Penetrating and inserting combined type electroplating workpiece clamp

A workpiece fixture and insert group technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve problems such as small problems, increased processing costs, and uneven obstacles, so as to improve the accuracy level, improve the operation efficiency, and improve the yield rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

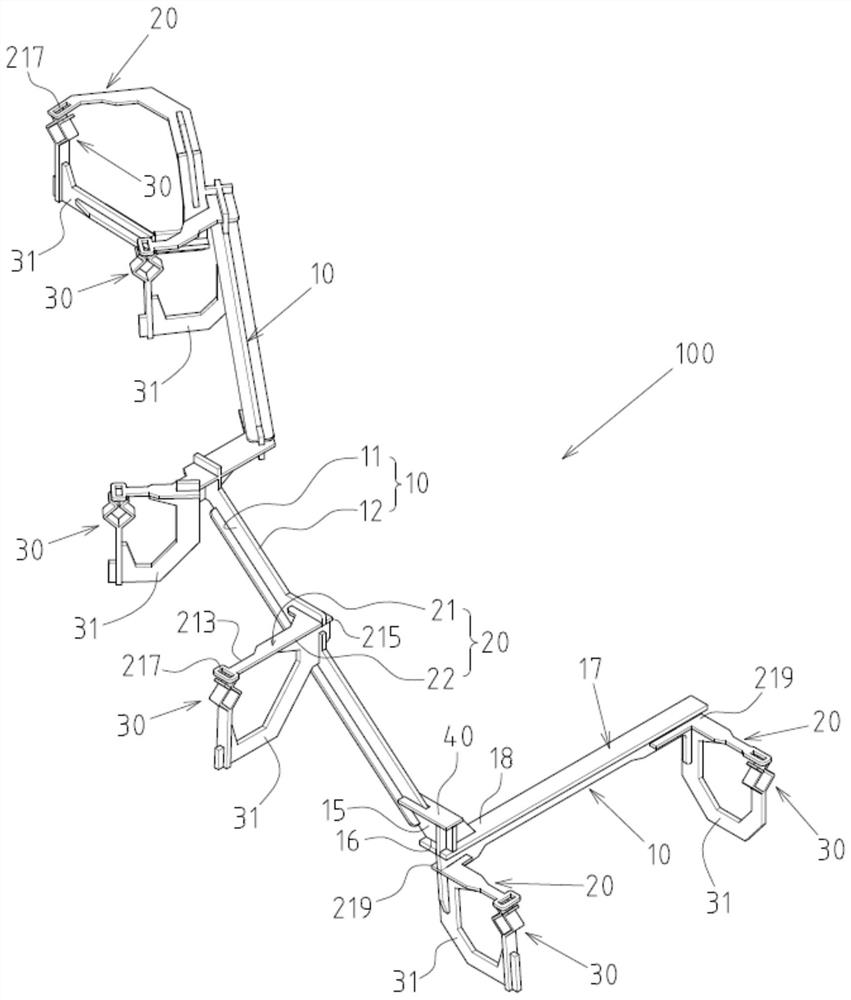

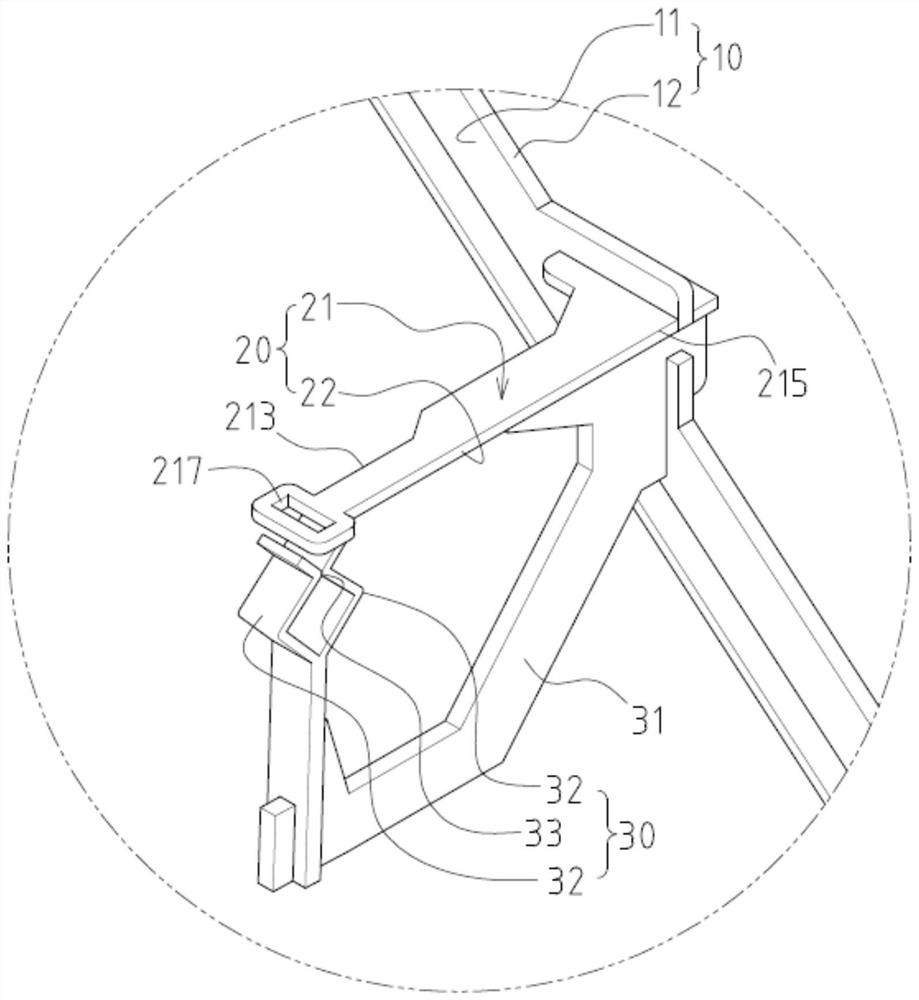

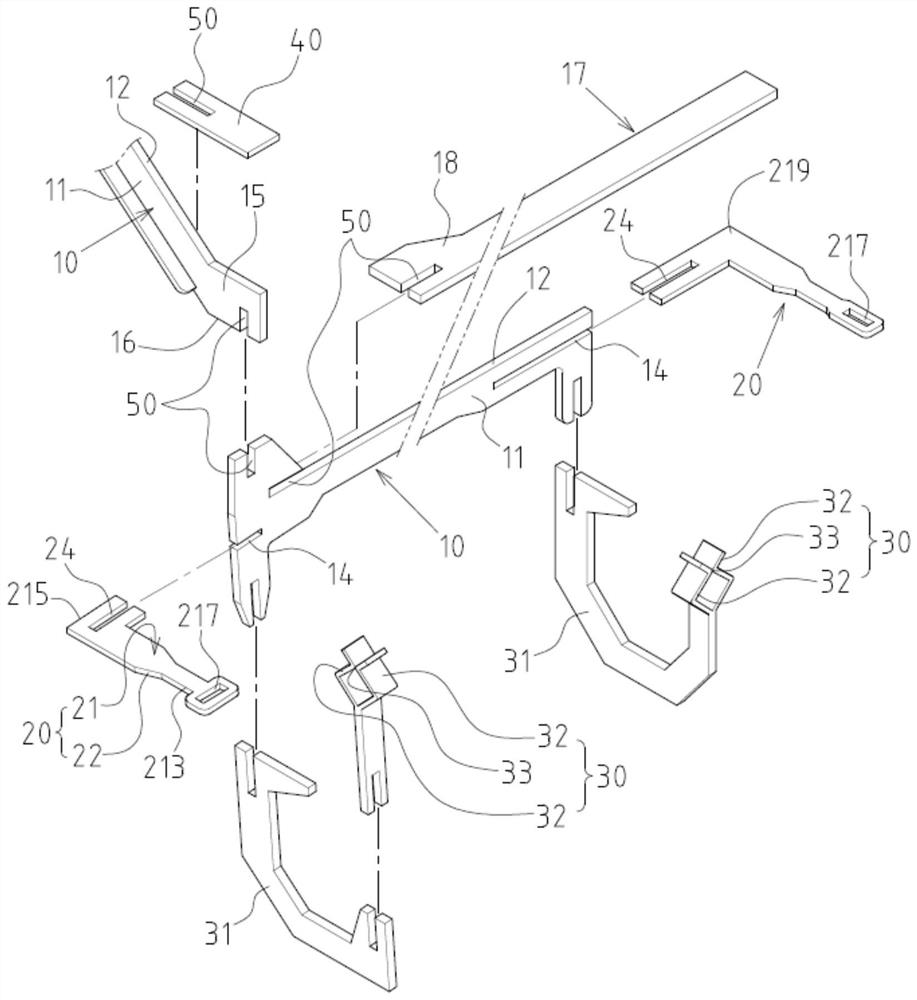

[0027] see Figure 1 to Figure 5 Shown is the preferred embodiment of the present invention for the plug-in plate combination electroplating workpiece fixture, but these embodiments are for illustration purposes only, and are not limited by this structure in the patent application.

[0028] The electroplating workpiece fixture 100 is used for inserting and clamping positioning of an electroplating workpiece 200 in a preset form (such as Figure 6 and Figure 7 As shown), the electroplating workpiece 200 is formed with a plurality of plug pins 201 for plugging into the electroplating workpiece fixture 100 .

[0029] The electroplating workpiece fixture 100 includes a main frame body 10 and a plurality of support plates 20 that are interfitted with each other, wherein the main frame body 10 includes two oppositely facing two frame surfaces 11 and one side edge 12 formed on the periphery of the two frame surfaces 11; Each bracket plate 20 includes an inserting plate surface 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com