Patents

Literature

113results about How to "Guaranteed encapsulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

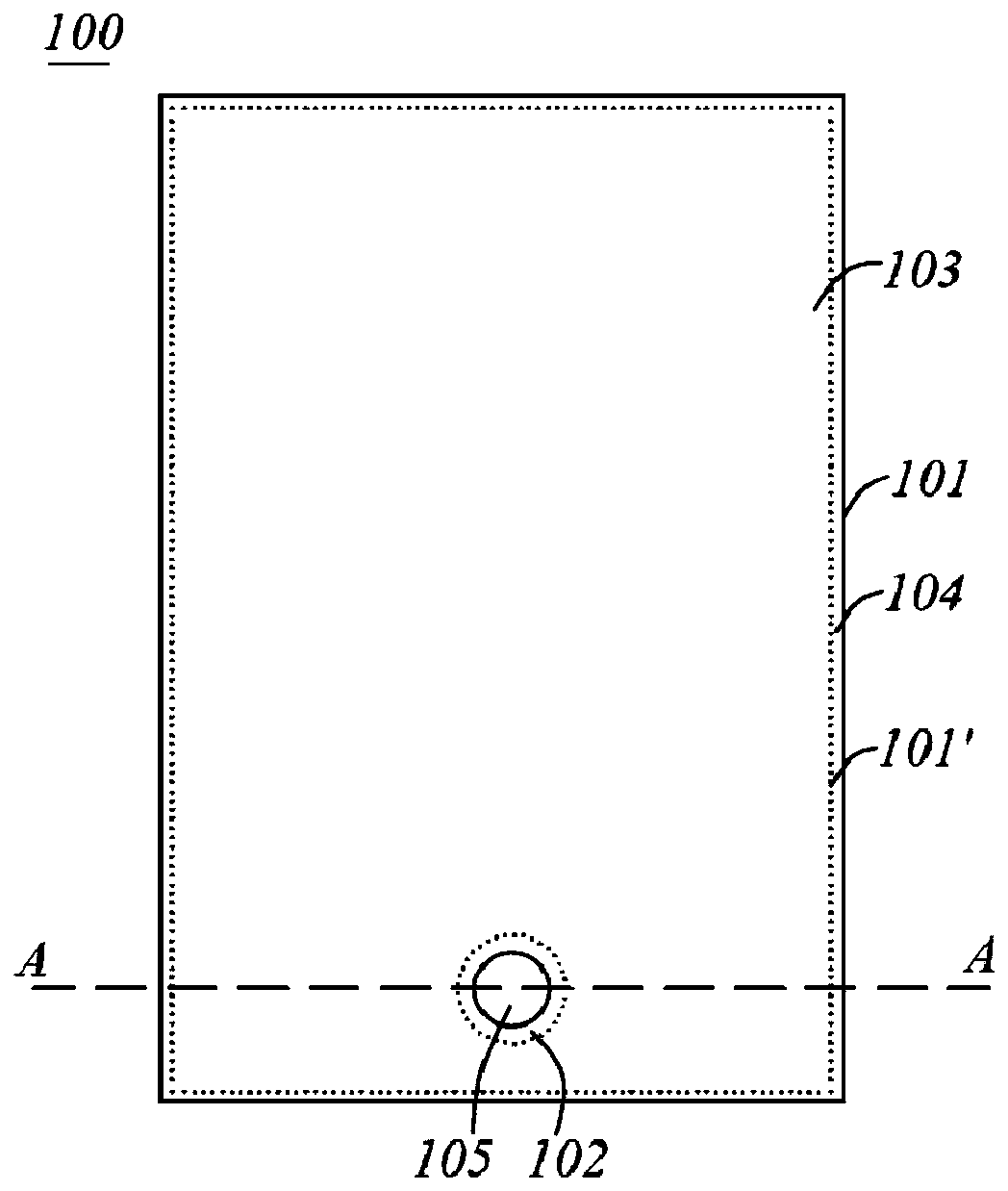

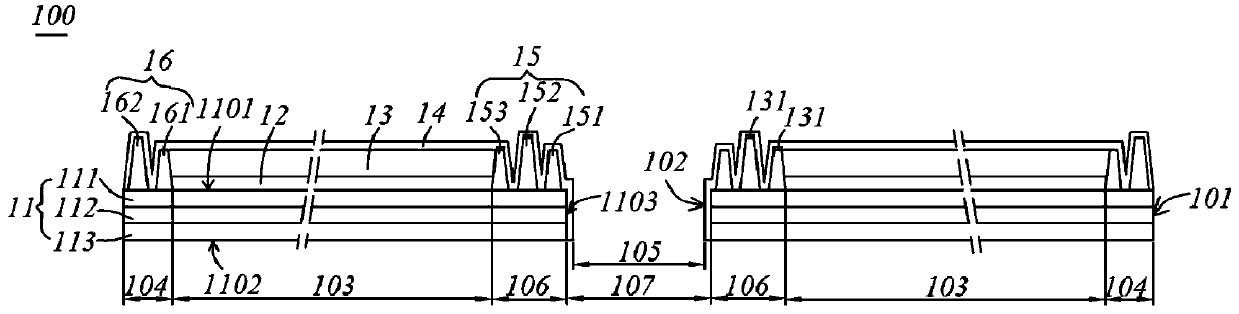

OLED display panel and a method for manufacturing same, and OLED display device

PendingCN109860411ABlock the flowReduce climbing distanceSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureDisplay device

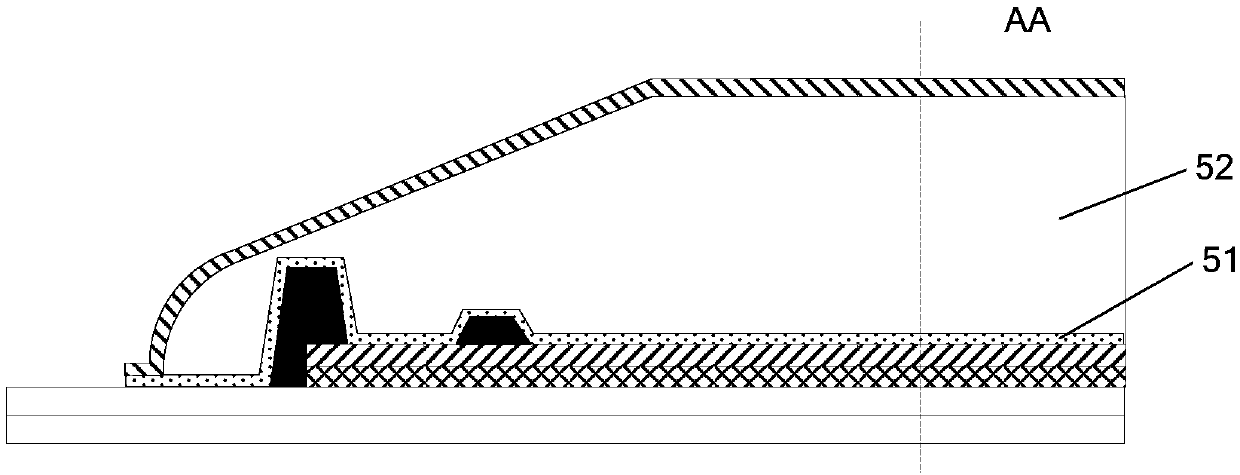

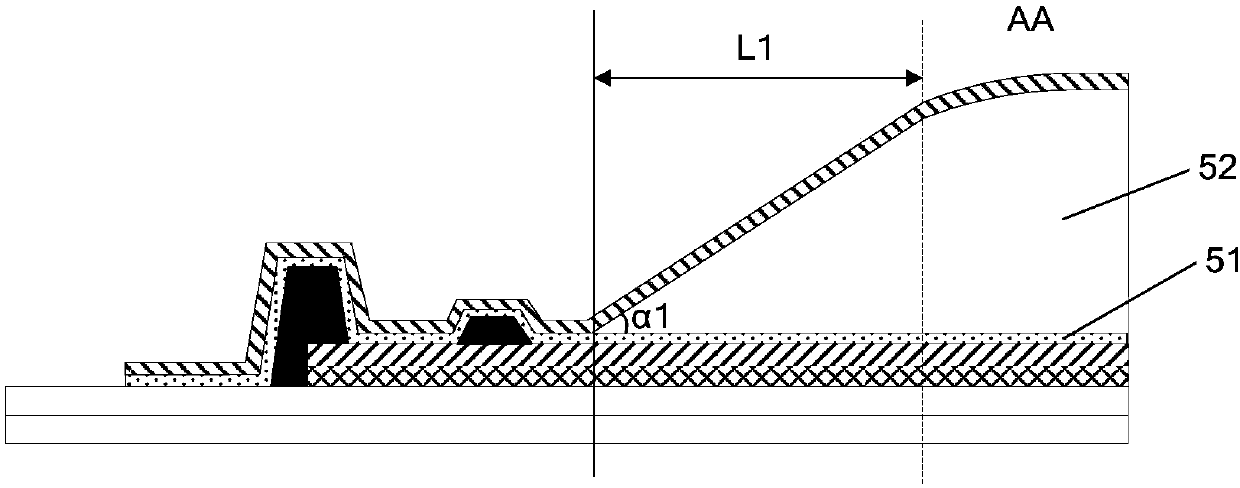

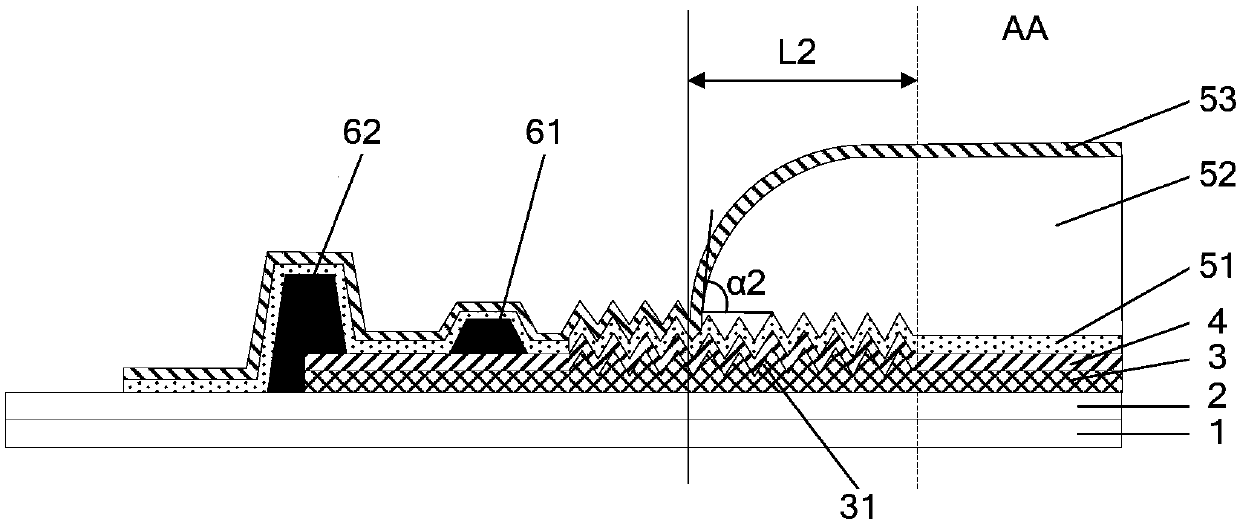

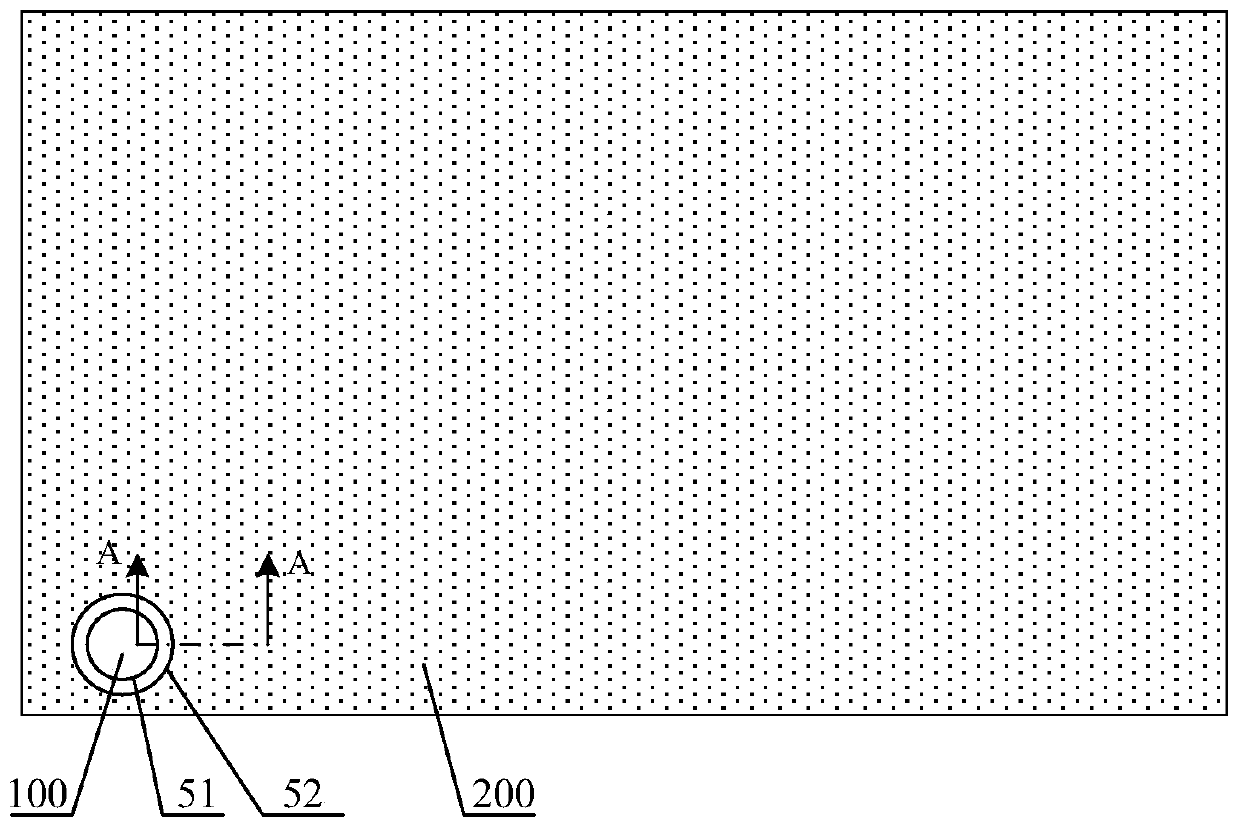

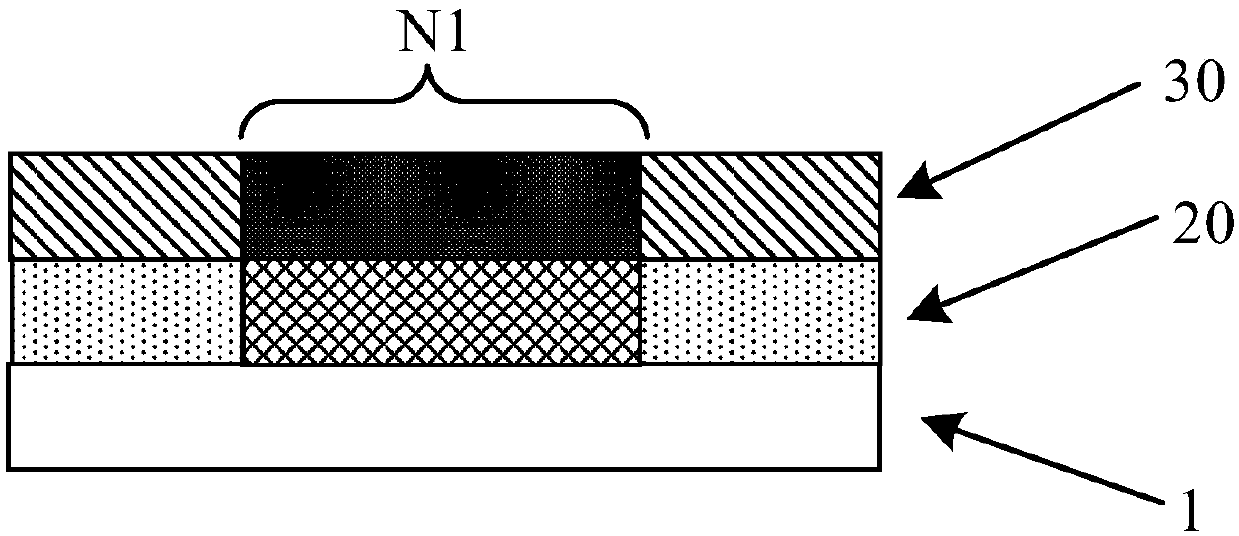

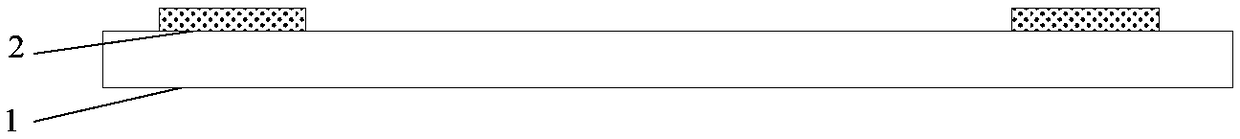

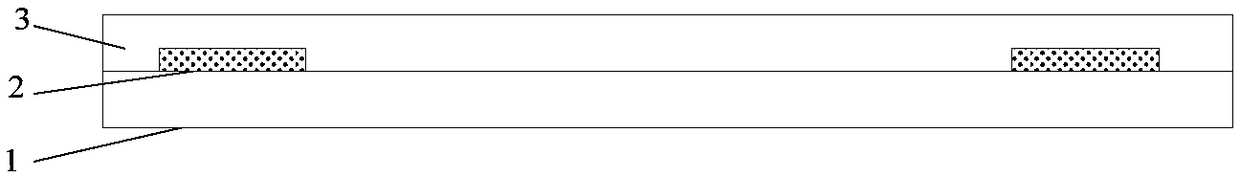

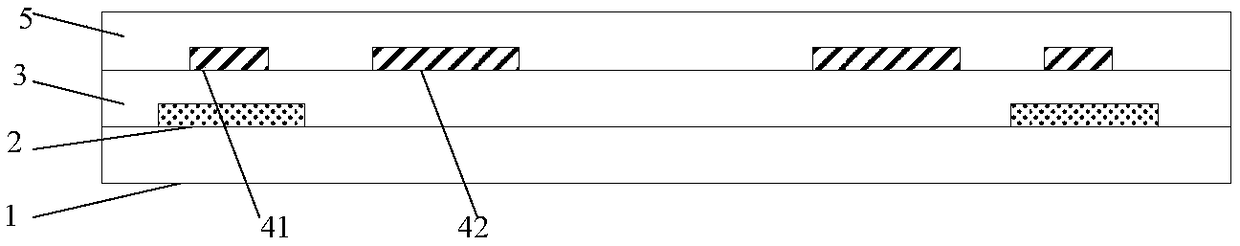

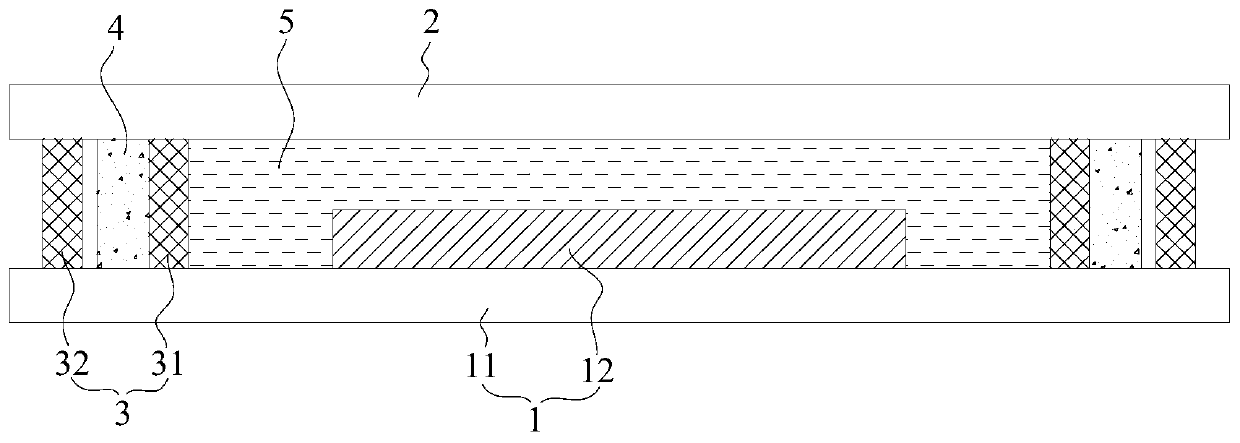

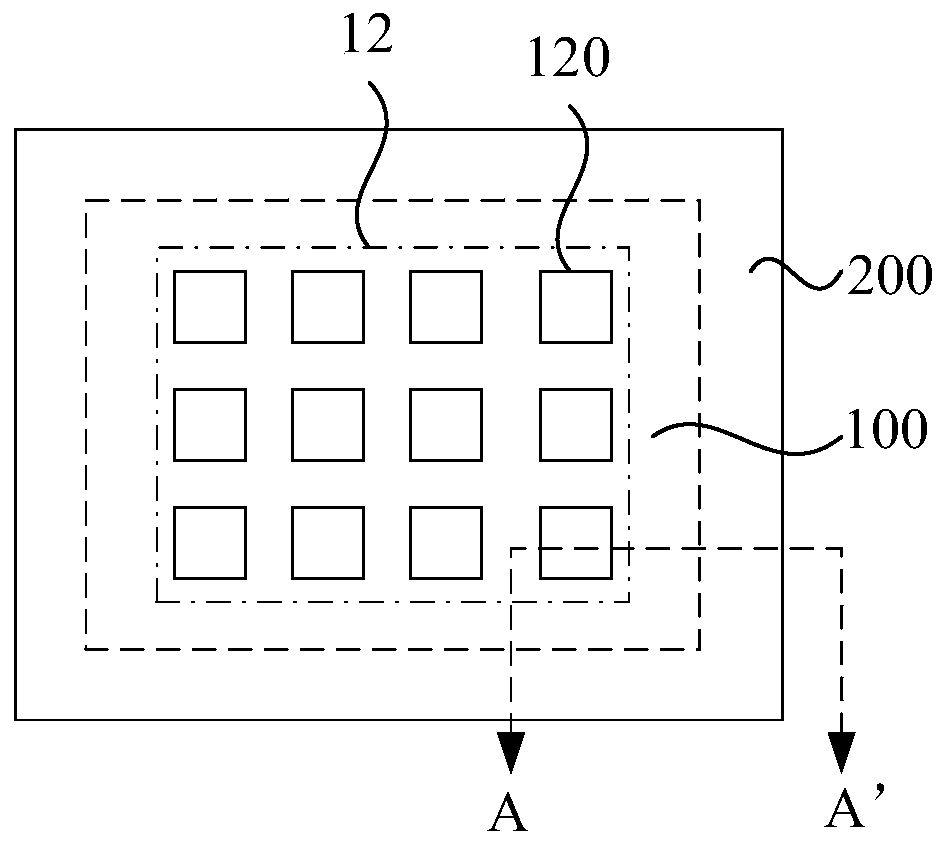

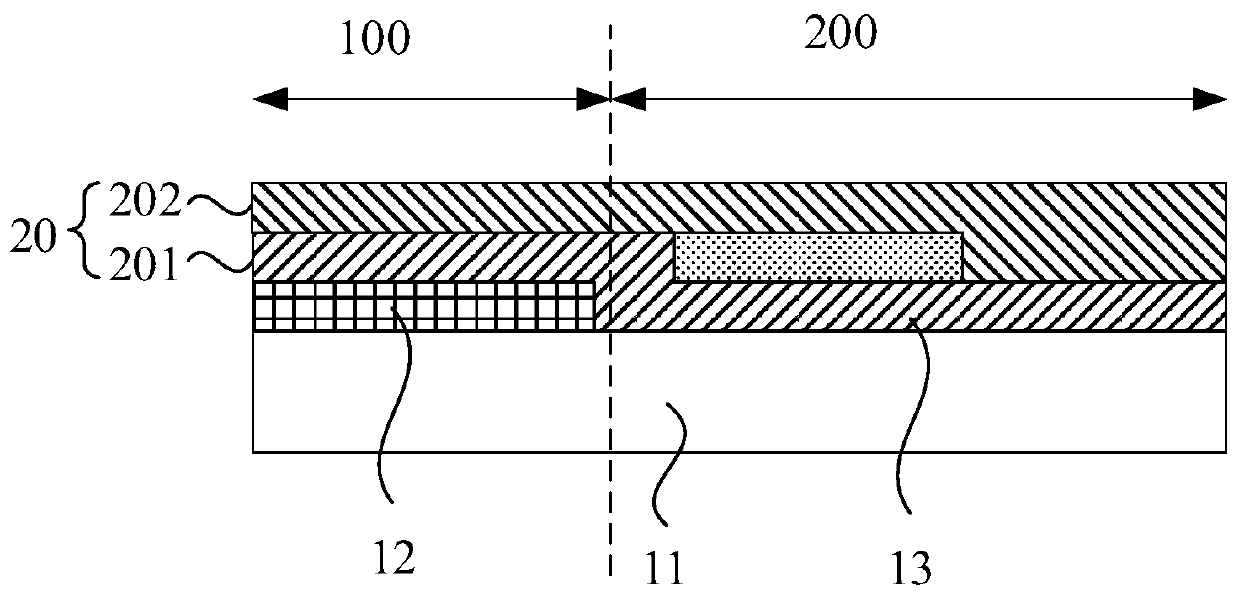

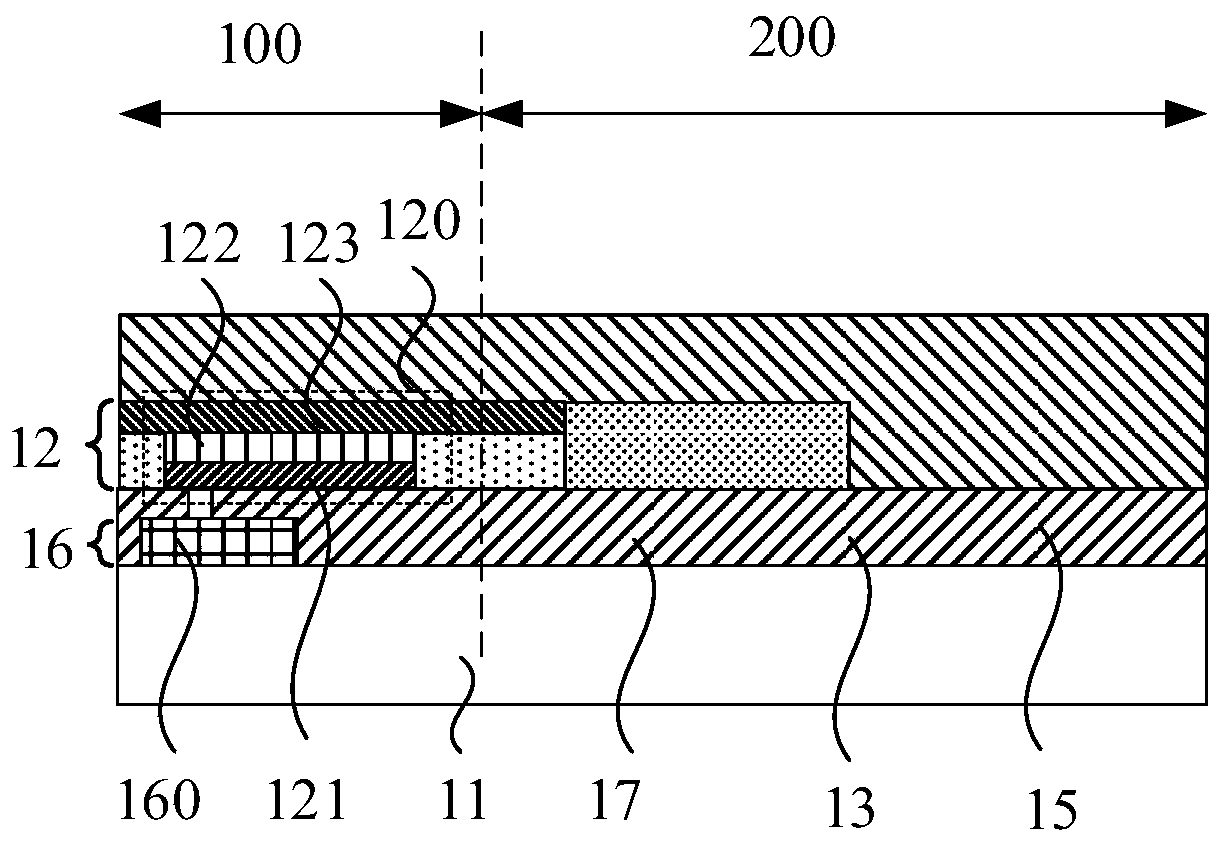

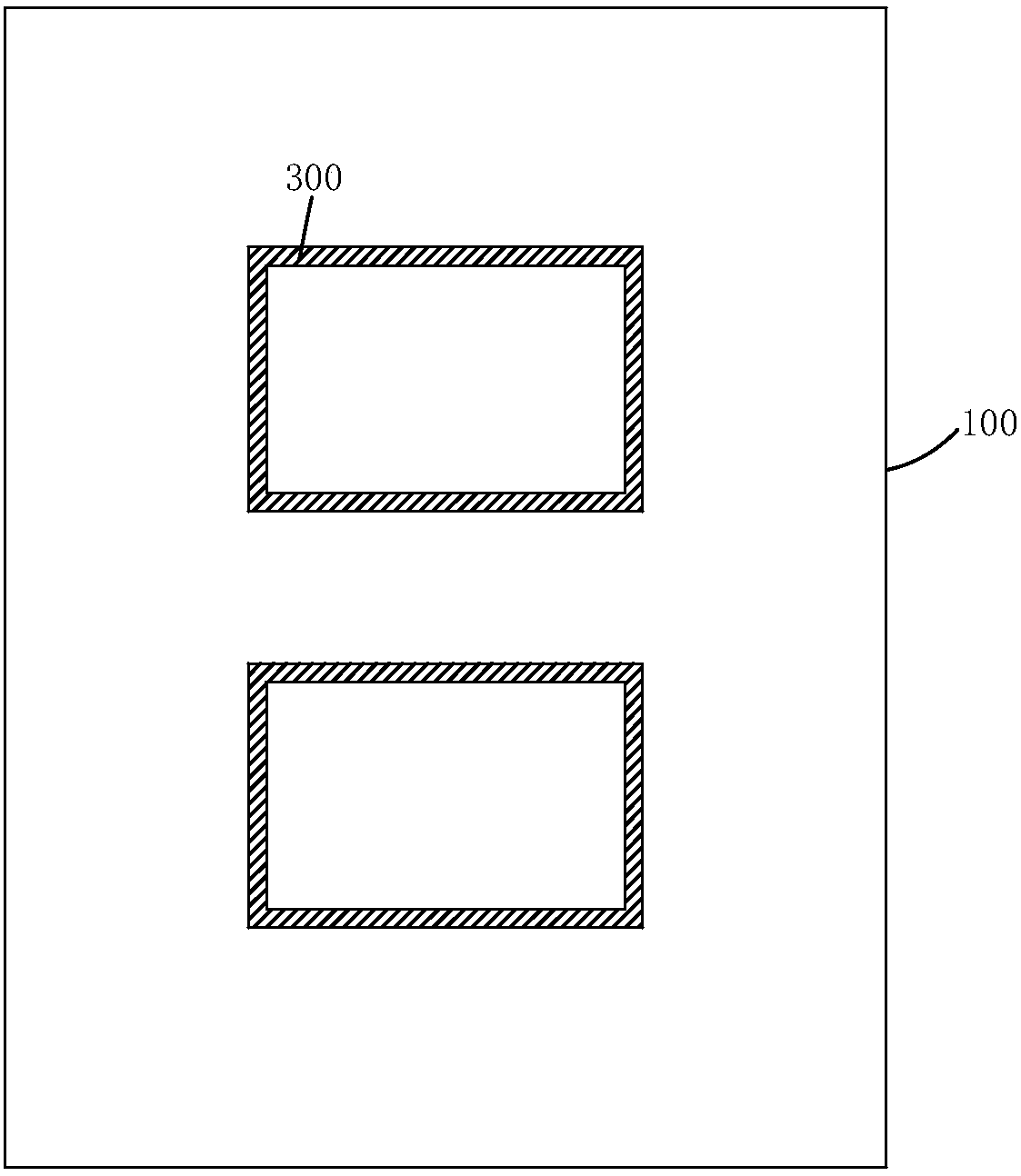

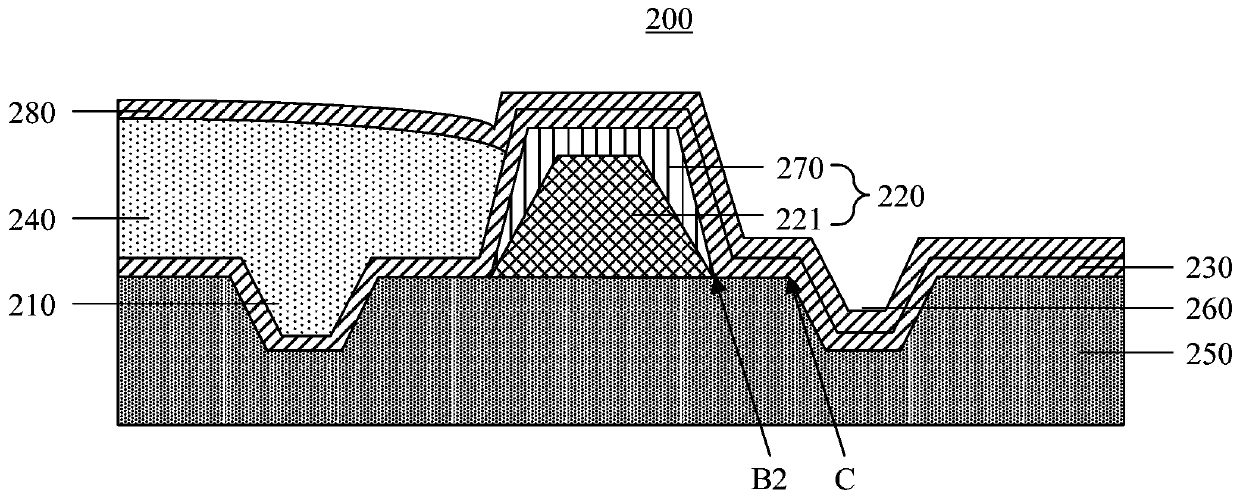

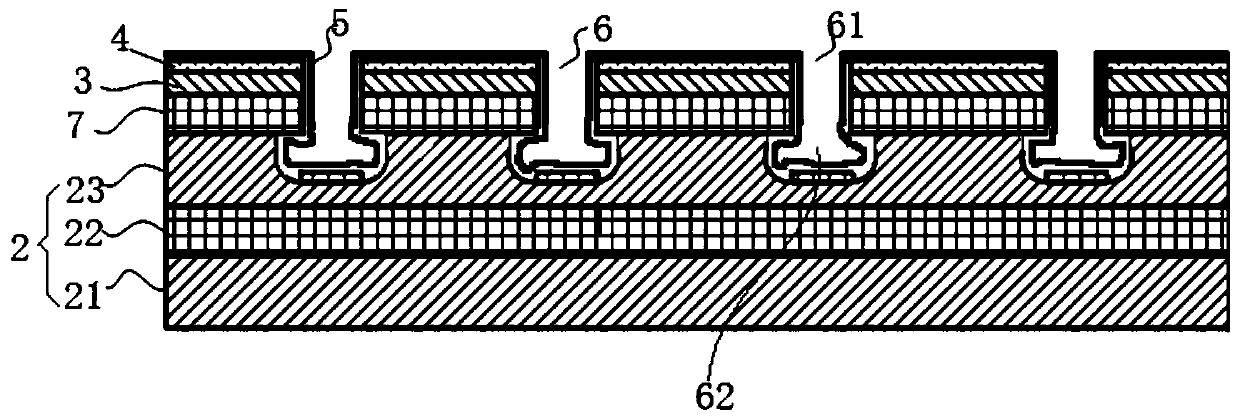

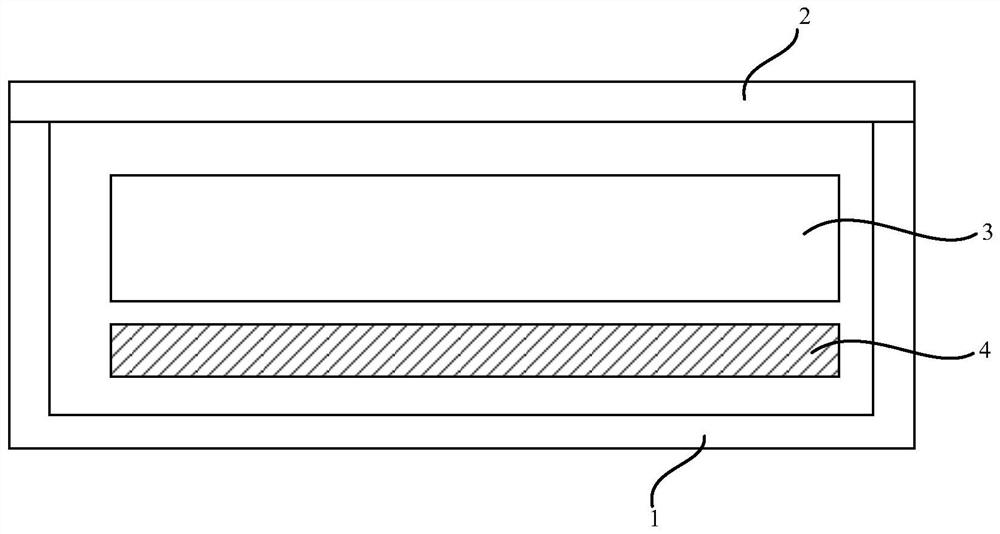

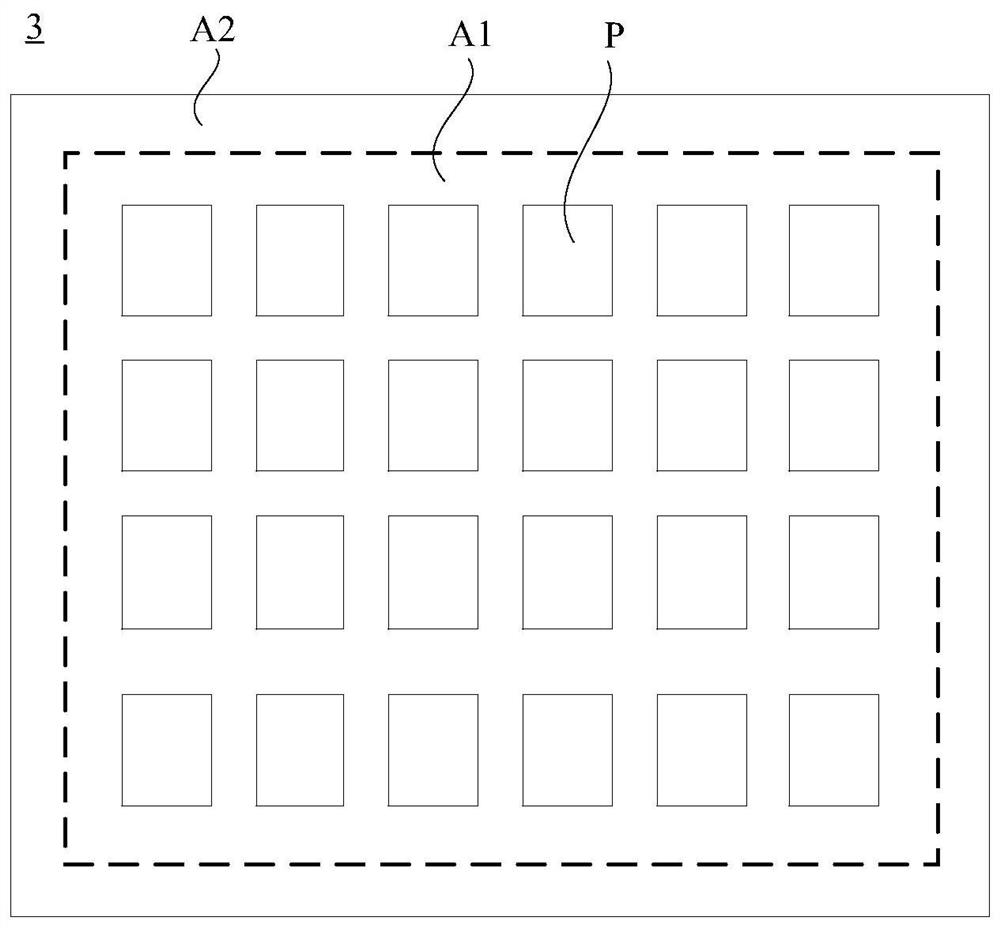

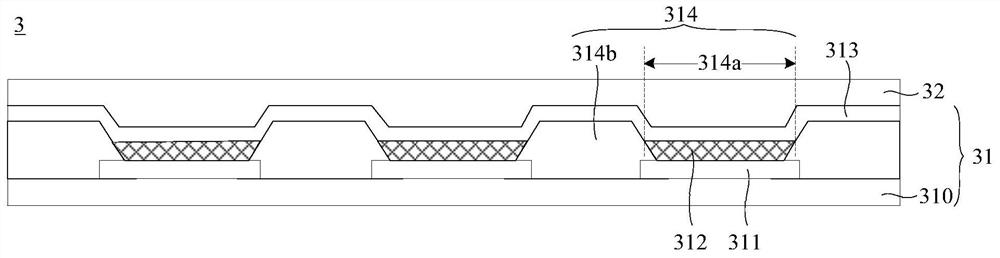

The present invention provides an OLED display panel and a method for manufacturing the same, and an OLED display device. A concave-convex structure is arranged at one side, far away from a substrate,on a planarization layer, after an organic light-emitting functional layer and an inorganic first package layer are formed on the planarization layer, positions of the organic light-emitting functional layer and the first package layer corresponding to the concave-convex structure are non-flat surfaces, namely concave-convex structures with the same shapes are formed at the positions, corresponding to the concave-convex structure, on the organic light-emitting functional layer and the first package layer; when an organic second package layer is formed, the non-flat surface of the first package layer can block the flow of the second package layer to a certain extent to reduce the liquidity of the second package layer, reduce the climbing distance of the edge of the second package layer andincrease the edge stress and an angle of gradient so as to achieve the product narrow-frame design, improve the thickness uniformity of the edges of the second package layer, avoid bad mura of a non-display area and ensure the package effect.

Owner:BOE TECH GRP CO LTD +1

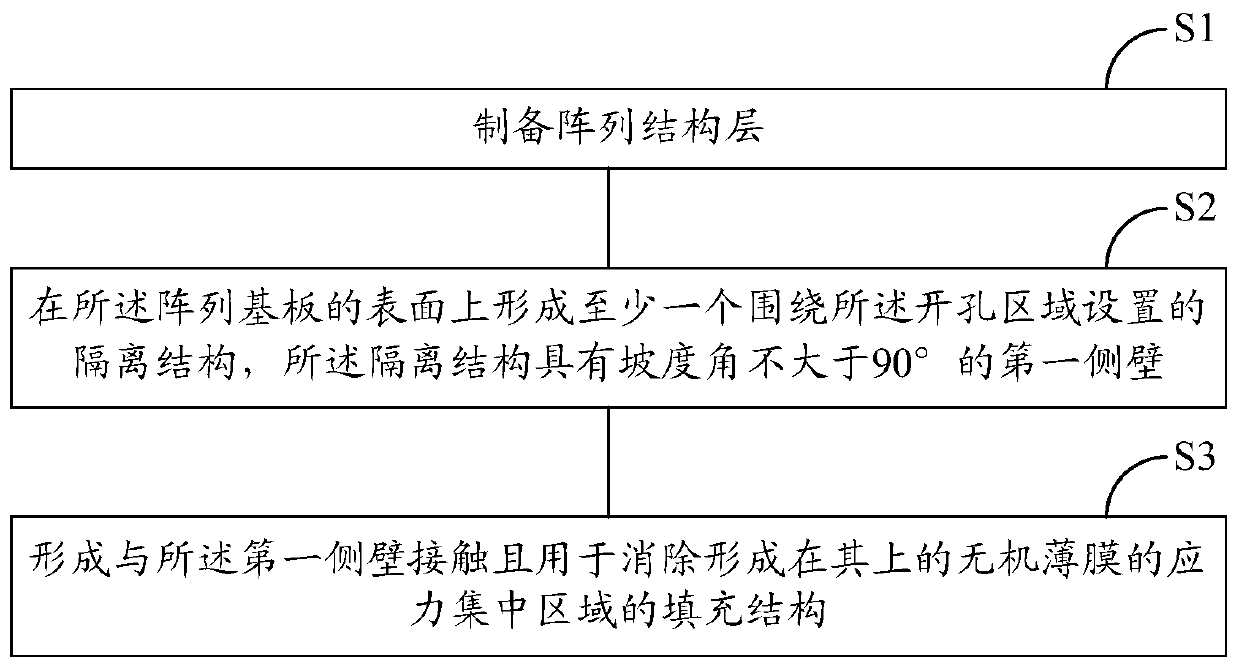

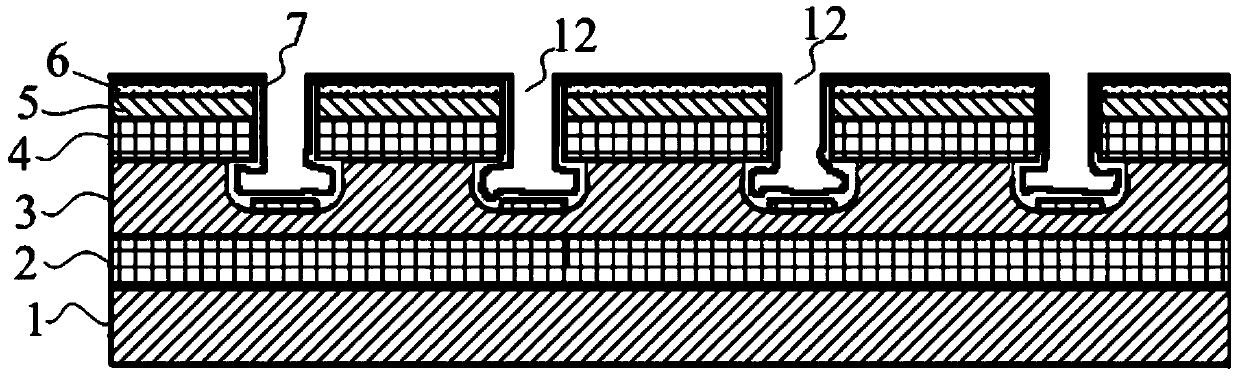

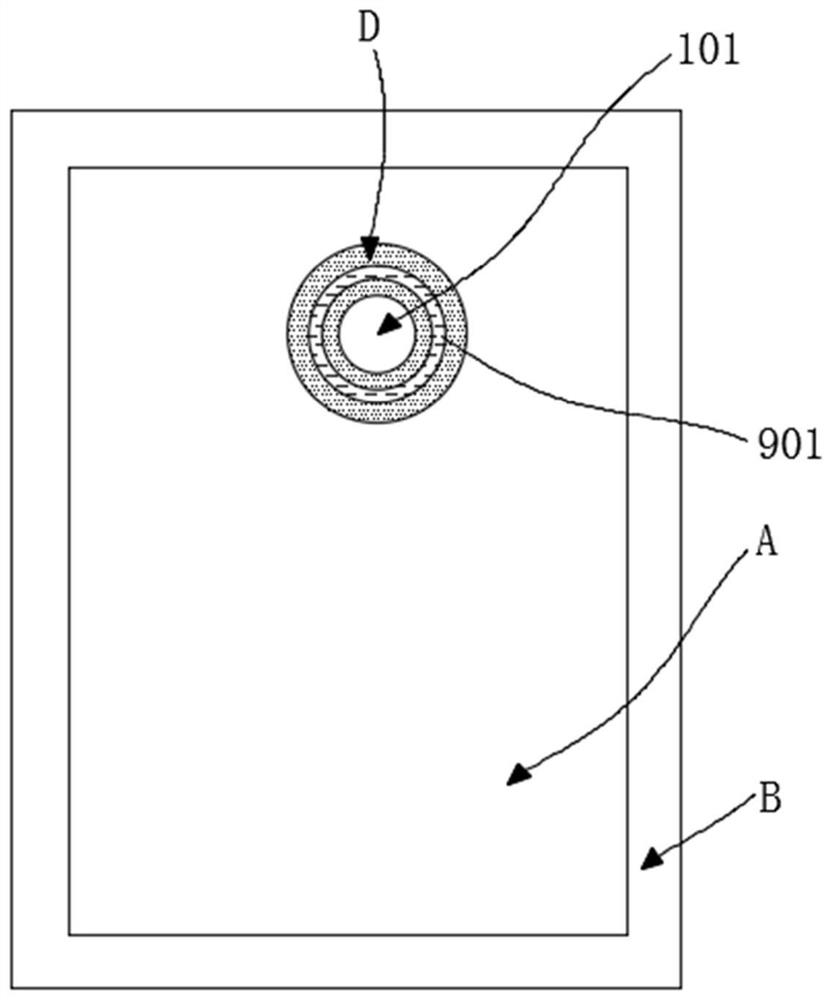

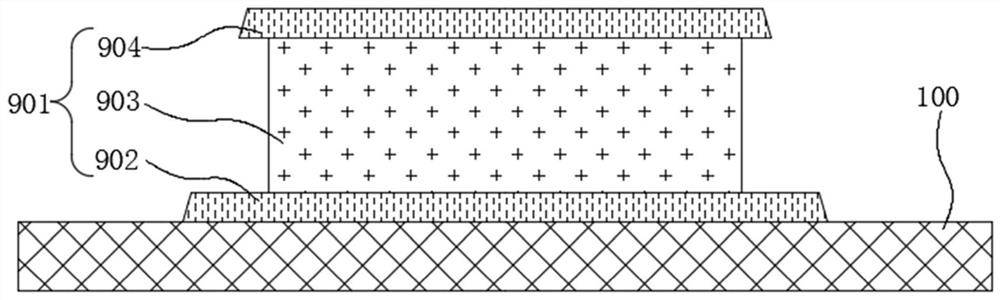

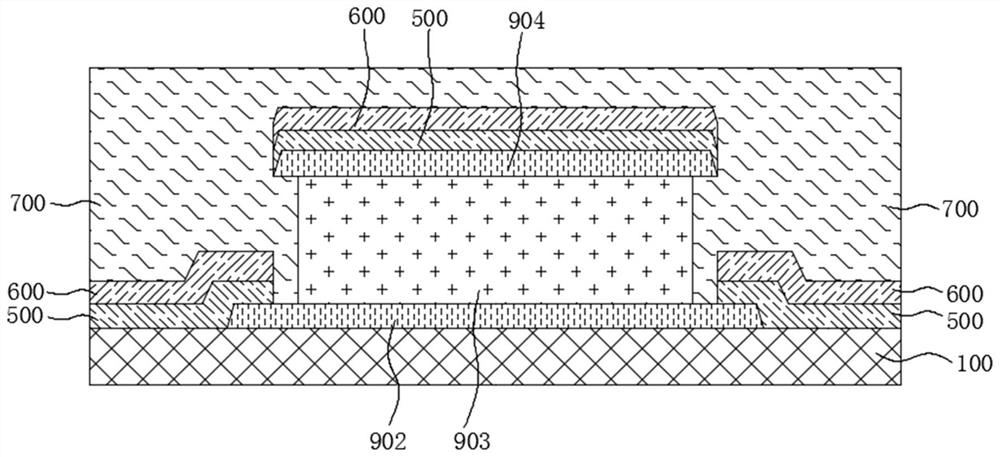

Display substrate, manufacturing method thereof, and display device

ActiveCN109742117AAvoid crackingEnsure film thickness uniformitySolid-state devicesSemiconductor/solid-state device manufacturingStress concentrationSlope angle

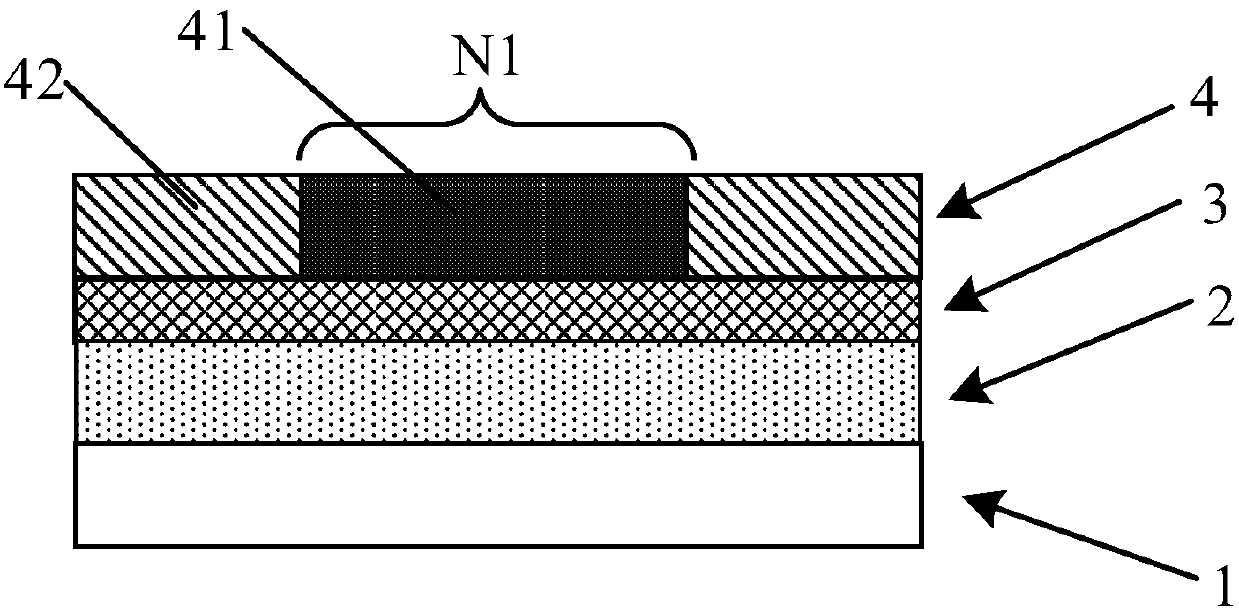

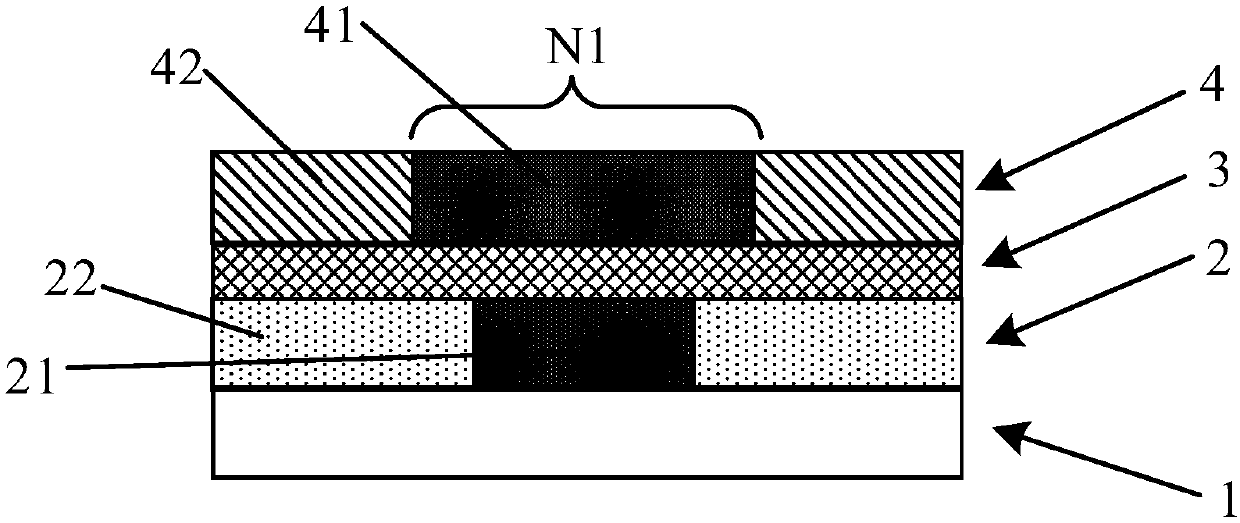

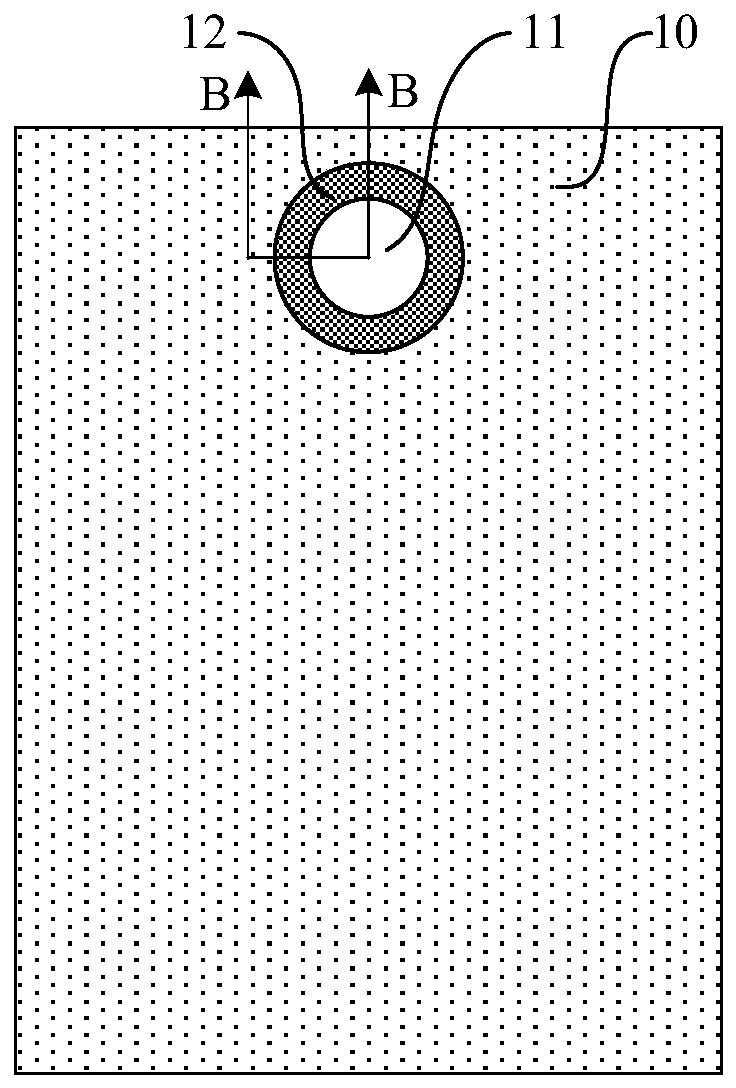

The invention discloses a display substrate and a manufacturing method thereof, and a display device. The display substrate comprises a display region, an opening region is arranged in the display region; the manufacturing method comprises the following steps: preparing an array structure layer; forming at least one isolation structure surrounding the opening region on a surface of the array structure layer, wherein the isolation structure is provided with a first sidewall with a slope angle not more than 90 DEG; and forming a filling structure contacting with the first sidewall and used for eliminating a stress concentration region of an inorganic film thereon, wherein the filling structure bears an inorganic film by replacing the isolation structure, and the filing structure can eliminate the stress concentration region of the inorganic film formed thereon. Therefore, the stress concentration region is prevented from being formed on the inorganic film, the package film invalidation is avoided, and the dependence of the package film surrounding the opening region is improved.

Owner:BOE TECH GRP CO LTD

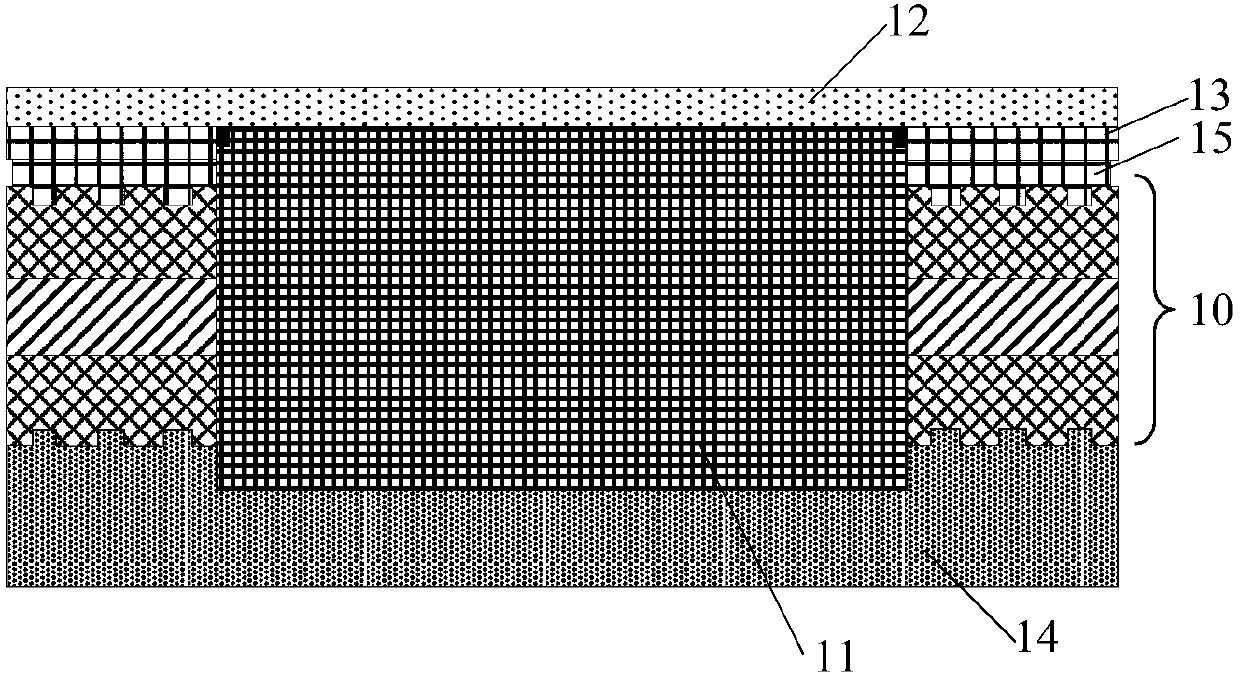

Frame sealing adhesive, preparation method thereof, display panel and preparation method thereof

ActiveCN108034373AImprove bendabilityMake sure that the glue will not openFinal product manufactureFilm/foil adhesivesElastomerAdhesive

The invention belongs to the field of display technology, and particularly relates to a frame sealing adhesive, a preparation method thereof, a display panel and a preparation method thereof. The frame sealing adhesive comprises a substrate and an adhesive layer arranged on at least one side of the substrate, wherein the substrate is a first elastomer material; the adhesive layer comprises a second elastomer material and a crosslinking agent. Both the substrate and the adhesive layer of the frame sealing adhesive are made of elastomer materials, and the adhesive layer also contains the crosslinking agent to adjust the storage modulus of the adhesive layer, so that the frame sealing adhesive has high bending performance at the same time, can bear larger stress, and has higher viscosity to ensure that the frame sealing adhesive does not come apart when the display panel is folded. Thus, damage of the frame sealing adhesive during folding or bending of a flexible display panel can be avoided, and high packaging performance is ensured.

Owner:BOE TECH GRP CO LTD

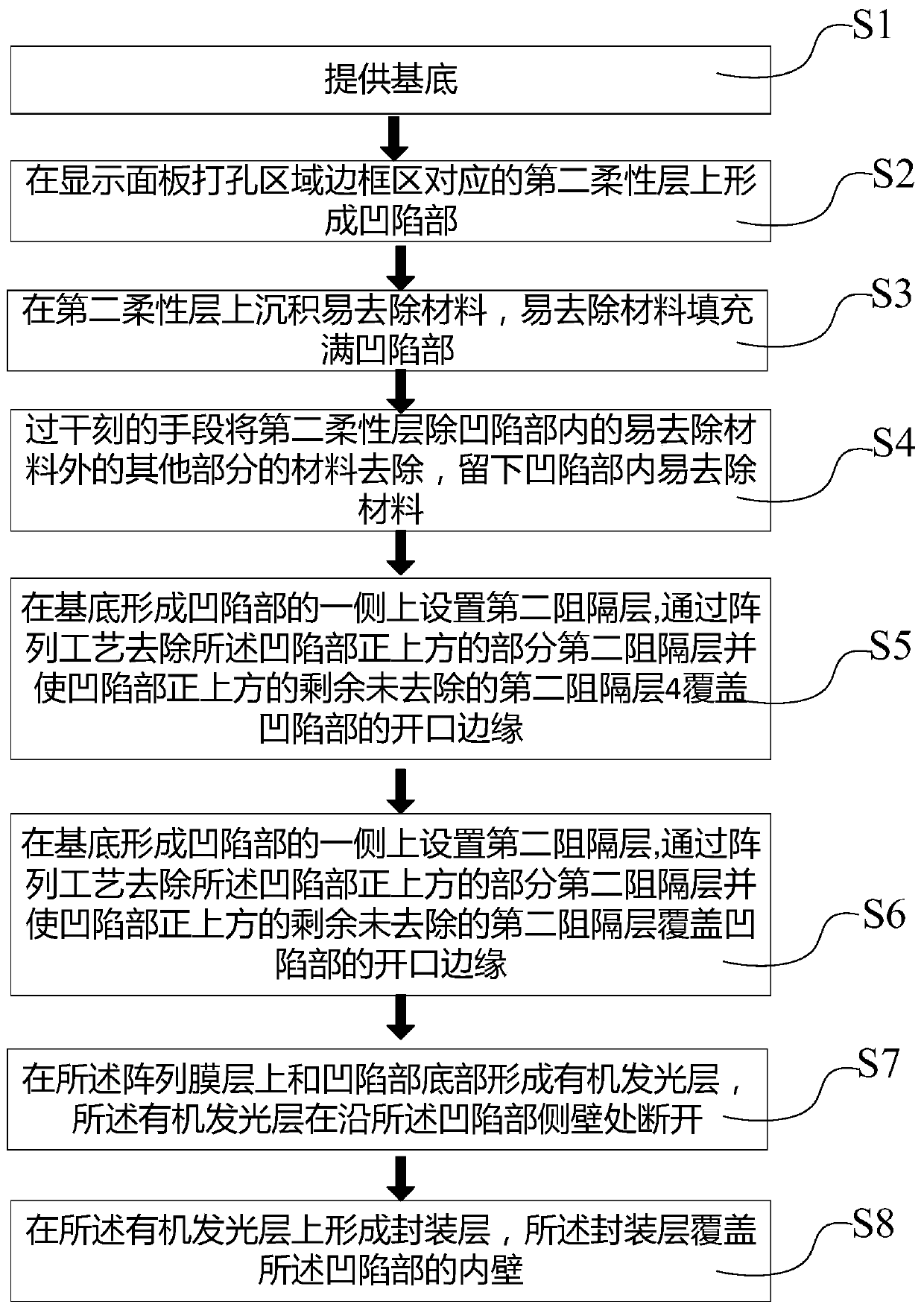

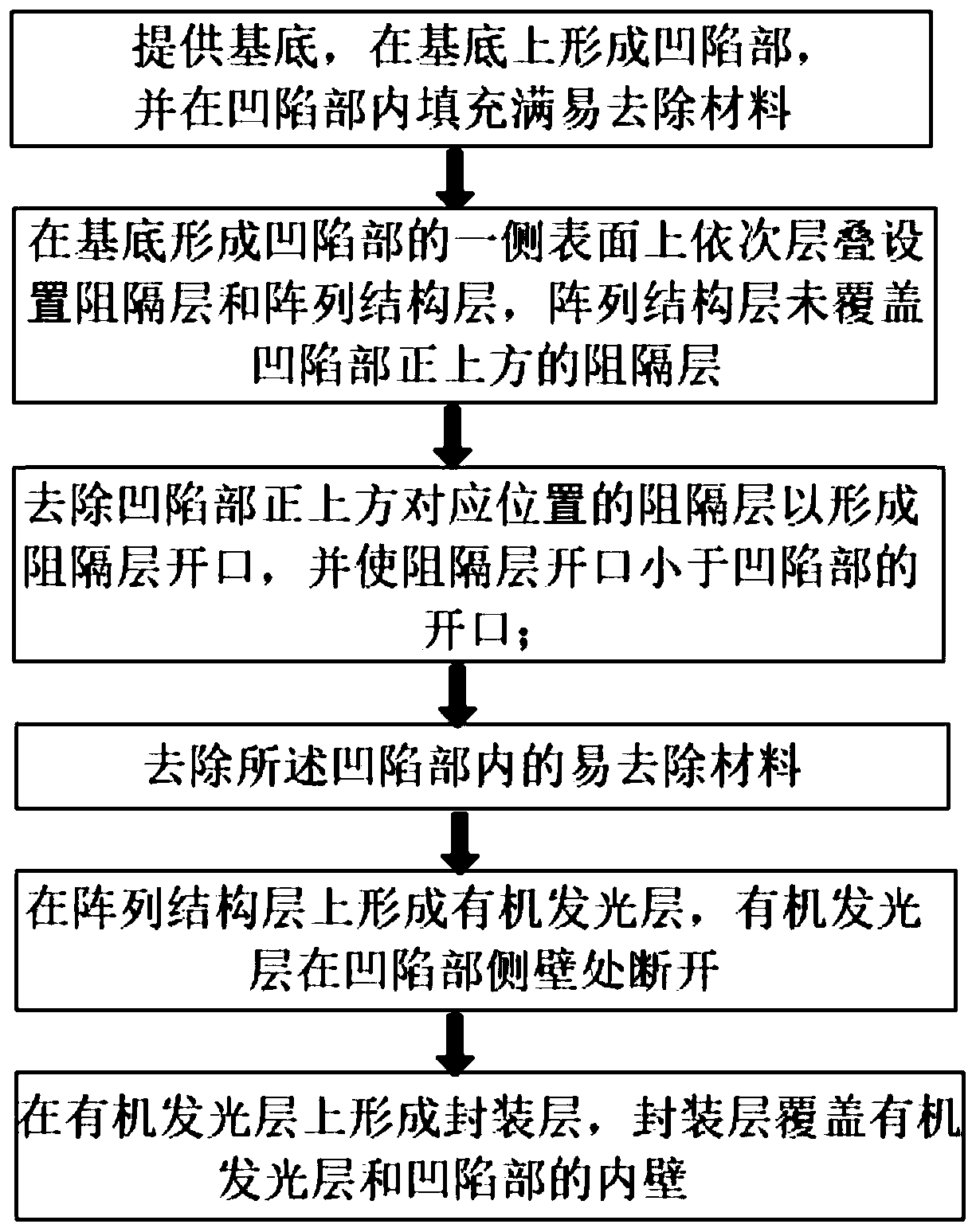

Display panel preparation method, display panel and display device

InactiveCN110459700AReduce adverse effectsAvoid destructionSolid-state devicesSemiconductor/solid-state device manufacturingPunchingDisplay device

The invention provides a display panel preparation method, a display panel and a display device. The method is characterized in that before an array film layer is prepared, a depression portion is formed on a substrate corresponding to a border area of a punching area, adverse effects on the array film during formation of the depression portion on the substrate after the array process is avoided,moreover, a depression portion of a non-display area is filled with an easily removable material, after the array film is prepared by the array process, a part of a second barrier layer directly abovethe depression portion is removed, the remaining unremoved second barrier layer directly above the depression portion is made to cover an opening edge of the depression portion, then, the easily removable material in the depression portion is removed, during subsequent formation of an organic light emitting layer, the organic light emitting layer is disconnected at the depression portion, when the display area is punched, the organic light emitting common layer can be effectively removed or disconnected in the punching area, and thereby the water and the oxygen are prevented from entering theorganic light emitting film layer of the display area along an inner side wall of the depression portion.

Owner:YUNGU GUAN TECH CO LTD

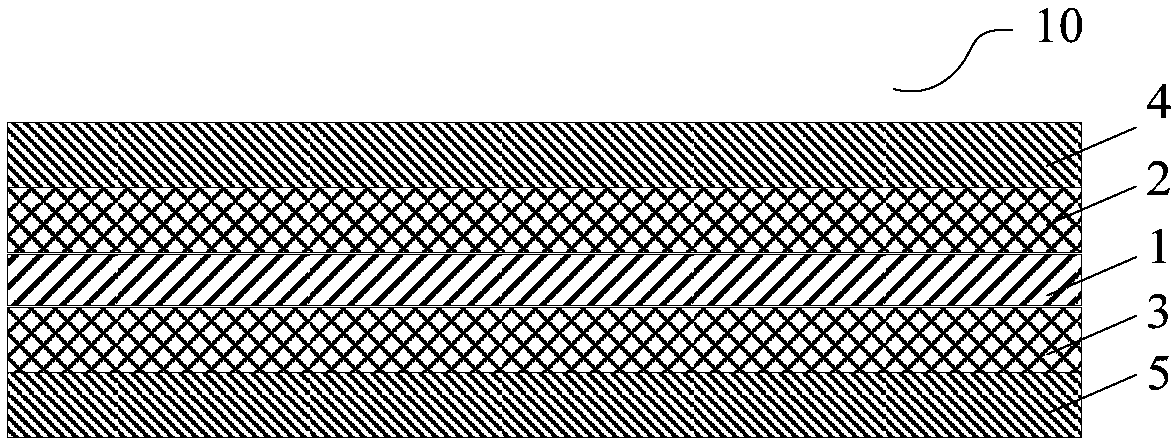

Extrusion-type backing plate for photovoltaic cell and preparation method of backing plate

ActiveCN105462238AGuaranteed encapsulation effectImprove flame retardant performanceFinal product manufactureSynthetic resin layered productsPolyamideEngineering

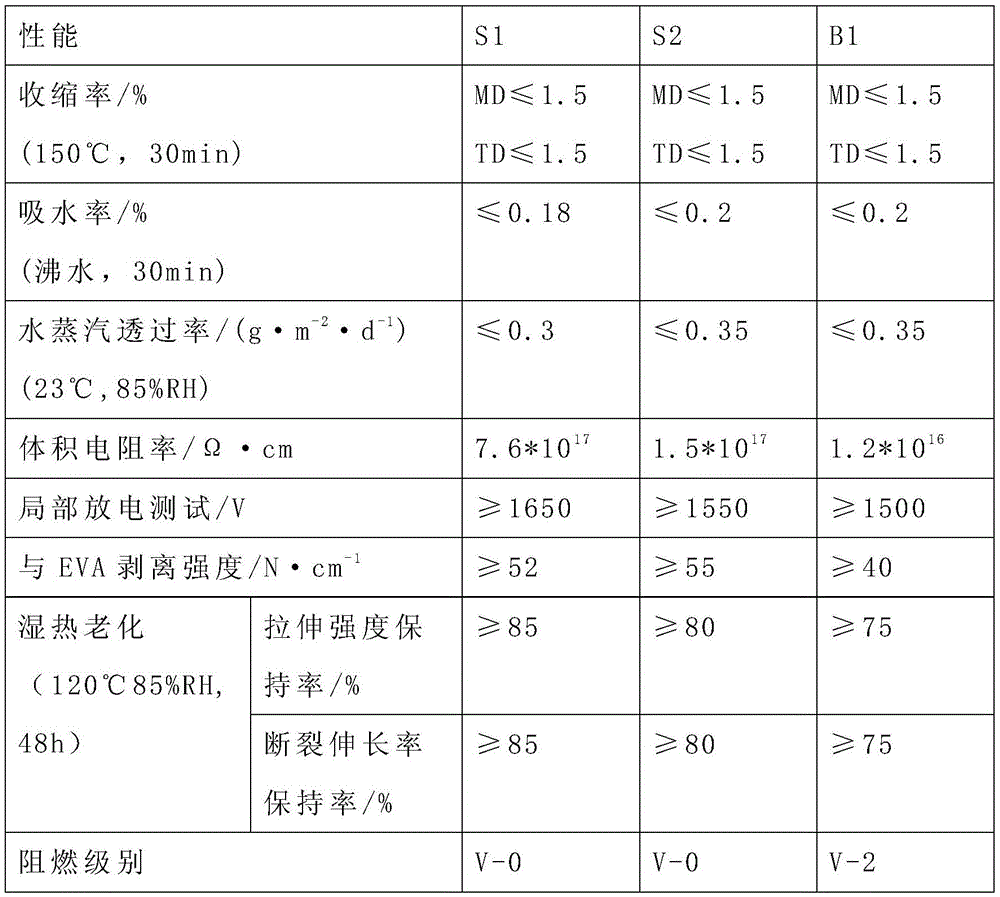

The invention discloses an extrusion-type backing plate for a photovoltaic cell. The backing plate comprises an upper surface layer, a core layer and a lower surface layer, wherein the upper surface layer is composed of polyamide resin, filler, a flame retardant and additives, the core layer is composed of polypropylene resin and grafted polyethylene modified polyamide resin, filler, flame retardant and additives, the lower surface layer is composed of polyamide resin, flame retardant, a coupling agent and additives, the flame retardant is composed of a nanoscale inorganic flame retardant subjected to surface treatment and red phosphorus, the nanoscale inorganic flame retardant is selected from aluminum hydroxide and / or magnesium hydroxide of 10-100 nm, and a used surface treating agent is ethylene-based polyhedral oligomeric silsesquioxane of 1-5 nm. The extrusion-type backing plate is good in flame-retardant effect which reaches the A level through combustion tests, and it can be guaranteed that the flame retardant has no influence on the mechanical property, aging-resistant property, waterproof property, insulating property and the like of the extrusion-type backing plate.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

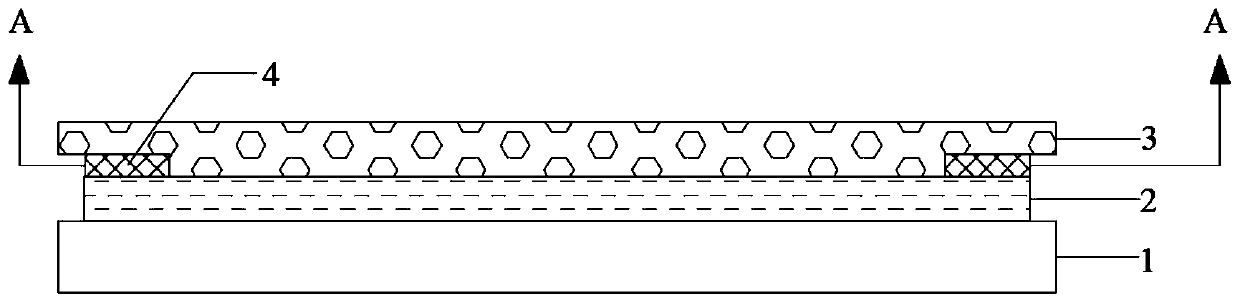

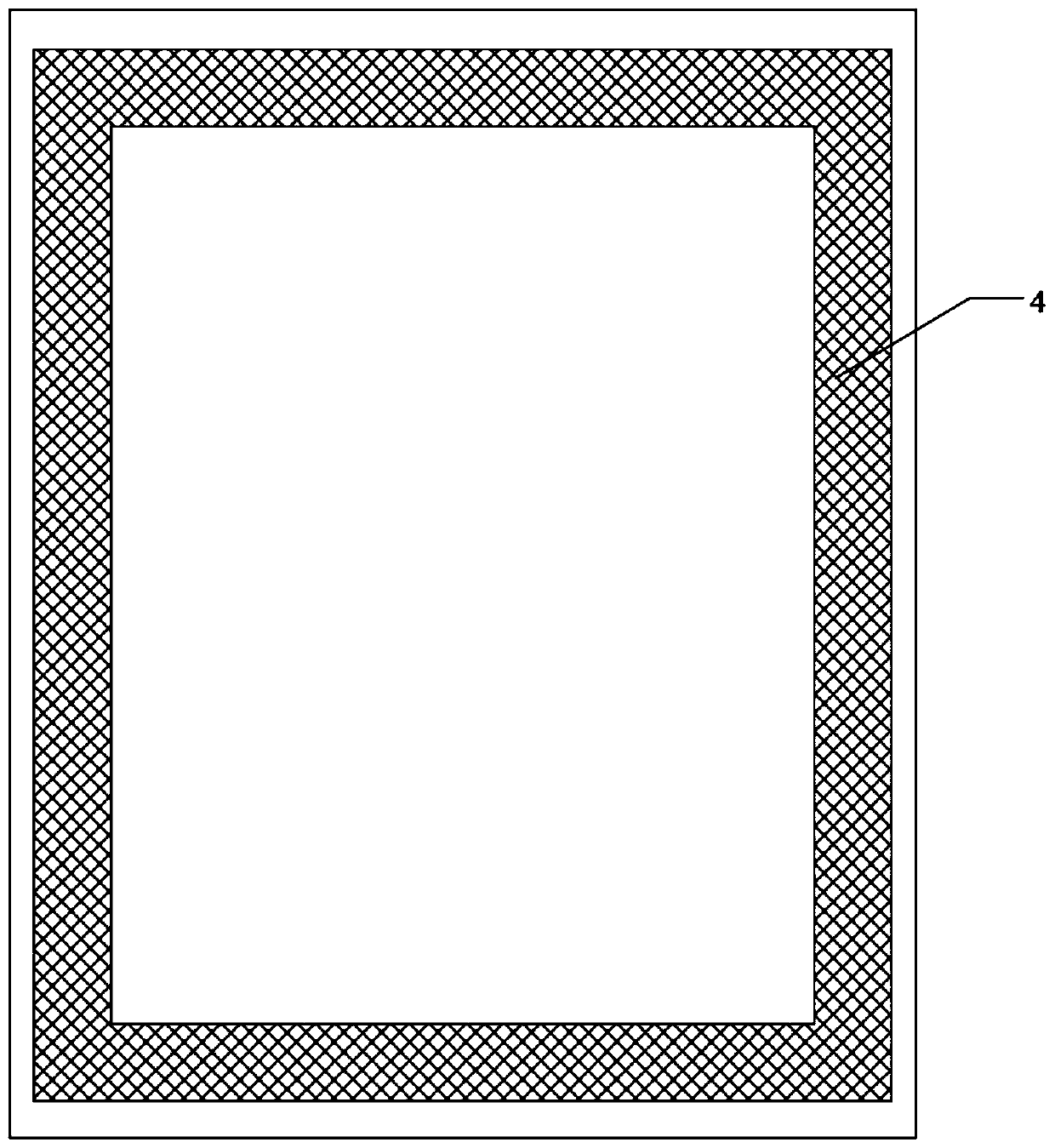

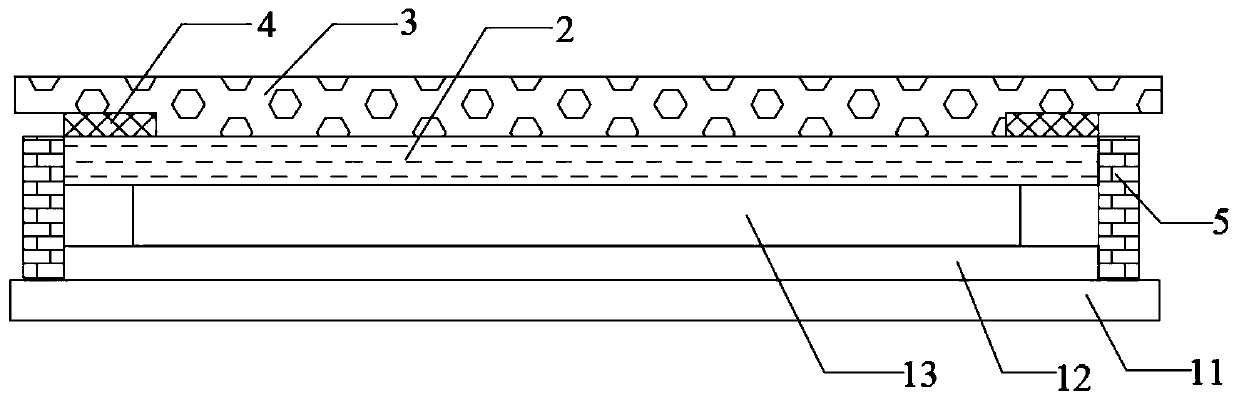

Package structure and flexible display device with the same

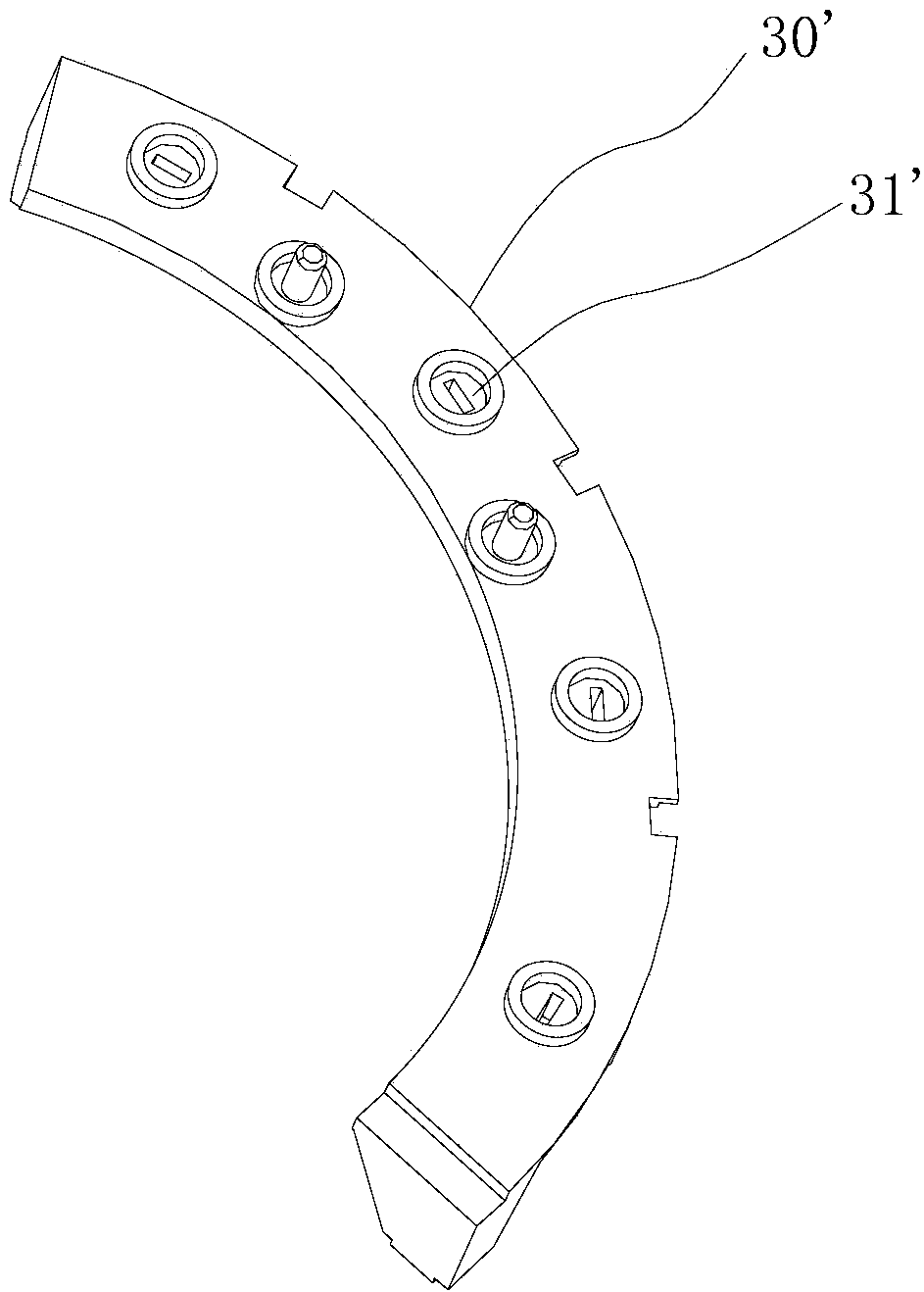

ActiveCN108054292AGuaranteed encapsulation effectImprove bending performanceSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayMechanical engineering

The embodiment of the invention provides a package structure and a flexible display device with the same. The package structure comprises a bending area and a non-bending area, and modulus of elasticity of the bending area is lower than the modulus of elasticity of the non-bending area. According to the package structure and the flexible display device with the same, by means of setting the bending area of the package structure as a low elastic modulus material, the purpose that bending performance of the package structure is effectively improved while the package effect of the package structure is guaranteed is achieved.

Owner:YUNGU GUAN TECH CO LTD

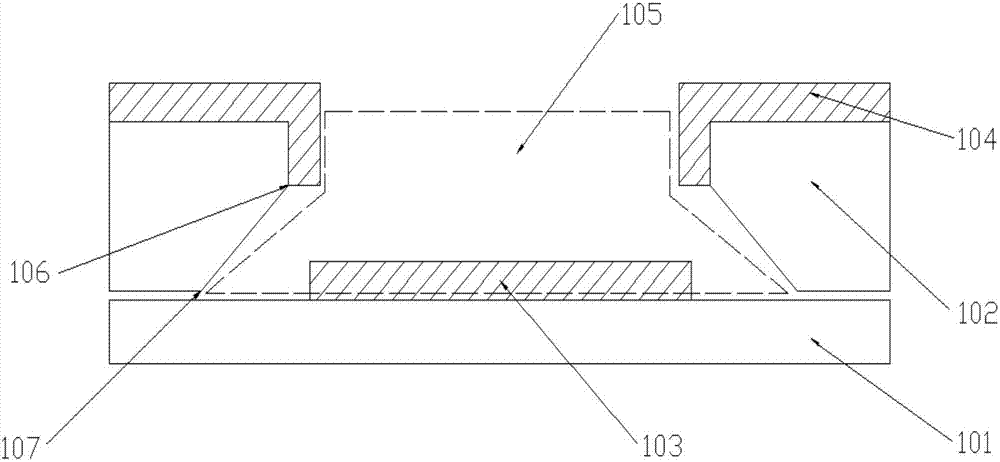

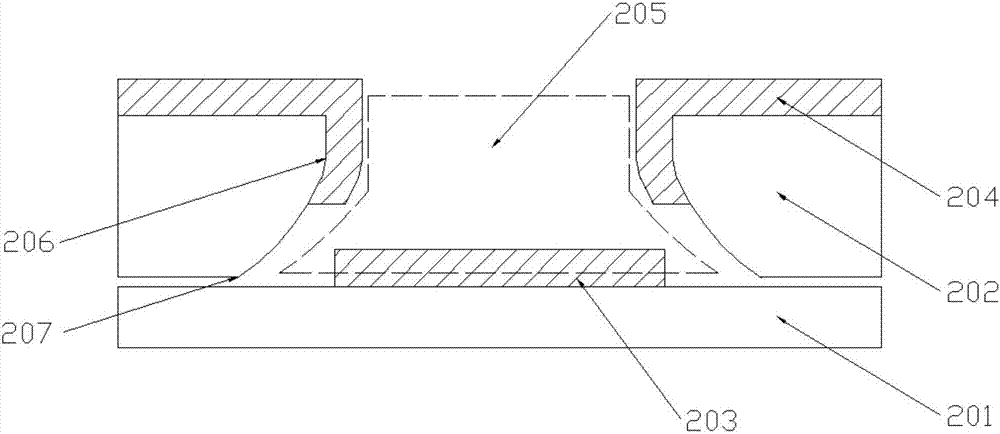

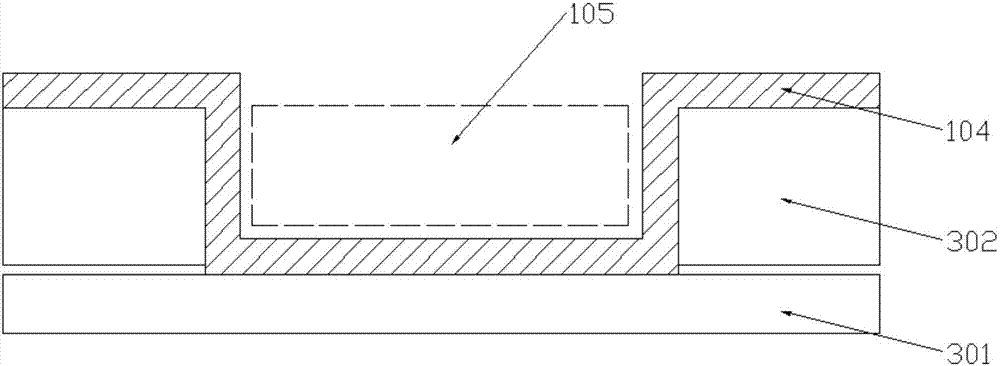

OLED (organic light emitting diode) display substrate, manufacture method thereof and display device

ActiveCN109360843AGuaranteed encapsulation effectIncrease exposureFinal product manufactureSolid-state devicesGraphicsDisplay device

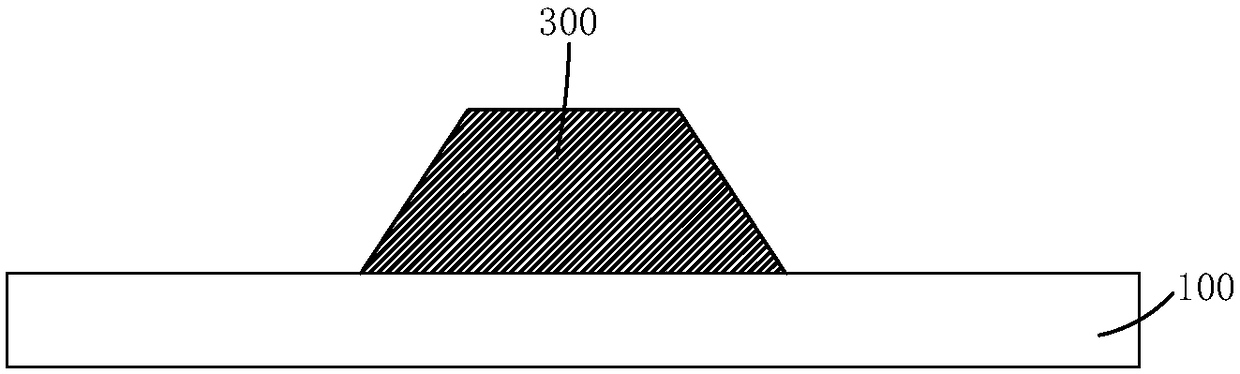

The invention provides an OLED (organic light emitting diode) display substrate, a manufacture method thereof and a display device, and belongs to the technical field of display. The manufacture method of the OLED display substrate includes the steps: forming an inverted table-shaped structure enclosing a cutting area on the periphery of the cutting area of the OLED display substrate; forming a reflective graphic between the inverted table-shaped structure and a base plate of the OLED display substrate before forming the inverted table-shaped structure. When a cathode of the OLED display substrate is formed, the edge of the cathode on the upper surface of the inverted table-shaped structure naturally fractures. The orthographic projection of the inverted table-shaped structure on the baseplate is positioned in the orthographic projection of the reflective graphic on the base plate. The packaging effect of the OLED display substrate can be ensured, and the performance of the display device is further ensured.

Owner:BOE TECH GRP CO LTD

Display device, display panel and manufacturing method thereof

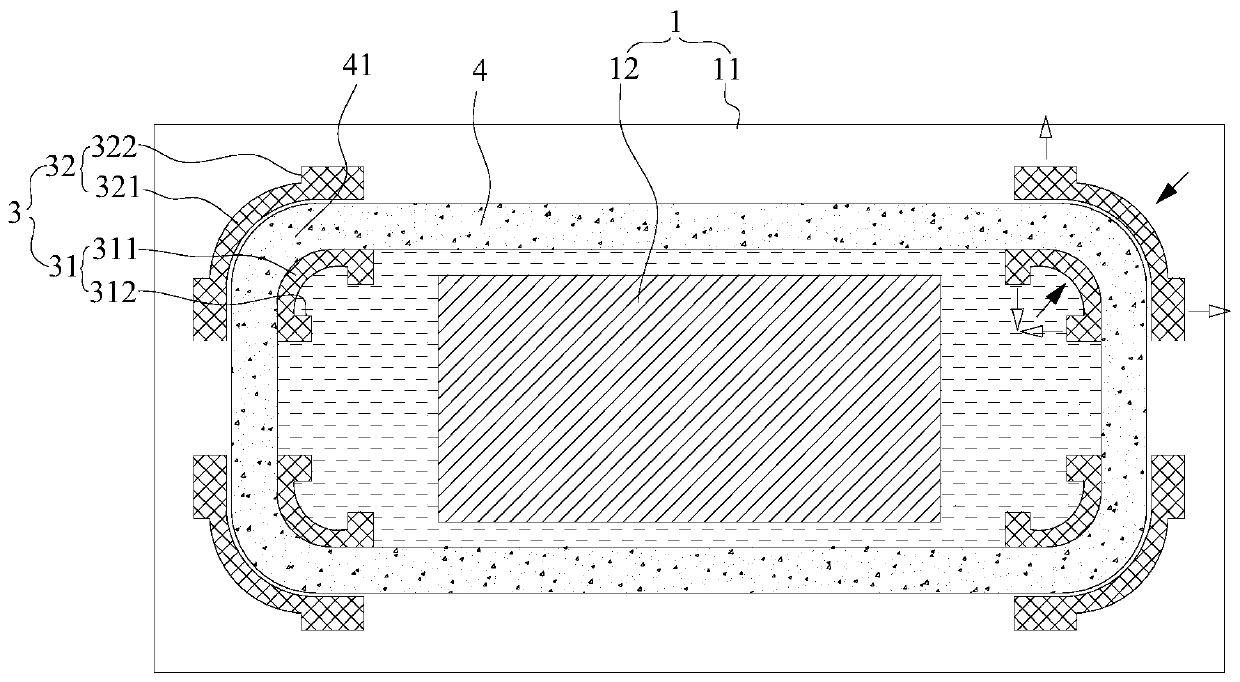

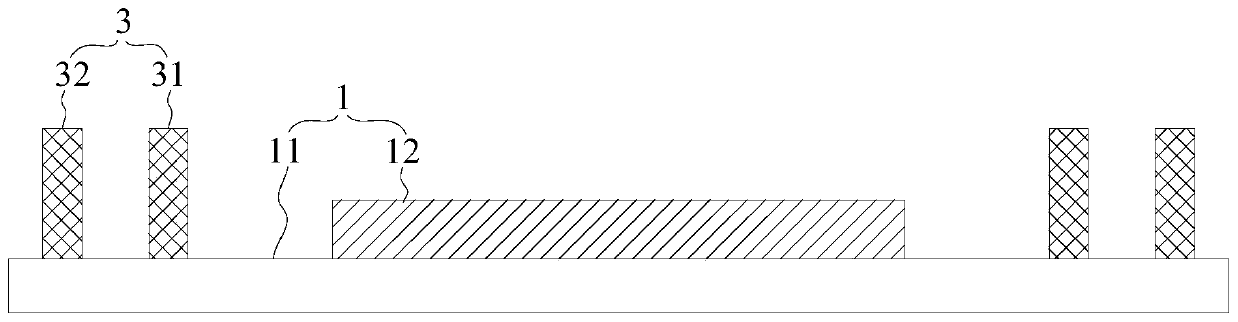

ActiveCN110350013AHigh strengthAvoid it happening againSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a display device, a display panel and a manufacturing method thereof, and relates to the technical field of display. The display panel comprises a display substrate, a cover plate, a reinforcing layer, a retaining wall and a filling layer. The display substrate is provided with a display region and a peripheral region surrounding the display region. The cover plate and thedisplay substrate are arranged in a mutual covering way. The reinforcing layer is arranged in the peripheral region and is located between the display substrate and the cover plate. The reinforcing layer comprises a plurality of curved first protective corners which are spaced around the display region. The retaining wall is arranged in the peripheral region and is located between the display substrate and the cover plate. The retaining wall has a closed annular structure surrounding the reinforcing layer and is provided with a plurality of curved corners. The inner wall of each corner is correspondingly matched and fit with the outer wall of each first protective corner in a one-to-one way. The filling layer fills in the space formed by the display substrate, the cover plate, the first protective corners and the retaining wall through enclosing and the filling layer is matched and fit with the inner wall of the first protective corners. The display panel can improve the packaging effect and the reliability.

Owner:BOE TECH GRP CO LTD

Organic light-emitting display panel, preparation method and display device

ActiveCN109755410AGuaranteed encapsulation effectPrevent infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

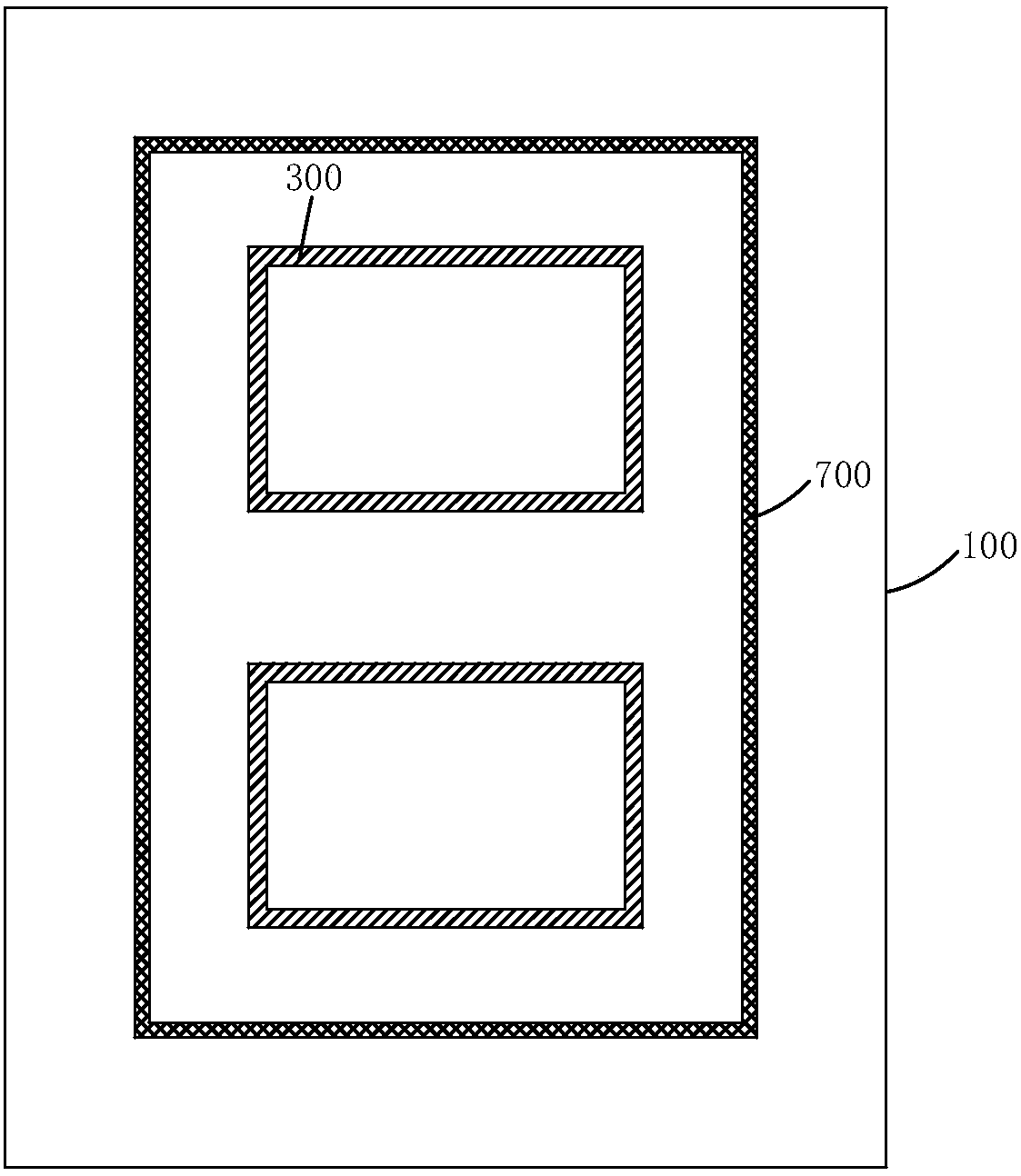

The invention discloses an organic light-emitting display panel, a preparation method and a display device, wherein the organic light-emitting display panel comprises a display area and a non-displayarea surrounding the display area, the display panel comprises a substrate, an organic light-emitting structure array layer, a plurality of film layers, and a hydrophobic structure; the organic light-emitting structure array layer is located in the display area of the substrate; the plurality of film layers are located on one side of the substrate facing the organic light-emitting structure arraylayer and extend to the non-display area; and the hydrophobic structure is located between any two adjacent film layers of the plurality of film layers in the non-display area. According to the organic light-emitting display panel, the preparation method and the display device provided by the embodiment of the invention, water and oxygen can be effectively prevented from seeping into the gaps of the film layers in the non-display area, the light-emitting material and the cathode material in the organic light-emitting display panel are prevented from being corroded, effective blocking of waterand oxygen is realized, and the packaging effect of the organic light-emitting display panel is guaranteed.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

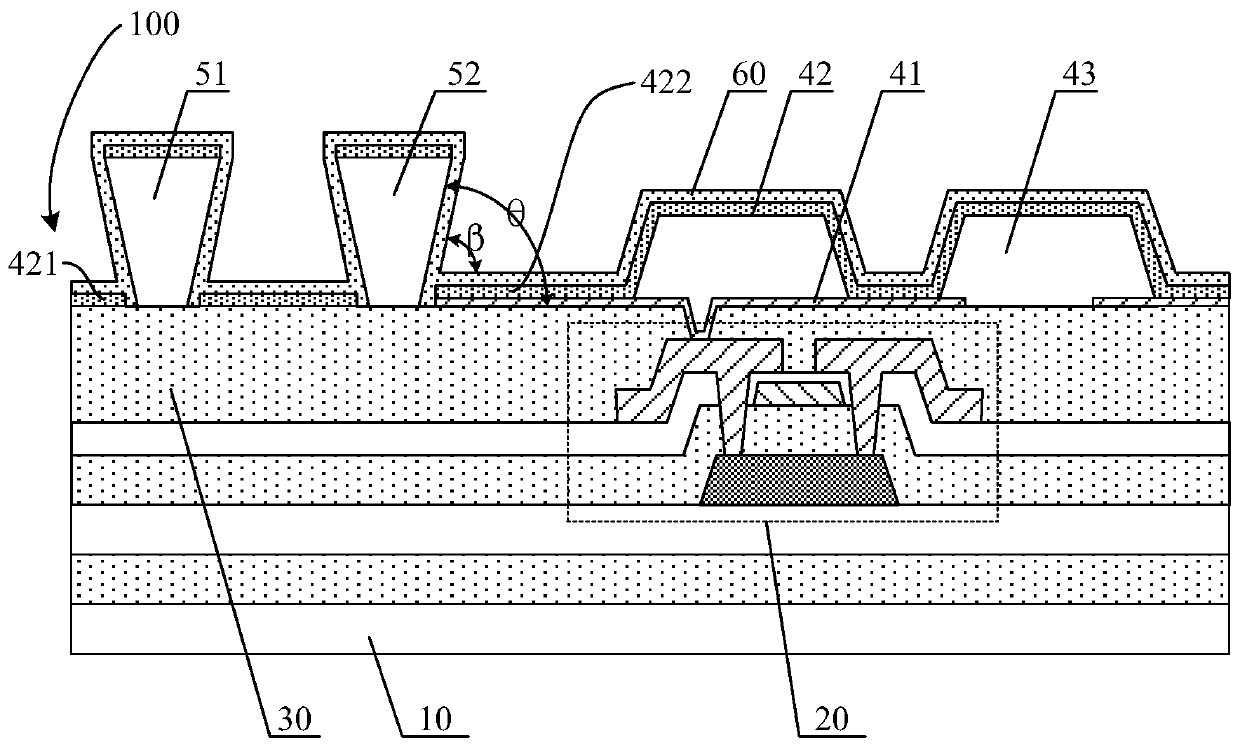

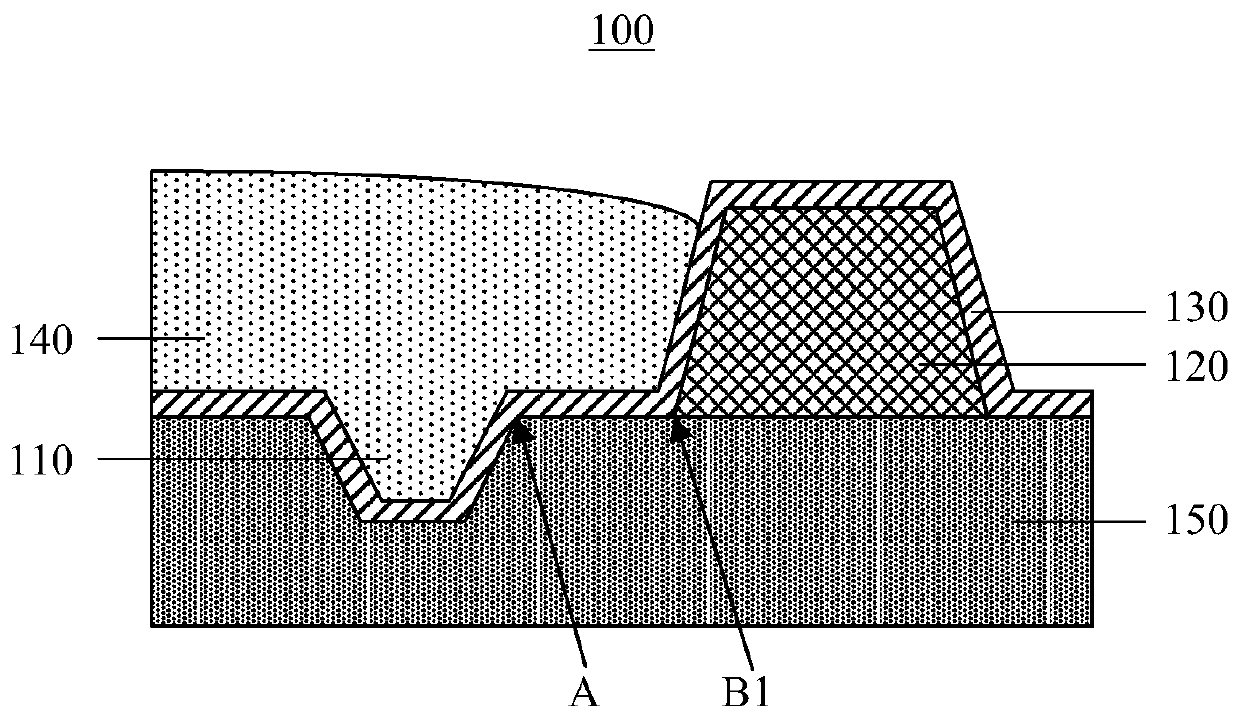

Display panel and manufacturing method thereof, and display device

ActiveCN110783491AEliminates sharp surfacesConsistent thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceStructural engineering

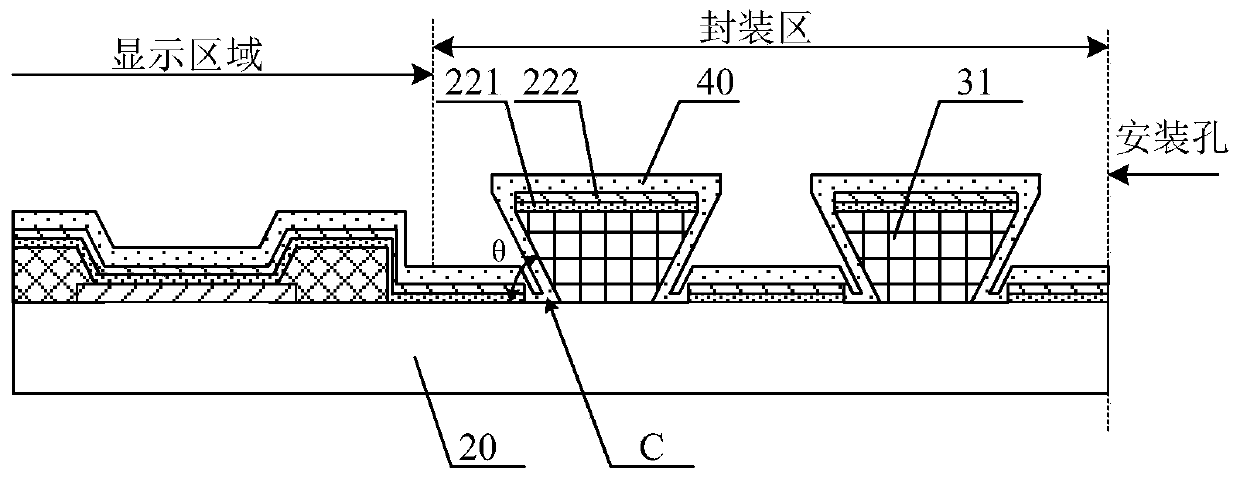

The invention discloses a display panel and a manufacturing method thereof, and a display device. The display panel comprises an installation hole and a packaging area surrounding the installation hole. The packaging area comprises a substrate base plate and an isolation structure arranged on the substrate base plate. The isolation structure comprises an isolation column and gentle layers formed behind the isolation column and located on two sides of the isolation column. Each gentle layer comprises a filling part making contact with a side wall of the isolation column, and a surface of one side, deviating from the substrate base plate, of the filling part is gradually away from the substrate base plate in a direction from a position away from the isolation column to the position close tothe isolation column. By using the display panel, a sharp surface located at a bottom of the side wall of the isolation column is eliminated so that the surface of the bottom of the side wall of the isolation column is gentle, a film thickness of an inorganic packaging layer can be more uniform, packaging failure is avoided, a packaging effect is guaranteed, and a service life of a display area OLED is ensured.

Owner:BOE TECH GRP CO LTD

OLED display panel and manufacturing method thereof

InactiveCN108389981AImprove production yieldReduce generationLamination ancillary operationsSolid-state devicesParticulatesAdhesive

The invention provides an OLED display panel and a manufacturing method thereof. According to the manufacturing method of the OLED display panel, a light-shielding film is arranged on a packaging cover plate, and the laser can be prevented from irradiating electrodes on an OLED substrate in the laser scanning process of a frame adhesive. In this way, electrodes are effectively protected. Meanwhile, the part of the light-shielding film, overlapped with the film region of the frame adhesive, has a gradually-reduced light transmittance, so that the film region of the frame adhesive can be prevented from being burnt by the excessive laser energy. The packaging effect is fully guaranteed, and the generation of particulate matters is reduced. In addition, the surface of the light-shielding film,irradiated by the laser, is set to be a frosted surface, so that the laser irradiated on the light-shielding film can generate the diffuse reflection. As a result, the laser is prevented from being directly reflected to a laser head, so that the laser head is protected from being damaged by burns. The OLED display panel is prepared by adopting the above manufacturing method of the OLED display panel, so that the OLED display panel is good in packaging effect and high in production yield.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

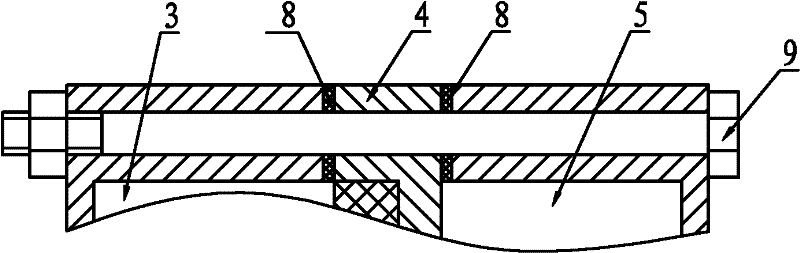

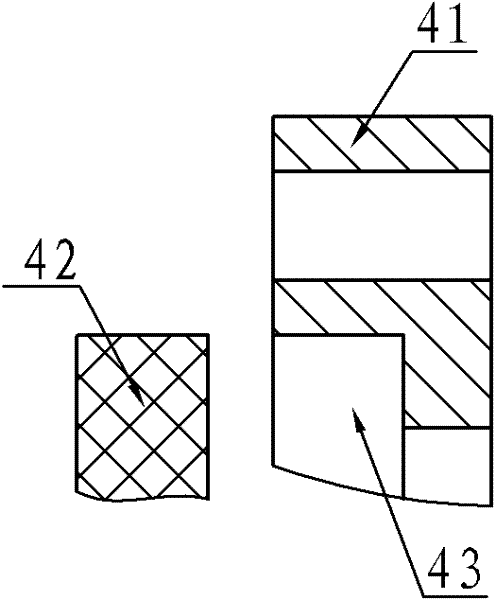

Device for detecting sealing performance of silica gel for packaging solar modules

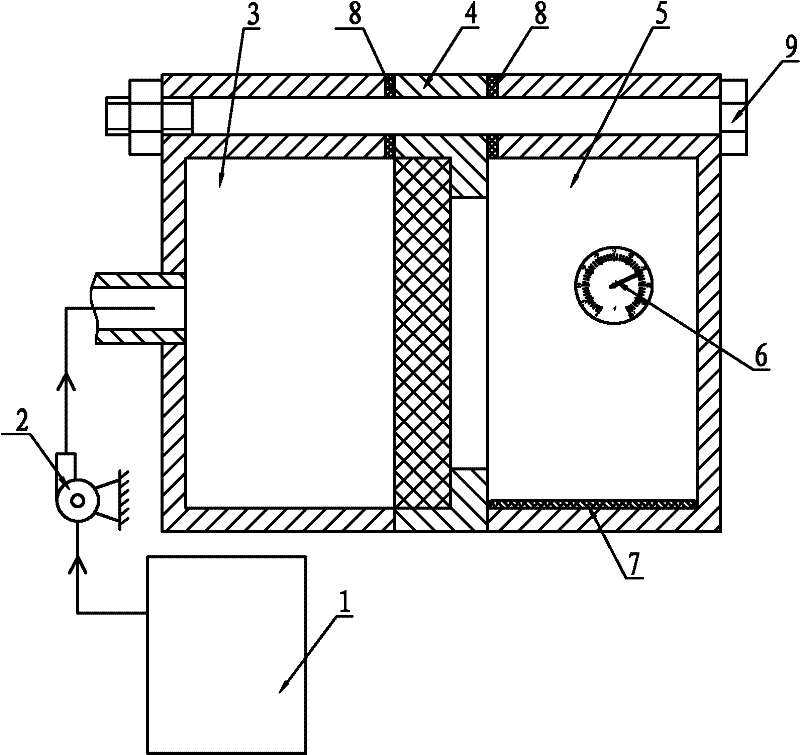

ActiveCN102226733AGuaranteed encapsulation effectGuaranteed service lifeDetection of fluid at leakage pointWater vaporTest frame

The invention discloses a device for detecting the sealing performance of silica gel for packaging solar modules. The device comprises an experimental gas storage box, a circulating pressure pump, a pressure air chamber, a bond-line test frame, an airtight test chamber, a humidometer, a dust-loaded plate, an end face seal gasket and a fastener, wherein the humidometer is arranged in the airtight test chamber, and the dust-loaded plate is horizontally arranged at the bottom of the airtight test chamber; the bond-line test frame is arranged between the pressure air chamber and the airtight test chamber, and the bond-line test frame, the pressure air chamber and the airtight test chamber are fixedly connected by the end face seal gasket and the fastener; an output end of the circulating pressure pump is in closed connection with an air inlet of the pressure air chamber, and an air suction end of the circulating pressure pump is communicated with the experimental gas storage box; and the pressure of the cavity of the pressure air chamber ranges from (1.5*10<5>Pa) to (2.0*10<5>Pa). The device can be used for detecting the isolation performance of the silica gel (for packaging solar modules) to water vapor and dust in the air.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

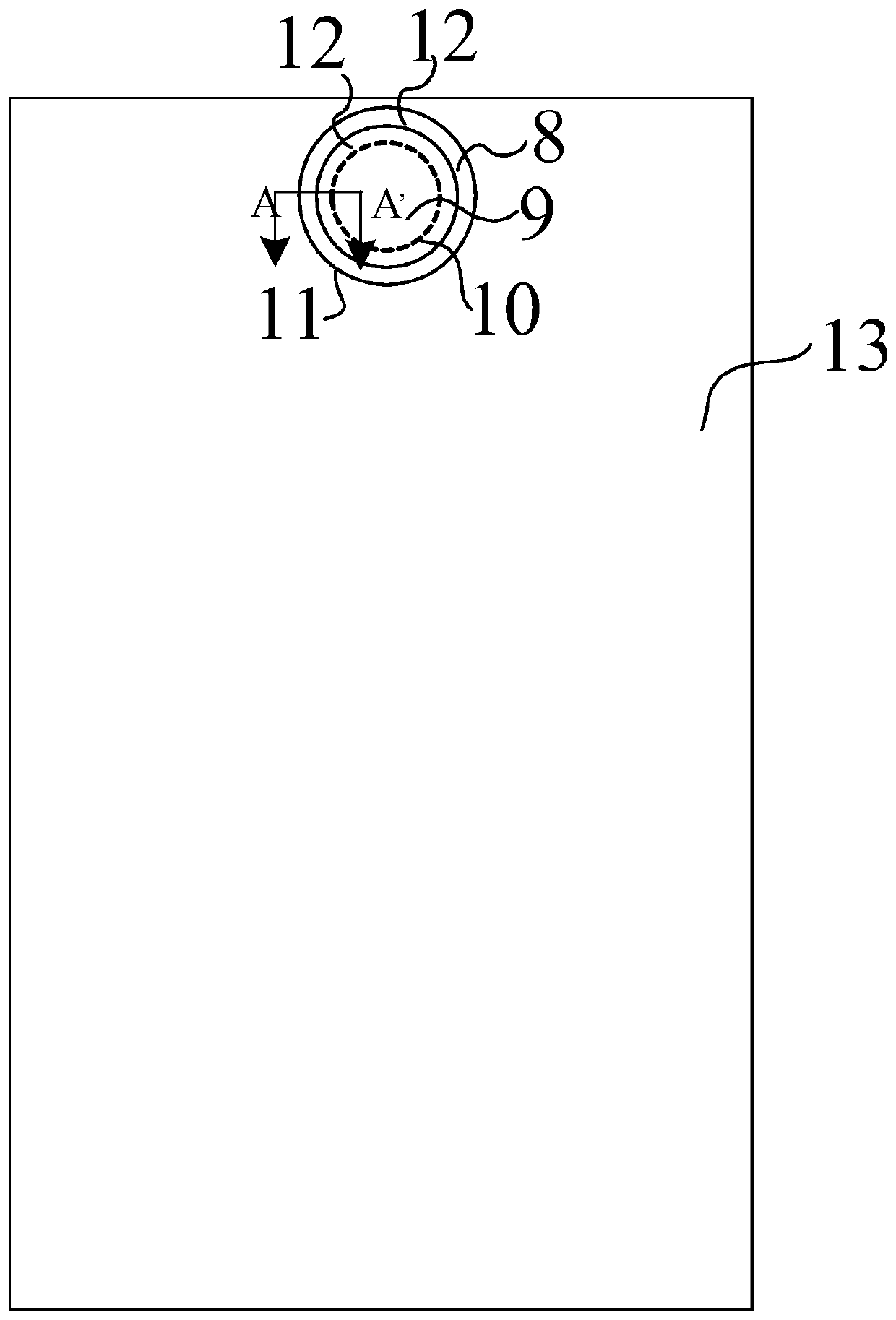

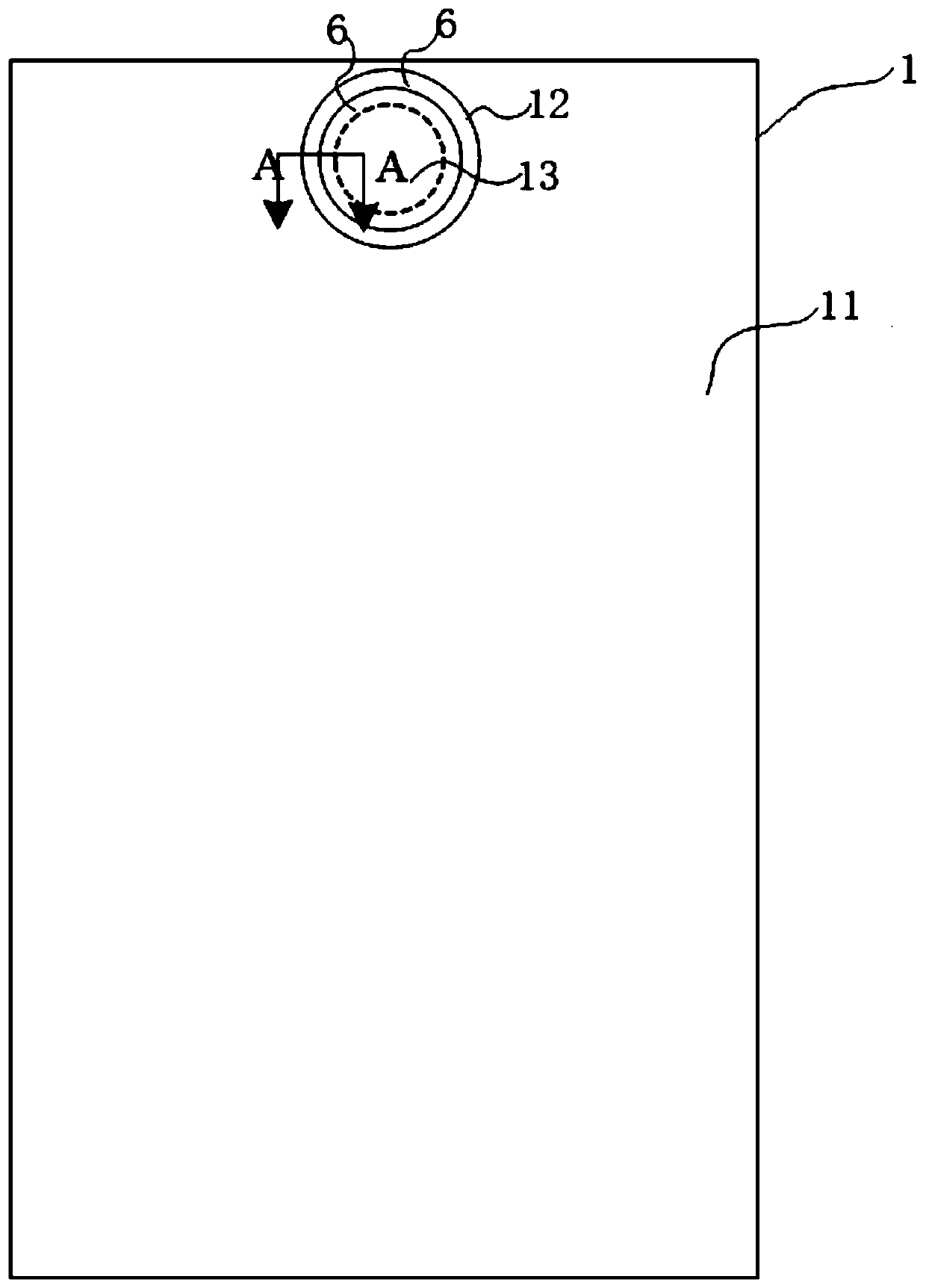

Display device, display panel and manufacture method thereof

ActiveCN109904346AIncrease distanceExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

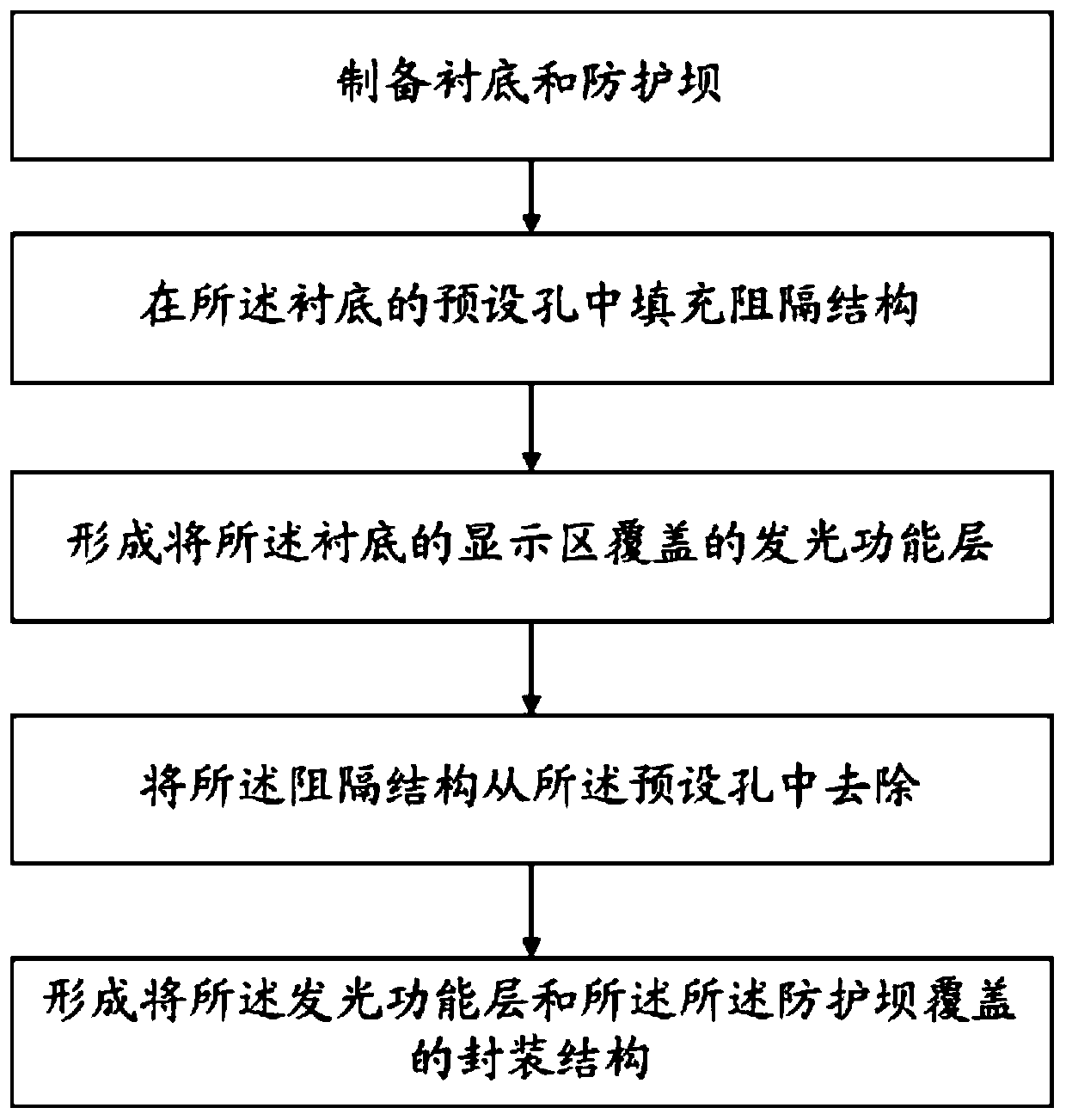

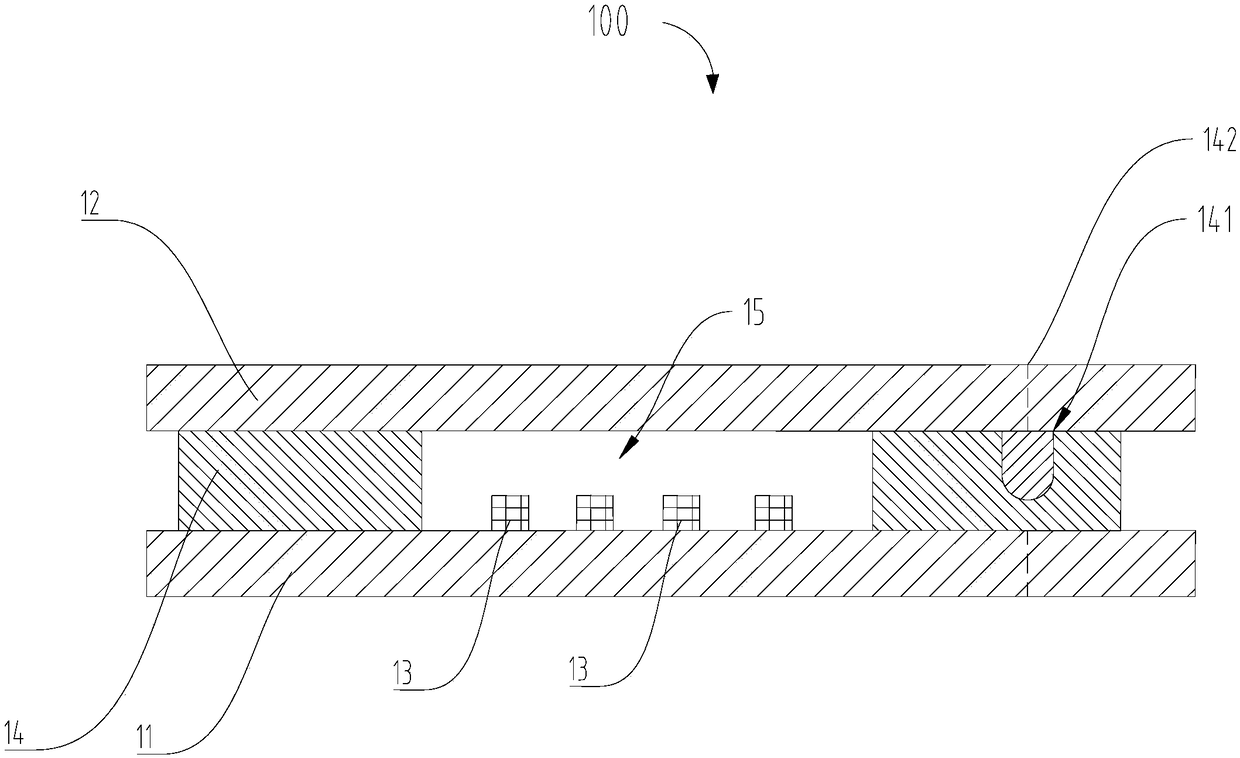

The invention discloses a display device, a display panel and a manufacture method thereof. The display panel comprises a substrate, a protective dam, and a light-emitting unit, wherein the substratehas a preset hole, a protective area arranged around the preset hole, and a display area isolated from the preset hole by the protective area, the light-emitting unit covers the display area, the protective dam is convex in the thickness direction of the substrate in the protective area, and the protective dam comprises a firm dam, a second dam and a third dam that surround the preset hole in sequence from near to far. The invention further provides a display device comprising the display panel and a method of preparing the display panel. Water and oxygen at the preset hole are prevented fromeroding the light-emitting functional layer.

Owner:YUNGU GUAN TECH CO LTD

Display panel, display panel preparation method and display device

ActiveCN108598284AGuaranteed yieldReduced end-face contact areaSolid-state devicesSemiconductor/solid-state device manufacturingBiochemical engineeringDisplay device

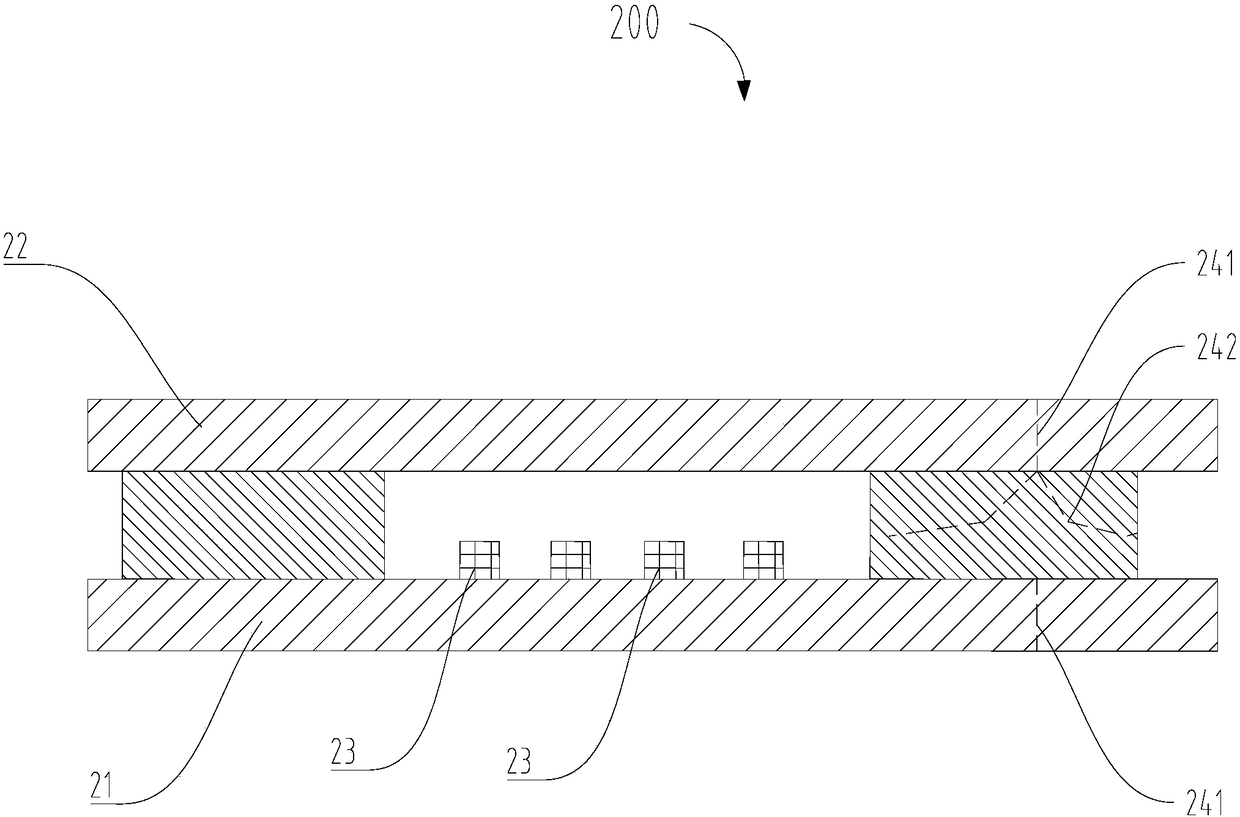

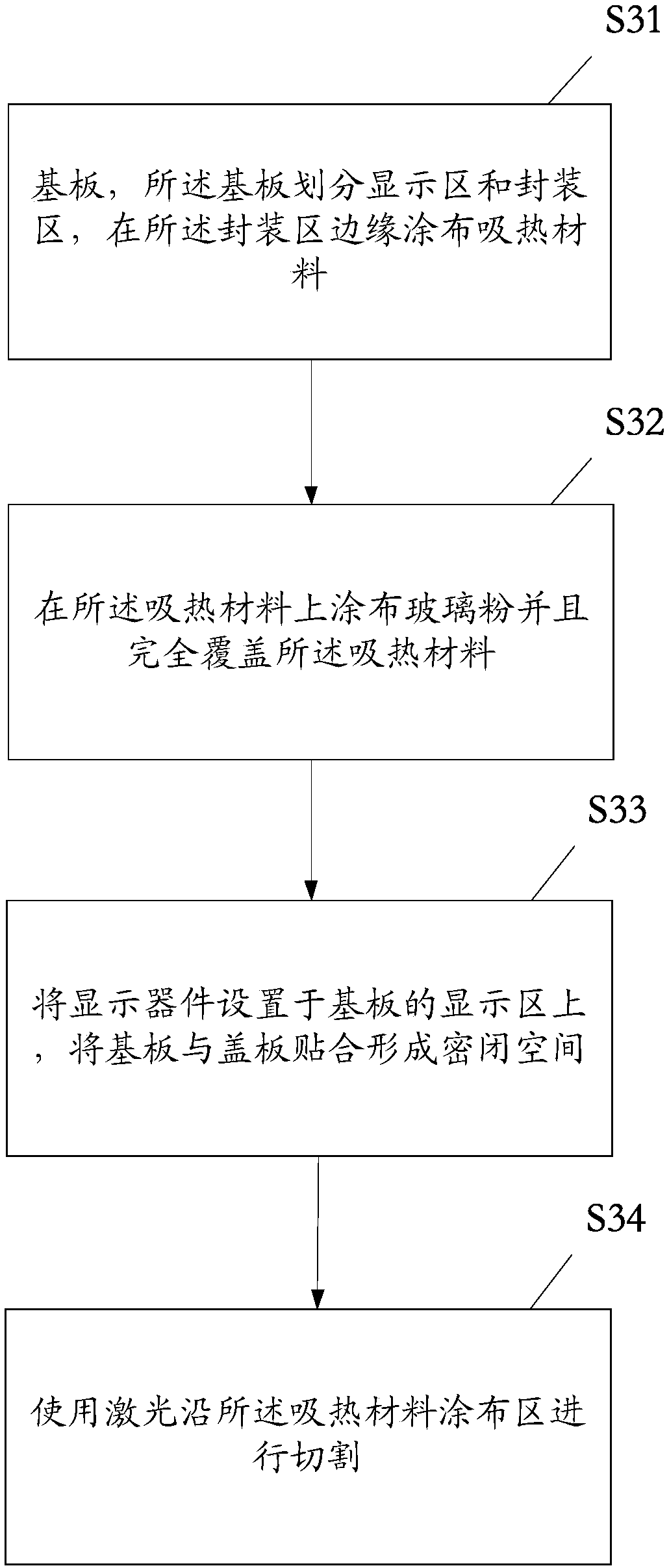

The invention provides a display panel, comprising a base plate, a cover plate set opposite to the base plate, and a packaging layer which is adhered with the base plate and the cover plate. A sealedspace for placing display devices is encircled by the base plate, the packaging layer and the cover plate. A groove is set on the packaging layer. The opening of the groove faces or back on to the cover plate. The groove is filled with a solid heat-absorption material. The invention also provides a packaging method and a display device. According to the display panel provided by the invention, through setting of the groove on the packaging layer, when a cutter cuts the packaging layer, the contact the side wall of the groove is avoided, so an end face contact area when the cutter processes thepackaging layer is reduced, and the cut margin is compressed. The narrow frame design is realized, and a packaging effect and a packaging yield are ensured.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Array substrate, preparation method thereof and display device

PendingCN113497089AGuaranteed encapsulation effectImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an array substrate, a preparation method thereof and a display device, and belongs to the technical field of display. The array substrate is provided with a hole opening area and a hole frame area. The preparation method of the array substrate comprises the steps that a source-drain metal layer is formed on one side of a substrate, a first isolation column surrounding a hole opening area is formed in a hole frame area of the source-drain metal layer, and the first isolation column comprises a first metal layer and a second metal layer located on the side, away from the substrate, of the first metal layer; forming a planarization layer at least covering the side surface of each first metal layer; forming a pixel electrode layer; forming a protective layer covering the pixel electrode layer, wherein the protective layer exposes the hole frame area; removing the part, located in the hole frame area, of the planarization layer; partially etching the first metal layer from the side surface to form a third metal layer; removing the protective layer; and sequentially forming an organic light-emitting layer and a common electrode layer. The preparation method of the array substrate can improve the yield of the array substrate.

Owner:BOE TECH GRP CO LTD +1

Display panel, preparation method thereof and display device

ActiveCN110880561APrevent overflowReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingComposite materialStructural engineering

The embodiment of the invention provides a display panel, a preparation method thereof and a display device. The display panel comprises a first groove, a retaining wall, a first inorganic layer and an organic layer. The first groove and the retaining wall are arranged on the substrate, the first groove is closer to the display area of the display panel than the retaining wall, and the retaining wall comprises a first organic layer far away from the substrate. The first inorganic layer is disposed on the first groove and the first organic layer. The second organic layer is arranged on the first inorganic layer close to one side of the display area relative to the first organic layer. According to the technical scheme, the number of the retaining walls can be reduced, the frame of the display panel is reduced, and a narrow frame is achieved.

Owner:YUNGU GUAN TECH CO LTD

Electrochemical battery and preparation method thereof

ActiveCN105368336AGuaranteed encapsulation effectFully filledFinal product manufactureFilm/foil adhesivesEngineeringElectrochemistry

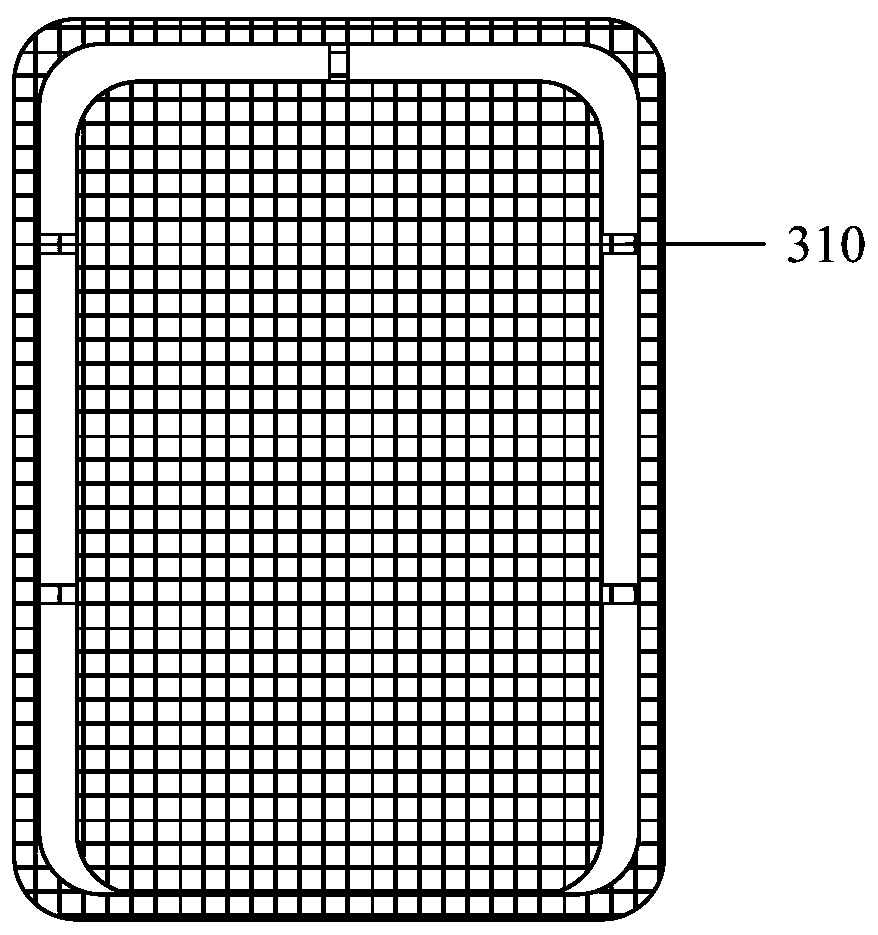

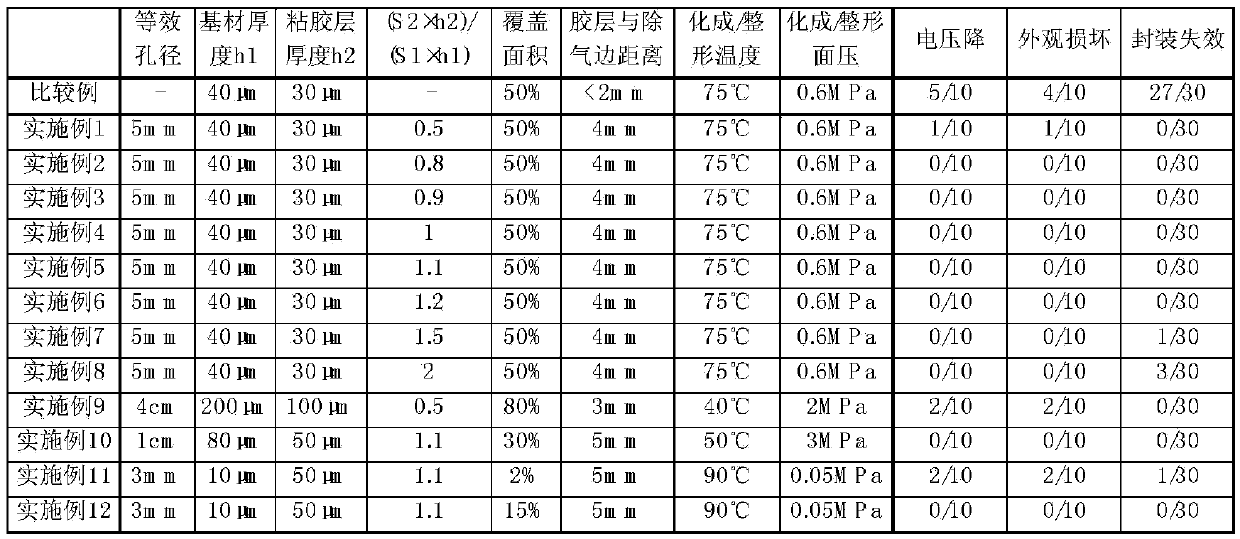

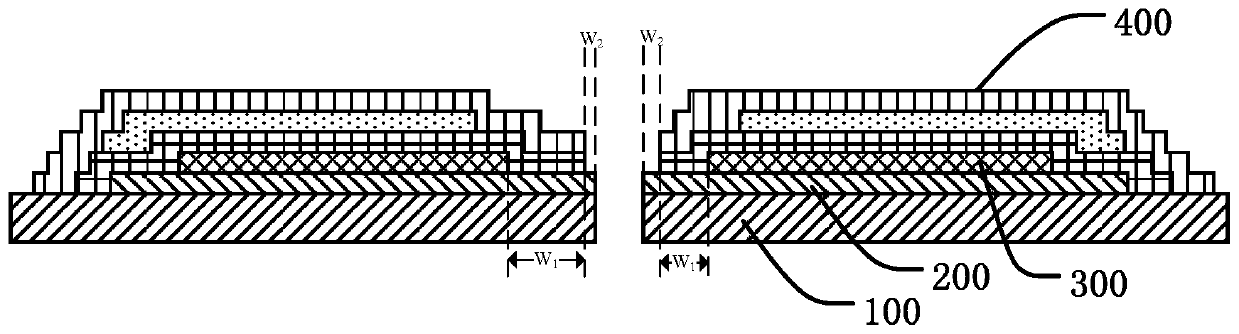

The invention belongs to the field of adhesive tape and electrochemical batteries and particularly relates to an adhesive tape and an electrochemical battery with the adhesive tape. The adhesive tape comprises a base material and an adhesive layer. The adhesive layer is attached to at least one surface of the base material, the adhesive tape is of a porous structure, the area of the hole region is S1, and the area of the non-hole region is S2; the thickness of the base material is h1, and the thickness of the adhesive layer is h2; (S2*h2) / (S1*h1) is smaller than or equal to 2. The electrochemical battery with the adhesive tape comprises a naked battery cell and an outer packaging part. The adhesive tape is arranged between the naked battery cell and the outer packaging part, and the naked battery cell and the outer packaging part closely adhere together. In the adhesive tape, (S2*h2) / (S1*h1) is smaller than or equal to 2, in other words, the volume of the portion, in the non-hole region, of the adhesive layer is smaller than or equal to twice of the volume of the portion, in the hole region, of the base material, the hole region has enough space to contain the portion, overflowing from the non-hole region, of the adhesive layer at the moment, and therefore the situation because of uncontrolled flowing of the adhesive layer, the packaging reliability of the battery is finally affected is limited.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

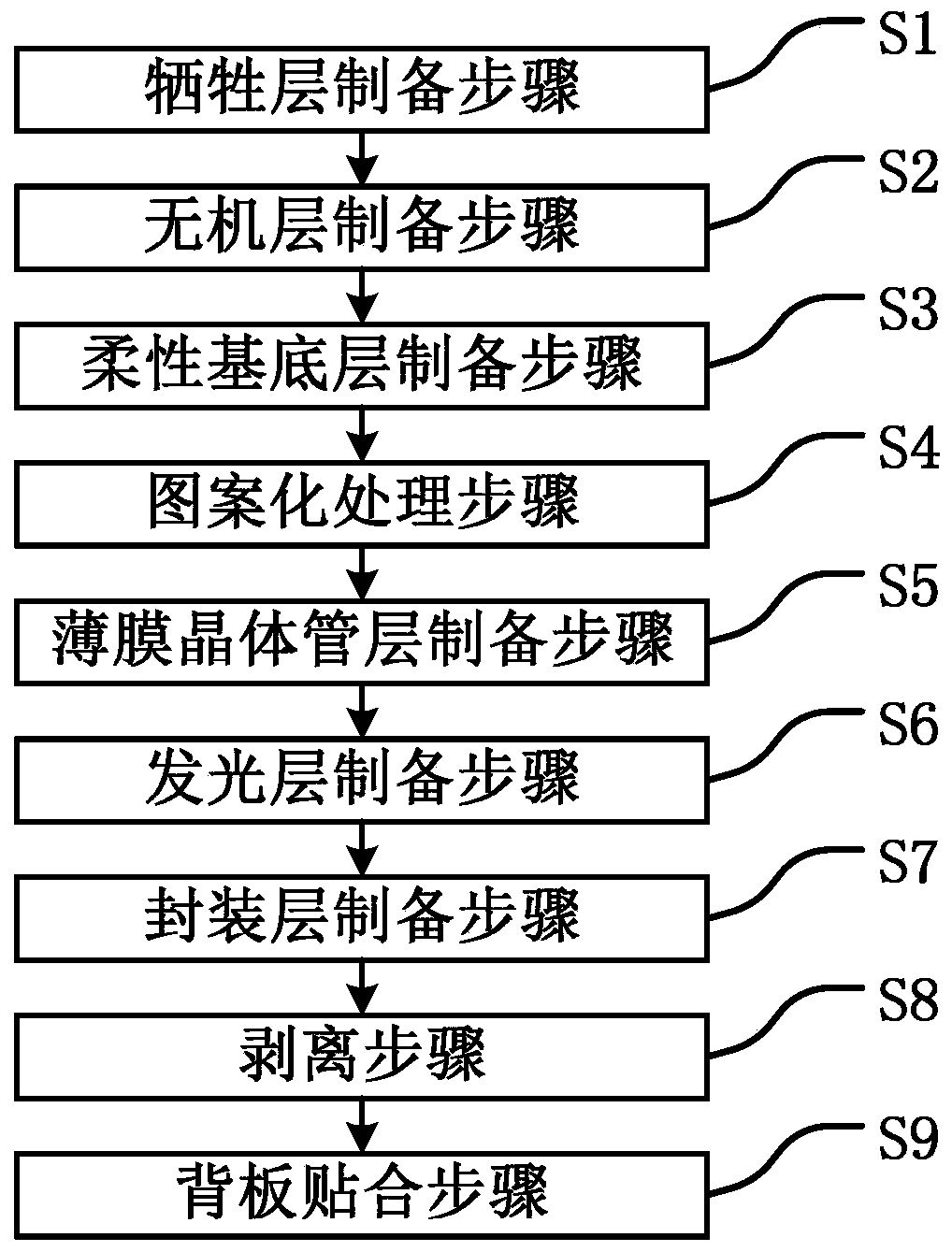

Display panel and preparation method thereof

ActiveCN110729335AIncrease the areaIncrease the screen ratioSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneEngineering

The invention provides a display panel and a preparation method thereof. The display panel comprises a backplane, an inorganic layer, a flexible substrate layer, a thin film transistor layer, a lightemitting layer and a packaging layer. The backplane is provided with a first through hole. The flexible substrate layer is provided with a second through hole which is opposite to the first through hole. The thin film transistor layer is provided with a third through hole which is opposite to the second through hole. The light emitting layer is provided with a fourth through hole which is oppositeto the third through hole. The display panel has the advantages that the area of the display region is increased and the screen-to-body ratio of the display panel is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Display panel preparation method, display panel and display device

ActiveCN111146366AReduce adverse effectsAvoid destructionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a display panel preparation method, a display panel and a display device. According to the preparation method, before an array film layer is prepared, a concave part is formed on a substrate corresponding to the frame region of a punching region, so that adverse effects on the array film layer when a concave part is formed on the substrate after an array process are avoided;the concave part of a non-display area is filled with an easily-removed material; after preparation of the array film layer by an array process is completed, part of a barrier layer right above the concave part is removed, the remaining unremoved barrier layer right above the concave part covers the edge of the opening of the concave part, and then the easily-removed material in the concave partis removed; and an organic light-emitting layer is disconnected at the concave part in the subsequent forming process of the organic light-emitting layer, so that the organic light-emitting common layer in the punching area can be effectively removed or disconnected when a display area is punched so as to avoid water and oxygen from entering the organic light-emitting film layer in the display area along the inner side wall of the concave part.

Owner:YUNGU GUAN TECH CO LTD

Display panel and display device

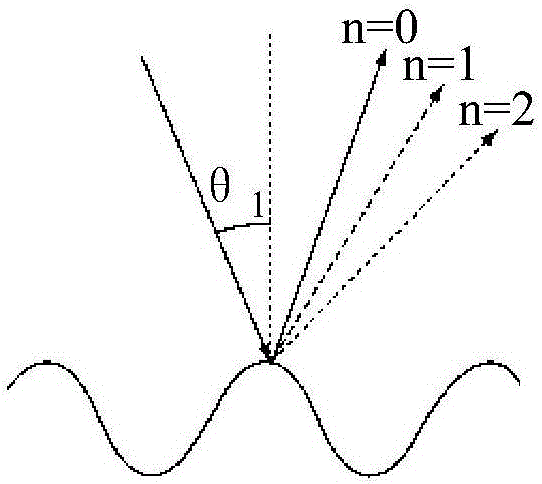

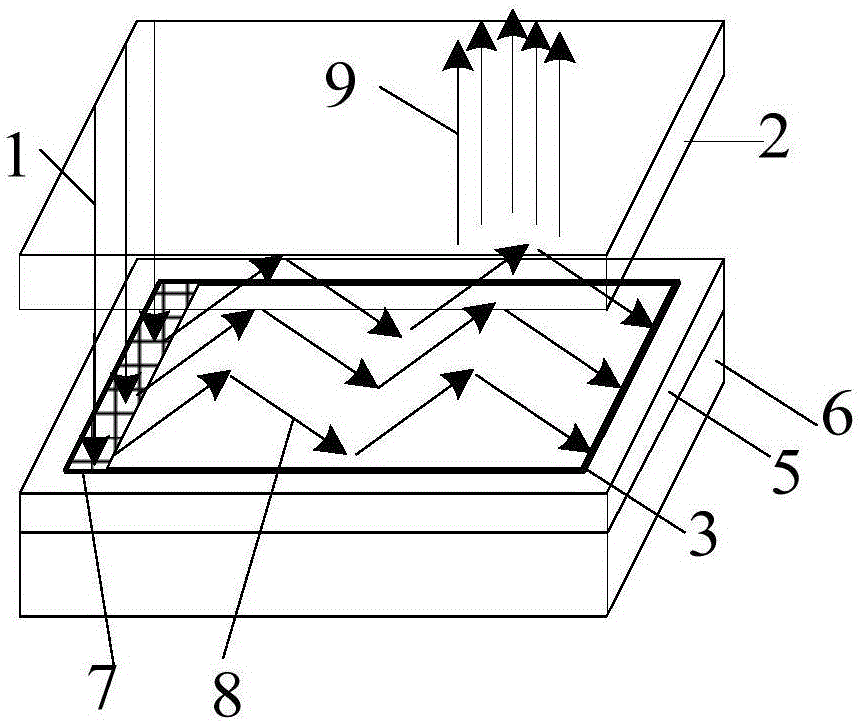

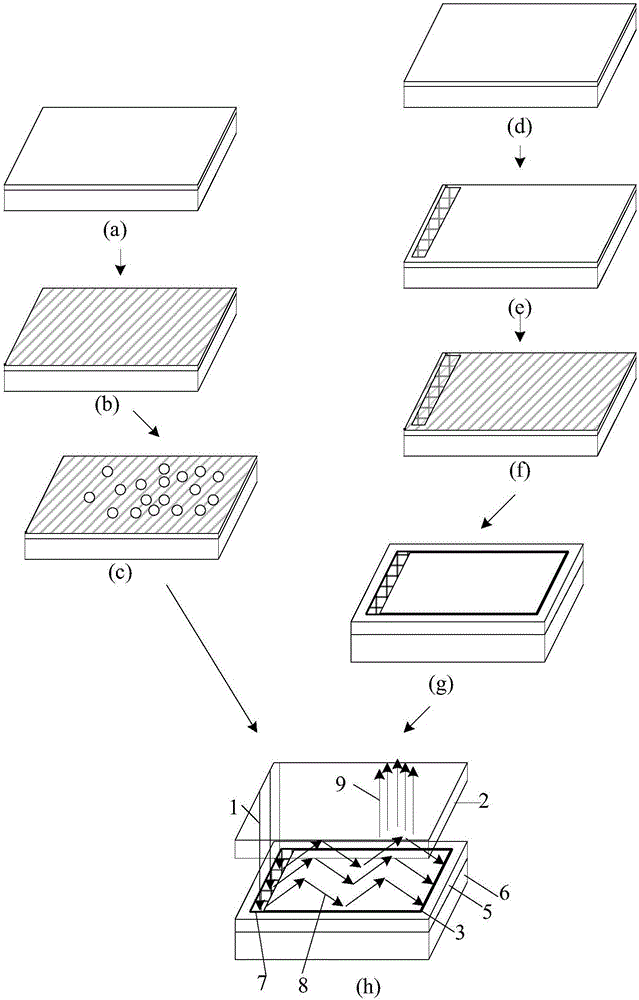

ActiveCN106773255AAvoid absorptionGuaranteed encapsulation effectNon-linear opticsDisplay deviceEngineering

The invention provides a display panel and a display device and belongs to the technical field of display. The display panel comprises a first substrate, a second substrate, a liquid crystal box and a seal agent, wherein the first substrate and the second substrate are arranged oppositely, the liquid crystal box is positioned between the first substrate and the second substrate, and the seal agent is used for adhering the first substrate to the second substrate. Ray reflecting structures are arranged on the surface, facing the second substrate, of one side of the first substrate and are capable of reflecting rays incident into the display panel from the second substrate, so that incident rays are subjected to total reflection in the display panel for many times. The display panel is capable of improving brightness and contrast.

Owner:BOE TECH GRP CO LTD

Mask for encapsulation of organic light emitting diode (OLED) thin film

InactiveCN107546336AGuaranteed encapsulation effectAvoid generatingVacuum evaporation coatingSolid-state devicesLight-emitting diodePellicle membrane

The invention provides a mask for encapsulation of an organic light emitting diode (OLED) thin film. The mask comprises a hollow part and a cover part, wherein the hollow part comprises an opening hole used for forming a thin film encapsulation layer on a substrate, the cover part is used for covering a non-film encapsulation region of the substrate, one surface, in contact with the substrate, ofthe cover part is a first surface, one surface, far away from the substrate, of the cover part is a second surface, and at one side, in contact with the substrate, of the cover part arranged around the opening hole, a corner cut is formed at least one part of an edge of the cover part. By the mask, the technical problem that a large amount of particles are generated during raising of the mask to further cause failure of thin film encapsulation due to a continuous thin film generated on the substrate and the mask and at a connection position of the substrate and the mask of the mask for encapsulation of the OLED thin film in the prior art is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

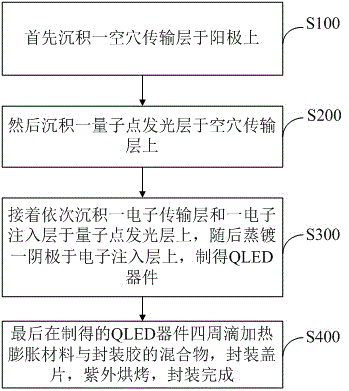

Quantum dot LED and preparation method thereof

ActiveCN106058065AImprove stabilityAdjust the wavelengthSolid-state devicesSemiconductor/solid-state device manufacturingCooking & bakingQuantum dot

The invention discloses a quantum dot LED and a preparation method thereof. The method comprises the steps that a cavity transmission layer is deposited on an anode; a quantum dot luminescent layer is deposited on the cavity transmission layer; an electron transmission layer and an electron injection layer are deposited on the quantum dot luminescent layer successively; a cathode is vapor-plated on the electron injection layer to prepare a QLED device; and a mixture of a thermal expansion material and a packaging glue is added to the periphery of the prepared QLED device drop by drop, a cover sheet is packaged, infrared baking is carried out, and packaging is completed. According to the invention, the packaging glue is mixed with the thermal expansion material, so that the packaging effect can be ensured, heat is conducted out timely, and the stability of the QLED device is enhanced. More importantly, the added thermal expansion material is very sensitive to heat, the thickness of the material can be adjusted according to temperature change, time that light emitted by the QLED device penetrates a thermal expansion material layer can be adjusted, and the wavelength of light penetrating the thermal expansion material layer is adjusted to optimize the color rendering performance.

Owner:TCL CORPORATION

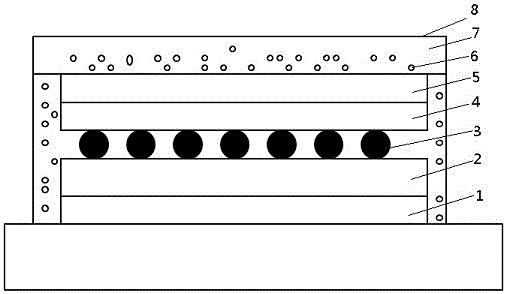

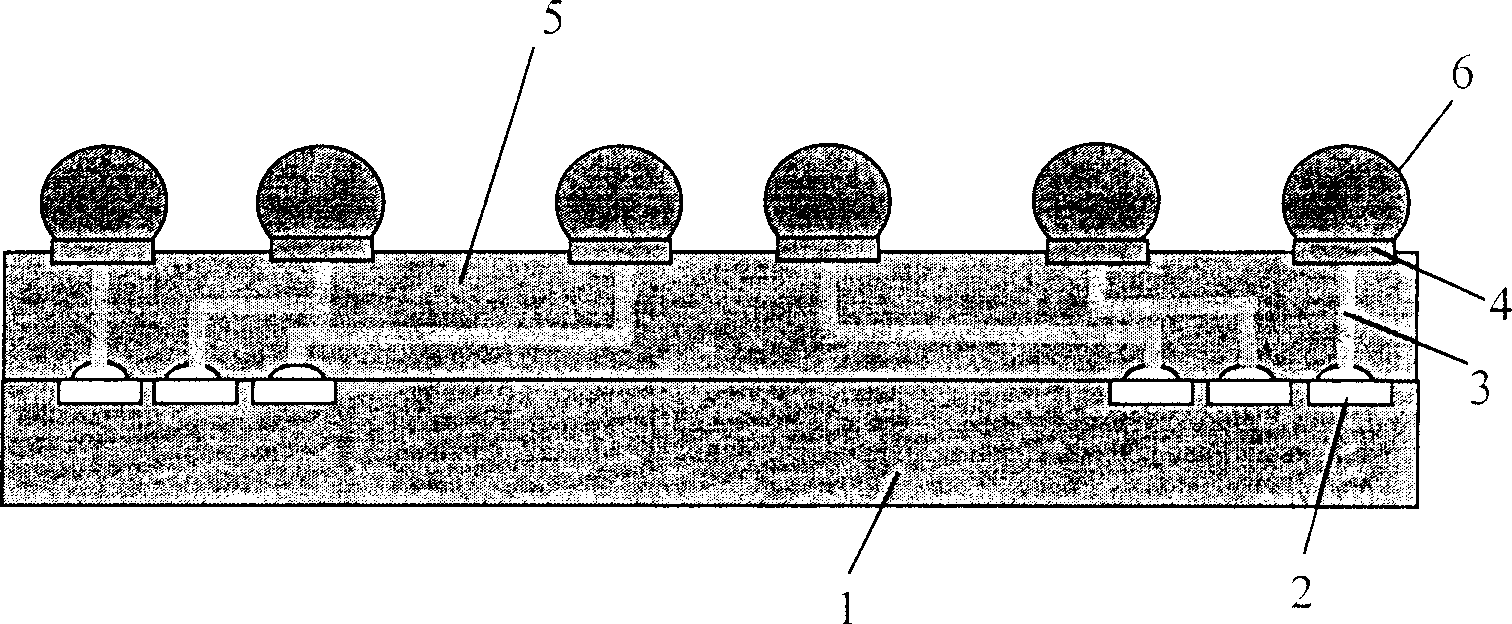

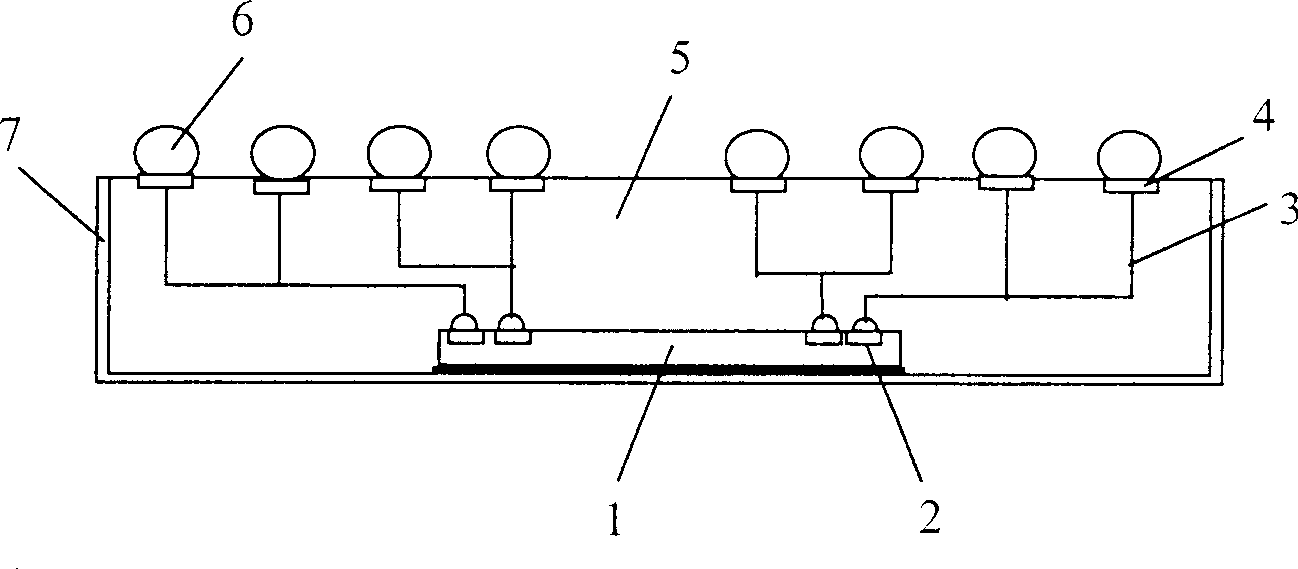

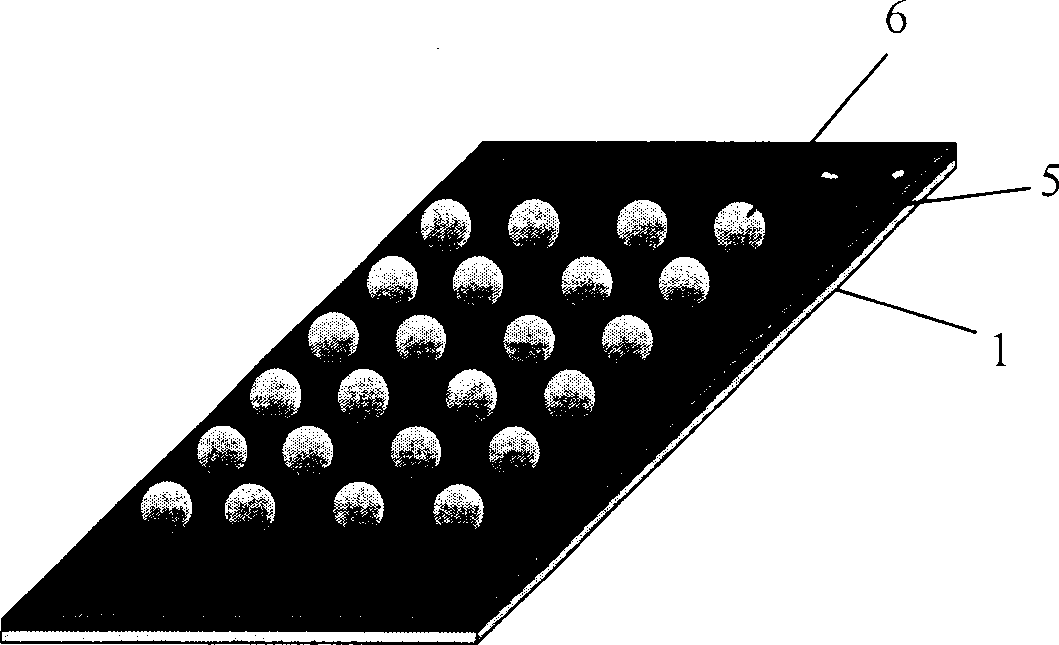

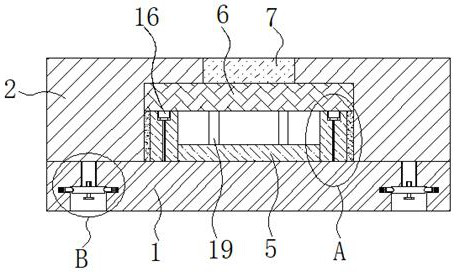

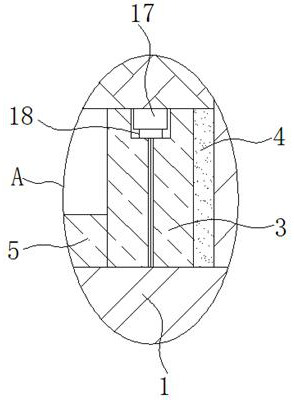

Chip packaging structure

InactiveCN1462070AGuaranteed encapsulation effectReduce packaging costsSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

A package structure without substrate for chip is composed of chip and the weld balls welded onto pads, and features that said weld balls are positioned on the one chip surface where the pads for leading wires are positioned, said pads are connected to the pads for leading wires on chip via metal wires, and the filler is filled between metal wires. Its advantage is low cost caused by omitting substrate.

Owner:ASE ASSEMBLY & TEST SHANGHAI

Evaporation mask plate and display panel

PendingCN111676447AAvoid scratchesGuaranteed encapsulation effectVacuum evaporation coatingSolid-state devicesPhysicsElectrical and Electronics engineering

The embodiment of the invention provides an evaporation mask plate and a display panel, and relates to the technical field of display. The problem that spacers in a to-be-evaporated substrate are scratched by the evaporation mask plate can be solved. The evaporation mask plate is arranged between an evaporation source and the to-be-evaporated substrate; at least one spacer is arranged on one side,close to the evaporation source, of the to-be-evaporated substrate; the evaporation mask plate comprises a mask plate body, wherein the mask plate body comprises a plurality of evaporation openings and shielding parts positioned at the peripheries of the evaporation openings; each shielding part is provided with a first surface far away from the evaporation source; the evaporation mask plate further comprises a plurality of supporting parts, the plurality of supporting parts are arranged on the first surfaces, and at least two supporting parts and the first surfaces form a containing cavity used for containing the spacers; and the supporting parts are used for being in contact with the to-be-evaporated substrate and supporting the mask plate body so that gaps can be formed between the first surfaces and the spacers.

Owner:BOE TECH GRP CO LTD

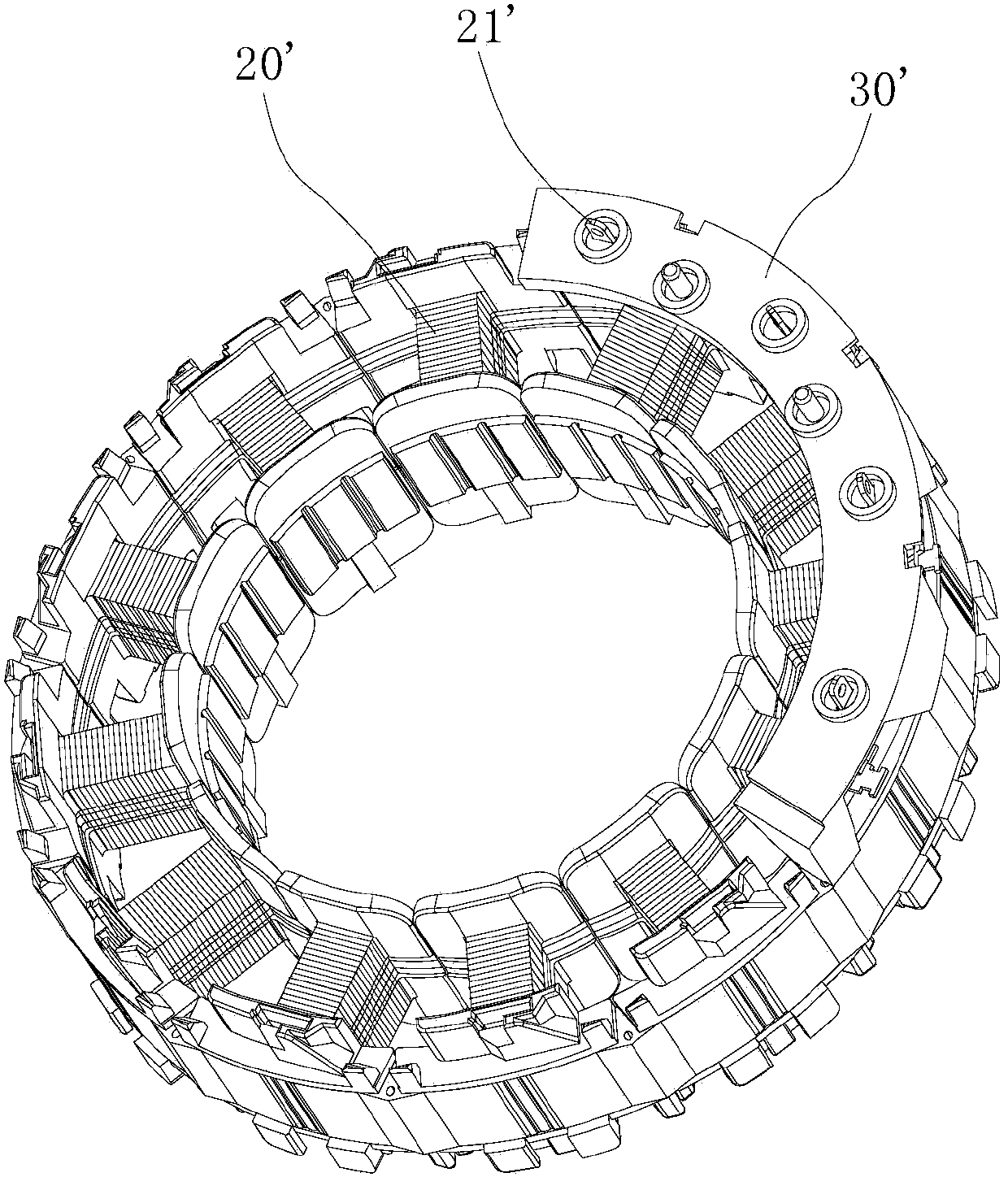

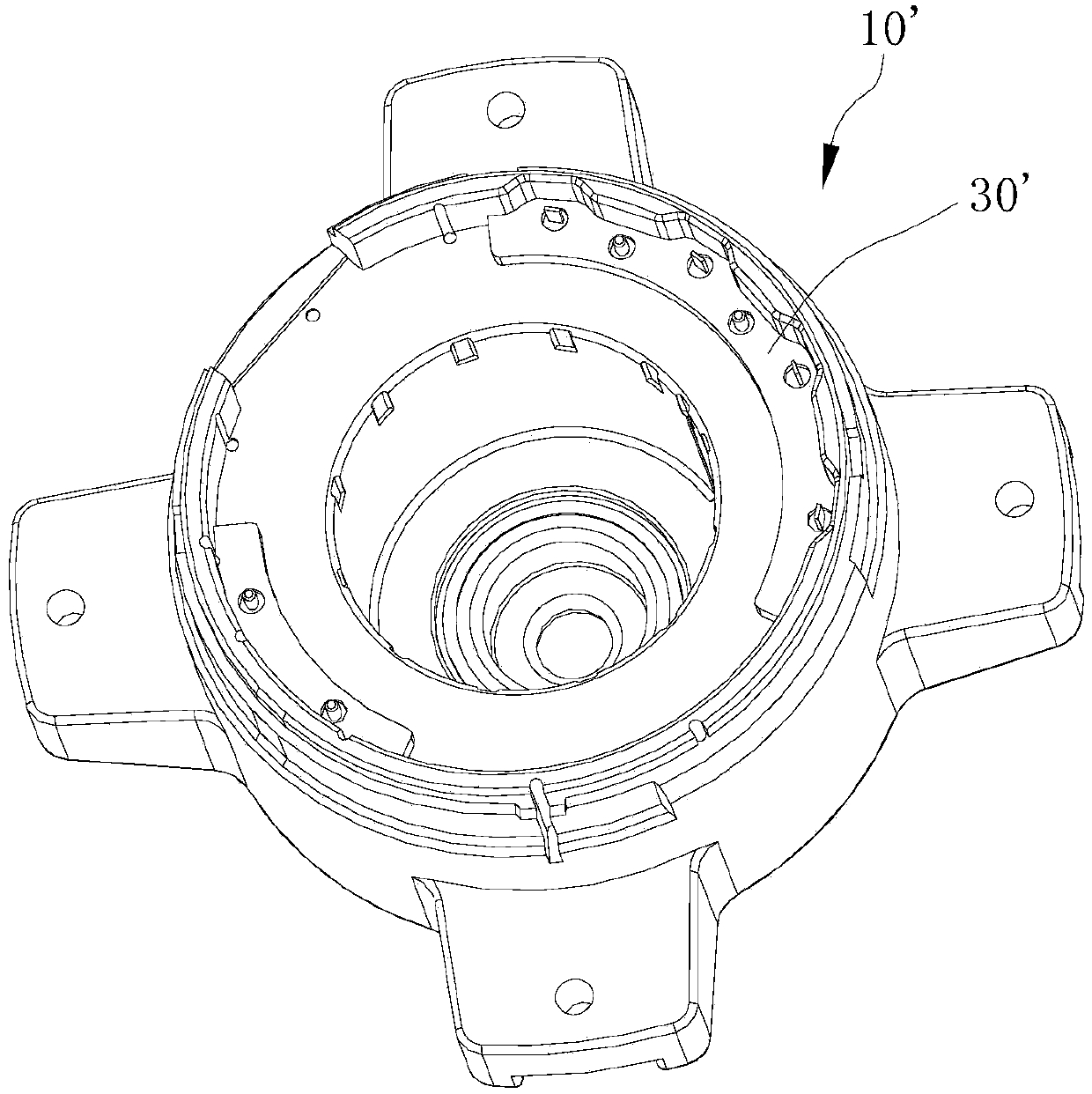

Motor, waterproof structure of motor stator winding and processing technology thereof

ActiveCN103746488AGuaranteed waterproof sealingGuaranteed encapsulation effectWindingsManufacturing dynamo-electric machinesEngineeringConductor Coil

The invention provides a waterproof structure of a motor stator winding. The waterproof structure comprises a packaging plate, a housing and a waterproof layer. The surface of the packaging plate is provided with a jack which is in plug-in cooperation with an electrode needle of a stator winding, and a depression surrounding the jack is provided with a packaging groove for a packaging material packaging the position of the electrode needle and the jack. The housing is packaged by a combined module assembled by a packaging plate and a stator winding, and a waterproof groove for filling the waterproof material is formed on the packaging groove. The waterproof layer is arranged in the waterproof groove. With the arrangement of the packaging groove, it brings convenience for sealing a gap formed by the electrode needle and the jack during packaging processing. Meanwhile, it is also beneficial to form the waterproof groove so as to fill the waterproof material and further guarantee waterproof sealing performance of the stator winding. The invention also provides a processing technology of the waterproof structure of the motor stator winding and a motor having the structure.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Photoelectric sensor packaging structure

InactiveCN112531032AGuaranteed tightnessFor quick maintenanceSemiconductor devicesEngineeringMechanical engineering

The invention relates to the technical field of sensor packaging, and discloses a photoelectric sensor packaging structure. The structure comprises a substrate and a packaging plate, the upper surfaceof the substrate is attached to the lower surface of the packaging plate, a frame body is fixedly connected to the upper surface of the substrate, a groove corresponding to the frame body is formed in the lower surface of the packaging plate, the frame body and the groove are arranged in a clamped mode, ,a matched sealing strip is installed at the joint of the frame body and the groove, a matchedcontrol processing chip is arranged in the frame body and electrically connected with the substrate, a matched photoelectric sensor chip is arranged at the groove bottom of the groove, the lower surface of the photoelectric sensor chip is attached to the top of the frame body, an opening is formed in the groove bottom of the groove and matched glass is fixedly mounted in the opening. According tothe invention, the packaging effect of the photoelectric sensor can be effectively ensured, the packaged photoelectric sensor can be conveniently maintained as required, and the maintenance efficiency is effectively ensured.

Owner:西安远讯光电科技有限公司

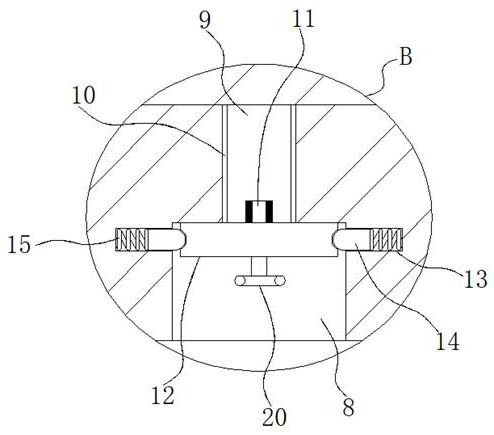

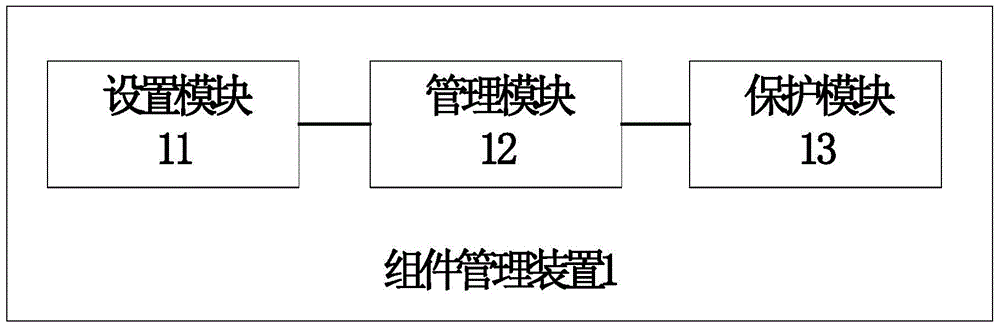

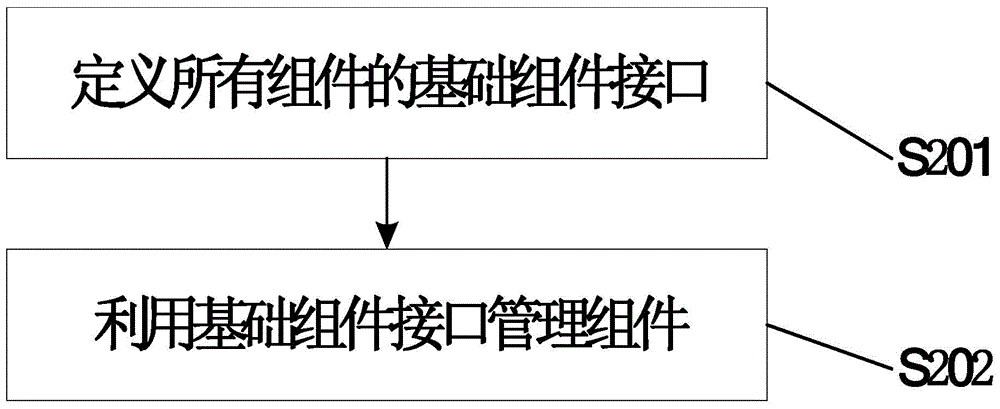

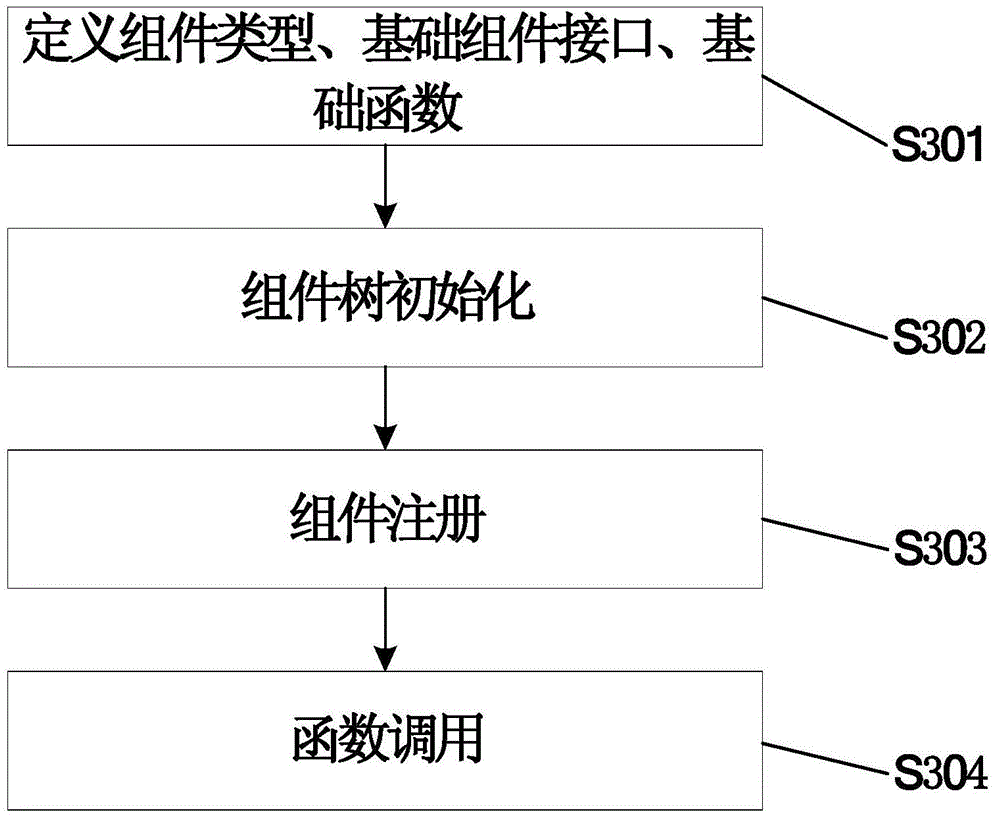

Component managing method and device

InactiveCN106293680AGuaranteed maintenanceGuaranteed encapsulation effectSpecific program execution arrangementsComputer scienceInternal function

The invention provides a component managing method and device so as to improve encapsulation of components. The component managing method comprises the following steps of defining basic component interfaces of all the components; and utilizing the basic component interfaces to manage the components. By implementing the embodiment of the invention, the unified basic component interfaces are supplied to uniformly manage register / calling and the like of component elements in different types in the components, when a member function defined in a target interface is used across the components, whether the component in which the function is located is loaded does not need to be concerned, and normal maintenance of a device code can be ensured; and modification of an internal function of each component is finished in each component, definition to a component external interface and calling of functions among the components are not influenced when no change occurs on inputting and outputting parameters, and therefore, the encapsulation of internal change in a single component is ensured.

Owner:ZTE CORP

Display panel and display device

ActiveCN111063824AEasy to peelNot easy to peel offSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

The invention provides a display panel. The display panel comprises a functional device layer, a thin film packaging layer which is positioned on one side of the functional device layer, a protectivefilm which is positioned on one side, far away from the functional device layer, of the thin film packaging layer, and a viscosity reduction layer which is positioned between the thin film packaging layer and the protective film, covers the edge of the thin film packaging layer and is used for reducing the viscosity between the edge of the thin film packaging layer and the protective film. According to the display panel provided by the embodiment of the invention, the viscosity reduction layer is arranged at the edge of the thin film packaging layer, so that the viscosity between the edge of the thin film packaging layer and the protective film is reduced. The viscosity between the edge of the thin film packaging layer and the protective film is reduced, so that the edge of the thin film packaging layer with the weakest adhesive force is not easy to peel off from the functional device layer, and the thin film packaging layer is not easy to peel off when the protective film is removed.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

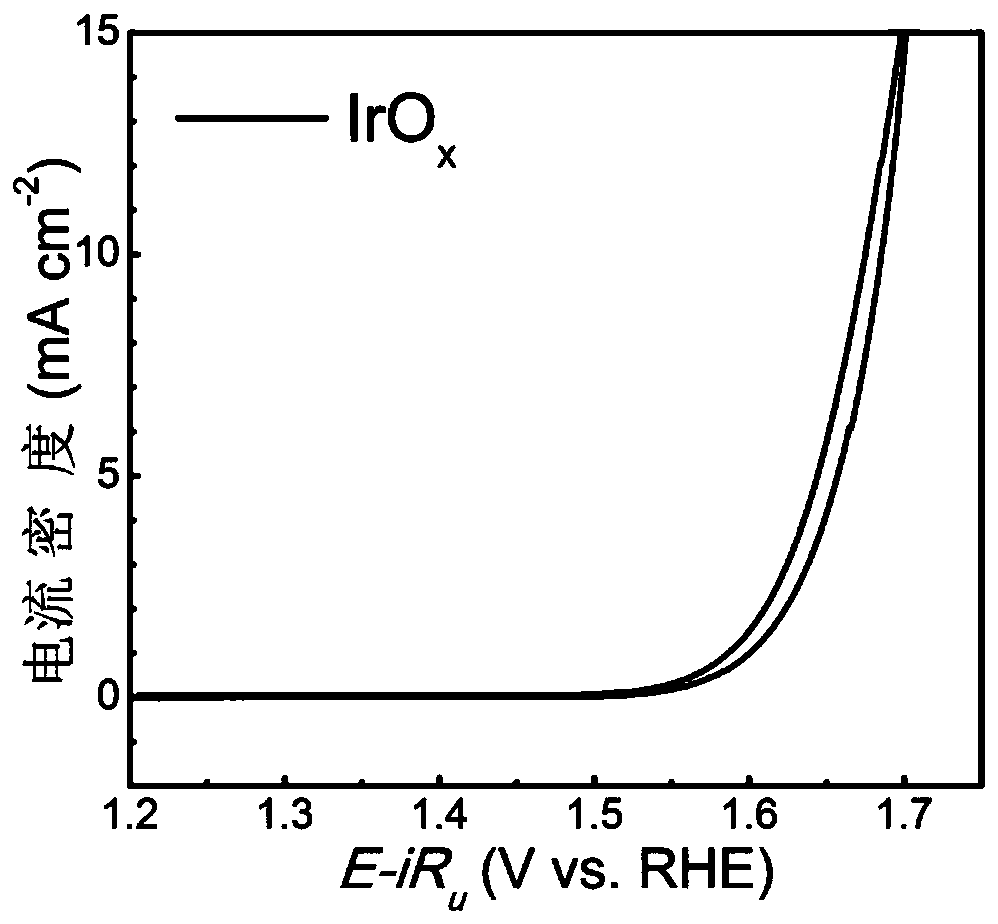

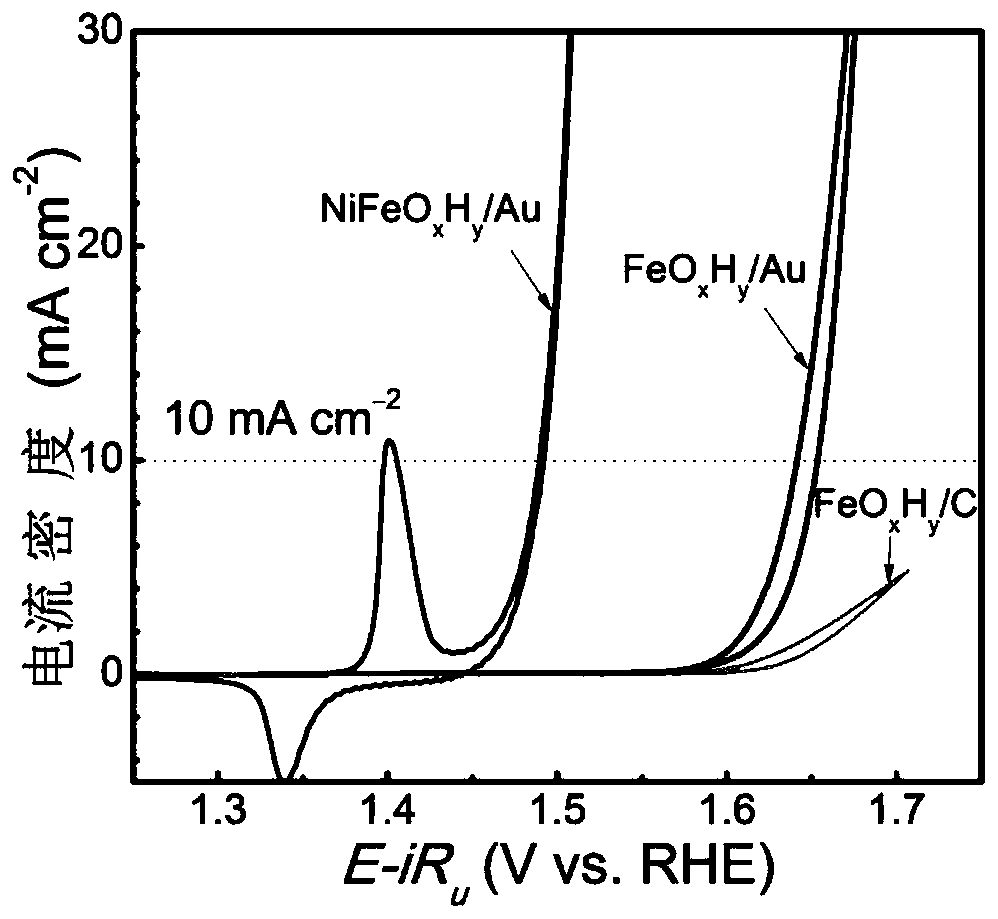

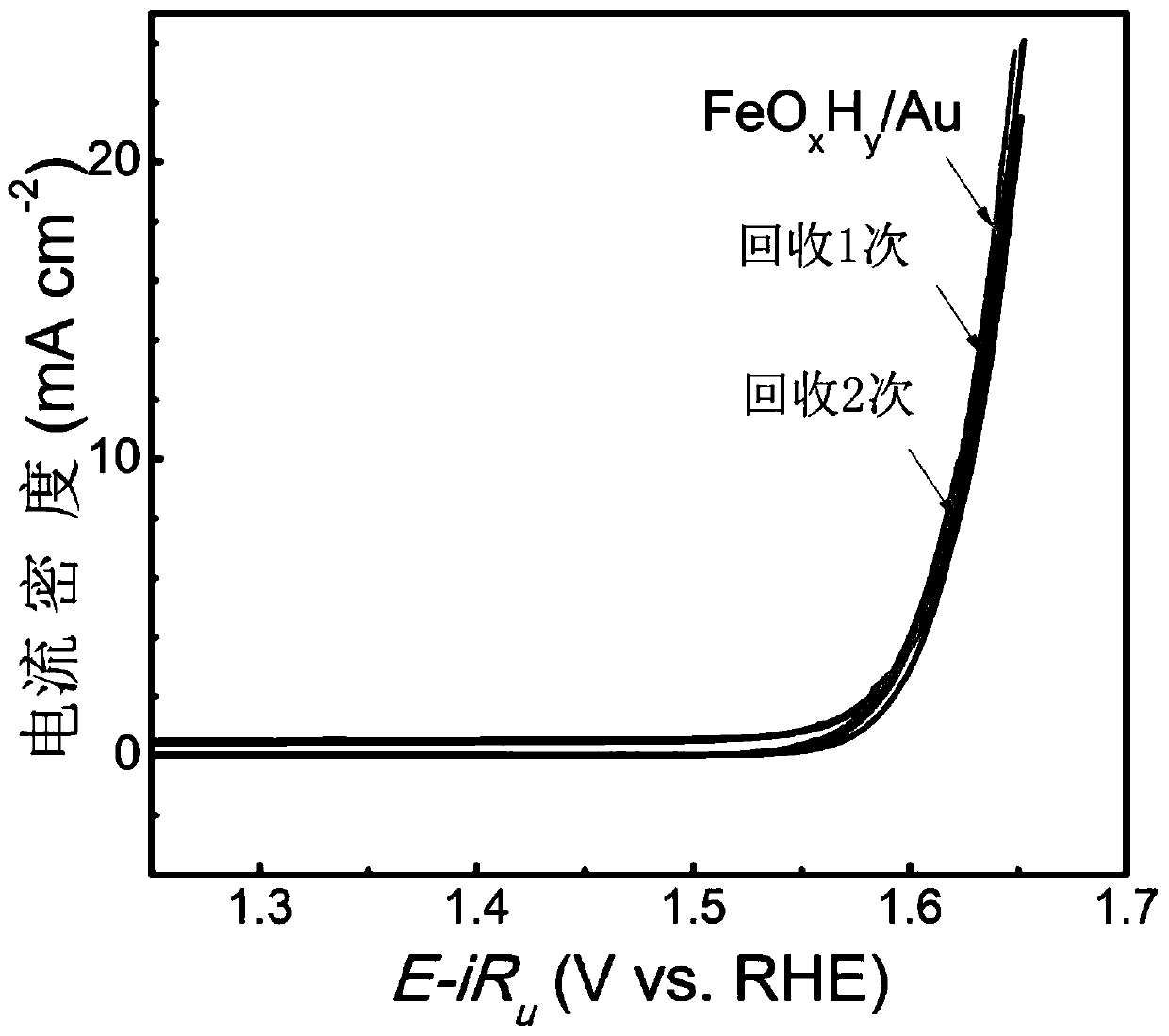

Recyclable electrocatalytic electrode, preparation method and recovery method

InactiveCN110318067AImprove stabilityAccelerated corrosionCell electrodesChemical recyclingRecovery methodHot-melt adhesive

The invention relates to a recyclable electrocatalytic electrode, a preparation method and a recovery method. The electrode comprises a conductive substrate, a wire, and an electrocatalyst layer formed on at least part of the surface of the substrate. The conductive substrate is connected with the wire through a conductive adhesive, the electrode is packaged through a resin or a resin composition,the package encapsulates the conductive substrate and the connecting point of the conductive substrate and the wire and only makes the electrocatalyst layer on the surface of the conductive substrateexposed in the environment, and the resin or the resin composition comprises a hot-melt adhesive component.

Owner:TSINGHUA UNIV

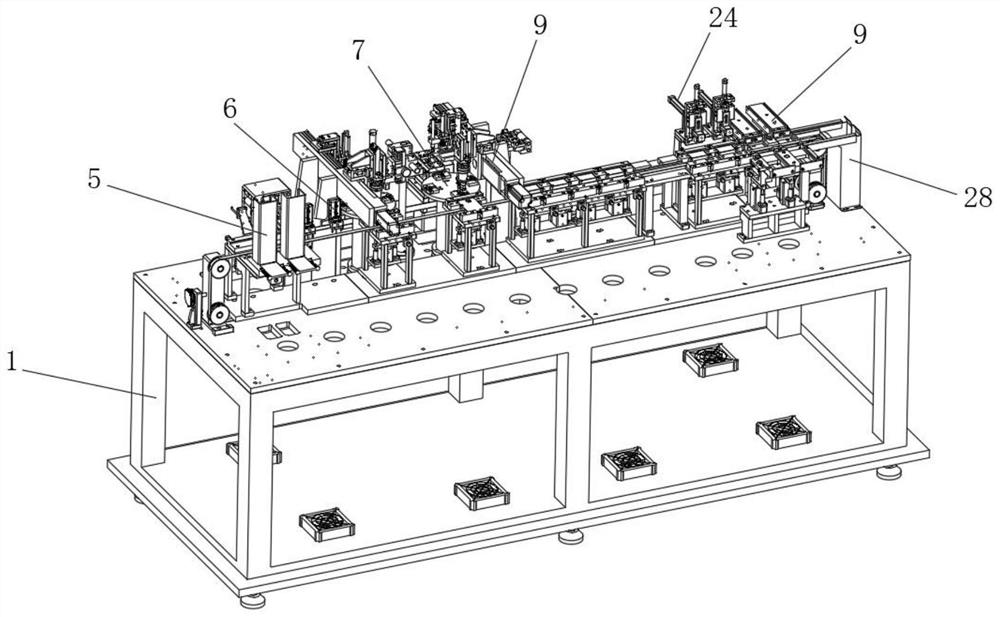

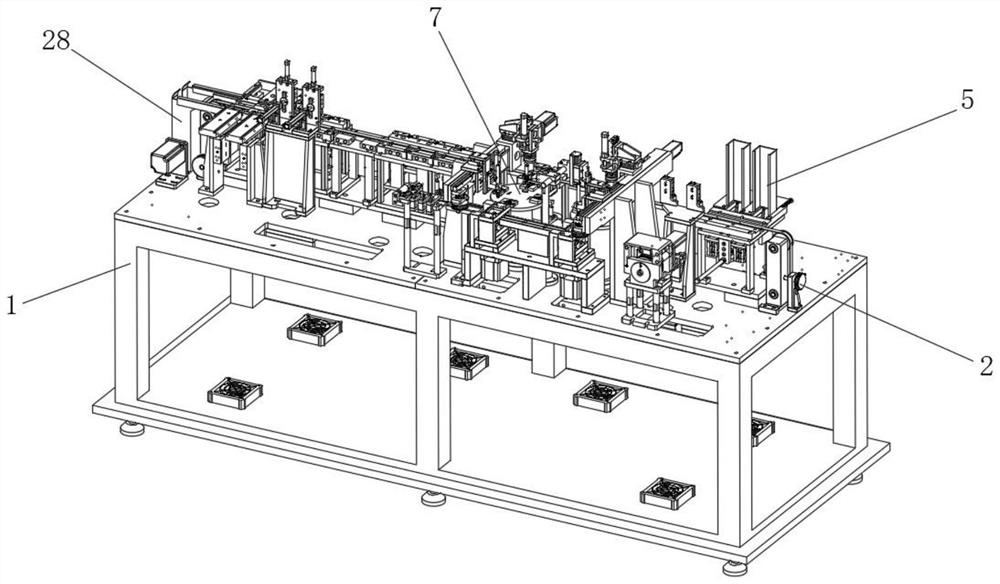

Direct-current direct-drive type driving chip with multiple packaging forms and packaging device and method

PendingCN113725193AHigh Efficiency Chip PackagingSolve balance problemsSemiconductor/solid-state device detailsSolid-state devicesAssembly lineStructural engineering

The invention relates to the technical field of chip packaging, and discloses a direct-current direct-drive type driving chip with multiple packaging forms and a packaging device and method. Stable and ordered blanking is completed through a simple mechanical structure by arranging an electric telescopic rod and the like, rapid heat fusion packaging is achieved by adopting a fluorescence labeling mode in cooperation with a hot melting gun, different chip packaging shells can be selected in a self-adaptive manner while precise packaging is realized, and the packaging efficiency is improved. Two clamping blocks at the corresponding positions are driven to rotate with the corresponding rotating shafts as the axes through the arrangement of clamping air cylinders and the like, then the clamping blocks on the two sides clamp the two sides of a to-be-packaged chip, the packaging stability is further improved, the displacement influence on the to-be-packaged chip caused by the operation of a conveying belt is avoided, a pushing plate pushes the corresponding to-be-packaged chip into a defective product groove through the operation of a material returning air cylinder, defective product collection is completed, and the packaging effect of an assembly line is ensured.

Owner:深圳市谦诚半导体技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com