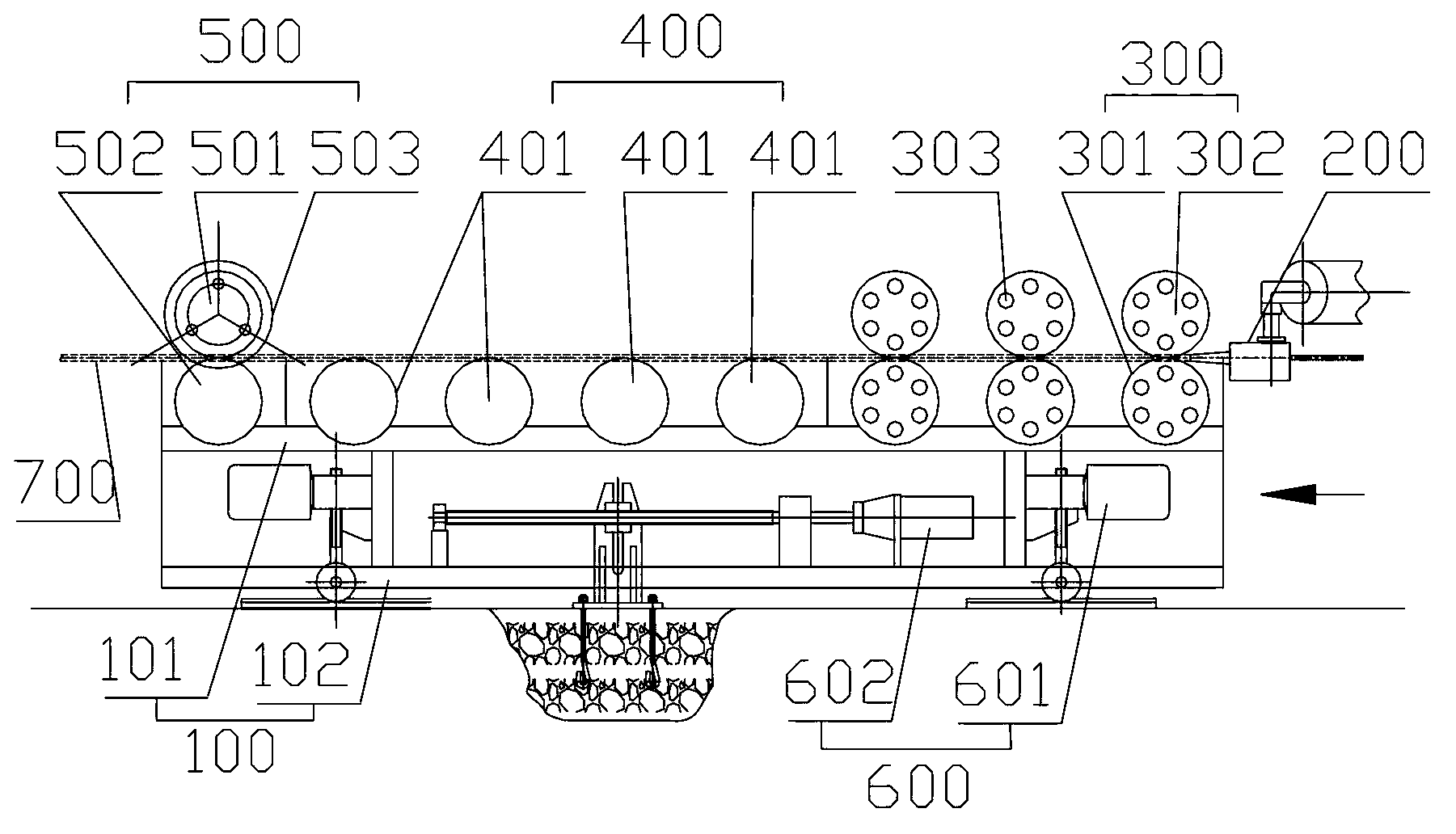

Rolling sizing device

A technology of rolling and sizing mechanism, applied in the field of rolling and sizing device, can solve the problems of limited friction coefficient between traction device and product surface, insufficient traction force for continuous production, small traction force area, etc., so as to achieve smooth surface and eliminate bending. , the effect of improving the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

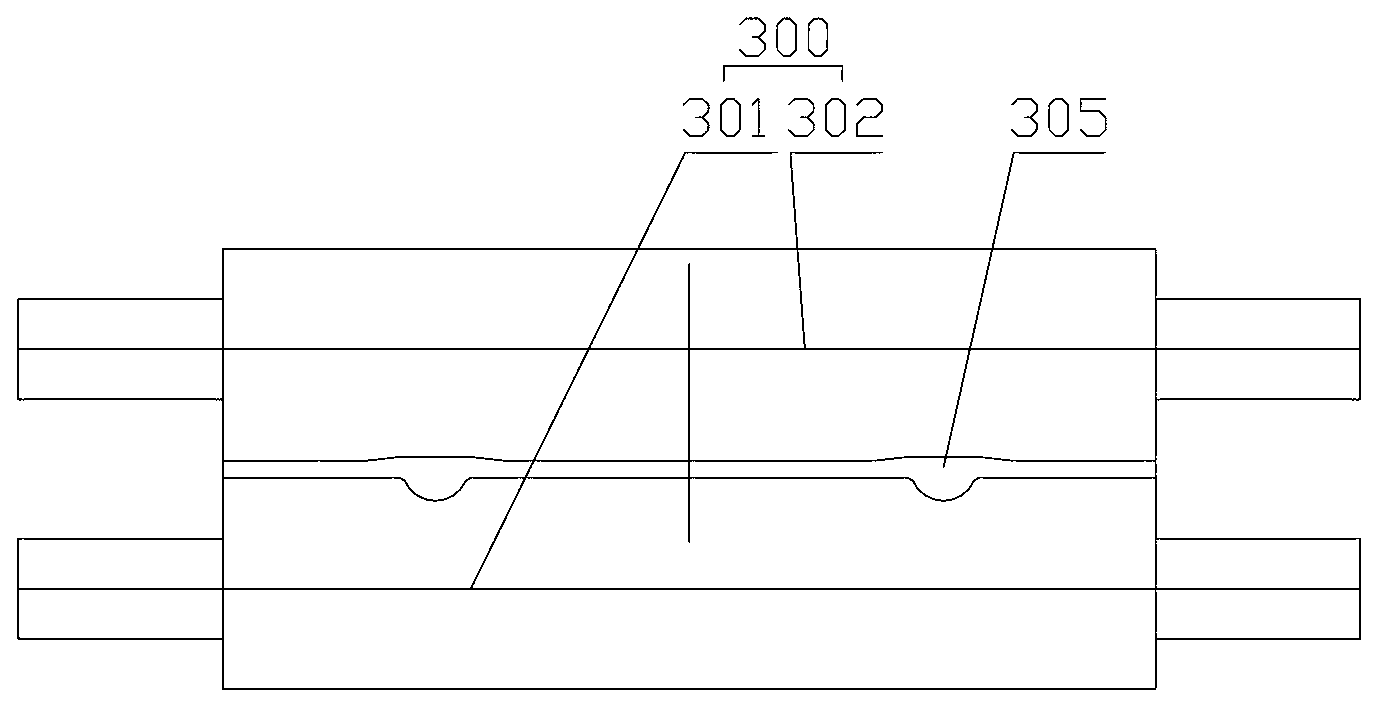

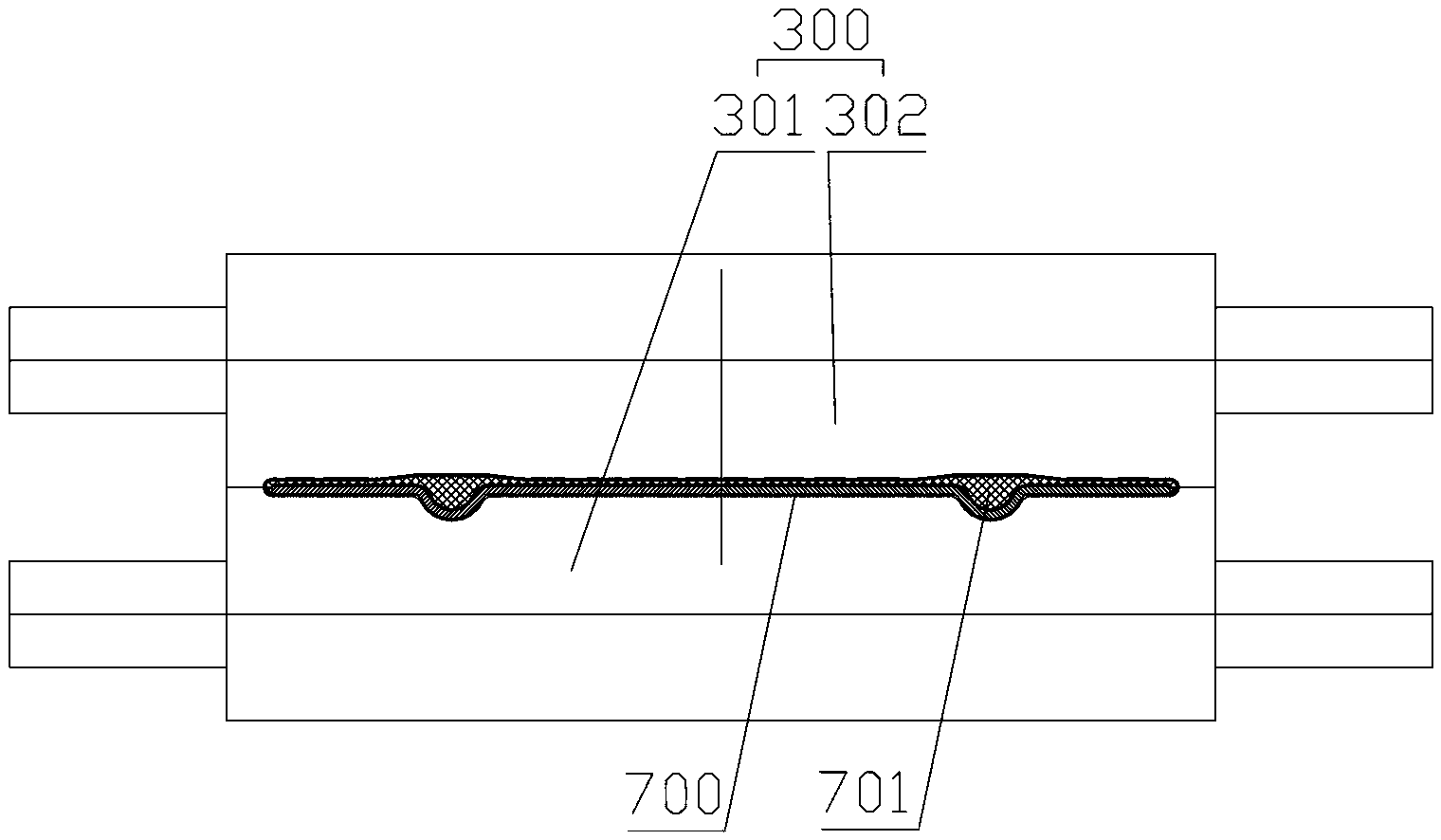

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0031] Orientation definition: according to the direction of movement of the strip-shaped thermoplastic composite material, the orientation close to the thermoplastic composite extrusion die is the front, and the orientation away from the extrusion die is the rear.

[0032] The strip-shaped thermoplastic composite material of the present invention can be used for the manufacture of strip-shaped thermoplastic composite products and spiral tubular thermoplastic composite products, that is, the strip-shaped thermoplastic composite material can be made into strip-shaped thermoplastic composite products after shaping, or After shaping, it is made into a spiral tubular thermoplastic composite product by spiral welding.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com