Plastic telescopic pipe and method for manufacturing same

A telescopic tube, plastic technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipes, etc., can solve the problems of easy to spread and not easy to fold, and achieve the effect of not easy to spread, beautiful appearance and accurate shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

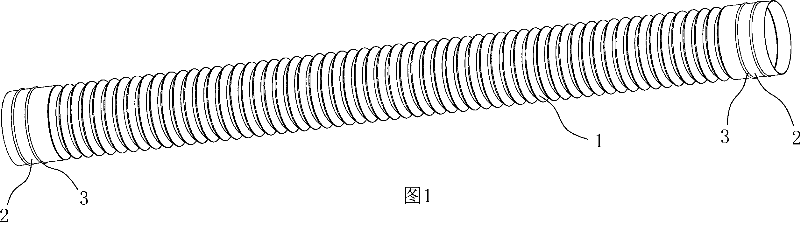

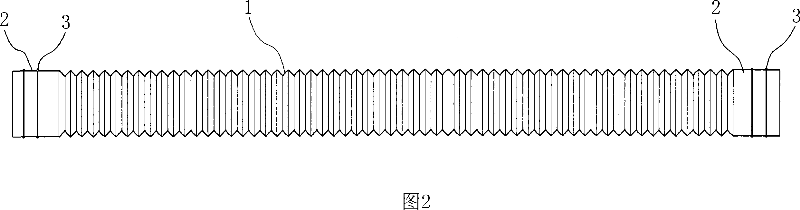

[0025] As schematically shown in Figures 1 to 5, it is a preferred embodiment of the plastic telescopic tube of the present invention. As shown in Figures 1 to 5, the plastic telescopic tube of this embodiment has a bellows-shaped tube body 1. When the tube body 1 is stretched out, its outer diameter D is 102 mm, its inner diameter d is 86 mm, and the peak distance S is 17mm. Both ends of the pipe body 1 are integrally connected with a joint 2, and two circles of annular ribs 3 are formed on the joint 2 for connection and positioning.

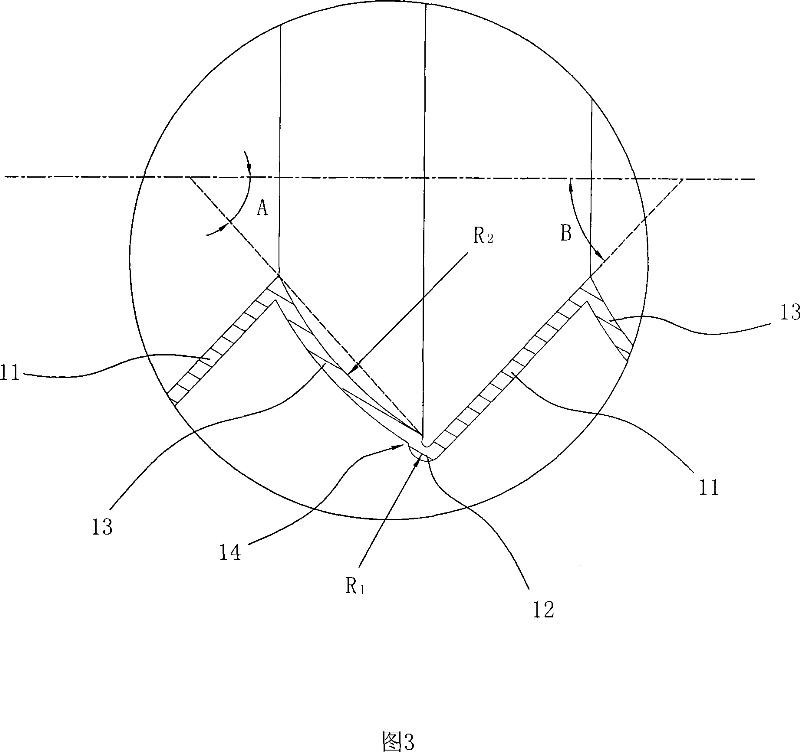

[0026] Seen from the longitudinal section of the pipe body 1 in its extended state, the pipe wall is alternately connected by the right side wall 11, the arc-shaped crest wall 12 and the left side wall 13 to form a continuous wave shape, and the arc of the crest wall 12 The radius of curvature R 1 1 mm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com