Rotating shaft type turnover flanging method and flanging machine

A technology of a rotating shaft and an edge machine, which is applied in the field of a rotating shaft-type overturned hemming method and a hemming machine, can solve the problems such as the influence of the yield, the effect of the hemming needs to be improved, and the surface of the sheet is easily scratched, so as to achieve convenient and fast hemming. , The folding angle and shape are not limited, and the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

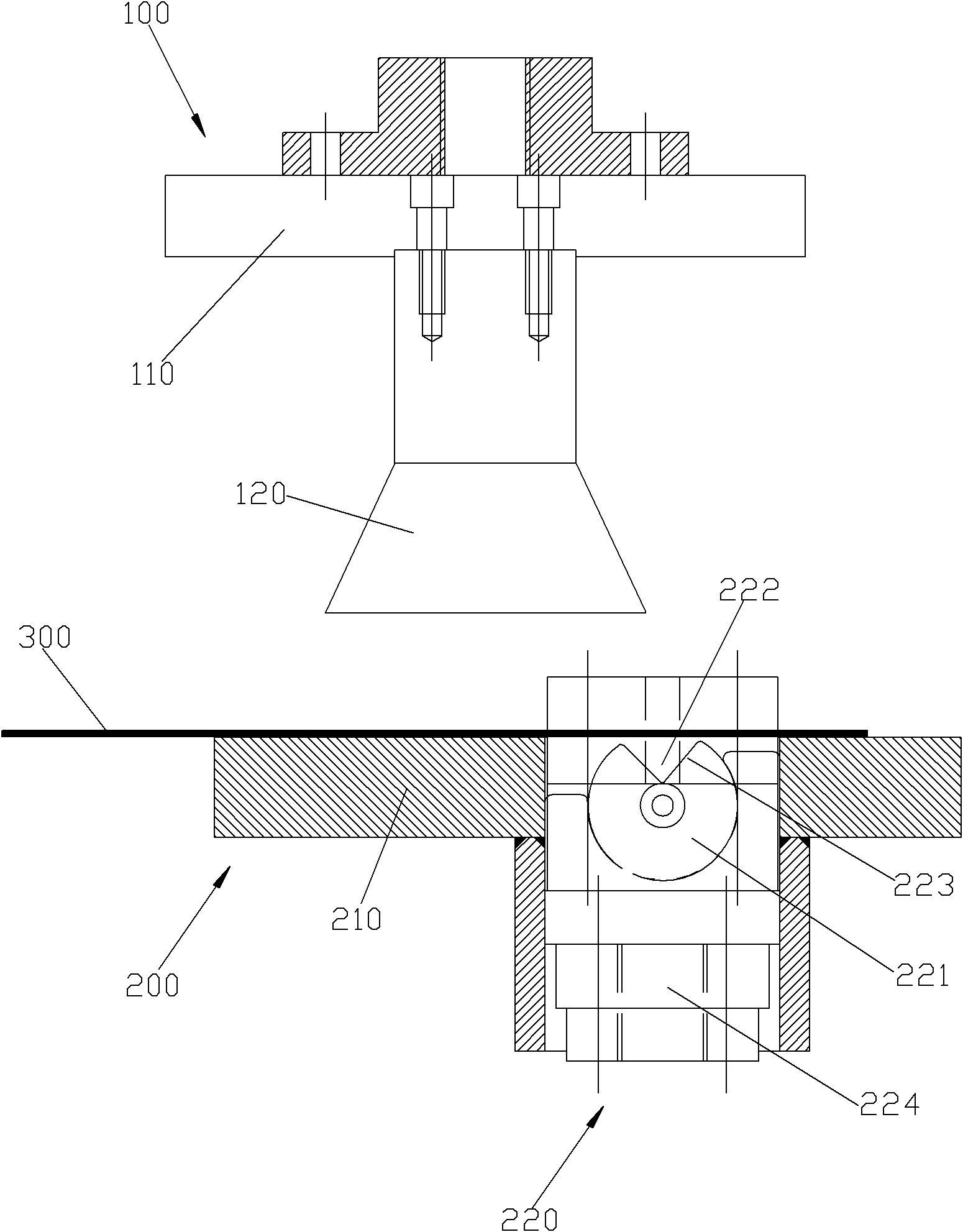

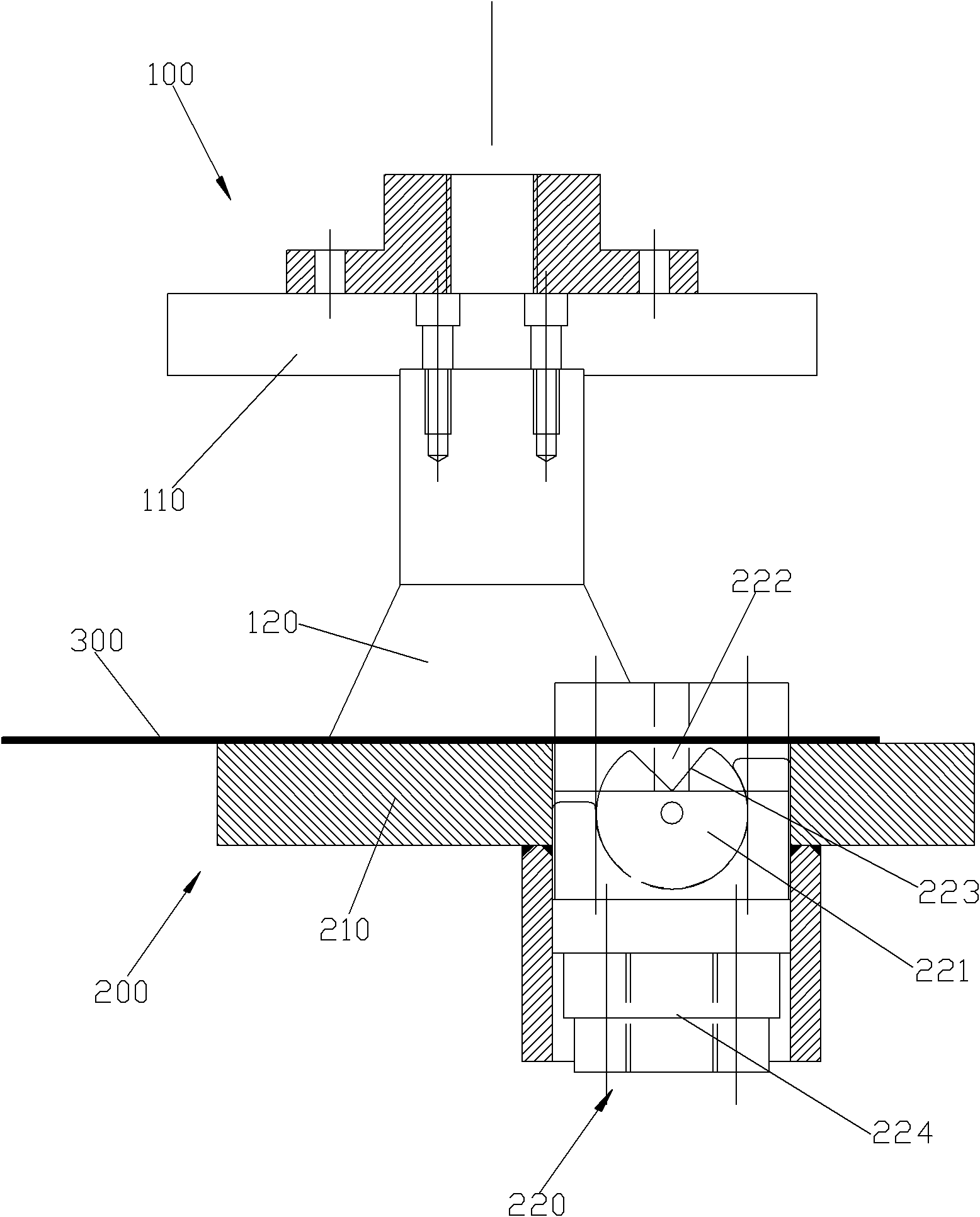

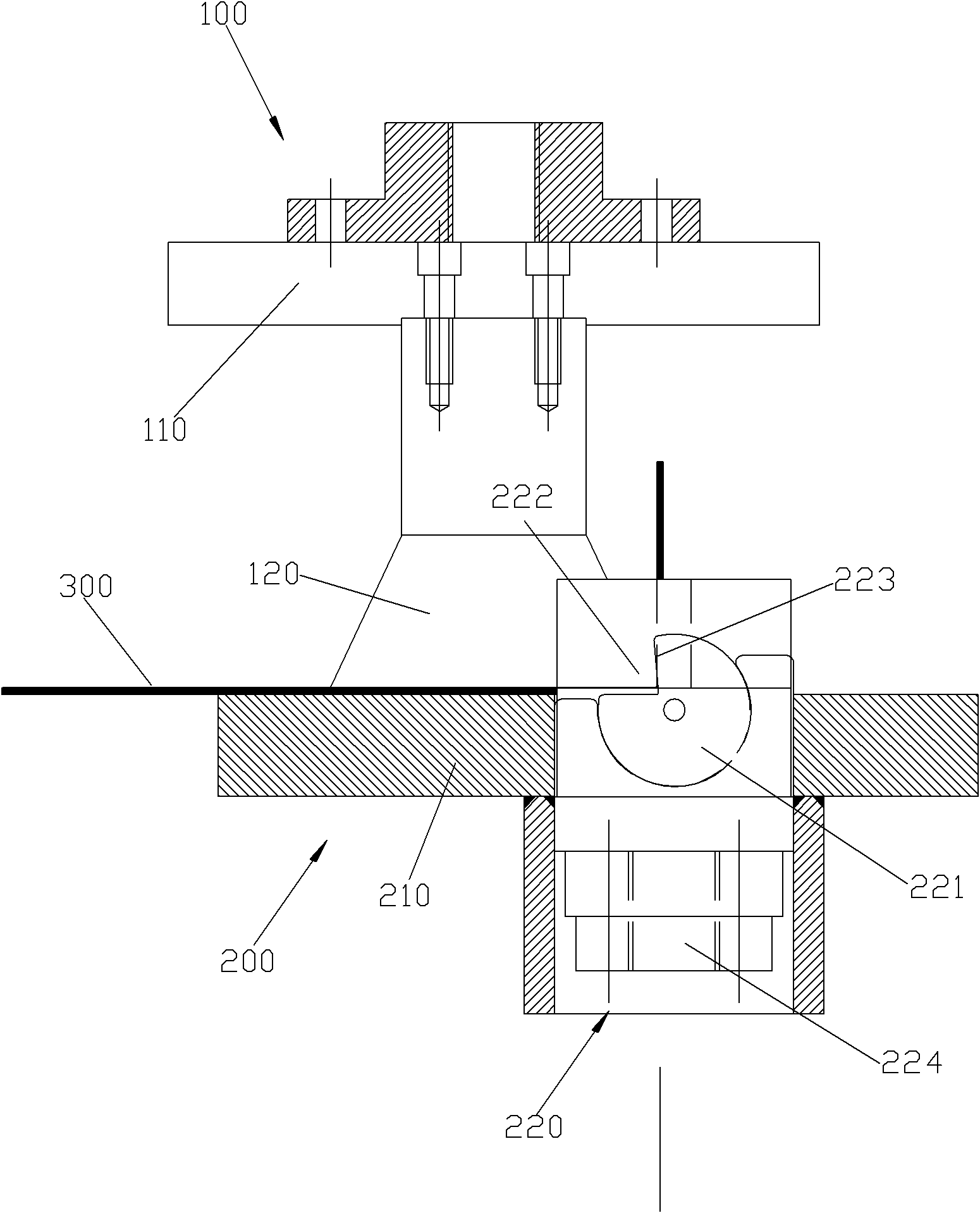

[0041] Please check Figure 1 to Figure 9 , a rotating shaft type flipping and folding machine, which includes an upper device 100 and a lower device 200.

[0042] The upper device 100 includes an upper plate, an upper pressing plate 120 and an upper power mechanism. The upper power mechanism is mounted on the upper plate and connected to the upper platen 120 so as to drive the upper platen 120 to move up and down relative to the upper plate. In this embodiment, the left-right section of the upper platen 120 is a trapezoid with a large bottom and a small top. In this embodiment, the upper power mechanism adopts a hydraulic mechanism, which includes a hydraulic body and a hydraulic rod, the hydraulic body is fixed on the upper plate, and the end of the hydraulic rod is fixed to the upper platen 120 through the positioning seat 110 .

[0043] The lower device 200 includes a lower plate 210, a turning combination device 220 and a lower power mechanism.

[0044] The turning com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com