Mask for encapsulation of organic light emitting diode (OLED) thin film

A thin-film packaging and masking technology, applied in the field of masking, can solve the problems of tearing and cracking, a large number of particles, affecting the effect of thin-film packaging, etc., and achieve the effect of guaranteeing the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention aims at the existing OLED thin-film packaging mask, and solves the problem of the prior art OLED thin-film packaging mask, the generation of continuous thin film at the substrate, the mask and the junction of the two, and the rising process of the mask. It is easy to tear and break in the film, thus causing a large number of particles to be generated, and then causing the technical problem of the failure of the thin film package. The embodiment of the present invention can solve this defect.

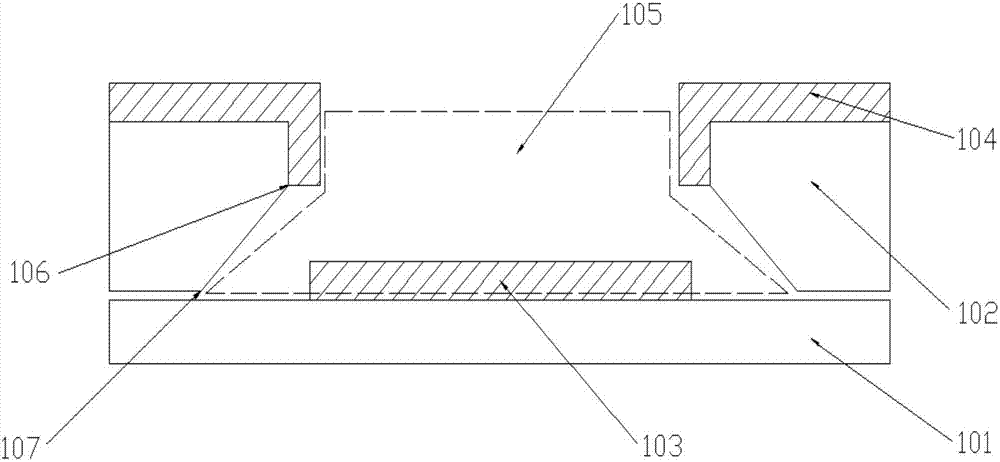

[0028] Such as figure 1 As shown, the sectional view of the mask plate for OLED thin film encapsulation provided by Embodiment 1 of the present invention, the mask plate for OLED thin film encapsulation provided by the present invention includes: a hollowed out portion, and the hollowed out portion includes a The opening 105 of the layer 103; the cover part 102, the cover part 102 is used to cover the non-thin-film encapsulation area of the substrate 101, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com