Ramie hulling machine

A sheller and ramie technology, which is applied in mechanical treatment, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of high residual glue content in hemp bone and hemp husks, high labor intensity, and low work efficiency, and improve the quality of ramie The effect of improving the quality of shelling, improving the quality of shelling, and improving the quality of flax

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

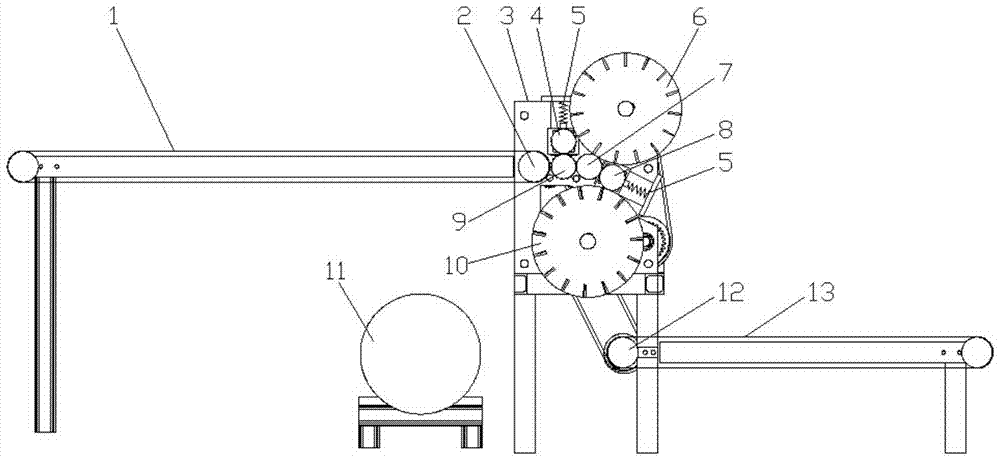

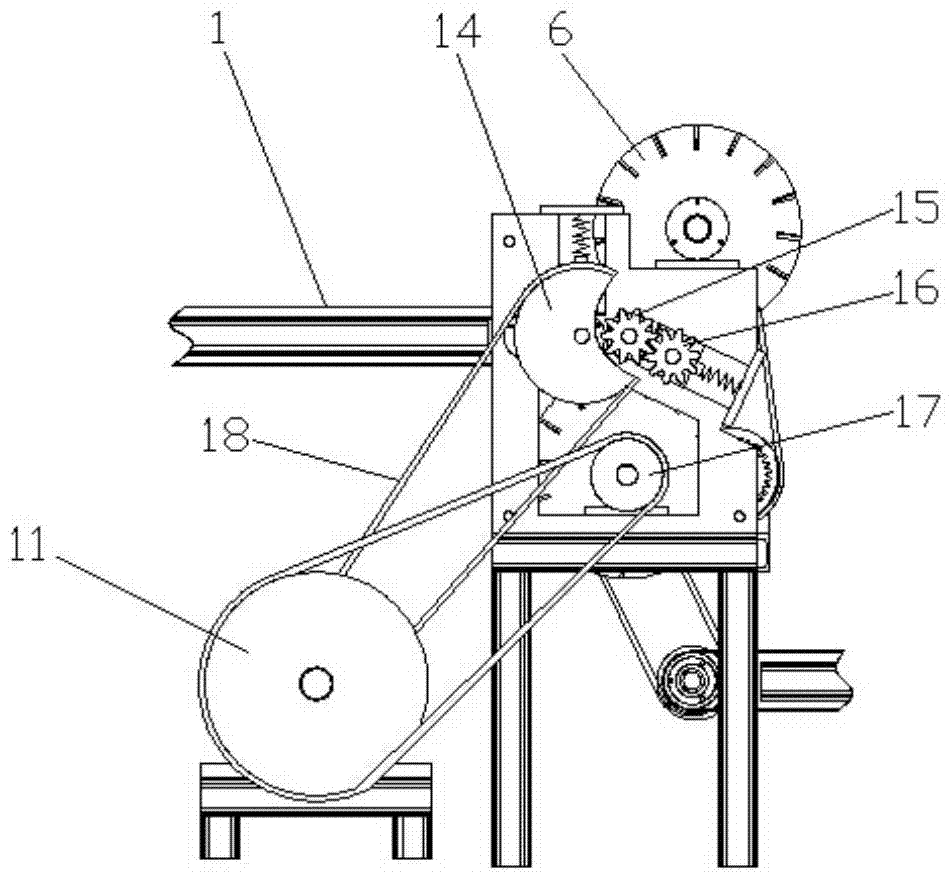

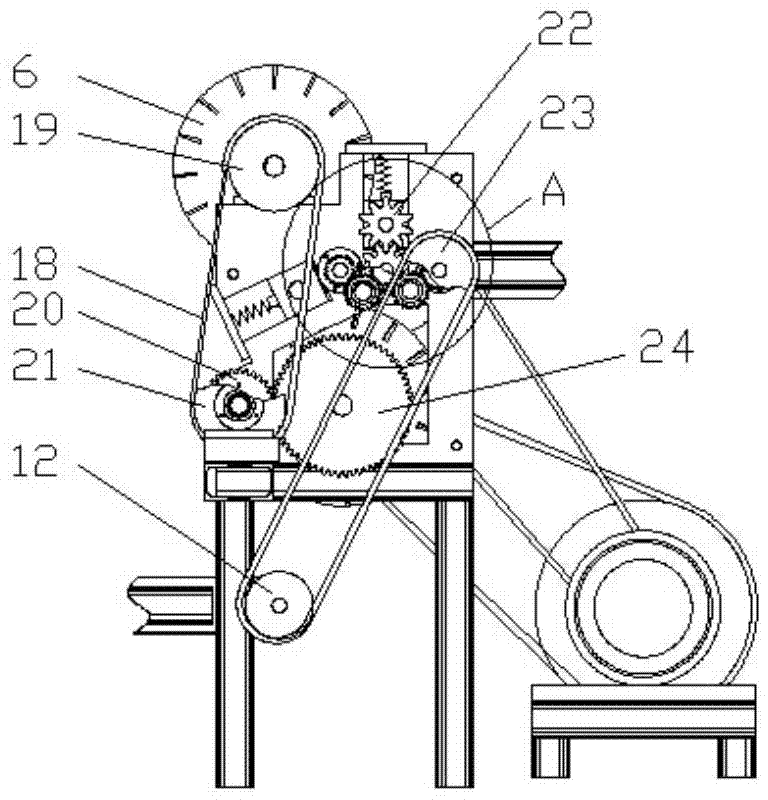

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] As shown in the accompanying drawings, the structure of the ramie shelling machine is as follows: it includes a hemp feeding mechanism, a shelling mechanism, a hemp discharging mechanism and a driving motor; Frame and the upper blade peeling hemp roller 6 and the lower blade hemp roller 10 that are located on the frame 3, the upper blade hemp peeling roller 7 and the lower blade hemp roller 7 that are located between the upper blade peeling hemp roller 10 and the lower blade hemp roller 10 Ma Guang roller 8 is located between the upper groove roller 4 and the lower groove roller 9 that are intermeshed between the upper peeling Ma light roller 7 and the output end of the feeding mechanism;

[0030] One end of the central axis of the lower blade peeling hemp roller 10 is provided with the first belt pulley 17, and the other end is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com