Improved cylinder curling machine

A technology of crimping machine and cylinder, applied in the field of cylinder crimping machine, can solve the problems of unsuccessful crimping, small force on the mouth, and difficulty in crimping the mouth, and achieves the effect of low rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

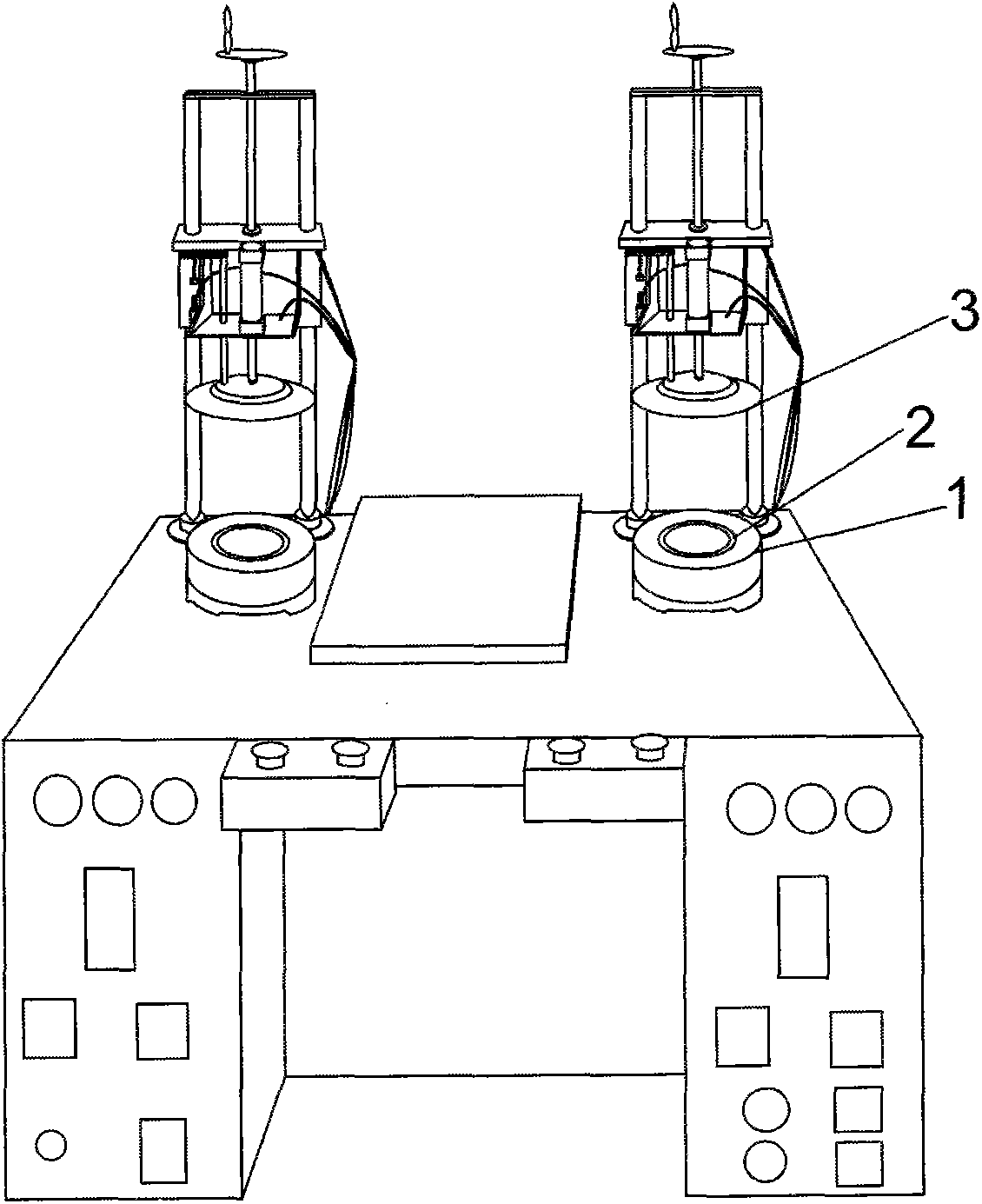

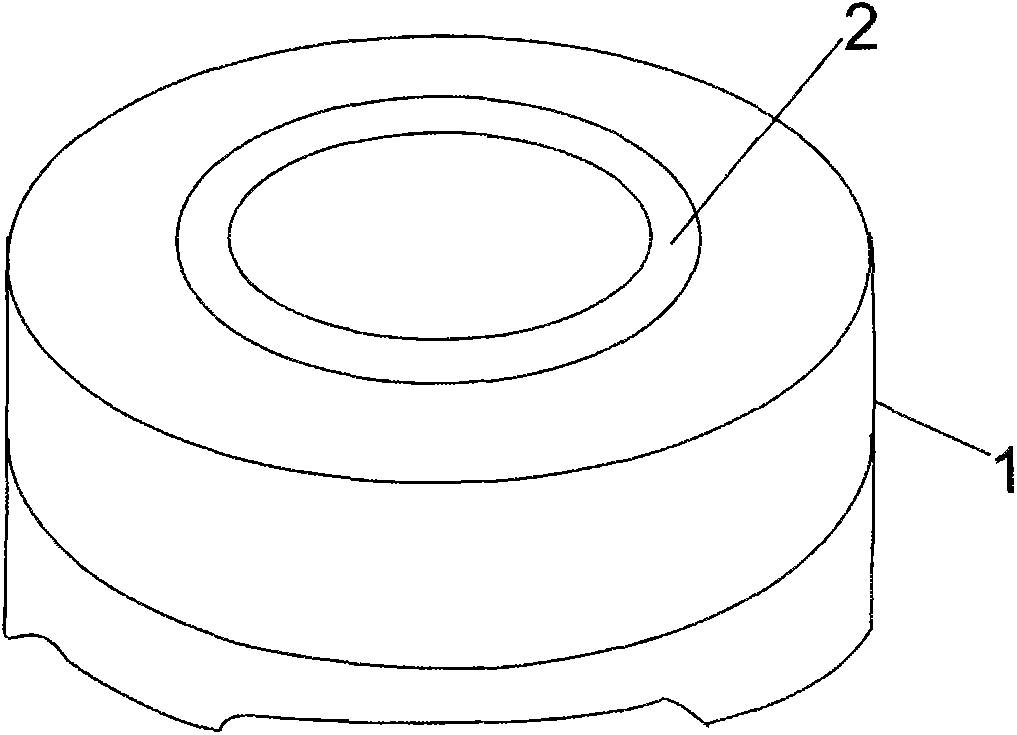

[0022] Embodiment 1: as figure 1 and figure 2 As shown, a cylinder crimping machine includes an upper mold 3 and a lower mold 1, and an annular groove 2 is provided on the upper surface of the lower mold.

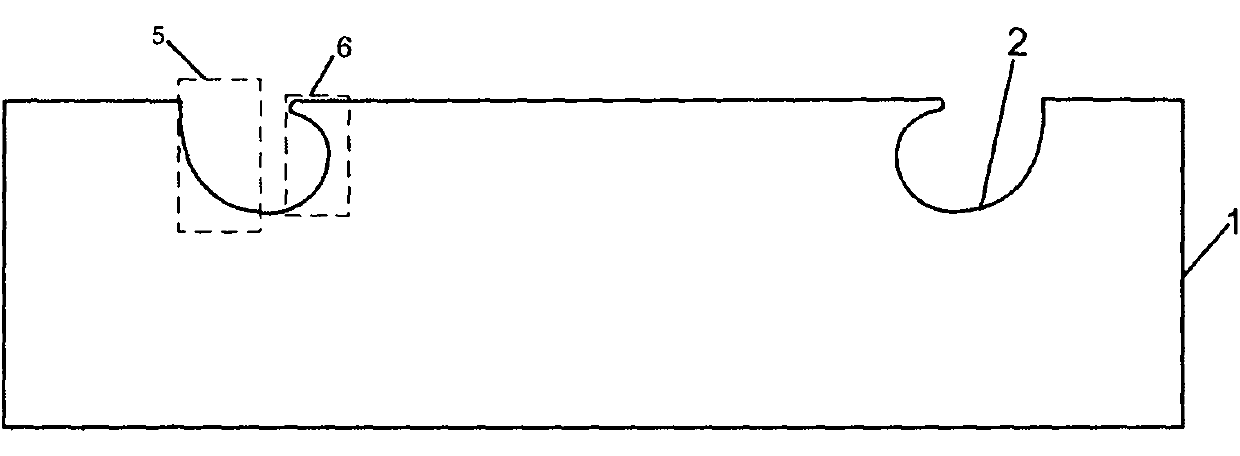

[0023] Such as image 3 and Figure 4 As shown, the annular groove 2 is composed of a half U-shaped groove 1 with an upward opening and a U-shaped groove 2 6 with a horizontal opening. The bottom 51 of the half U-shaped groove and the lower side wall 61 of the U-shaped groove 2 Smooth transition connection.

[0024] Such as Figure 7 As shown, the existing common crimping machine notch is U-shaped. The crimping machine of this kind of notch will be like Figure 5 The straight PVC items shown work well when crimped. This is mainly because the straight PVC product can withstand the pressure of the relatively large upper mold 3 without bending. When the upper mold is pressed down, the mouth of the straight PVC product will turn over along the ordinary U-shaped notch a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com