Device for detecting sealing performance of silica gel for packaging solar modules

A solar cell and sealing performance technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of vulcanized rubber thickness limitation, etc., to ensure the service life and ensure the packaging effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

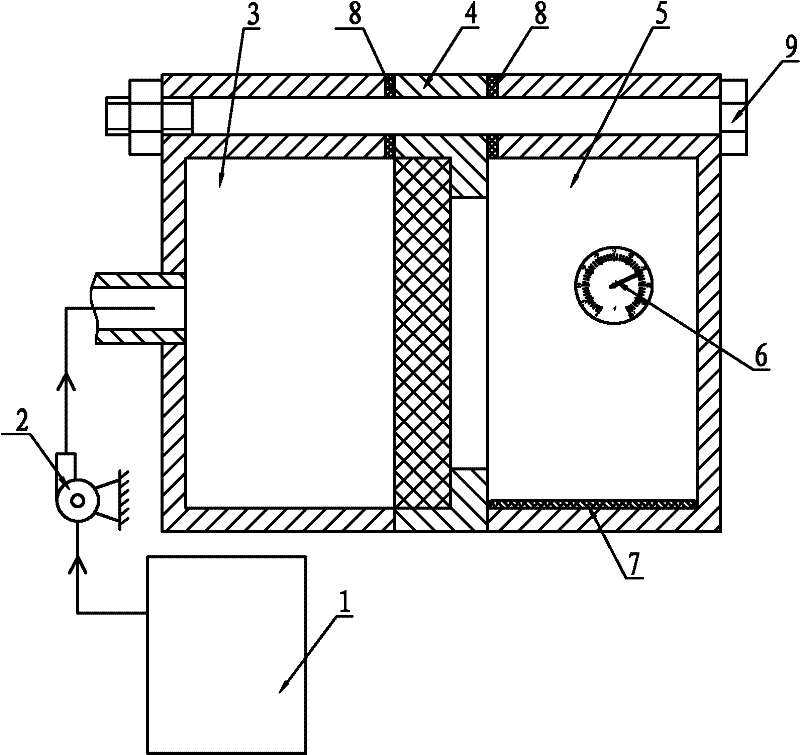

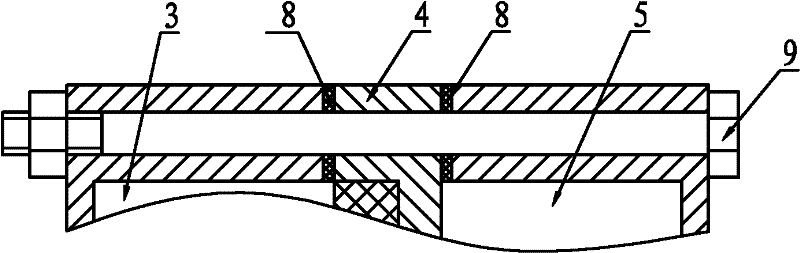

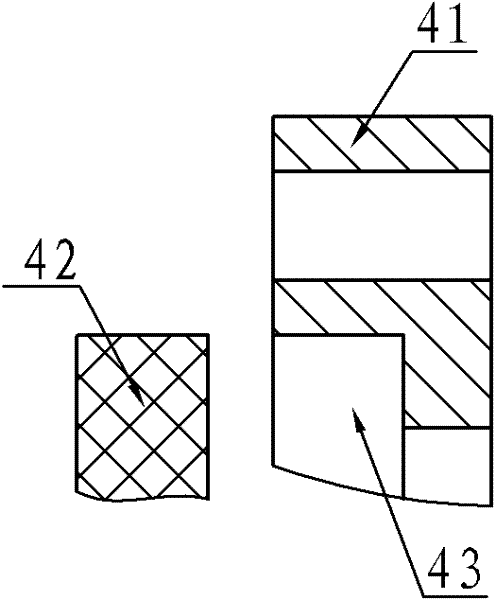

[0020] A sealing performance detection device for silica gel used in solar cell module packaging, such as figure 1 , figure 2 , image 3 As shown, it includes test gas storage tank 1, circulating pressure pump 2, pressure gas chamber 3, adhesive layer test frame 4, airtight test chamber 5, hygrometer 6, dust-carrying plate 7, end face gasket 8 and fasteners 9 , the pressure air chamber 3 is a box body with openings at both ends of the surrounding airtight; the adhesive layer test frame 4 is composed of a frame 41 and a cured adhesive layer plate 42, and is provided in the frame 41 to facilitate sizing to form a cured adhesive layer. The notch 43 of the plate 42, the cured adhesive layer plate 42 is sealed and cured on the notch 43; the airtight test chamber 5 is a sealed box with one side opening, the hygrometer 6 is arranged in the airtight test chamber 5, and the dust-carrying plate 7 Horizontally placed on the bottom of the airtight test chamber 5; the opening size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com