Folded tricycle and punching pipe coiling element thereof

A technology for stamping rolls and tricycles, which is applied in the field of transportation, can solve the problems of seldom edge-rolling and rolling tubes, etc., and achieves the effects of simple production, simple folding and folding, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

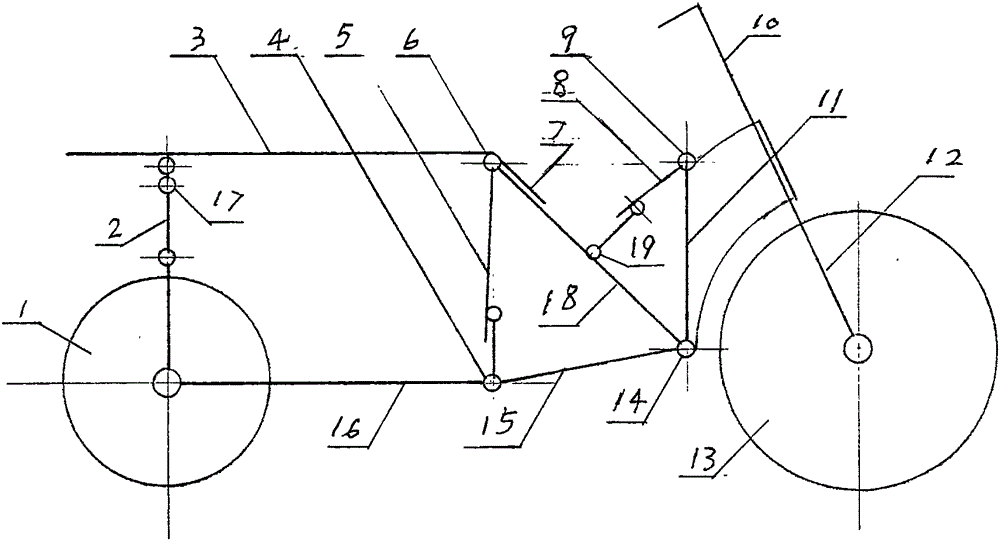

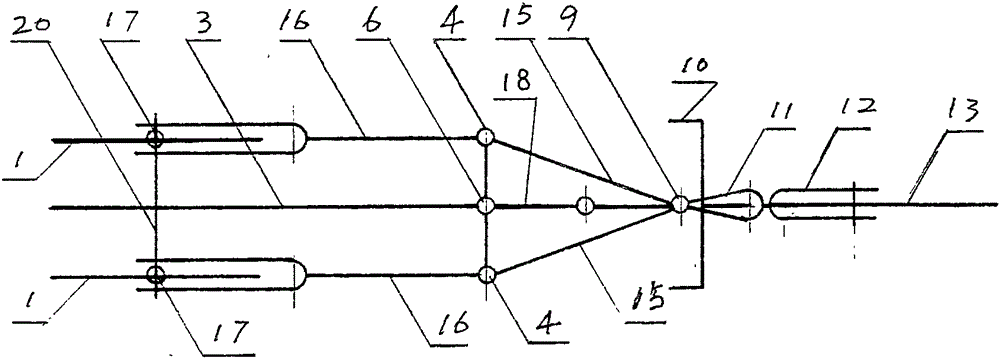

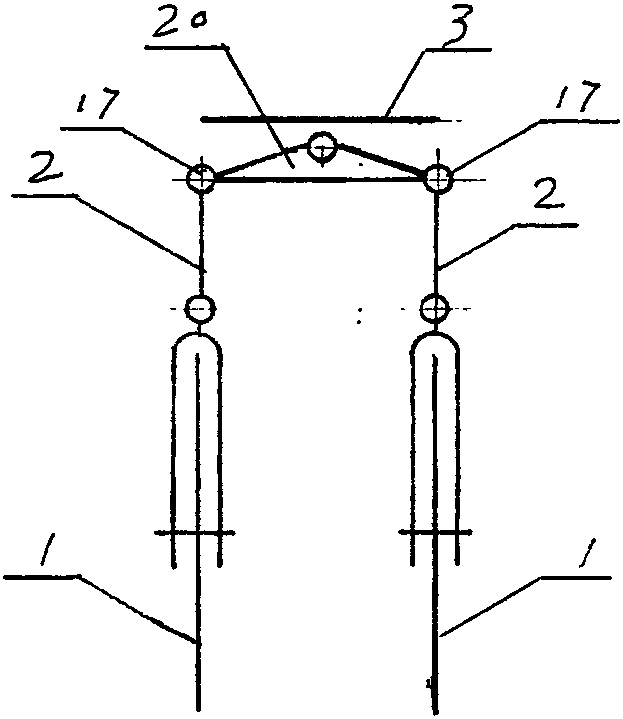

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, be a kind of folding tricycle that is formed with triangle.

[0024] Its structure is like this: an elongated seat plate 3, the front end of seat plate 3 is movably linked to each other with the upper end of a diagonal upright bar 18 of a forward slanting brace. From the joint forward, the front end of the seat plate 3 also extends along the slanting upright bar 18 , and stretches out a section of the seat plate head 7 overlapping with the slanting upright bar 18 and pressed on the slanting upright bar 18 forward and downward. Straight seat board 3 and inclined upright bar 18 have just constituted an inwardly bent like this, the obtuse angle activity structure that can not turn outwards. Seat plate 3 rear ends link to each other with left and right rear wheels 1 respectively again by seesaw 20, left and right ball head shaft 17, left and right damping springs 2, left and right flat forks 14 again. T...

Embodiment 2

[0026] Such as Figure 5 - Figure 10 Shown are the cross-sections of several curling tubes picture .

[0027] The so-called stamped rolled pipe parts: use the stamping method and the rolled pipe die to roll out the edge of the stamped part like a pipe, which can increase the strength of the other part or fit the round edge and round pipe.

[0028] The coiled tube can be rolled along the geometric shape of the stamping part; it can be rolled according to the direction of strength, and tube shapes 23 and 24 with different sizes at both ends can be rolled out; tube shapes 21, 22 and tubes with different sizes at both ends can also be rolled out Double bobbin tubes 25, 26 of the same size on both sides; can be rolled into profiles 29, 30; two stamping parts can roll out the inner and outer sheathing pipes 27, 28 together, and the sheathing pipes can be rolled into tightly wrapped Tight fit, can also roll out a sliding fit that can slide relatively; between the tubes and t...

Embodiment 3

[0030] Such as Figure 11 , Figure 12 , Figure 13 Shown is the front of a package assembly, steering hinge, steering stem and fork. The steering rod 10 and the front fork 12 that can relatively slide up and down and shock absorption are a pair of rolled tube structures with inner and outer sheaths. The outer steering rod 10 is rolled with a pair of sliding sleeves 32 that can be guided and a hinge tube 31 that can turn left and right. The front fork 12 of the inner package is rolled with a pair of sliding sleeves 33 that can be guided. The middle package is a damping spring 34 .

[0031] Rotation such as aforementioned steering rod 10, front fork 12, hinge 31 and in the sliding parts, can make slide bearing with good lubricating properties such as polytetrafluoroethylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com