Recyclable electrocatalytic electrode, preparation method and recovery method

A technology of electrocatalysis and electrocatalysis, which is applied in the field of electrochemistry, can solve the problems of unstable electrodes, insufficient performance, poor reuse of conductive substrates, etc., and achieve the effects of reducing production costs, improving stability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] The preparation method of the present invention at least comprises the following steps:

[0102] a step of connecting a wire to a conductive substrate, the wire being connected to the conductive substrate through a conductive adhesive;

[0103] the step of depositing an electrocatalyst layer, depositing an electrocatalyst on at least part of the surface of the conductive substrate;

[0104] In the encapsulation step, the conductive substrate, the conductive substrate and the connection point of the conductive substrate are encapsulated by a resin or a resin composition, and only the electrocatalyst layer on the surface of the conductive substrate is exposed to the environment.

[0105] Steps for Connecting Wires to Conductive Substrates

[0106] In the present invention, the connection between the wire and the conductive substrate can be realized by the aforementioned conductive adhesive. Specific ways that can be enumerated include:

[0107] At least a part of one...

Embodiment approach

[0127] The invention provides a method for preparing and recovering an electrocatalytic electrode that can be recycled. In a typical embodiment of the invention, it includes the following steps:

[0128] Step 1) using a surface deposition method to deposit an electrocatalyst layer on a conductive substrate;

[0129] Step 2) Using a conductive adhesive to connect the conductive substrate to the metal wire, encapsulating the conductive substrate with molten hot melt adhesive, exposing the surface of the substrate with a certain area, and making a working electrode;

[0130] The operation sequence of step 1) and step 2) can be interchanged.

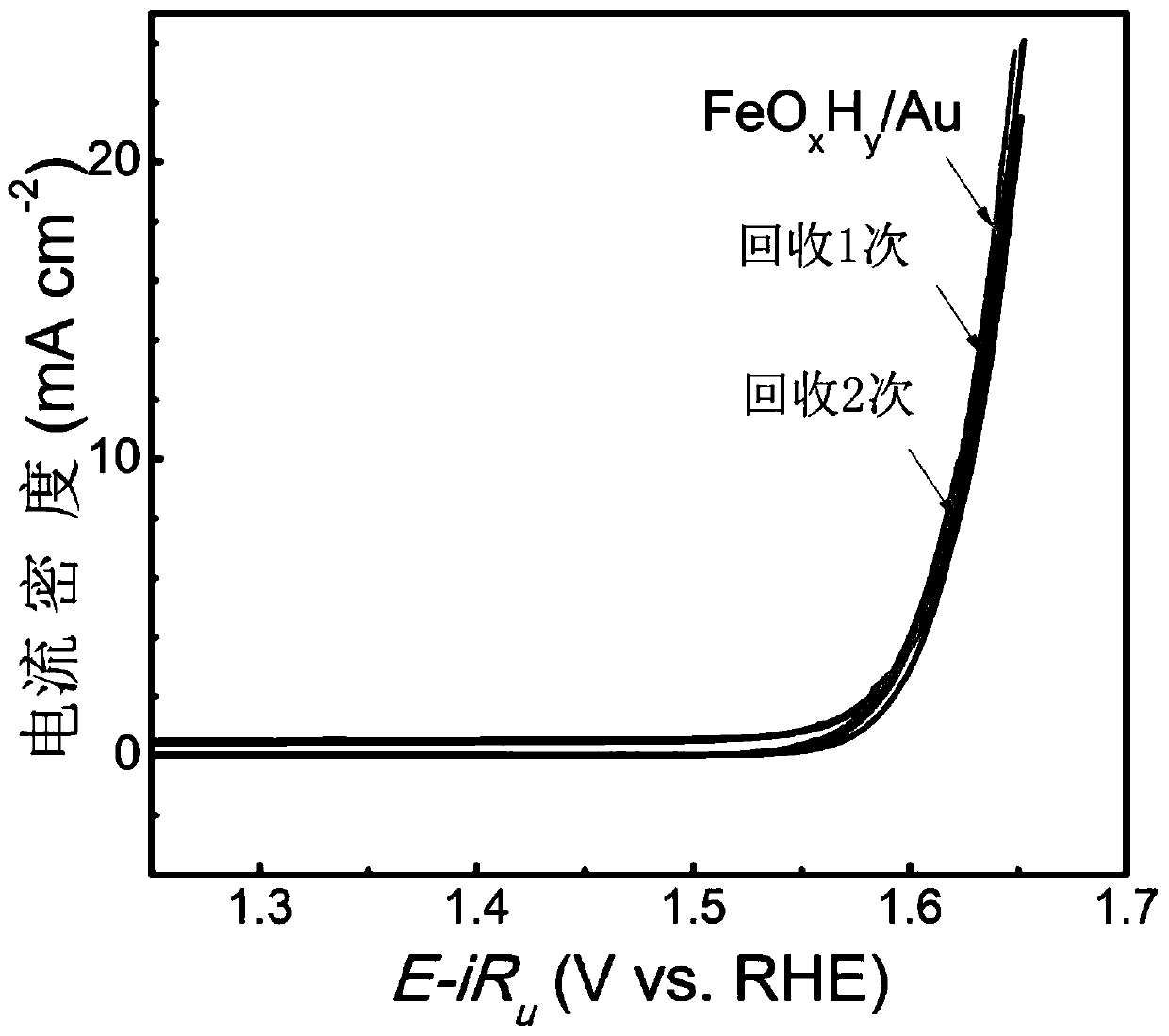

[0131] Methods for recycling electrocatalytic electrodes include

[0132] After the electrode is soaked in an organic solvent (a mixture of methanol, ethanol and isopropanol in any proportion), remove the hot-melt adhesive package and remove the connecting wire;

[0133] Put the conductive substrate into the H 2 SO 4 Solution, acetone, i...

Embodiment

[0143] Reference examples and working examples of the present invention are described below.

[0144] Reference example

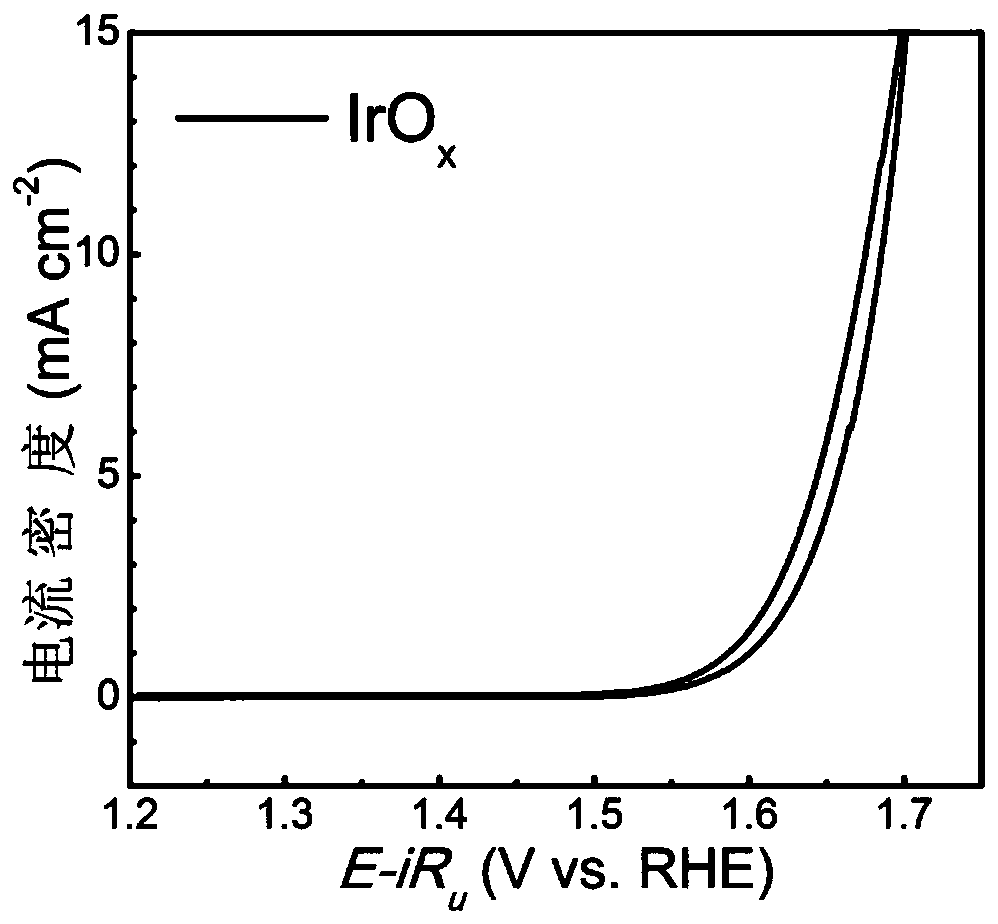

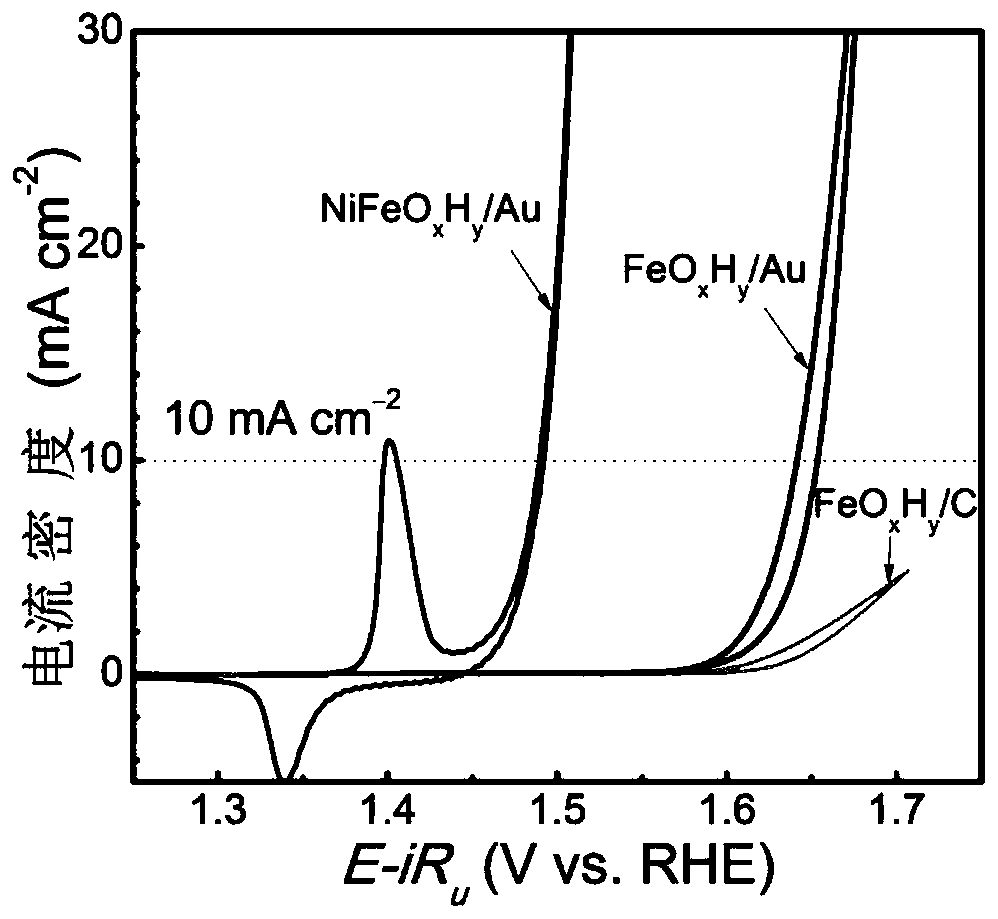

[0145] Noble metal oxide IrO x Preparation of Powder Dispersion Electrode

[0146] (a) Quartz glass slices with a size of 10×10×1 mm were cut out, cleaned ultrasonically with acetone, isopropanol and ultrapure water (18.2 MΩcm) for 30 min, and then cleaned with N 2 After drying, a 10 nm metal Ti layer was sputtered in a magnetron sputtering vacuum chamber, followed by a 100 nm thick metal Au layer to make an Au conductive substrate.

[0147] (b) Weigh 2.5mg IrO x The electrocatalyst powder sample was transferred to a 2mL glass bottle, and 970μL of isopropanol, 20μL of ultrapure water and 10μL of 5% Nafion solution were added to prepare 1mL of IrO-containing x After ultrasonic treatment for 0.5 h, measure 40 μL of the dispersion and evenly drop it onto the Au conductive substrate in step (a). After drying at room temperature for 10 minutes, use molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com