Head and soft roll lithium ion battery package method by employing same

A lithium-ion battery and sealing head technology, which is applied to small-sized batteries/battery packs, large-sized batteries/battery packs, secondary batteries, etc., can solve the problems of degassing packaging and false sealing, and achieve the guaranteed packaging effect, The packaging effect is better and more reliable, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

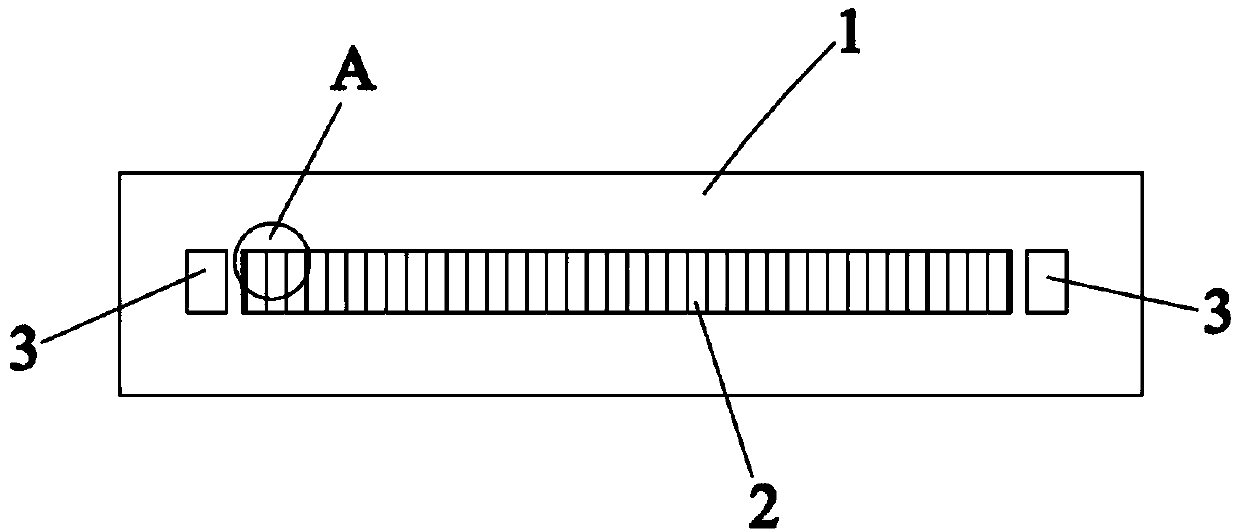

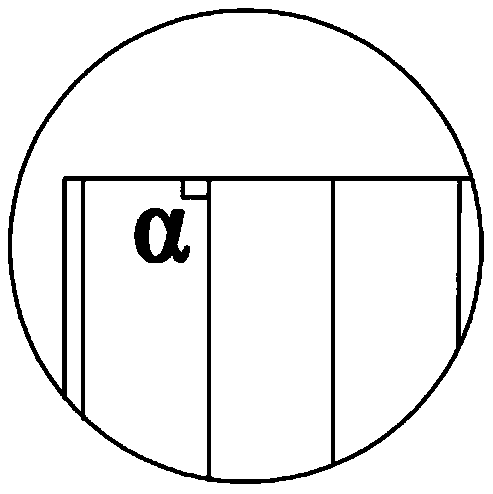

[0038] Such as Figure 1~2 As shown, this embodiment provides a head, including a base 1, a head body 2 installed on the base 1, and limit blocks 3 located at both ends of the head body 2, and the sealing surface of the head body 2 is provided with waves tooth. Such as Figure 9 As shown, the spacing L of the wave teeth 1 0.1~0.3mm. Depth D of wave teeth 1 0.05~0.2mm. The wave teeth form an ∠α with the length direction of the head main body 2, and ∠α is 90°. The height difference between the upper surface of the limiting block 3 and the sealing surface of the head body 2 is twice the product of the thickness of the aluminum-plastic film and the deformation rate, and the deformation rate is 20-75%.

[0039] This embodiment also provides a soft pack lithium-ion battery packaging method using the head described in this embodiment, including the following steps:

[0040] Step 1, using the sealing head described in this embodiment to package the soft-pack lithium-ion battery...

Embodiment 2

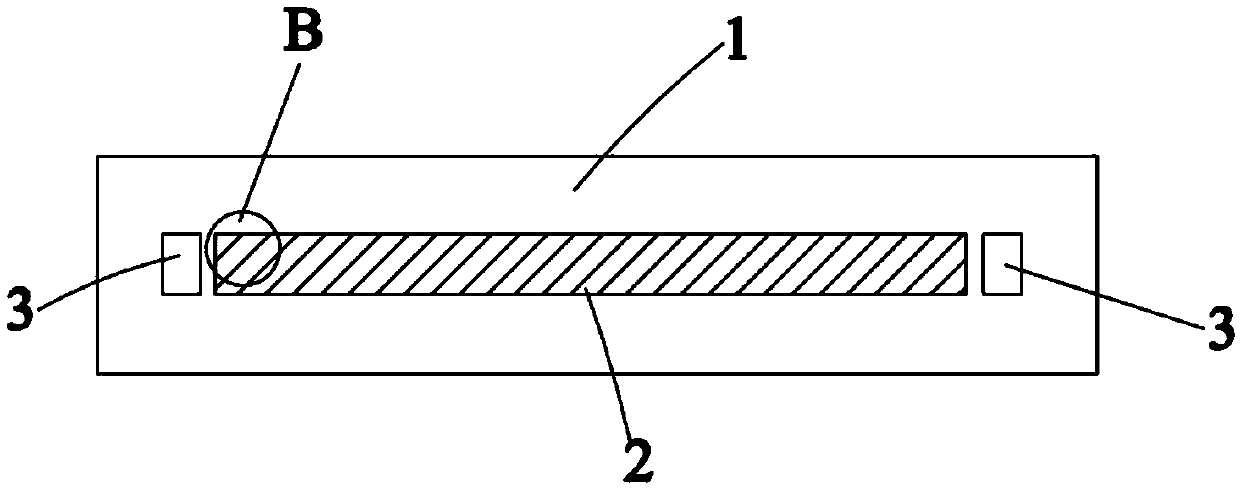

[0043] Such as Figure 3~4 As shown, this embodiment provides a head, including a base 1, a head body 2 installed on the base 1, and limit blocks 3 located at both ends of the head body 2, and the sealing surface of the head body 2 is provided with waves tooth. Such as Figure 9 As shown, the spacing L of the wave teeth 1 0.1~0.3mm. Depth D of wave teeth 1 0.05~0.2mm. The wavy teeth form an angle of ∠α, ∠α or 30-45° with the length direction of the main body 2 of the head. The height difference between the upper surface of the limiting block 3 and the sealing surface of the head body 2 is twice the product of the thickness of the aluminum-plastic film and the deformation rate, and the deformation rate is 20-75%.

[0044] This embodiment also provides a soft pack lithium-ion battery packaging method using the head described in this embodiment, including the following steps:

[0045] Step 1, using the sealing head described in this embodiment to package the soft-pack lith...

Embodiment 3

[0048] Such as Figure 5~6 As shown, this embodiment provides a sealing head, which includes a base 1, a sealing head body 2 installed on the base 1, and limiting blocks 3 located at both ends of the sealing head body 2. Teeth. Such as Figure 10~11 As shown, the pitch L of the mesh teeth 2 0.1~0.3mm. Depth D of mesh teeth 2 0.05~0.2mm. The textured teeth form a ∠β with the length direction of the main body 2 of the head, and ∠β is 45°. The area S of the tooth head of the mesh tooth is 0.002~0.04mm 2 . The height difference between the upper surface of the limiting block 3 and the sealing surface of the head body 2 is twice the product of the thickness of the aluminum-plastic film and the deformation rate, and the deformation rate is 20-75%.

[0049] This embodiment also provides a soft pack lithium-ion battery packaging method using the head described in this embodiment, including the following steps:

[0050] Step 1, using the sealing head described in this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com