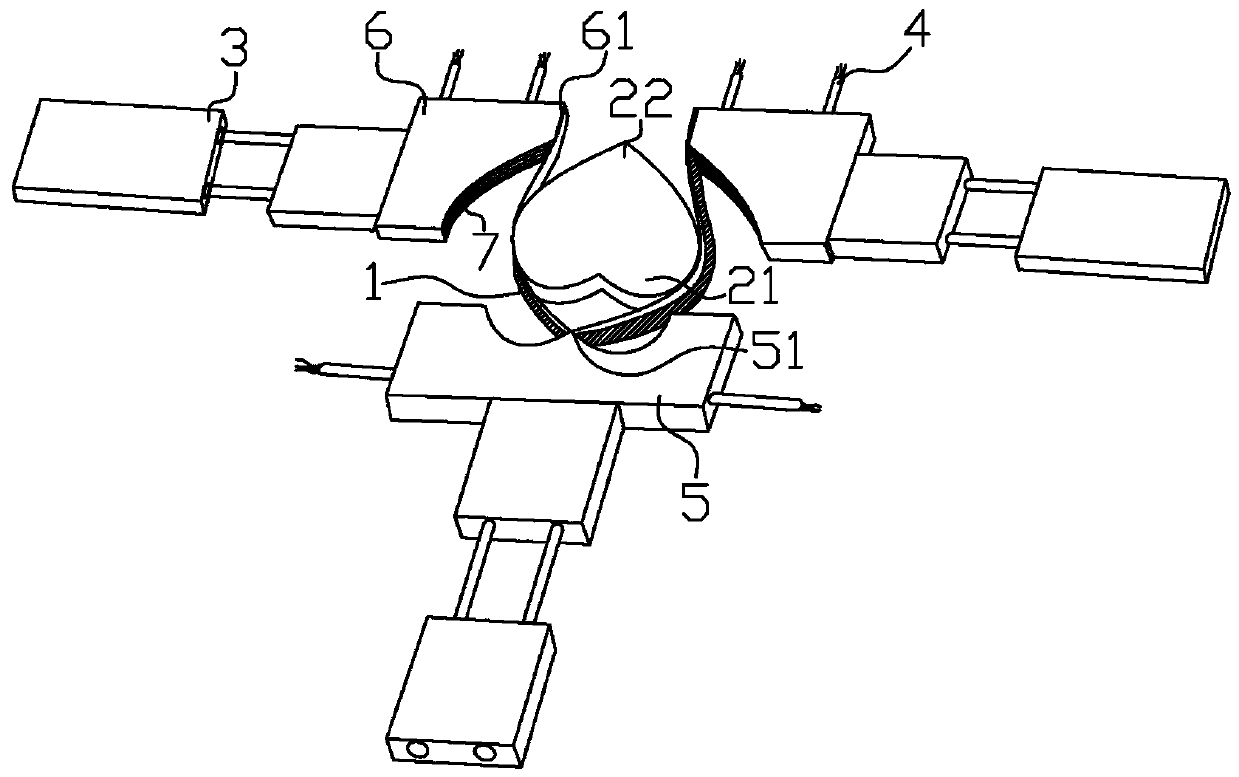

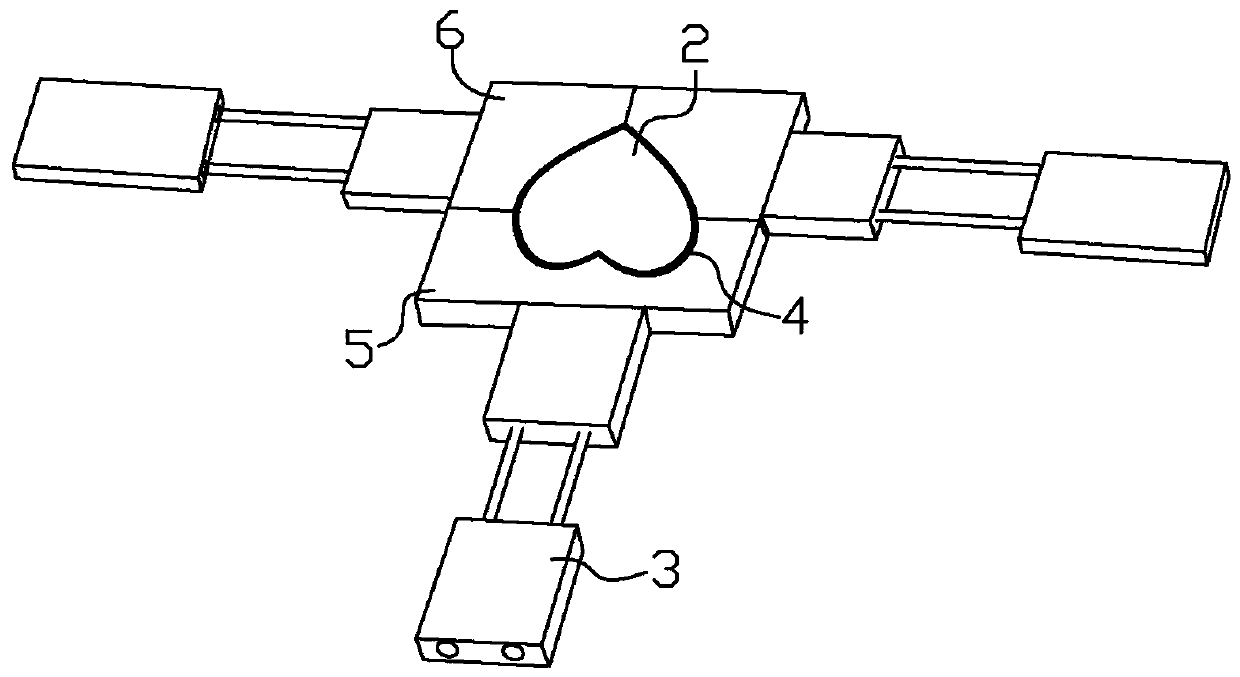

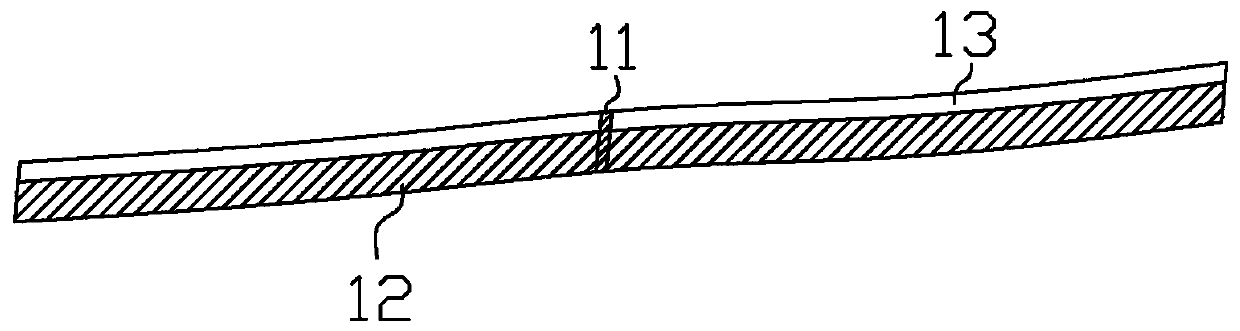

[0035] Embodiment 1: A wrapping shaping structure of a packaging box, including a heart-shaped wrapping shaping device and a wrapping 1 arranged in the heart-shaped wrapping shaping device; the wrapping 1 includes a lower hemming layer 12 and the upper unilateral layer 13; the heart-shaped peripheral shaping equipment includes a heart-shaped shaping block 2 and a push block driven by a piston-type pneumatic cylinder 3.

[0036] A heating device 4 is arranged inside the shaped block 2, and the heating device 4 is a polyimide heating film arranged on the inner wall of the outline of the shaped block 2, and the shaped block 2 is in contact with the surrounding edge 1 Aluminum heat-conducting wire 7 is provided on the side; the shaped block 2 includes a recessed part 21 and a cone part 22 integrally connected, and the recessed part 21, that is, the heart-shaped shaped block 2 includes two protrusions and a recess The tapered portion 22 is the portion on the heart-shaped shaped blo...

Embodiment 2

[0039] Embodiment 2: A surrounding shaping structure of a packaging box, including a heart-shaped surrounding shaping equipment and a surrounding edge 1 arranged in the heart-shaped surrounding shaping equipment; the surrounding edge 1 includes a lower hemming layer 12 and the upper unilateral layer 13; the heart-shaped peripheral shaping equipment includes a heart-shaped shaping block 2 and a push block driven by a piston-type pneumatic cylinder 3.

[0040] A heating device 4 is arranged in the push block, and the heating device 4 is a heating rod arranged in the push block, and a copper heat conduction plate is arranged on the side wall of the push block in contact with the surrounding edge 1. Inlaid wire 7; the shaped block 2 includes a concave portion 21 and a cone portion 22 integrally connected, the concave portion 21, that is, the heart-shaped shaped block 2 includes two protrusions and a concave position, and the cone portion 22 That is, the heart-shaped shaping block ...

Embodiment 3

[0043] Embodiment 3: a method for shaping the surrounding edge of a packaging box, comprising the following steps:

[0044] ① Turn on the heating device 4 located on the push block for preheating;

[0045] ② Manipulate the piston-type pneumatic cylinder 3 so that there is a gap between the main push block 5 and the two auxiliary push blocks 6 and the shaping block 2;

[0046] ③ Connect the groove bar 11 of the surrounding edge 1 to the push block protrusion 51 of the main push block 5, and position it;

[0047] ④ Manipulate the piston-type pneumatic cylinder 3 of the main pushing block 5 to push the surrounding edge 1 onto the recess 21 of the shaping block 2;

[0048] 6. Manipulate the two auxiliary push blocks 6 to push the rest of the surrounding edge 1 onto the shaped block 2;

[0049] ⑦After 0.5 seconds to set the shape, operate the piston-type pneumatic cylinder 3 to return the push block, and take out the shaped edge 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com