Display panel and display device

A display panel and display device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the brightness and contrast of the display device, low light injection efficiency, etc., to ensure the packaging effect, improve the light import efficiency, and avoid absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

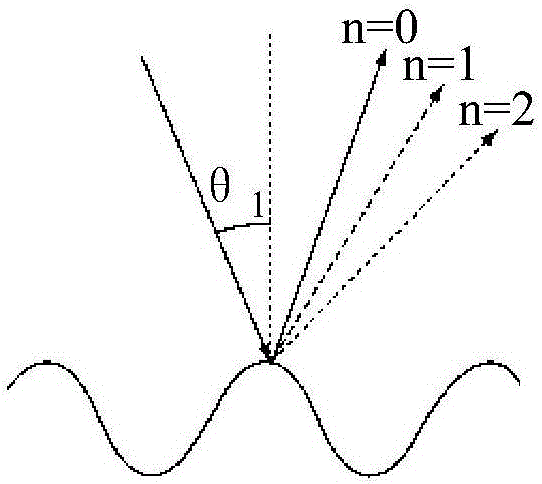

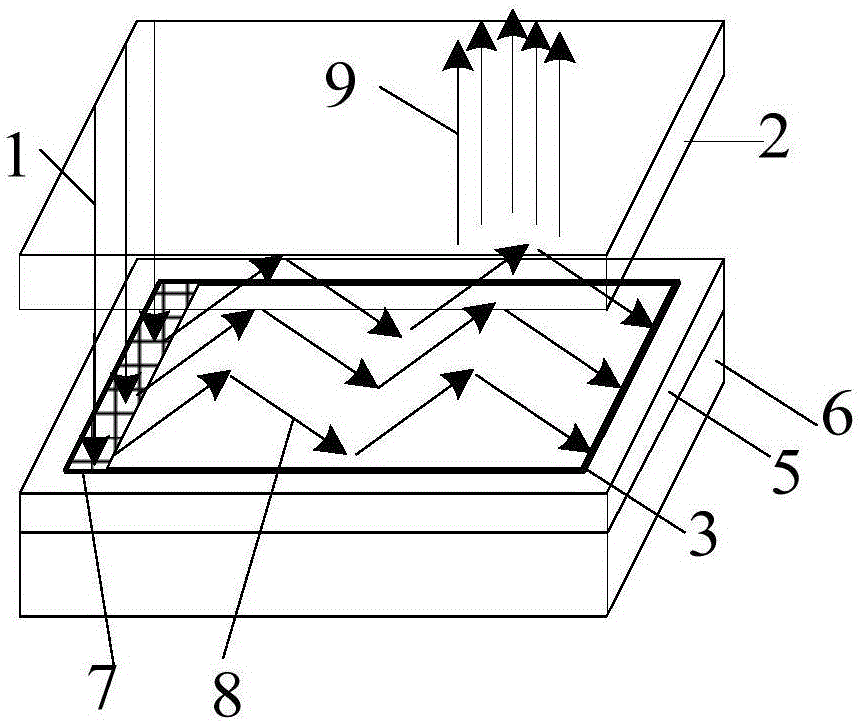

[0029] This embodiment provides a display panel, including a first substrate and a second substrate oppositely arranged, a liquid crystal cell located between the first substrate and the second substrate, and a liquid crystal cell for bonding the first substrate and the second substrate. A frame sealant, the surface of the first substrate facing the second substrate is provided with a light reflection structure, and the light reflection structure can reflect the light incident into the display panel from the second substrate side, so that The incident light is totally reflected multiple times in the display panel.

[0030] In this embodiment, the light source is arranged on the outside of one of the substrates of the display panel, and the light incident from the light source into the display panel is reflected by a light reflection structure, so that the incident light is totally reflected multiple times in the display panel, along the The direction parallel to the substrates...

Embodiment 2

[0040] This embodiment provides a display device, which includes the above-mentioned display panel, and also includes a light source arranged on the surface of the second substrate facing away from the first substrate, and the light reflection structure faces the The light output side of the light source.

[0041] In this embodiment, the light source is arranged on the outside of one of the substrates of the display panel, and the light incident from the light source into the display panel is reflected by a light reflection structure, so that the incident light is totally reflected multiple times in the display panel, along the The direction parallel to the substrates propagates within the display panel. Because the light source of the present invention is arranged outside the display panel, it can ensure the encapsulation effect of the liquid crystal cell; in addition, because the light source is not arranged on the side of the display panel, it can avoid the absorption of in...

Embodiment 3

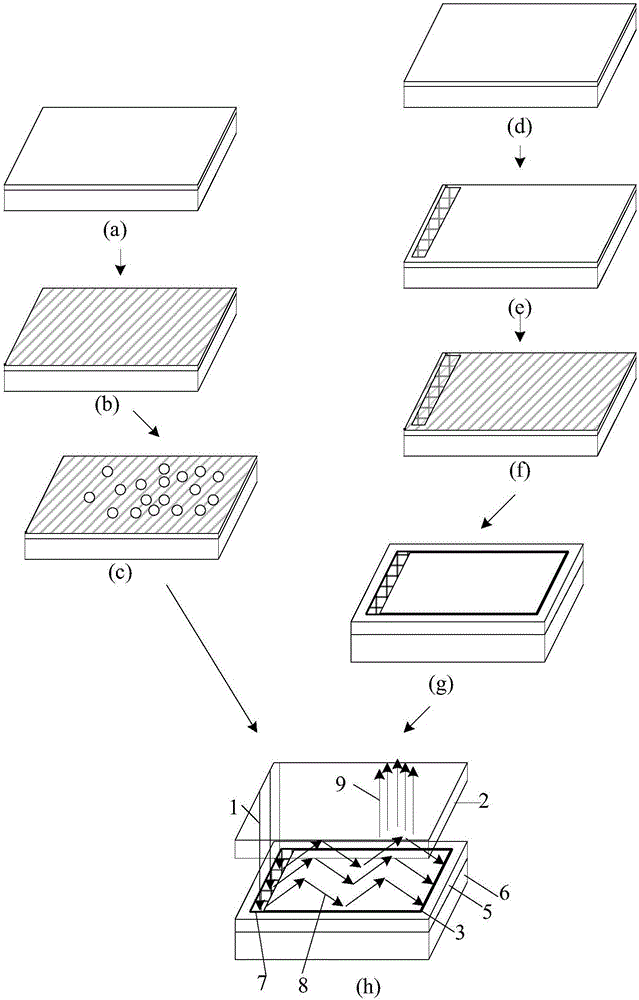

[0046] This embodiment provides a method for manufacturing a display panel, such as image 3 As shown, this embodiment specifically includes:

[0047] Step a: provide a second substrate 2, the second substrate 2 can be a quartz substrate or a glass substrate, the second substrate 2 is cleaned, and then an ITO layer is sputtered on the second substrate 2, and the thickness of the ITO layer can be 180- 220nm, pattern the ITO layer to form a common electrode;

[0048] Step b: performing PI film coating and orientation on the second substrate 2 formed with the common electrode;

[0049] Specifically, polyimide (PI) is coated on the side where the common electrode is formed on the second substrate 2, which can be put into a liquid crystal substrate spin coater for spin coating, and the rotation speed is set to 2500 rotations for 120s; The coated second substrate 2 is placed in a glass container, then placed in an oven, dried and preheated for 30 minutes at 80°C, and then baked fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com