Removable shaping mould

A shaping mold removal technology, applied in the direction of manufacturing tools, wood processing equipment, wood bending, etc., can solve the problems of increased processing costs, waste, low efficiency, etc., achieve precise bending and shaping, and improve the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

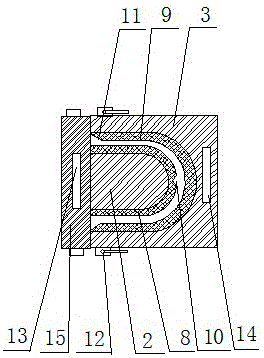

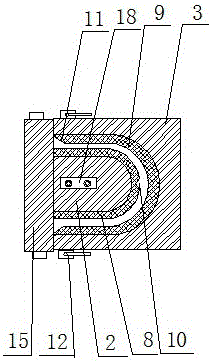

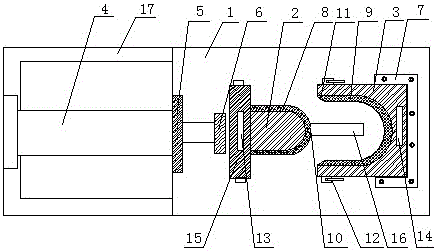

[0023] A removable shaper such as figure 1 and figure 2 , including a sizing inner mold, a sizing outer mold 3 and a lock 12 for connecting the sizing inner mold and the sizing outer mold 3, the sizing outer mold 3 is provided with a sizing groove, and the sizing inner mold includes a sizing bump 2, the sizing groove and the sizing convex Block 2 is formed with shaped gaps.

[0024] The removable shaping mold can move the object while shaping the object, so that it is convenient to move after shaping.

[0025] The shaping bump 2 is provided with a buffer block one 8, and the shaping groove is provided with a buffer block two 9. By arranging the first buffer block 8 and the second buffer block 9, buffering can be performed during bending. The buffer block one 8 is provided with a limiting groove 10 . The buffer block one 8 is U-shaped, and the limiting groove 10 is arranged on the central axis of the buffer block one 8 . The limiting groove 10 is a U-shaped groove or a V-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com