Production technology of cylindrical moxibustion tool

A production process and technology of moxibustion tools, applied in the field of medicine, can solve problems such as moxa can not be burned normally, moxa has poor compression and shaping effect, and moxa surface is easy to fall off, so as to prevent unstable product quality and speed up installation efficiency , The effect of simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiment:

[0031] The moxa velvet of the cylindrical moxibustion tool of the embodiment of the present invention is obtained by the following method: select the aged Artemisia argyi that has been dried for more than one year, mash the leaves of Artemisia argyi to a degree of 85-95 mesh, and mash The final Artemisia argyi powder is dried. There are not too many requirements for the preparation of moxa in actual production. The moxa prepared by other methods can be used in this production process, but the purity and particle size of the moxa prepared by the above method are guaranteed. It works even better when used.

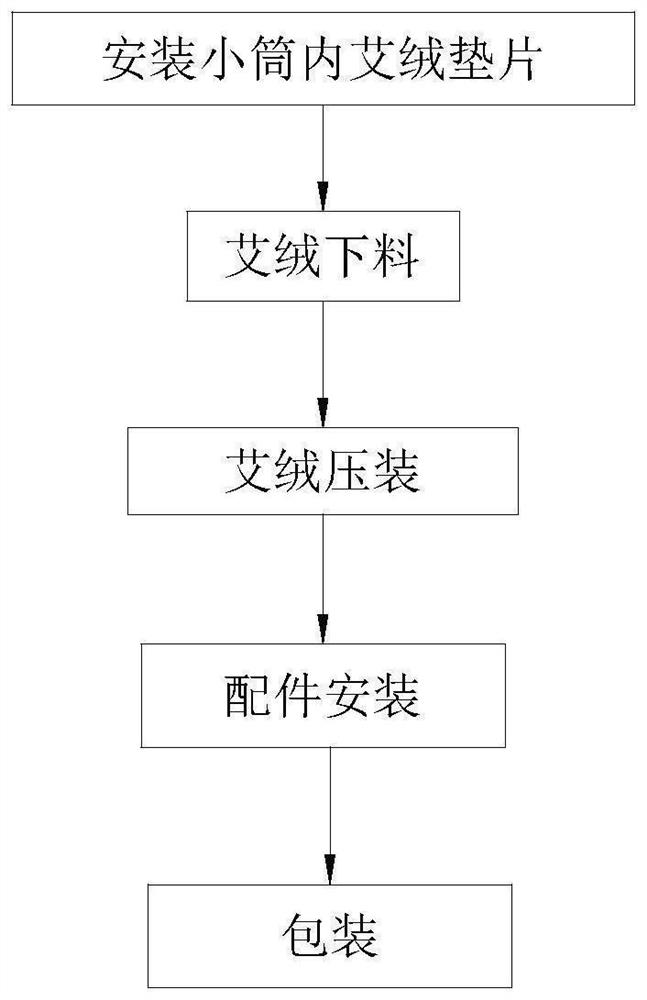

[0032] Such as figure 1 As shown, its production process of the tubular moxibustion tool of the embodiment of the present invention comprises the following steps:

[0033] S1. Install the moxa velvet gasket in the small tube: install the small tube of the cylindrical mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com