Display panel preparation method, display panel and display device

A technology for display panels and display areas, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. The effect of improving the display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

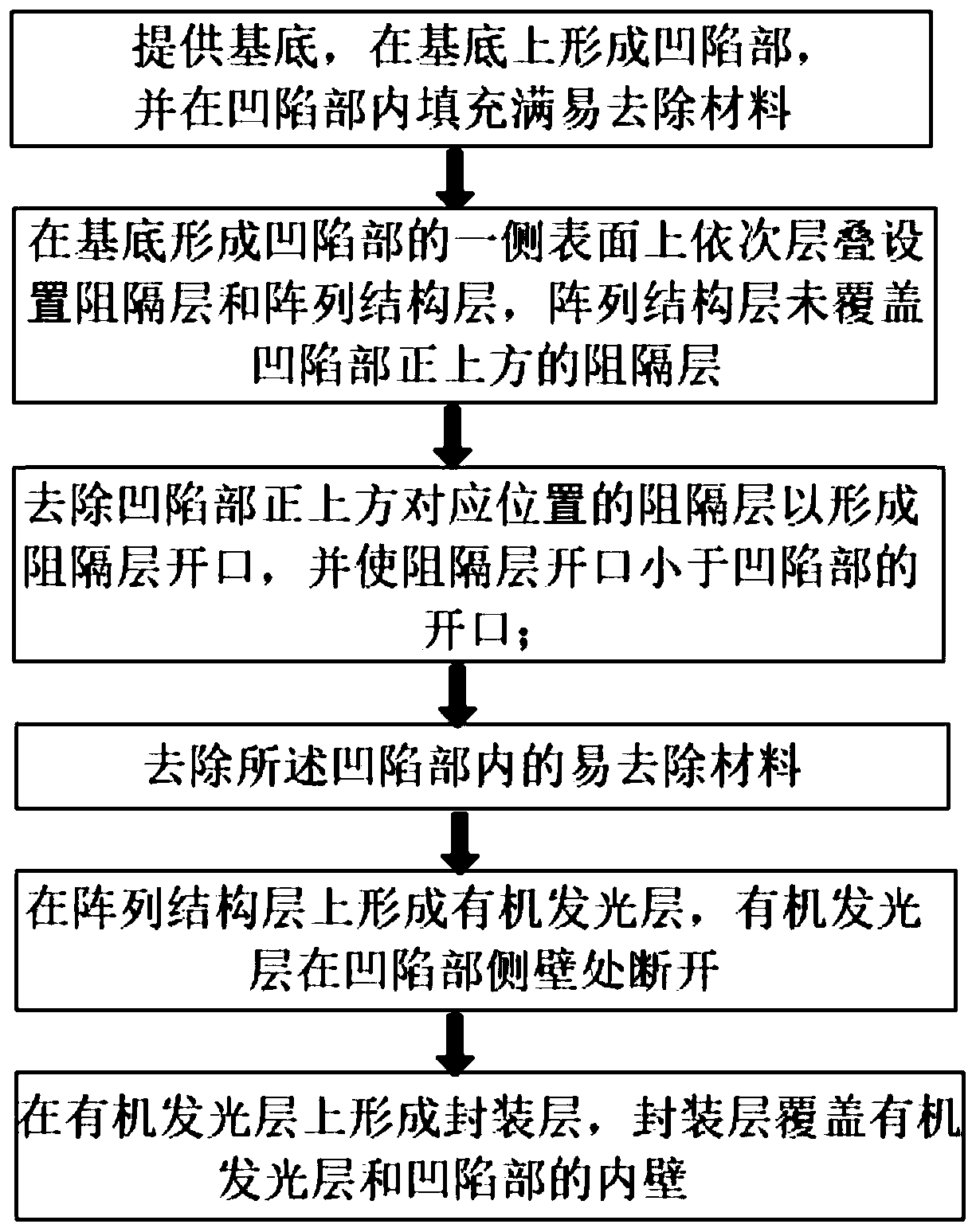

Method used

Image

Examples

Embodiment

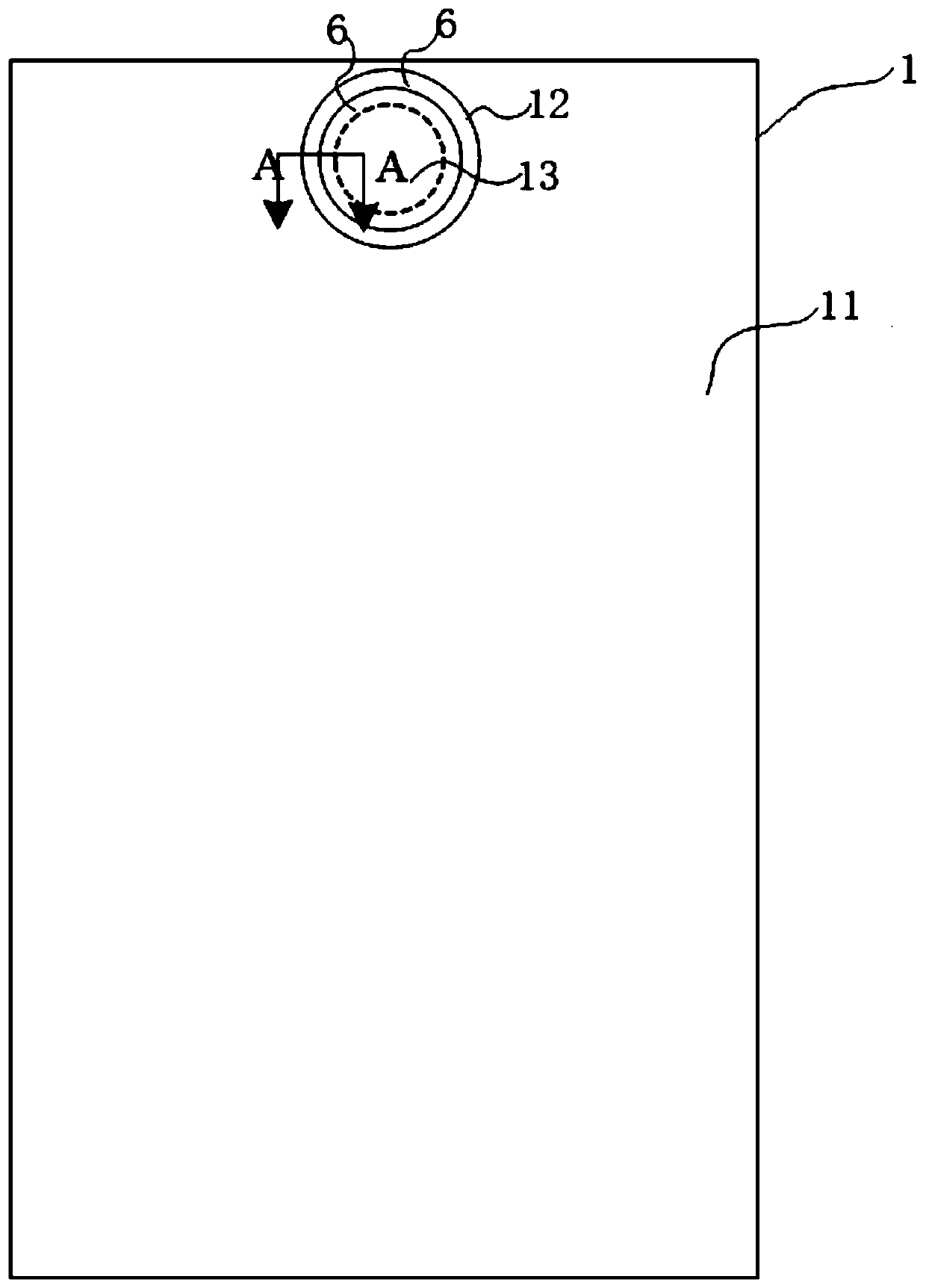

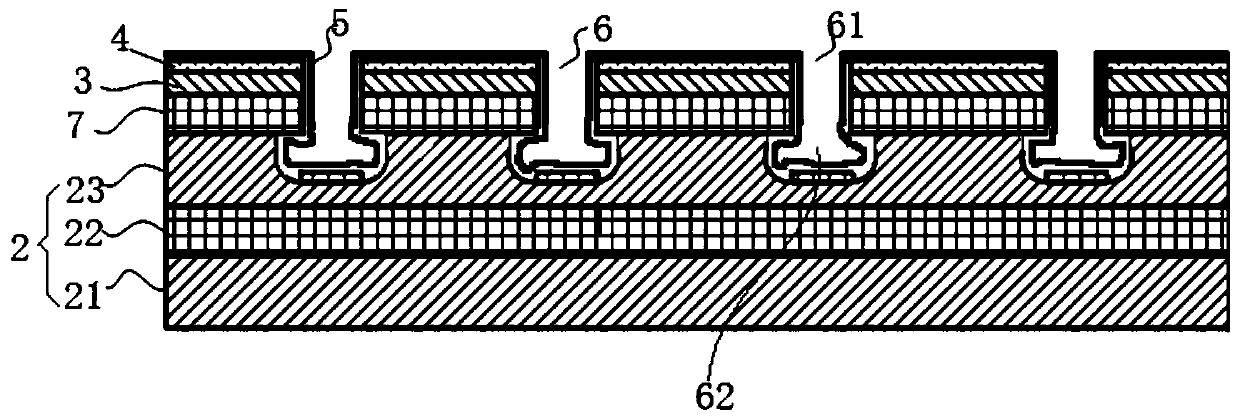

[0040] The present invention provides a display device, wherein the display device can be a television, a mobile phone, a tablet, a computer, a camera, etc.; the display device includes a display panel 1 . The display panel 1 of this embodiment includes a substrate 2, an array structure layer 3, an organic light-emitting layer 4, and an encapsulation structure 5 that are sequentially stacked. figure 2 As shown, the display panel 1 includes a display area 11, a spacer area 12 and a non-display area 13, the spacer area 12 separates the display area 11 and the non-display area 13, and the spacer area 12 is provided with several Partition grooves 6 arranged at intervals.

[0041] Wherein the non-display area 13 in this embodiment is an open area, and an opening is provided therein, and the opening is used for placing a camera, a sensor and / or an earpiece. The opening in this embodiment is a round hole, so the partition groove 6 is a plurality of concentric circles with different...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com