OLED (organic light emitting diode) display substrate, manufacture method thereof and display device

A technology for display substrates and manufacturing methods, applied in the fields of final product manufacturing, sustainable manufacturing/processing, photovoltaic power generation, etc., can solve the problems of removing pixel defining layer materials and affecting the packaging effect of organic light-emitting display performance, etc., to achieve guaranteed performance, Guarantee the effect of encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

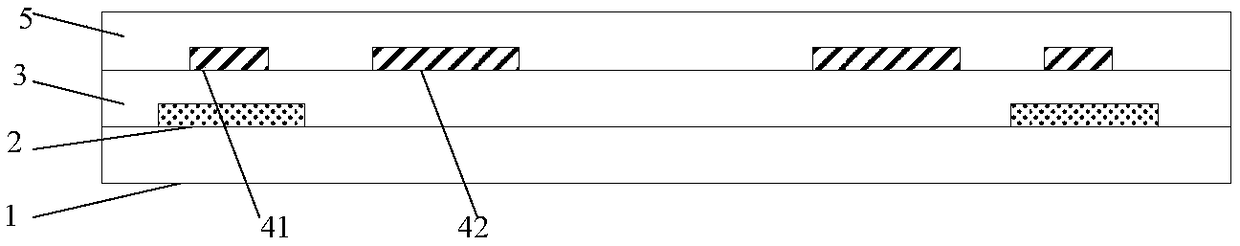

[0089] Such as Figure 1-Figure 11 As shown, the manufacturing method of the OLED display substrate of this embodiment includes the following steps:

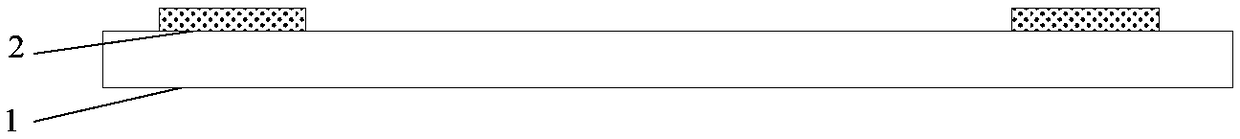

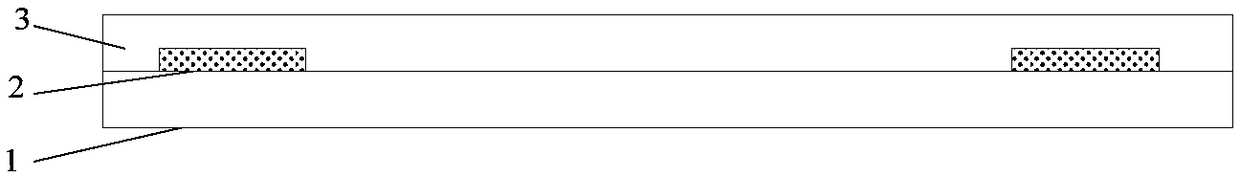

[0090] Step 1, such as figure 1 As shown, a base substrate 1 is provided, and an active layer 2 of a thin film transistor is formed on the base substrate 1;

[0091] Wherein, the base substrate 1 can be a rigid substrate or a flexible substrate, the rigid substrate includes a glass substrate and a quartz substrate, and the flexible substrate includes a PI (polyimide) substrate.

[0092] Specifically, a layer of semiconductor material is deposited on the base substrate 1, a layer of photoresist is coated on the semiconductor material, and a mask is used to expose the photoresist to form photoresist unretained regions and The photoresist completely reserved area, wherein, the photoresist completely reserved area corresponds to the area where the pattern of the active layer 2 is located, and the photoresist unreserved area corres...

Embodiment 2

[0120] The manufacturing method of the OLED display substrate of this embodiment includes the following steps:

[0121] Step 1. Provide a base substrate, and form a reflective pattern on the base substrate;

[0122] Wherein, the base substrate may be a rigid substrate or a flexible substrate, the rigid substrate includes a glass substrate and a quartz substrate, and the flexible substrate includes a PI (polyimide) substrate.

[0123] Specifically, sputtering or thermal evaporation can be used to deposit a thickness of about The metal layer, the metal layer can be Cu, Al, Ag, Mo, Cr, Nd, Ni, Mn, Ti, Ta, W and other metals and alloys of these metals, the metal layer can be a single-layer structure or a multi-layer structure, many Layer structure such as Cu\Mo, Ti\Al\Ti, Mo\Al\Mo, etc. A layer of photoresist is coated on the metal layer, and a mask is used to expose the photoresist, so that the photoresist forms a photoresist unreserved area and a photoresist reserved area, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com